Hollow Concrete Blocks Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431268 | Date : Nov, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Hollow Concrete Blocks Market Size

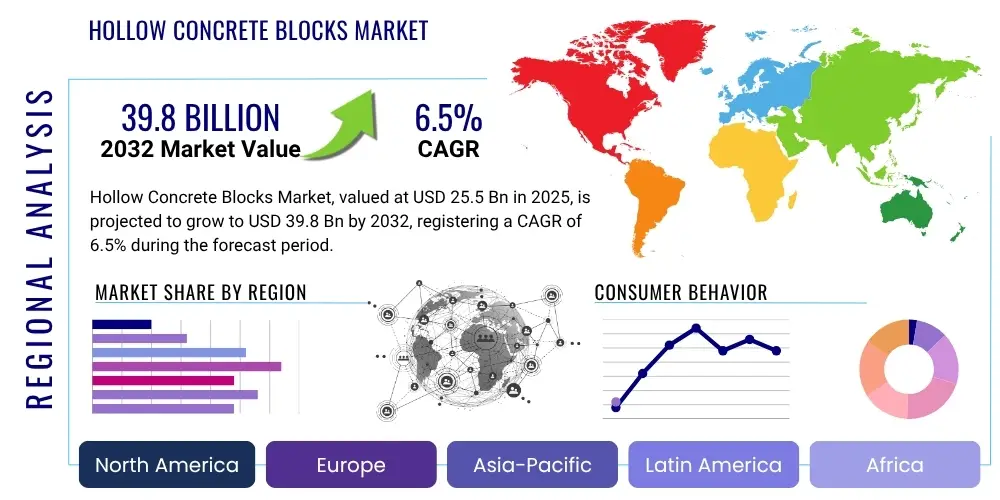

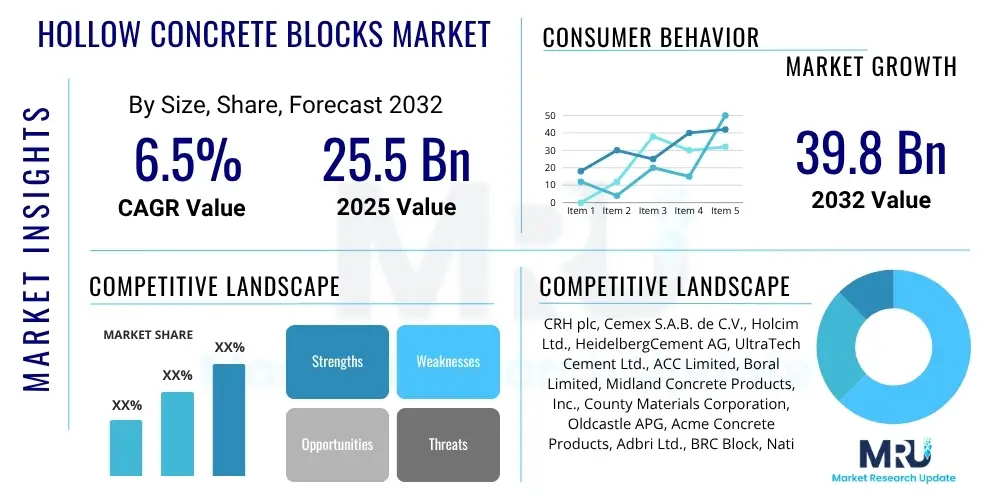

The Hollow Concrete Blocks Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032. The market is estimated at USD 25.5 Billion in 2025 and is projected to reach USD 39.8 Billion by the end of the forecast period in 2032.

Hollow Concrete Blocks Market introduction

The Hollow Concrete Blocks Market encompasses the production and distribution of precast concrete units featuring internal voids, widely utilized in the construction industry. These blocks, known for their structural integrity and thermal insulation properties, serve as a fundamental building material. The product essentially involves a mixture of cement, aggregates, and water, molded into various shapes and sizes with hollow cores, and then cured. They are a staple in modern construction due to their ease of installation, durability, and cost-effectiveness compared to traditional masonry units.

Major applications of hollow concrete blocks span across residential, commercial, industrial, and infrastructure projects, including walls, foundations, partition walls, and retaining structures. Their inherent benefits include reduced material consumption, lighter structures requiring less foundation work, superior insulation against heat and sound, and enhanced fire resistance. Moreover, the uniformity in size and shape of these blocks contributes to faster construction times and reduced labor costs on site.

Key driving factors for the market include rapid urbanization, especially in developing economies, leading to increased construction activities. The growing demand for affordable and sustainable housing, coupled with government initiatives promoting green building practices, further propels market expansion. Technological advancements in manufacturing processes, resulting in improved block quality and efficiency, also play a significant role in fostering market growth.

Hollow Concrete Blocks Market Executive Summary

The Hollow Concrete Blocks Market is experiencing robust growth, driven by an accelerating global construction sector and a rising emphasis on sustainable and cost-efficient building solutions. Business trends indicate a shift towards automated manufacturing processes and the adoption of advanced materials to enhance block properties such as strength, thermal performance, and eco-friendliness. Manufacturers are increasingly focusing on vertical integration and strategic partnerships to optimize supply chains and expand market reach, ensuring a consistent supply of quality products to meet burgeoning demand.

Regionally, Asia Pacific continues to dominate the market, largely due to extensive urbanization and infrastructure development projects in countries like China, India, and Southeast Asian nations. North America and Europe demonstrate steady growth, bolstered by renovation activities, adherence to stringent building codes emphasizing energy efficiency, and a mature construction industry. Emerging economies in Latin America, the Middle East, and Africa are also showing promising growth, fueled by population expansion and investments in commercial and residential developments.

In terms of segment trends, load-bearing hollow blocks maintain a significant market share due to their widespread use in structural applications. However, there is a growing interest in lightweight aggregate blocks and AAC (Autoclaved Aerated Concrete) blocks, driven by their superior insulation properties and reduced structural load. The residential construction segment remains the largest application area, although commercial and industrial construction are exhibiting strong growth as economies diversify and new facilities are established.

AI Impact Analysis on Hollow Concrete Blocks Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize the Hollow Concrete Blocks Market, particularly concerning manufacturing efficiency, quality control, and supply chain optimization. Common questions revolve around AI’s potential to predict material defects, automate production lines, optimize energy consumption in curing processes, and enhance logistics. There is also significant interest in AI's role in predictive maintenance for machinery, minimizing downtime, and improving worker safety, alongside concerns about the initial investment costs and the need for a skilled workforce to manage AI-driven systems. Users expect AI to bring about a new era of precision, sustainability, and cost reduction within the industry.

- AI-driven predictive maintenance for machinery reduces downtime and extends equipment lifespan.

- Optimized raw material blending through AI algorithms minimizes waste and ensures consistent product quality.

- Enhanced quality control using computer vision and machine learning for defect detection.

- Automated production scheduling and resource allocation improve manufacturing efficiency.

- Energy consumption optimization in curing processes via AI-powered climate control systems.

- Improved supply chain logistics and inventory management through predictive analytics.

- Robotics and AI integration in block handling and stacking operations increase speed and safety.

- Data analytics from production lines inform process improvements and new product development.

- AI facilitates smart design and customization of block types based on project specific requirements.

DRO & Impact Forces Of Hollow Concrete Blocks Market

The Hollow Concrete Blocks Market is significantly influenced by a confluence of driving forces, restraining factors, and emerging opportunities that collectively shape its trajectory. A primary driver is the accelerating pace of urbanization and industrialization across global economies, particularly in Asia Pacific and other developing regions, which necessitates rapid and large-scale construction. Governments worldwide are increasingly investing in infrastructure development, including roads, bridges, and public buildings, further bolstering demand for efficient and durable construction materials like hollow concrete blocks. The inherent benefits of these blocks, such as their cost-effectiveness, superior thermal insulation, and fire resistance, also contribute substantially to their adoption.

However, the market faces several notable restraints. Volatility in the prices of key raw materials, including cement and aggregates, can significantly impact production costs and profit margins for manufacturers. The availability of alternative building materials, such as bricks, timber, and advanced panel systems, poses competitive challenges, requiring hollow concrete block producers to continually innovate and differentiate their products. Furthermore, environmental regulations concerning dust emissions, waste management, and energy consumption in manufacturing processes can add compliance costs, particularly for smaller market players.

Despite these challenges, significant opportunities abound. The global shift towards sustainable and green building practices presents a lucrative avenue, as hollow concrete blocks, especially those incorporating recycled materials or optimized for energy efficiency (like AAC blocks), align well with environmental objectives. Advances in manufacturing technology, including automation and improved curing methods, offer prospects for enhanced production efficiency and quality. Moreover, the increasing adoption of prefabrication and modular construction techniques, where standardized blocks are highly valued, provides a robust growth pathway. The rising disposable incomes and changing lifestyles in emerging markets also fuel residential construction, creating a sustained demand for building materials.

Segmentation Analysis

The Hollow Concrete Blocks Market is meticulously segmented based on various factors, providing a detailed understanding of its dynamics and target audiences. These segmentations are crucial for market participants to identify niche opportunities, tailor product offerings, and devise effective strategies for growth and competitive advantage. The primary segmentation criteria include the type of block, the application area, the end-use within construction, and the manufacturing process employed.

- By Type:

- Load-Bearing Hollow Blocks: Designed to support structural loads.

- Non-Load-Bearing Hollow Blocks: Used for partitions and infill walls.

- Aerated Autoclaved Concrete (AAC) Blocks: Lightweight, excellent thermal insulation.

- Lightweight Aggregate Blocks: Incorporate lightweight aggregates for reduced density.

- By Application:

- Residential Construction: Single-family homes, multi-story apartments.

- Commercial Construction: Offices, retail spaces, hotels.

- Industrial Construction: Factories, warehouses, industrial facilities.

- Infrastructure Projects: Bridges, roads, public utilities.

- By End-Use:

- Walls: Exterior and interior structural and non-structural walls.

- Foundations: Base structures for buildings.

- Partitions: Internal dividing walls.

- Facades: External building surfaces.

- Retaining Walls: Structures to hold back soil or earth.

- By Manufacturing Process:

- Vibration Compaction: Common method using high-frequency vibration.

- High-Pressure Pressing: For denser, stronger blocks.

- Autoclaving: For AAC blocks, involving high-pressure steam curing.

Value Chain Analysis For Hollow Concrete Blocks Market

The value chain for the Hollow Concrete Blocks Market begins with the upstream analysis, which involves the sourcing and processing of raw materials. This stage is critical as the quality and cost-effectiveness of inputs directly impact the final product. Key raw materials include cement, aggregates (sand, gravel, crushed stone), and water, along with potential additives like fly ash, slag, or lightweight aggregates. Suppliers in this segment focus on efficient quarrying, crushing, and mixing operations to deliver consistent quality and timely supply to block manufacturers. Strategic relationships with raw material suppliers are vital for maintaining competitive pricing and ensuring uninterrupted production, guarding against supply chain disruptions.

The core of the value chain is the manufacturing process, where raw materials are combined, molded, and cured to produce hollow concrete blocks. This stage involves significant capital investment in machinery such as batching plants, block making machines (vibration compaction, high-pressure presses), and curing facilities (kilns, autoclaves). Manufacturers focus on optimizing production efficiency, maintaining stringent quality control, and innovating product designs to meet diverse construction requirements. Automation and adherence to industry standards play a crucial role in enhancing productivity and product integrity.

Downstream analysis covers the distribution channels and end-use of the blocks. Once manufactured, blocks are transported to various construction sites via a network of distributors, wholesalers, and sometimes directly to large construction firms. Direct sales channels are typically employed for large-scale projects, while indirect channels leverage a network of construction material retailers and hardware stores to reach smaller contractors and individual builders. Effective logistics and supply chain management are paramount to ensure timely delivery, minimize transportation costs, and reduce breakages. The final step involves the installation of these blocks in residential, commercial, industrial, and infrastructure projects, where their performance directly contributes to the structural integrity and longevity of the built environment.

Hollow Concrete Blocks Market Potential Customers

The primary potential customers and end-users of hollow concrete blocks span a broad spectrum within the construction industry, reflecting the versatility and fundamental nature of these building materials. Large-scale construction companies and developers represent a significant customer segment, particularly those engaged in extensive residential complexes, commercial high-rises, industrial parks, and public infrastructure projects. These entities often purchase in bulk, seeking reliable suppliers that can meet substantial volume requirements and adhere to strict project timelines and quality specifications.

Beyond major developers, independent contractors and small to medium-sized construction firms constitute another vital customer base. These buyers often source hollow concrete blocks for individual home builds, small commercial renovations, and local community infrastructure projects. Their purchasing decisions are often influenced by local availability, pricing, and the reputation of distributors. They value ease of access, prompt delivery, and materials that simplify the construction process.

Additionally, government agencies and municipal corporations are significant end-users for public works, housing projects, schools, hospitals, and other civic infrastructure developments. Their procurement often involves competitive bidding processes, emphasizing durability, cost-effectiveness, and compliance with national building standards. Furthermore, individual homeowners engaging in do-it-yourself (DIY) projects, small-scale extensions, or landscaping also represent a segment of potential customers, typically purchasing through retail hardware stores and building material outlets.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 25.5 Billion |

| Market Forecast in 2032 | USD 39.8 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | CRH plc, Cemex S.A.B. de C.V., Holcim Ltd., HeidelbergCement AG, UltraTech Cement Ltd., ACC Limited, Boral Limited, Midland Concrete Products, Inc., County Materials Corporation, Oldcastle APG, Acme Concrete Products, Adbri Ltd., BRC Block, National Cement Company, AfriSam, Hanson Building Products, E.P. Henry Corporation, Tremron, Lee Building Products, Titan America LLC |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hollow Concrete Blocks Market Key Technology Landscape

The Hollow Concrete Blocks Market's technology landscape is characterized by a continuous drive towards enhanced production efficiency, superior product quality, and increased sustainability. Advanced block-making machines, utilizing hydraulic and pneumatic systems coupled with precise vibration compaction technology, are central to modern manufacturing. These machines are capable of producing high-density, dimensionally accurate blocks at rapid rates, reducing labor dependency and increasing throughput. Furthermore, automated batching plants integrate sophisticated sensors and control systems to ensure accurate mixing ratios of cement, aggregates, and water, which is critical for maintaining consistent block strength and durability.

Curing technologies have also seen significant advancements. While traditional air curing remains prevalent, many manufacturers are adopting steam curing or autoclave curing processes, particularly for specialized blocks like Aerated Autoclaved Concrete (AAC). Steam curing accelerates the hydration of cement, leading to faster strength development and reduced curing times, enhancing overall production cycles. Autoclave curing, involving high-pressure steam, is essential for producing AAC blocks, which offers superior thermal insulation and lightweight properties. These controlled curing environments ensure optimal material performance and minimize the risk of shrinkage cracks.

Beyond core manufacturing, the integration of automation and data analytics is transforming the technology landscape. Robotics are increasingly used for handling, stacking, and packaging blocks, improving efficiency and worker safety. Enterprise Resource Planning (ERP) systems are deployed to manage raw material procurement, production scheduling, inventory, and logistics, providing real-time insights for operational optimization. Moreover, a focus on green technologies involves incorporating recycled materials such as fly ash and blast furnace slag into block formulations, as well as optimizing energy consumption throughout the production process, aligning with global sustainability objectives and regulatory pressures.

Regional Highlights

- Asia Pacific (APAC): Dominates the market due to rapid urbanization, extensive infrastructure development, and a booming residential construction sector in countries like China, India, and Southeast Asian nations. Government initiatives promoting affordable housing and smart cities further fuel demand. The region benefits from a large labor force and relatively lower production costs, attracting significant investment in manufacturing facilities.

- North America: Exhibits steady growth driven by a mature construction industry, ongoing renovation projects, and stringent building codes emphasizing energy efficiency and structural resilience. The adoption of sustainable building practices and technological advancements in block manufacturing contribute to market expansion. Investments in public infrastructure and commercial real estate also play a crucial role.

- Europe: Characterized by a focus on sustainable construction, energy-efficient buildings, and circular economy principles. Western European countries are strong adopters of advanced hollow concrete blocks, including AAC, for their superior insulation properties. Eastern Europe shows growth potential driven by economic development and increasing construction activities, albeit with varying regulatory landscapes.

- Latin America: Experiences moderate growth, primarily from expanding residential construction and public infrastructure investments. Countries like Brazil and Mexico are key markets, benefiting from urbanization trends and efforts to address housing deficits. Economic stability and foreign direct investment are crucial for sustained market development in this region.

- Middle East and Africa (MEA): Emerging as a significant market due to rapid population growth, ambitious government-led construction projects (e.g., smart cities, tourism infrastructure), and diversification efforts away from oil economies. Countries in the GCC region, along with South Africa, are leading the demand, with a strong focus on durable and heat-resistant building materials suitable for the local climate.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hollow Concrete Blocks Market.- CRH plc

- Cemex S.A.B. de C.V.

- Holcim Ltd.

- HeidelbergCement AG

- UltraTech Cement Ltd.

- ACC Limited

- Boral Limited

- Midland Concrete Products, Inc.

- County Materials Corporation

- Oldcastle APG

- Acme Concrete Products

- Adbri Ltd.

- BRC Block

- National Cement Company

- AfriSam

- Hanson Building Products

- E.P. Henry Corporation

- Tremron

- Lee Building Products

- Titan America LLC

Frequently Asked Questions

Analyze common user questions about the Hollow Concrete Blocks market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary benefits of using hollow concrete blocks in construction?

Hollow concrete blocks offer numerous advantages including enhanced thermal and sound insulation, reduced material consumption, lighter structural loads, faster construction times, and superior fire resistance. Their consistent dimensions simplify building processes and reduce labor costs.

How do hollow concrete blocks contribute to sustainable building practices?

They are inherently sustainable due to the potential for incorporating recycled aggregates like fly ash or slag, reducing waste. Their thermal properties contribute to energy-efficient buildings by minimizing heating and cooling needs, leading to lower carbon footprints over a building's lifecycle.

What are the main types of hollow concrete blocks available in the market?

Key types include load-bearing blocks for structural support, non-load-bearing blocks for partitions, Aerated Autoclaved Concrete (AAC) blocks known for lightness and insulation, and lightweight aggregate blocks which reduce overall building weight.

Which regions are driving the growth of the hollow concrete blocks market?

The Asia Pacific region is the primary growth driver due to extensive urbanization, infrastructure development, and a booming residential sector. North America and Europe also show steady growth, supported by renovation and sustainable building initiatives.

What impact does AI have on the manufacturing of hollow concrete blocks?

AI significantly impacts manufacturing through predictive maintenance for machinery, optimizing raw material blending for quality, enhancing quality control via computer vision, automating production scheduling, and improving energy efficiency in curing processes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager