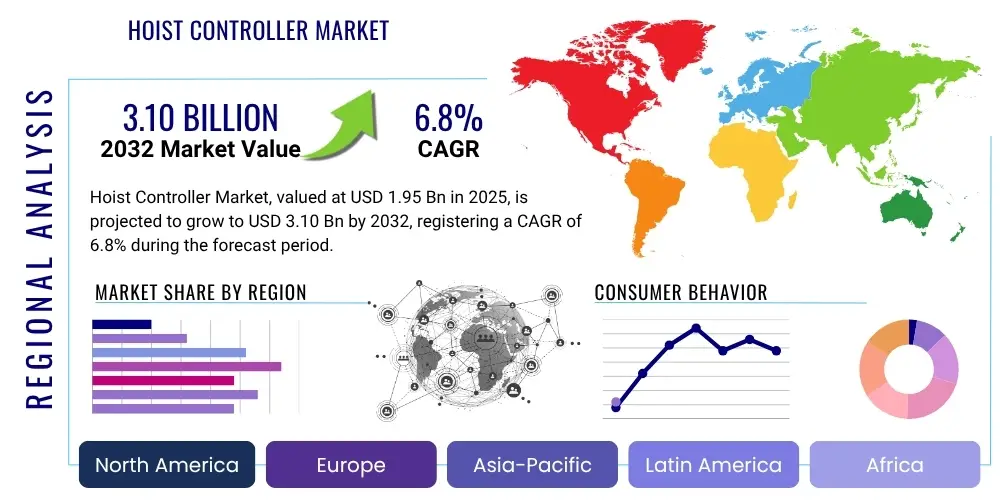

Hoist Controller Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431159 | Date : Nov, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Hoist Controller Market Size

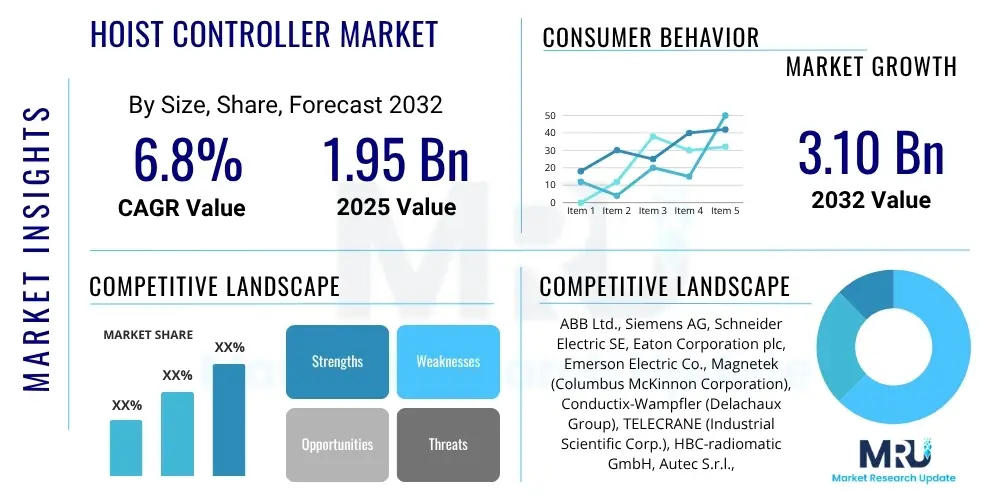

The Hoist Controller Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 1.95 billion in 2025 and is projected to reach USD 3.10 billion by the end of the forecast period in 2032.

Hoist Controller Market introduction

The Hoist Controller Market encompasses the comprehensive ecosystem of control systems and devices essential for the precise, safe, and efficient operation of hoists, cranes, and various lifting equipment across a multitude of industrial landscapes. These sophisticated instruments serve as the critical interface through which operators manage all aspects of load manipulation, including movement, speed regulation, and accurate positioning of heavy materials. The market offers a diverse range of products, spanning from conventional wired pendant controls, which provide direct manual command, to advanced wireless remote systems that enhance operator mobility and visibility, and highly integrated Programmable Logic Controllers (PLCs) coupled with Variable Frequency Drives (VFDs) for automated and finely tuned motion control. Each product type is designed to meet specific operational demands, emphasizing robustness, reliability, and user-friendliness in challenging industrial environments.

Major applications for hoist controllers are widespread, penetrating critical sectors such as construction, where they facilitate the erection of structures and management of heavy building materials; manufacturing, for assembly line operations and material flow within factories; logistics and warehousing, for efficient inventory handling and order fulfillment; and specialized heavy-duty applications in marine, mining, and oil and gas industries, where lifting of exceptionally heavy or hazardous materials is routine. The core benefits derived from implementing these advanced controllers are manifold: paramount among them is significantly enhanced operational safety, mitigating risks associated with manual handling and uncontrolled movements. Additionally, they contribute to superior efficiency through precise load placement, minimizing errors and reworks, and boosting overall productivity by enabling smoother, faster, and more controlled lifting cycles. These advantages underscore their indispensable role in modern industrial operations, driving continuous innovation in the market.

The Hoist Controller Market's robust growth trajectory is underpinned by several compelling driving factors. Global industrialization and urbanization initiatives are steadily increasing the demand for efficient material handling solutions across developing economies. Simultaneously, the accelerating adoption of automation in industrial processes necessitates sophisticated control systems that can integrate seamlessly with modern factory environments. A critical driver is the increasingly stringent global safety regulations and standards that mandate the use of reliable and advanced control technologies to prevent workplace accidents and ensure compliance. Furthermore, continuous technological advancements, particularly in wireless communication, sensor technology, and human-machine interfaces, are fostering the development of more intuitive, powerful, and connected hoist controllers. These interwoven factors collectively create a fertile ground for sustained market expansion, pushing manufacturers to innovate and deliver solutions that meet the evolving demands for safety, efficiency, and technological sophistication in material handling operations.

Hoist Controller Market Executive Summary

The Hoist Controller Market is undergoing significant transformation, driven by prevailing business trends that prioritize operational intelligence, connectivity, and enhanced safety. A prominent trend involves the widespread adoption of smart, interconnected control systems that leverage Internet of Things (IoT) capabilities for real-time data acquisition, remote monitoring, and advanced diagnostics. This shift enables predictive maintenance strategies, drastically reducing unscheduled downtime and optimizing operational workflows. Furthermore, there is a strong emphasis on developing modular and customizable solutions that can be readily integrated into existing infrastructure while meeting diverse application-specific requirements. The competitive landscape is also characterized by strategic partnerships, mergers, and acquisitions, as key players seek to broaden their technological expertise, expand their product portfolios, and consolidate their market presence across various geographical regions. Manufacturers are also increasingly focusing on sustainable and energy-efficient designs, incorporating features like variable frequency drives (VFDs) to reduce power consumption and support green industrial initiatives. These business trends reflect a market striving for greater operational excellence, technological synergy, and environmental responsibility, setting the stage for continuous innovation and market evolution.

Regional trends within the Hoist Controller Market reveal distinct growth patterns and maturity levels across different geographies. The Asia Pacific (APAC) region stands out as the primary growth engine, fueled by rapid industrialization, massive infrastructure development projects, and a booming manufacturing sector, particularly in countries like China, India, and Southeast Asian nations. This region is witnessing substantial investments in factory automation and logistics, driving a strong demand for both conventional and advanced hoist control solutions. North America and Europe represent mature markets, characterized by high levels of technological adoption, stringent safety regulations, and a sustained demand for high-performance, precision-oriented, and compliant control systems. Innovation in these regions often focuses on advanced wireless technologies, integration with Industry 4.0 initiatives, and solutions that emphasize ergonomic design and enhanced operator interfaces. Emerging markets in Latin America, the Middle East, and Africa are also demonstrating steady growth, driven by increasing industrial activity, mining operations, and large-scale construction projects, albeit with a focus on durable and cost-effective solutions that can withstand challenging environmental conditions.

Segment trends within the Hoist Controller Market highlight a clear shift towards advanced and more flexible control mechanisms. The wireless control segment is experiencing significant traction, increasingly preferred over wired pendant controls due to the benefits of enhanced operator mobility, improved visibility, and superior safety by keeping operators at a safe distance from the load. This trend is further supported by advancements in radio frequency (RF) technologies, which ensure reliable and interference-free communication. Another key trend is the growing integration of Variable Frequency Drives (VFDs) into hoist control systems. VFDs provide unparalleled precision in motor speed control, allowing for smooth acceleration and deceleration, reduced mechanical stress on components, and significant energy savings, thereby enhancing both operational efficiency and equipment longevity. Furthermore, there is a rising demand for intelligent control systems that offer diagnostic feedback, data logging capabilities, and remote troubleshooting. This reflects a broader industry movement towards smart material handling solutions, where data-driven insights are leveraged to optimize performance, schedule predictive maintenance, and ensure the highest levels of safety and operational uptime for diverse hoisting applications.

AI Impact Analysis on Hoist Controller Market

User inquiries regarding AI's impact on the Hoist Controller Market predominantly revolve around how artificial intelligence can fundamentally revolutionize and enhance material handling operations. Common questions explore AI's potential to significantly improve safety protocols, optimize operational efficiency, enable highly accurate predictive maintenance, and pave the way for more autonomous hoisting solutions. Users are keen to understand how AI-driven systems can drastically reduce the likelihood of human error, improve load stability through sophisticated algorithmic control, and provide real-time diagnostic insights to prevent costly equipment malfunctions before they occur. There is considerable interest in AI's contribution to broader smart factory initiatives, providing granular data and actionable intelligence on equipment utilization, energy consumption patterns, and overall workflow optimization within complex industrial environments. Expectations are high for AI to facilitate the development of intelligent, self-learning control systems that can adapt dynamically to varying operational conditions and loads. While the long-term vision includes fully autonomous hoisting, initial concerns often touch upon the reliability of AI decision-making, cybersecurity risks associated with data integration, and the critical need for robust regulatory frameworks to govern AI deployment in safety-critical applications. These discussions collectively shape the perception of AI as a transformative force, promising substantial advancements in performance, safety, and operational intelligence for hoist control systems.

- Enhanced Predictive Maintenance: AI algorithms analyze vast datasets from hoist controllers, including motor currents, temperature, vibration, and usage patterns, to accurately forecast potential equipment failures, optimize maintenance schedules, and minimize costly unscheduled downtime by identifying anomalies proactively.

- Optimized Load Handling and Sway Control: AI systems can process real-time sensor data from load cells, cameras, and accelerometers to dynamically adjust hoist movements, suggest optimal lifting trajectories, and actively suppress load sway, ensuring smoother, safer, and more precise positioning, which reduces stress on both the load and mechanical components.

- Improved Operator Assistance and Training: AI-powered interfaces can provide intelligent, real-time feedback to operators, proactively identify potential hazards, and offer adaptive training simulations. This enhances operator proficiency, reduces reaction times to critical events, and reinforces safer operating practices.

- Development of Autonomous Operation Capabilities: While still in nascent stages, AI holds immense potential for enabling semi-autonomous or fully autonomous hoist operations, particularly in repetitive, high-volume, or hazardous industrial environments. This involves advanced vision systems, sensor fusion, and AI-driven decision-making algorithms that can execute tasks without direct human intervention, improving consistency and safety.

- Advanced Energy Efficiency Management: AI can dynamically optimize hoist motor speeds and power consumption based on real-time load conditions, operational requirements, and energy tariffs. This intelligent optimization leads to substantial energy savings and a reduced carbon footprint, aligning with global sustainability goals.

- Superior Anomaly Detection and Diagnostics: Machine learning models can analyze complex operational data patterns to detect subtle anomalies that might indicate impending mechanical or electrical issues, often long before human operators or traditional monitoring systems would identify them, allowing for timely intervention.

- Seamless Integration with IoT and Smart Factories: AI acts as the intelligent processing layer, ingesting and interpreting data from numerous IoT sensors integrated across industrial equipment. This provides holistic insights into material flow, equipment health, and overall factory performance, facilitating better decision-making and contributing to the realization of Industry 4.0 objectives.

DRO & Impact Forces Of Hoist Controller Market

The Hoist Controller Market is significantly influenced by a complex interplay of drivers, restraints, and opportunities, alongside broader impact forces that shape its evolution. Among the primary drivers, the accelerating trend of industrial automation across manufacturing, logistics, and warehousing sectors stands out, as companies seek to enhance productivity, streamline operations, and reduce reliance on manual labor. Furthermore, the global proliferation of stringent industrial safety regulations and occupational health standards mandates the adoption of advanced and highly reliable control systems to prevent accidents, protect workers, and ensure secure material handling operations. The continuous growth in construction and infrastructure development projects worldwide, particularly in emerging economies, also fuels a sustained demand for high-capacity, precise, and efficient hoisting equipment and their corresponding sophisticated controllers. Additionally, technological advancements in wireless communication, sensor integration, and human-machine interfaces are driving innovation, offering more intuitive, connected, and powerful control solutions that contribute to market expansion by delivering enhanced performance and user experience.

However, the market's growth trajectory is tempered by several notable restraints. A significant barrier to widespread adoption is the relatively high initial capital investment required for advanced hoist control systems, which can be particularly challenging for small and medium-sized enterprises (SMEs) with limited budgets. The inherent complexity associated with integrating sophisticated control technologies into diverse industrial environments also poses a hurdle, often requiring specialized expertise and extensive customization. Moreover, a persistent shortage of skilled personnel capable of effectively operating, maintaining, and troubleshooting these advanced control systems can impede their optimal utilization and deter potential buyers. Economic slowdowns or uncertainties in key industrial sectors, such as manufacturing or construction, can lead to reduced capital expenditure on new equipment, thereby restraining market growth. These factors collectively necessitate a careful balance between technological innovation, cost-effectiveness, and ease of deployment to overcome market resistance and foster broader adoption.

Despite the challenges, the Hoist Controller Market presents numerous compelling opportunities for growth and innovation. The increasing integration of Internet of Things (IoT) capabilities into hoist control systems allows for advanced connectivity, real-time performance monitoring, remote diagnostics, and predictive maintenance. This significantly enhances system reliability, operational efficiency, and overall asset management, opening new avenues for value creation. The expansion of smart factory concepts and Industry 4.0 initiatives across various industries, particularly in rapidly industrializing regions, creates fertile ground for manufacturers to introduce highly integrated, data-driven, and intelligent hoist control solutions. Furthermore, the growing demand for customizable and modular control systems, which can be tailored to specific application requirements and adapted to evolving operational needs, provides a competitive advantage for agile manufacturers. Beyond direct market opportunities, broader impact forces such as ongoing technological advancements in areas like AI and machine learning continue to influence product development, pushing towards more autonomous and adaptive control systems. Regulatory changes, particularly those aimed at enhancing workplace safety and environmental performance, also act as catalysts for the adoption of more advanced and compliant hoist controllers. Lastly, global economic conditions, including industrial output, investment cycles, and trade policies, significantly shape the overall demand environment, underscoring the dynamic nature of the Hoist Controller Market.

Segmentation Analysis

The Hoist Controller Market is meticulously segmented to offer a granular understanding of its diverse components, technologies, and end-user applications. This comprehensive segmentation is crucial for stakeholders to identify specific market niches, analyze competitive dynamics, and formulate targeted strategies for product development and market penetration. The classifications are typically based on product design, operational methodology, communication technologies, and the particular industrial environment served, enabling a detailed assessment of market trends, growth drivers, and challenges within each distinct category. Understanding these segments is paramount for effective business planning, allowing companies to align their offerings with specific customer needs and market demands, thereby optimizing resource allocation and enhancing market responsiveness. The continuous evolution of industrial practices and technological innovations consistently refines these segments, leading to the emergence of highly specialized and advanced control solutions designed for optimal performance in distinct operational contexts and ensuring a tailored approach to market opportunities.

- By Product Type:

- Pendant Controls: Wired systems featuring push-buttons for direct manual operation, often designed for ergonomics and heavy-duty industrial use.

- Radio Remote Controls: Wireless systems offering operator mobility, improved visibility, and enhanced safety, including handheld and belly-box transmitters with varying line-of-sight capabilities.

- Programmable Logic Controllers (PLCs): Industrial digital computers adapted for control of manufacturing processes, providing flexible and customizable control logic for complex hoist systems.

- Variable Frequency Drives (VFDs): Electronic devices that control the speed of AC induction motors, crucial for precise speed control, smooth acceleration/deceleration, and energy efficiency in hoists.

- Master Controllers: Joystick-operated controllers providing multi-axis control, typically used for complex crane and hoist applications requiring proportional control.

- Push Button Stations: Standalone or integrated control units with simple on/off or speed selection buttons, often used for basic hoisting functions.

- By Operation Type:

- Wired Control: Systems that rely on physical cables for communication between the operator interface and the hoist control panel, offering robust but less mobile operation.

- Wireless Control: Systems utilizing radio frequencies for communication, providing operators with greater freedom of movement and enhanced safety from a distance.

- By End-User Industry:

- Manufacturing: Includes automotive assembly, heavy machinery fabrication, and general manufacturing, utilizing hoists for production lines and material movement.

- Construction: Encompasses building construction, civil engineering, and infrastructure projects, requiring hoists for lifting heavy materials and components.

- Logistics and Warehousing: Involves material handling in distribution centers, ports, and storage facilities for efficient inventory management and order fulfillment.

- Ports and Marine: Applications in container terminals, shipyards, and offshore platforms for heavy lifting and cargo handling in harsh environments.

- Mining and Metallurgy: Used in ore extraction, material processing, and equipment maintenance in demanding mining and metal refining operations.

- Oil and Gas: Critical for drilling operations, platform maintenance, and equipment handling in upstream, midstream, and downstream sectors.

- Aerospace and Defense: Precision lifting for aircraft assembly, maintenance, and handling of specialized components.

- Power Generation: Applications in power plants for turbine maintenance, fuel handling, and heavy equipment installation.

- By Application:

- Single Speed Hoists: Basic hoists with one lifting speed, controlled by simple on/off commands.

- Multi Speed Hoists: Hoists offering discrete speed options (e.g., fast/slow), providing more control over load movement.

- Variable Speed Hoists: Hoists equipped with VFDs for continuous and precise speed adjustment, ideal for delicate or heavy loads.

- Bridge Cranes: Overhead cranes spanning a bay, used for moving loads along a horizontal axis within a fixed area.

- Gantry Cranes: Similar to bridge cranes but supported by legs that run on rails, often used outdoors or in large industrial settings.

- Jib Cranes: Cranes with a horizontal arm (jib) extending from a vertical mast or wall, providing circular work areas.

- Monorail Systems: Hoists running on a single overhead track, used for linear material transport.

- By Component:

- Transmitters: Handheld or belly-box units used by operators to send commands to the hoist.

- Receivers: Units mounted on the hoist or crane that receive signals from the transmitter and relay them to the control panel.

- Controllers (Logic Units): The core processing units, often PLCs, that interpret commands and execute movements.

- Buttons and Switches: Manual interface components for operator input.

- Cables and Connectors: For wired systems and internal wiring of control panels.

- Batteries and Chargers: For wireless transmitters.

- Enclosures: Protective casings for electronic components, designed to withstand industrial environments.

Value Chain Analysis For Hoist Controller Market

The value chain for the Hoist Controller Market commences with crucial upstream activities, involving the meticulous sourcing of diverse raw materials and specialized components. This stage includes procurement of plastics for housings, various metals for structural parts and connectors, advanced electronic components such as microcontrollers, semiconductors, resistors, and capacitors, alongside specialized wiring and communication modules. Key suppliers in this phase often include global electronics manufacturers, material science companies, and precision engineering firms. The quality, reliability, and availability of these foundational components are paramount, as they directly influence the performance, durability, and safety characteristics of the final hoist controller product. Maintaining robust relationships with a diversified supplier base is critical for ensuring supply chain resilience and cost-effectiveness in a competitive market, thereby establishing a strong foundation for subsequent stages of production and assembly.

Proceeding downstream, the value chain focuses on the intricate processes of manufacturing, assembly, and integration. Original Equipment Manufacturers (OEMs) and specialized control system integrators undertake the transformation of raw materials and components into fully functional hoist control systems. This involves complex processes such as circuit board manufacturing, component assembly, wiring, software programming, and rigorous quality assurance testing. These finished hoist control units are then channeled through various distribution networks to reach a diverse base of end-users. The distribution landscape is multifaceted, encompassing direct sales channels where manufacturers engage directly with large industrial clients, crane manufacturers, or system integrators to offer bespoke solutions and foster strong, long-term relationships. This direct approach often facilitates deeper technical support and customization, which is crucial for complex industrial projects. Simultaneously, indirect channels play a pivotal role, leveraging an extensive network of distributors, wholesalers, and value-added resellers (VARs) who provide broader market reach, localized inventory, installation services, and after-sales support, particularly crucial for reaching smaller enterprises and diverse geographic markets. The increasing prominence of online platforms and e-commerce portals also serves as an emerging direct channel, offering convenience and broader accessibility for standard product offerings, reflecting a digital transformation in market access.

Beyond sales and distribution, the value chain extends to crucial after-sales services, which significantly contribute to customer satisfaction and loyalty. This includes technical support, maintenance contracts, spare parts availability, and repair services, all of which are vital for ensuring the longevity and continuous optimal performance of hoist controllers in demanding industrial environments. Effective management across the entire value chain, from securing reliable upstream material and component supplies to efficient manufacturing, strategic downstream distribution, and comprehensive post-sales support, is not only crucial for achieving market competitiveness but also for fostering innovation and adapting to evolving industry standards and customer expectations. Companies that excel in streamlining these processes, ensuring quality at every stage, and providing exceptional customer service throughout the product lifecycle tend to gain a significant advantage in the Hoist Controller Market, demonstrating a holistic approach to delivering value.

Hoist Controller Market Potential Customers

The Hoist Controller Market serves a vast and diverse clientele, comprising industrial sectors that heavily rely on precise and safe material handling operations for their core business processes. Key potential customers predominantly include manufacturing plants across various sub-sectors, such as automotive, aerospace, heavy machinery, and general industrial manufacturing. These entities extensively utilize hoists and cranes for everything from moving raw materials along assembly lines to positioning large components for fabrication and transporting finished goods within their facilities. The demand here is driven by the need for increased automation, improved production efficiency, and stringent quality control, making advanced hoist controllers indispensable for maintaining seamless operational flow and ensuring worker safety in high-volume production environments.

Another significant customer segment is the global construction industry, encompassing building construction, infrastructure development, and civil engineering projects. Companies in this sector require robust and highly reliable hoist controllers for lifting and positioning heavy structural elements, precast concrete components, and other construction materials on job sites. The harsh and dynamic conditions of construction sites necessitate controllers that offer extreme durability, precise control over heavy and often irregularly shaped loads, and enhanced safety features to manage risks effectively. Similarly, the logistics and warehousing sector represents a rapidly growing customer base, driven by the increasing complexity of global supply chains and the need for optimized inventory management. These companies invest in efficient hoist control systems to facilitate rapid loading and unloading, precise stacking, and streamlined movement of goods within distribution centers and storage facilities, thereby enhancing operational speed and accuracy.

Specialized heavy industries also constitute a critical segment of potential customers. This includes ports and marine industries, where advanced controllers are essential for handling large-scale container operations, shipbuilding, and offshore platform maintenance, often in corrosive and demanding environments. The mining and metallurgy sectors are significant buyers, utilizing hoist controllers for ore extraction, material processing, and heavy equipment maintenance in challenging and remote locations, demanding systems with exceptional ruggedness and reliability. Furthermore, the oil and gas industry relies on hoist controllers for drilling operations, equipment installation, and maintenance on rigs and refineries. Even smaller enterprises, such as fabrication workshops and repair facilities, represent potential customers for more compact and versatile hoist controller solutions for their daily lifting tasks. The common thread among these diverse buyers is the overarching need for enhanced safety, superior operational efficiency, precision in load manipulation, and strict adherence to industry-specific regulations, all of which advanced hoist controllers are designed to address.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.95 Billion |

| Market Forecast in 2032 | USD 3.10 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., Siemens AG, Schneider Electric SE, Eaton Corporation plc, Emerson Electric Co., Magnetek (Columbus McKinnon Corporation), Conductix-Wampfler (Delachaux Group), TELECRANE (Industrial Scientific Corp.), HBC-radiomatic GmbH, Autec S.r.l., Ikusi (Danobatgroup), Alpha Wireless, ELCA S.r.l., REM Device, Scanreco AB, Cattron Group International, NBB Controls + Components GmbH, Flexco (FLEX Industrial Control), Jay Electronique, Delta Controls (Delta Wasp). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hoist Controller Market Key Technology Landscape

The Hoist Controller Market's technological landscape is characterized by continuous innovation aimed at enhancing safety, precision, efficiency, and connectivity in material handling operations. A cornerstone technology in modern hoist control is the Variable Frequency Drive (VFD), which allows for precise and smooth control of motor speed, thereby reducing mechanical stress on gears and ropes, minimizing load sway, and significantly improving energy efficiency by matching motor output to actual load requirements. This leads to extended equipment lifespan and lower operating costs. Complementing VFDs are advanced Programmable Logic Controllers (PLCs), which serve as the robust computational brain of complex hoist systems, offering unparalleled flexibility in programming control logic for intricate sequences, safety interlocks, and automated movements, making them ideal for integration into smart factory environments. These PLCs are typically interfaced with Human-Machine Interfaces (HMIs) that provide intuitive graphical displays for monitoring operational parameters, diagnostics, and easy operator interaction.

Wireless communication technologies are fundamentally transforming hoist control, with Radio Remote Control (RRC) systems being a prime example. These systems utilize advanced radio frequency (RF) protocols to provide operators with greater mobility, improved line of sight to the load, and enhanced safety by allowing them to control hoists from a safe distance. Modern RRCs feature robust interference immunity, extended ranges, and ergonomic designs, often incorporating feedback displays for real-time operational status. Furthermore, the integration of Internet of Things (IoT) sensors and connectivity platforms is a rapidly expanding area, enabling hoist controllers to become intelligent, data-generating devices. IoT allows for real-time monitoring of operational metrics such as load weight, motor current, temperature, and cycle counts, facilitating remote diagnostics, proactive maintenance scheduling, and detailed performance analytics, contributing significantly to operational uptime and efficiency. This connectivity also supports integration into broader industrial digital ecosystems, paving the way for data-driven operational improvements.

Beyond control and connectivity, safety technologies remain a critical area of development within the hoist controller market. Features such as emergency stop functions, redundant control circuits, sophisticated load limiters, anti-collision systems using ultrasonic or laser sensors, and safe torque off (STO) capabilities are continuously being enhanced to meet increasingly stringent global safety standards and mitigate operational risks. The emerging influence of Artificial Intelligence (AI) and Machine Learning (ML) algorithms is beginning to shape the next generation of hoist controllers. AI can be leveraged for predictive maintenance by analyzing historical data patterns, optimizing lifting paths to prevent sway, and potentially enabling semi-autonomous or fully autonomous operational modes in controlled environments. These advanced technologies collectively aim to deliver more reliable, safer, and highly efficient material handling solutions, addressing the evolving and demanding requirements of modern industries by pushing the boundaries of what hoist controllers can achieve.

Regional Highlights

The global Hoist Controller Market exhibits diverse growth patterns and strategic significance across its key geographical regions. North America, encompassing the United States and Canada, represents a highly mature and technologically advanced market. The region is characterized by substantial investments in industrial automation, a robust manufacturing sector, and significant ongoing infrastructure development projects. Strict regulatory frameworks and a strong emphasis on worker safety compel industries to adopt high-performance, precision-oriented, and compliant hoist control systems. North America is a hub for innovation, particularly in advanced wireless solutions, integrated IoT capabilities, and ergonomic designs that prioritize operator comfort and efficiency. The demand for highly reliable and intelligent controllers capable of seamless integration into complex industrial ecosystems remains consistently strong, driven by the need for continuous operational uptime and enhanced productivity.

Europe, including key economies such as Germany, France, the United Kingdom, and Italy, is another pivotal market segment with a long-standing industrial heritage. This region demonstrates a strong demand for sophisticated hoist control systems that adhere to rigorous European safety standards (e.g., CE marking) and environmental regulations. European industries are increasingly focused on energy-efficient solutions, smart factory initiatives, and the integration of control systems into broader Industry 4.0 frameworks. Countries within the European Union are actively modernizing their industrial infrastructure and logistics networks, leading to a sustained and growing demand for technologically advanced hoist controllers that offer precision, durability, and a high degree of connectivity. The market here is also influenced by a preference for modular and customizable solutions that can be adapted to specific application requirements across diverse manufacturing and processing industries.

The Asia Pacific (APAC) region, which includes powerhouses like China, India, Japan, and South Korea, is unequivocally projected to be the fastest-growing market for hoist controllers. This rapid expansion is fueled by unprecedented industrialization, colossal infrastructure development projects (such as extensive railway networks and smart cities), and an exponentially expanding manufacturing base across various sectors. China, in particular, is a dominant force in the regional market due owing to its vast manufacturing output, increasing automation adoption in heavy industries, and government initiatives aimed at modernizing its industrial base. India's burgeoning industrial sector, coupled with supportive government policies like "Make in India," is also contributing significantly to market growth. The demand in APAC is characterized by a balance between the need for cost-effective yet reliable solutions and a rapidly growing inclination towards advanced wireless, IoT-enabled, and smart control systems. Latin America, with key economies such as Brazil and Mexico, presents emerging market opportunities driven by industrial expansion, significant mining activities, and ongoing infrastructure investments. While the pace of adoption for advanced technologies might be slower compared to developed regions, there is a steady demand for durable, efficient, and robust hoist controllers. Finally, the Middle East and Africa (MEA) region is experiencing notable growth, primarily propelled by substantial investments in the oil and gas sector, large-scale construction projects (especially in the UAE and Saudi Arabia), and expanding logistics hubs in South Africa. These regions prioritize rugged and reliable systems that can withstand harsh environmental conditions, with a gradual shift towards more advanced and remotely managed solutions to enhance operational safety and efficiency in critical, heavy-duty applications. Each region's unique economic, regulatory, and industrial landscape collectively shapes the global market for hoist controllers.

- North America: Dominant market for advanced and highly automated solutions, driven by mature manufacturing sectors, continuous infrastructure investment, and stringent safety regulations. Strong emphasis on wireless, IoT-integrated, and ergonomic designs.

- Europe: Key market characterized by high adoption of energy-efficient, high-performance, and compliant systems; focus on smart factory integration, robust regulatory adherence, and modernization of industrial infrastructure.

- Asia Pacific (APAC): The fastest-growing market globally, propelled by rapid industrialization, extensive infrastructure development, and expanding manufacturing bases, particularly in China and India. Balancing cost-effectiveness with a growing demand for advanced solutions.

- Latin America: Emerging market driven by steady industrial growth, significant mining operations, and infrastructure projects; consistent demand for durable and efficient hoist controllers, with increasing interest in modern solutions.

- Middle East and Africa (MEA): Growth primarily from investments in oil and gas, large-scale construction, and logistics sectors; preference for rugged systems adaptable to harsh environments, with a gradual shift towards advanced remote management for enhanced safety and efficiency.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hoist Controller Market.- ABB Ltd.

- Siemens AG

- Schneider Electric SE

- Eaton Corporation plc

- Emerson Electric Co.

- Magnetek (Columbus McKinnon Corporation)

- Conductix-Wampfler (Delachaux Group)

- TELECRANE (Industrial Scientific Corp.)

- HBC-radiomatic GmbH

- Autec S.r.l.

- Ikusi (Danobatgroup)

- Alpha Wireless

- ELCA S.r.l.

- REM Device

- Scanreco AB

- Cattron Group International

- NBB Controls + Components GmbH

- Flexco (FLEX Industrial Control)

- Jay Electronique

- Delta Controls (Delta Wasp)

Frequently Asked Questions

What types of hoist controllers are available in the market and what are their primary uses?

The hoist controller market offers a diverse range of types to suit various industrial needs. These include traditional wired pendant controls, ideal for direct manual operation and offering robustness in demanding environments; advanced wireless radio remote controls, which provide operators with enhanced mobility, improved visibility, and superior safety by allowing control from a distance; and sophisticated integrated systems utilizing Programmable Logic Controllers (PLCs) with Variable Frequency Drives (VFDs) for automated, precise, and energy-efficient motion control in complex industrial setups. Specialized master controllers and push button stations are also common for specific operational requirements.

How do hoist controllers contribute significantly to industrial safety and operational efficiency?

Hoist controllers are critical for enhancing industrial safety by enabling precise and controlled movement of heavy loads, thereby preventing accidents caused by uncontrolled motion, human error, or equipment malfunction. They integrate vital safety features such as emergency stop buttons, load limiters, anti-collision systems, and redundant safety circuits, which are essential for meeting stringent safety regulations and protecting both personnel and valuable equipment. In terms of operational efficiency, these controllers facilitate smoother acceleration and deceleration, accurate load positioning, and optimized material flow. Wireless options further improve efficiency by allowing operators greater flexibility and an unobstructed view of the lifting area, streamlining workflows and reducing cycle times.

What are the primary factors driving the growth and expansion of the hoist controller market?

The hoist controller market's growth is primarily driven by several key factors. These include the escalating global trend towards industrial automation, as businesses seek to boost productivity and reduce labor costs across manufacturing, logistics, and warehousing sectors. Secondly, increasingly stringent industrial safety regulations worldwide necessitate the adoption of advanced, reliable, and compliant control systems to prevent workplace accidents. Furthermore, continuous growth in infrastructure development and construction projects globally fuels a strong demand for high-capacity and efficient hoisting equipment. Finally, ongoing technological advancements in areas like wireless communication, sensor integration, and human-machine interfaces are driving innovation, leading to more intelligent, connected, and user-friendly control solutions.

What is the current and prospective role of AI and IoT technologies in modern hoist control systems?

AI and IoT are playing a transformative role in modern hoist control systems, pushing towards smarter and more autonomous operations. IoT integration enables real-time performance monitoring, remote diagnostics, and data logging, facilitating highly effective predictive maintenance strategies that reduce downtime and optimize operational efficiency. AI algorithms analyze this data to forecast potential failures, optimize lifting paths for better load stability, and even suggest energy-efficient operational parameters. Prospectively, AI holds the potential to enable semi-autonomous or fully autonomous hoist operations, particularly in repetitive or hazardous environments, by enhancing decision-making capabilities and improving safety through advanced perception and control systems, integrating seamlessly into broader smart factory ecosystems.

Which geographical regions are leading the market in terms of hoist controller adoption and technological innovation?

North America and Europe currently lead the market in the adoption of advanced, high-performance, and compliant hoist control solutions. These regions are characterized by mature industrial bases, significant investments in automation, and strict safety regulations, driving demand for innovative wireless, IoT-integrated, and ergonomic systems. However, the Asia Pacific (APAC) region, especially China and India, is projected to be the fastest-growing market. This growth is fueled by rapid industrialization, massive infrastructure development, and expanding manufacturing sectors, where there is a strong and increasing demand for both cost-effective and technologically advanced hoist controllers to modernize their industrial capabilities.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager