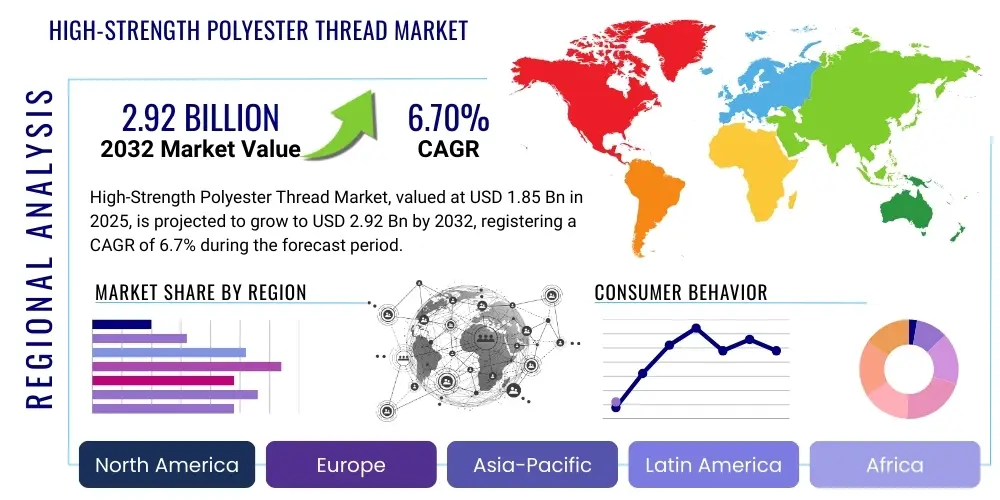

High-Strength Polyester Thread Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427823 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

High-Strength Polyester Thread Market Size

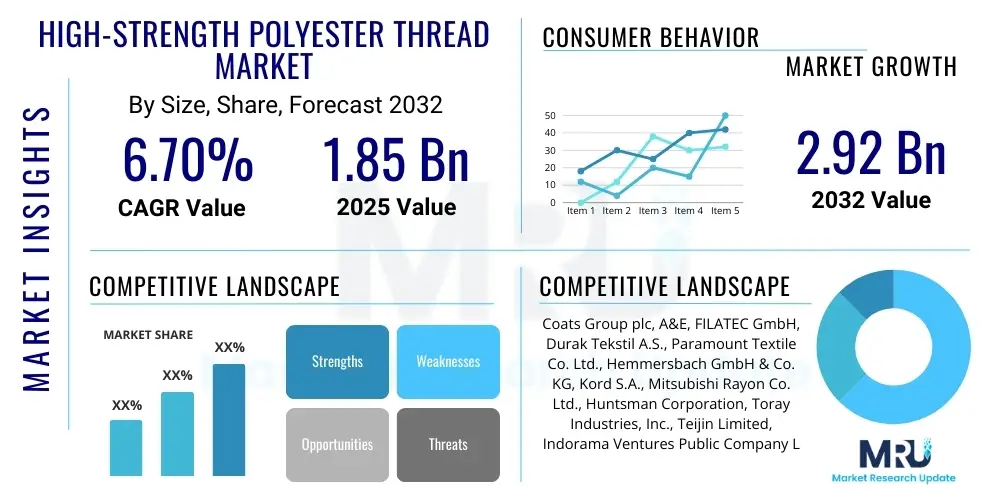

The High-Strength Polyester Thread Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% between 2025 and 2032. The market is estimated at USD 1.85 Billion in 2025 and is projected to reach USD 2.92 Billion by the end of the forecast period in 2032.

High-Strength Polyester Thread Market introduction

The High-Strength Polyester Thread Market encompasses the production and distribution of polyester threads specifically engineered for superior tensile strength, abrasion resistance, and dimensional stability. These threads are crucial in applications demanding exceptional durability and performance under strenuous conditions. Polyester, a synthetic polymer, offers inherent advantages such as resistance to UV radiation, moisture, chemicals, and microbial degradation, making it ideal for various industrial and consumer-grade products. Its versatility in processing allows for different deniers and constructions, catering to a broad spectrum of end-use requirements.

The primary product description involves threads manufactured from high-tenacity polyester fibers, often multifilament or spun, which undergo specialized spinning and finishing processes to enhance their strength characteristics. Major applications span across critical sectors including automotive (seatbelts, airbags, upholstery), marine (sails, boat covers, fishing nets), geotextiles (reinforcement, erosion control), industrial sewing (heavy-duty bags, footwear, luggage), and sporting goods (tents, outdoor gear). These threads provide structural integrity, ensure product longevity, and contribute significantly to safety and reliability in their respective uses. The benefits of high-strength polyester thread include its exceptional load-bearing capacity, minimal elongation, excellent colorfastness, and resistance to environmental stressors, which translate into reduced maintenance and replacement costs for end-users.

Driving factors for this market include the robust growth in automotive production, particularly the increasing demand for enhanced safety features; expansion of infrastructure projects utilizing geotextiles; the thriving e-commerce sector boosting demand for durable packaging and logistics materials; and innovations in textile manufacturing processes. Furthermore, the rising consumer preference for long-lasting and high-performance products across various categories, coupled with stringent regulatory standards for product safety and quality in industries like automotive and personal protective equipment, continue to fuel the adoption of high-strength polyester threads globally. The market also benefits from technological advancements leading to more sustainable production methods and enhanced thread properties.

High-Strength Polyester Thread Market Executive Summary

The High-Strength Polyester Thread Market is characterized by dynamic business trends, marked by a strong emphasis on product innovation, sustainability initiatives, and strategic partnerships. Manufacturers are increasingly investing in research and development to create threads with enhanced properties such as improved fire resistance, anti-microbial features, and higher strength-to-weight ratios, catering to evolving industry demands. There is a notable trend towards automation in thread production and quality control, aiming to optimize operational efficiency and ensure consistent product quality. Furthermore, the market is witnessing consolidation through mergers and acquisitions as companies seek to expand their product portfolios, geographical reach, and technological capabilities, fostering a competitive landscape where vertical integration offers a distinct advantage.

Regional trends indicate significant growth opportunities across various geographies, with Asia Pacific emerging as a dominant market due to rapid industrialization, burgeoning manufacturing sectors, and increasing infrastructural development, particularly in countries like China and India. North America and Europe continue to be strong markets, driven by stringent regulatory standards for product quality and safety, alongside advanced automotive and industrial sectors. Emerging economies in Latin America and Africa are also showing promising growth potential, fueled by expanding manufacturing bases and increasing consumer purchasing power. The global supply chain for high-strength polyester thread is evolving, with an increasing focus on localized production and resilient supply networks to mitigate geopolitical risks and optimize logistics, especially in the wake of recent global disruptions.

Segmentation trends highlight distinct growth patterns across different application areas and product types. The automotive sector remains a significant consumer, with rising demand for safety components like seatbelts and airbags driving market expansion. The industrial textiles segment, encompassing applications such as geotextiles, conveyor belts, and filtration fabrics, is also experiencing robust growth due propelled by infrastructure development and increasing industrial output. In terms of product type, multifilament high-tenacity polyester threads are gaining traction due to their superior strength and durability characteristics. The market also observes an increasing demand for specialty threads designed for specific functionalities, such as those with enhanced UV resistance for outdoor applications or improved chemical resistance for harsh industrial environments, indicating a move towards specialized solutions to meet precise customer requirements.

AI Impact Analysis on High-Strength Polyester Thread Market

The integration of Artificial Intelligence (AI) is set to profoundly transform the High-Strength Polyester Thread Market by revolutionizing manufacturing processes, supply chain management, and product development. Common user questions often revolve around how AI can enhance thread quality, optimize production efficiency, and enable more sustainable practices. Users are keen to understand AIs role in predictive maintenance for machinery, ensuring minimal downtime, and its application in real-time quality control to detect defects early. There is significant interest in AI-driven material science, exploring how machine learning algorithms can accelerate the discovery and optimization of new polyester formulations for even higher strength and specialized properties. Furthermore, stakeholders anticipate AIs ability to create more agile and responsive supply chains, predicting demand fluctuations and optimizing inventory levels, thereby reducing waste and improving overall market responsiveness.

- AI-driven predictive maintenance for manufacturing equipment, minimizing downtime and optimizing operational efficiency.

- Enhanced real-time quality control through machine vision and AI algorithms, identifying defects with higher precision and speed.

- Optimization of production parameters (temperature, speed, tension) using AI to achieve consistent thread quality and strength.

- AI-powered demand forecasting and supply chain optimization, leading to reduced inventory costs and improved logistics efficiency.

- Accelerated material innovation and formulation development through AI and machine learning for novel polyester compounds.

- Automated inspection systems for finished thread spools, ensuring compliance with stringent industry standards.

- Personalized product development and customization based on AI analysis of customer needs and application specific requirements.

- Energy consumption optimization in manufacturing facilities through AI monitoring and control systems, enhancing sustainability.

- Intelligent route planning and freight optimization for distribution, reducing transportation costs and environmental impact.

- Robot-assisted handling and packaging of thread products, improving safety and speed in warehousing operations.

DRO & Impact Forces Of High-Strength Polyester Thread Market

The High-Strength Polyester Thread Market is significantly influenced by a complex interplay of drivers, restraints, and opportunities, shaped by underlying impact forces. Key drivers propelling market growth include the escalating demand from end-use industries such as automotive, where high-strength threads are essential for safety components like seatbelts and airbags, driven by increasing vehicle production and stringent safety regulations. The robust expansion of infrastructure projects globally, particularly in developing economies, fuels the demand for geotextiles and industrial textiles that rely heavily on high-strength polyester threads for reinforcement and durability. Furthermore, the booming e-commerce sector and the associated growth in packaging and logistics demand high-performance sewing threads. Consumer preference for durable and long-lasting products, coupled with continuous technological advancements leading to improved thread properties, further contributes to market expansion.

Conversely, the market faces several restraints that could impede its growth trajectory. Volatility in raw material prices, particularly for purified terephthalic acid (PTA) and monoethylene glycol (MEG), which are key precursors for polyester, can significantly impact production costs and profit margins for thread manufacturers. The emergence of alternative high-performance fibers, such as aramids and ultra-high molecular weight polyethylene (UHMWPE), although generally more expensive, poses a competitive threat in highly specialized applications. Environmental concerns regarding the disposal and recyclability of synthetic fibers also present a challenge, pushing manufacturers towards more sustainable and eco-friendly production methods, which can entail significant R&D investments. Additionally, stringent environmental regulations in developed countries may increase compliance costs for manufacturers, potentially affecting market competitiveness.

Opportunities within the market abound, driven by several impact forces. The increasing focus on lightweight materials in industries like automotive and aerospace offers a significant growth avenue, as high-strength polyester threads contribute to weight reduction while maintaining structural integrity. The burgeoning demand for smart textiles and wearable technology creates new application possibilities for these threads, particularly those with enhanced conductive or sensory properties. Investments in sustainable manufacturing processes, including the use of recycled polyester or bio-based polyester, present an opportunity for market differentiation and meeting evolving consumer and regulatory expectations. Furthermore, the expansion of global trade and the establishment of new manufacturing hubs in emerging economies present avenues for market penetration and geographical expansion, allowing manufacturers to tap into new consumer bases and leverage cost-effective production locales. The continuous innovation in spinning technologies and finishing treatments promises to unlock new performance benchmarks, expanding the utility and value proposition of high-strength polyester threads across diverse applications.

Segmentation Analysis

The High-Strength Polyester Thread Market is comprehensively segmented based on various factors, including product type, application, and geographical region, to provide a detailed understanding of its dynamics. This segmentation allows for precise market analysis, enabling stakeholders to identify key growth areas, understand competitive landscapes within specific niches, and tailor strategies to target particular end-use sectors. The diversity in product types reflects the varying tensile strength, denier, and specialized treatments required for different functionalities, while the application-based segmentation highlights the broad utility of these threads across industrial and consumer goods. Regional segmentation further provides insights into market maturity, regulatory environments, and economic drivers influencing demand across major global economies.

Understanding these segmentations is critical for market participants to effectively gauge demand patterns, assess technological advancements impacting specific categories, and identify untapped market potential. For instance, threads designed for marine applications often require enhanced UV and saltwater resistance, whereas those for automotive use prioritize extreme tensile strength and abrasion resistance. Each segment presents unique challenges and opportunities, requiring specialized product development and marketing approaches. The interplay between these segments often dictates the overall market trajectory, with growth in one application potentially driving demand for specific product types or influencing regional production capacities. Such granular analysis aids in strategic planning, investment decisions, and fostering innovation tailored to specific market needs and preferences.

- By Product Type

- Multifilament High-Tenacity Polyester Thread

- Spun High-Strength Polyester Thread

- Textured High-Strength Polyester Thread

- Monofilament High-Strength Polyester Thread

- Blended High-Strength Polyester Thread

- By Application

- Automotive Industry (Seatbelts, Airbags, Upholstery)

- Industrial Sewing (Footwear, Luggage, Heavy-Duty Bags)

- Marine & Outdoor Goods (Sails, Boat Covers, Tents, Fishing Nets)

- Geotextiles & Construction (Reinforcement Fabrics, Erosion Control)

- Sporting Goods (Camping Equipment, Ropes, Nets)

- Apparel & Fashion (Heavy-duty Stitching, Decorative)

- Filtration & Conveyor Belts

- Others (Medical Textiles, Agricultural Textiles)

- By End-Use Industry

- Textile Manufacturing

- Automotive & Transportation

- Building & Construction

- Sporting & Outdoor

- Packaging

- Agriculture

- Medical

- By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

High-Strength Polyester Thread Market Value Chain Analysis

The value chain for the High-Strength Polyester Thread Market begins with the upstream analysis, which primarily involves the procurement of raw materials. The foundational components are purified terephthalic acid (PTA) and monoethylene glycol (MEG), derived from petrochemical sources. These are polymerized to produce polyester chips or flakes, which serve as the primary input for fiber extrusion. Key suppliers in this stage include large petrochemical companies and chemical manufacturers. The quality and cost of these raw materials significantly influence the final products performance and pricing. Efficiency in raw material sourcing, including long-term contracts and diversified supplier bases, is crucial for maintaining competitive advantage and mitigating supply chain risks. Upstream activities also encompass research and development for new polyester formulations and sustainable raw material alternatives.

Moving downstream, the polyester chips are processed into high-strength polyester fibers through melt spinning, drawing, and texturizing processes. These fibers are then spun into threads, which may undergo additional treatments such as twisting, dyeing, lubrication, and finishing to impart specific properties like enhanced UV resistance, water repellency, or improved sewability. Thread manufacturers, such as those profiled in this report, are central to this stage, transforming raw fibers into finished threads tailored for various applications. Quality control, process optimization, and technological innovation in fiber and thread manufacturing are critical for creating high-performance products that meet stringent industry standards and customer specifications. The downstream analysis further extends to the various end-use industries that integrate these threads into their final products.

The distribution channel for high-strength polyester threads is multifaceted, involving both direct and indirect sales. Direct distribution often involves manufacturers supplying large volumes directly to major industrial clients, such as automotive component manufacturers, large-scale textile producers, or construction companies. This approach allows for direct communication, custom solutions, and strong customer relationships. Indirect distribution leverages a network of wholesalers, distributors, and agents who specialize in serving smaller manufacturers, tailors, and regional businesses. These intermediaries provide market reach, logistics support, and local market expertise. E-commerce platforms are also gaining traction, particularly for smaller orders or specialty threads. The choice of distribution strategy depends on factors such as target market size, geographical spread, product specialization, and supply chain efficiency. An effective distribution network ensures timely delivery, wide market access, and responsive customer service, ultimately contributing to market penetration and sustained growth.

High-Strength Polyester Thread Market Potential Customers

The High-Strength Polyester Thread Market serves a diverse range of potential customers, primarily comprising end-user industries that require materials with exceptional durability, tensile strength, and resistance to environmental factors. A significant segment of these customers comes from the automotive industry, including manufacturers of vehicles, automotive interiors, and safety components such as seatbelts, airbags, and tire cords. These buyers prioritize threads that meet stringent safety standards, exhibit high abrasion resistance, and maintain integrity under extreme conditions, ensuring vehicle longevity and passenger safety. The growth in global automotive production and the continuous evolution of vehicle safety features directly influence the demand from this critical customer base, driving innovation in thread properties and specifications.

Another major customer segment resides within the industrial textiles sector, which includes manufacturers of geotextiles for civil engineering applications (road construction, erosion control, land reclamation), filtration fabrics, conveyor belts, and protective coverings. These customers require threads capable of withstanding heavy loads, harsh chemicals, UV exposure, and prolonged outdoor use, providing structural integrity and extended service life to their products. Furthermore, manufacturers of sporting goods and outdoor equipment, such as tents, backpacks, climbing ropes, fishing nets, and marine canvas products, constitute a vital customer group. Their demand is driven by the need for threads that offer high strength-to-weight ratios, excellent UV resistance, and resistance to mildew and moisture, ensuring reliability and performance in demanding recreational and professional environments.

Beyond these large industrial users, the market also caters to the broader sewing and craft industry, particularly businesses focused on heavy-duty applications like footwear, luggage, industrial bags, and upholstery. These customers, though perhaps smaller in individual volume, collectively represent a substantial market share, emphasizing threads that provide strong, lasting seams and enhance the overall quality and durability of their finished goods. Emerging customer segments include medical textile manufacturers, for whom high-strength polyester threads are used in surgical sutures, implants, and medical device fabrication due to their biocompatibility and mechanical properties. The agricultural sector also presents potential, with applications in nets, tarpaulins, and other textile-based solutions. The diverse needs across these customer groups underscore the versatility and critical importance of high-strength polyester threads in numerous industrial and consumer applications.

High-Strength Polyester Thread Market Key Technology Landscape

The High-Strength Polyester Thread Market is continually shaped by advancements in various key technologies that enhance product performance, optimize manufacturing processes, and improve sustainability. A foundational technology is the development of high-tenacity spinning processes, such as high-speed melt spinning and two-stage drawing, which are crucial for aligning polymer chains to achieve superior tensile strength and reduced elongation in polyester fibers. Innovations in spinneret design and polymer rheology further contribute to creating finer denier fibers without compromising strength. Additionally, advanced heat setting and stabilization techniques are employed to ensure dimensional stability and resistance to shrinkage, which are critical properties for high-performance threads in demanding applications. These manufacturing process technologies form the bedrock upon which high-strength characteristics are built, allowing for the consistent production of threads that meet rigorous industrial standards.

Surface treatment and finishing technologies represent another vital aspect of the technological landscape, as they impart specific functional properties to the threads. This includes the application of specialized lubricants, waxes, and sizing agents to improve sewability, reduce friction during high-speed stitching, and enhance abrasion resistance. Furthermore, technologies for UV stabilization, flame retardancy, and antimicrobial treatments are increasingly integrated to extend the threads lifespan and performance in challenging environments. Developments in dyeing processes, particularly eco-friendly and low-water-consumption methods, are also gaining prominence, aligning with global sustainability initiatives. These finishing technologies transform raw polyester thread into specialized products tailored for specific end-use requirements, adding significant value and differentiating offerings in the competitive market.

Beyond core manufacturing and finishing, the market leverages a suite of digital and analytical technologies to optimize operations and drive innovation. Automation and robotics are increasingly utilized in thread winding, packaging, and quality inspection, enhancing efficiency, precision, and reducing labor costs. Sensor technologies and real-time data analytics are employed for process monitoring, allowing manufacturers to maintain optimal production parameters and promptly detect deviations in quality. Artificial Intelligence (AI) and Machine Learning (ML) algorithms are emerging as pivotal tools for predictive maintenance of machinery, optimizing material formulations for enhanced properties, and forecasting market demand. These digital technologies not only streamline production but also enable rapid prototyping and customization, allowing manufacturers to respond swiftly to evolving market needs and develop next-generation high-strength polyester threads with enhanced functionalities and improved environmental footprints.

Regional Highlights

- Asia Pacific: This region stands as the largest and fastest-growing market for high-strength polyester thread, primarily driven by rapid industrialization, burgeoning automotive manufacturing sectors in countries like China, India, Japan, and South Korea, and massive infrastructure development requiring geotextiles. The presence of a vast textile manufacturing base and increasing disposable incomes fueling demand for durable consumer goods further contribute to its dominance.

- North America: A mature market characterized by stringent regulatory standards for safety and quality in automotive, aerospace, and industrial sectors. Demand is consistently high from the automotive industry, active sports and outdoor equipment manufacturers, and a strong focus on advanced materials. Innovations in sustainable production and high-performance applications are key drivers here.

- Europe: This region represents a significant market with a strong emphasis on sustainability, technological innovation, and high-quality industrial applications. Countries like Germany, Italy, and France are major consumers, particularly in the automotive, marine, and high-end industrial textile sectors. Strict environmental regulations also drive demand for eco-friendly and recycled polyester thread solutions.

- Latin America: An emerging market exhibiting steady growth, propelled by expanding automotive production in Brazil and Mexico, coupled with increasing investments in infrastructure and construction projects. The regions growing textile and apparel industries also contribute to the demand, albeit with a focus on cost-effective yet high-performance solutions.

- Middle East & Africa: This region is experiencing nascent but growing demand, primarily fueled by urbanization, diversification of economies away from oil, and investments in construction and infrastructure. Demand for technical textiles in industrial and protective applications is on the rise, with increasing opportunities for market entry and expansion for thread manufacturers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the High-Strength Polyester Thread Market.- Coats Group plc

- A&E (American & Efird)

- FILATEC GmbH

- Durak Tekstil A.S.

- Paramount Textile Co. Ltd.

- Hemmersbach GmbH & Co. KG

- Kord S.A.

- Mitsubishi Rayon Co. Ltd.

- Huntsman Corporation

- Toray Industries, Inc.

- Teijin Limited

- Indorama Ventures Public Company Limited

- Reliance Industries Limited

- Hyosung Corporation

- Dupont de Nemours, Inc.

- Kolon Industries, Inc.

Frequently Asked Questions

What are the primary applications of High-Strength Polyester Thread?

High-Strength Polyester Thread finds extensive applications across various industries, notably in automotive for seatbelts and airbags, industrial sewing for footwear and luggage, marine and outdoor goods like sails and tents, and geotextiles for construction and erosion control. Its exceptional durability and resistance make it ideal for products requiring superior strength and longevity.

What key factors are driving the growth of the High-Strength Polyester Thread Market?

Market growth is primarily driven by the increasing demand from the automotive industry due to enhanced safety requirements, the expanding infrastructure development boosting geotextile usage, and the robust growth of e-commerce necessitating durable packaging and textile components. Additionally, consumer preference for long-lasting products and ongoing technological advancements contribute significantly.

How does AI impact the manufacturing of High-Strength Polyester Thread?

AI significantly impacts manufacturing by enabling predictive maintenance for machinery, optimizing production parameters for consistent quality, and enhancing real-time defect detection through machine vision. It also aids in demand forecasting, supply chain optimization, and accelerating material innovation, leading to more efficient and sustainable production processes.

Which regions are key contributors to the High-Strength Polyester Thread Market?

Asia Pacific is the leading and fastest-growing region, driven by extensive industrialization and manufacturing in countries like China and India. North America and Europe also hold substantial market shares, characterized by strong automotive and industrial sectors and stringent quality regulations. Latin America and MEA are emerging with increasing infrastructure development.

What are the main challenges faced by the High-Strength Polyester Thread Market?

The market faces challenges such as volatility in raw material prices (PTA, MEG), competition from alternative high-performance fibers (e.g., aramids), and increasing environmental concerns regarding the disposal and recyclability of synthetic threads. Compliance with stringent environmental regulations also poses an operational and cost challenge for manufacturers.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager