Homogenizer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430797 | Date : Nov, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Homogenizer Market Size

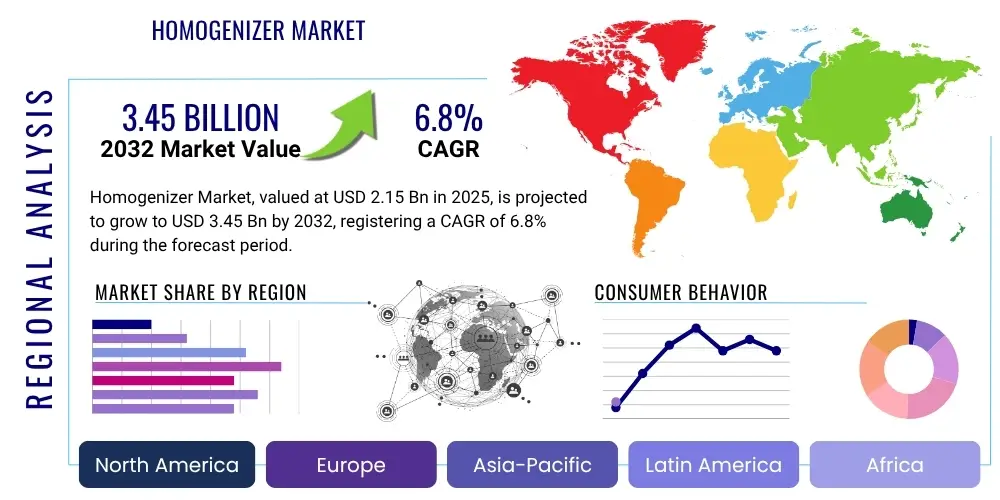

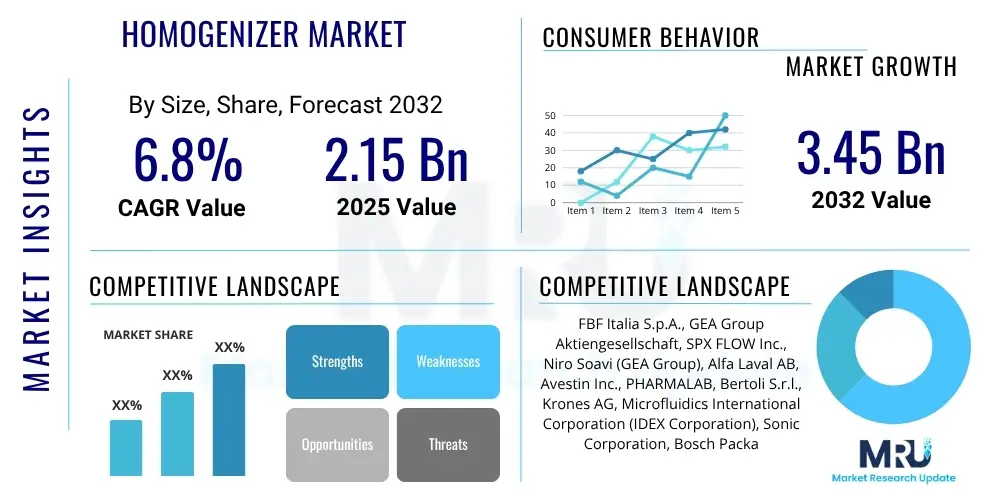

The Homogenizer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 2.15 Billion in 2025 and is projected to reach USD 3.45 Billion by the end of the forecast period in 2032.

Homogenizer Market introduction

The Homogenizer Market encompasses a sophisticated array of mechanical devices fundamentally engineered to reduce the particle size of various liquid and semi-liquid mixtures, thereby creating stable and uniform emulsions, dispersions, and suspensions. This process, known as homogenization, is paramount across a multitude of industrial applications, where the objective is to achieve product stability, enhance textural properties, improve bioavailability, extend shelf life, and ensure consistent quality. Homogenizers operate by subjecting fluid streams to intense mechanical forces, typically high shear, turbulence, cavitation, or impaction, causing larger particles or immiscible liquid droplets to break down into significantly finer, uniformly distributed constituents, thereby preventing phase separation and sedimentation.

The product portfolio within this market segment is diverse, comprising various types such as high-pressure homogenizers, low-pressure homogenizers, ultrasonic homogenizers, and mechanical homogenizers, including rotor-stator mixers and valve-based systems. High-pressure homogenizers, a prominent category, force fluid through a precisely engineered, narrow adjustable gap at very high velocities, leveraging the principles of extreme turbulence, shear, and cavitation to achieve substantial particle reduction. Ultrasonic homogenizers, in contrast, utilize high-frequency sound waves to induce cavitation, where microscopic bubbles rapidly form and collapse, generating localized shear forces powerful enough for nano-emulsification and cell disruption. Each type is meticulously designed and optimized for specific viscosities, desired particle sizes, and application requirements, ensuring tailored solutions for complex industrial challenges.

The major applications of homogenizers span critical sectors including the food and beverage industry, pharmaceutical and biotechnology, cosmetics and personal care, and specialized chemical manufacturing. In food and beverage, these machines are indispensable for dairy products like milk, yogurt, and ice cream to prevent fat separation and achieve a smooth mouthfeel; for fruit juices to enhance stability and appearance; and for sauces and dressings to ensure consistent texture. For pharmaceuticals, homogenizers are vital in preparing stable drug suspensions, emulsions, and liposomal formulations, which are crucial for improving drug solubility, bioavailability, and targeted delivery. The inherent benefits of homogenization, such as superior product stability, extended shelf life, enhanced sensory attributes, improved nutrient absorption, and consistent batch-to-batch quality, are significant driving factors for market growth. These are further augmented by increasing consumer demand for high-quality, stable processed products and a continuous drive for innovation in research and development across scientific disciplines requiring precise control over material properties.

Homogenizer Market Executive Summary

The Homogenizer Market is currently experiencing a period of robust and dynamic expansion, underpinned by escalating demand from a wide array of end-use industries and consistent advancements in homogenization technologies. Key business trends underscore a strategic shift towards automation, intelligent process control, and enhanced energy efficiency in homogenizer designs. Manufacturers are increasingly focusing on developing sophisticated systems that offer greater customization, enabling users to optimize processes for specific product formulations and achieve stringent quality specifications. There is a growing emphasis on integrating homogenizers into Industry 4.0 frameworks, facilitating data-driven decision-making, remote monitoring, and seamless integration with broader manufacturing execution systems. This drive for operational excellence and cost reduction is reshaping the competitive landscape and promoting innovation in equipment design and functionality.

Regional trends reveal the Asia Pacific (APAC) region as the undeniable powerhouse for market growth, demonstrating both dominance and rapid expansion. This surge is primarily attributable to the burgeoning food and beverage sector, significant investments in pharmaceutical manufacturing, and the rapid pace of biotechnology research and development in economic giants like China, India, and Japan. These countries are not only expanding their domestic production capabilities but also becoming key players in global supply chains. North America and Europe, while representing more mature markets, continue to exhibit steady and incremental growth, driven by stringent regulatory environments that demand high levels of product quality and safety, alongside a strong emphasis on adopting advanced, often premium, processing technologies for high-value applications. These regions also contribute significantly to technological innovation and the development of next-generation homogenizers.

Segment-wise, high-pressure homogenizers maintain their leading position within the market due to their broad utility and proven effectiveness across diverse applications, particularly in the dairy and pharmaceutical sectors where precise and consistent particle size reduction is critical. However, ultrasonic homogenizers are rapidly gaining traction and market share, especially in specialized applications within biotechnology, nanotechnology, and advanced materials science, where their ability to achieve ultra-fine particle sizes and perform cell disruption efficiently offers distinct advantages. The market is also witnessing a discernible trend towards modular and scalable homogenizer systems, which provide manufacturers with the flexibility to adapt to varying production volumes and new product introductions without significant capital expenditure. These comprehensive trends collectively indicate a market that is not only growing in size but also evolving technologically to meet increasingly complex industrial and consumer demands, emphasizing precision, efficiency, and adaptability.

AI Impact Analysis on Homogenizer Market

The integration of Artificial Intelligence (AI) within the homogenizer market directly addresses critical user inquiries concerning process optimization, predictive maintenance, rigorous quality control, and accelerated research and development. End-users are increasingly asking how AI can transcend traditional homogenization practices, ushering in unprecedented levels of precision, operational efficiency, and equipment reliability. The prevailing themes center on leveraging AI to enable real-time, adaptive process adjustments, anticipate and mitigate equipment failures before they manifest, guarantee consistent product quality through intelligent, automated monitoring, and drastically expedite the discovery of optimal formulation parameters. Ultimately, the expectation is that AI will deliver substantial operational improvements, significant cost reductions, and a competitive edge in product innovation, transforming the entire lifecycle of homogenization processes.

- AI-driven process optimization facilitates real-time, dynamic adjustment of critical homogenization parameters, including pressure, temperature, flow rate, and valve settings. This is achieved by continuously analyzing multi-variate sensor data (e.g., rheological properties, particle size distribution) through machine learning algorithms, leading to superior product consistency, minimized batch variations, and reduced material waste.

- Predictive maintenance capabilities, powered by advanced machine learning models, analyze vast datasets from homogenizer operations such as vibration patterns, motor performance, and pressure fluctuations. This enables accurate forecasting of potential component wear or equipment malfunctions, allowing for proactive scheduling of maintenance interventions, which significantly minimizes unplanned downtime and extends the operational lifespan of the machinery.

- AI profoundly enhances quality control by integrating computer vision and advanced analytical techniques (e.g., spectral analysis). It can rapidly analyze microscopic images or spectroscopic data of homogenized products to ensure ultra-uniform particle size distribution, detect agglomeration, or identify deviations from established quality benchmarks with higher precision and speed than conventional manual inspection methods.

- Accelerated Research and Development is achieved as AI platforms can rapidly screen and simulate countless permutations of formulations and processing conditions. By leveraging historical data and computational fluid dynamics (CFD) simulations, AI predicts optimal homogenization parameters for new product development, drastically reducing the number of physical experiments, cutting down time-to-market, and lowering R&D expenditures.

- AI algorithms are employed to optimize energy consumption within homogenizers by learning complex operational patterns and identifying inefficiencies. By dynamically adjusting motor speeds, pump pressures, and other energy-intensive settings based on real-time load requirements, AI contributes significantly to reducing power usage and supports the adoption of more sustainable manufacturing practices.

- Remote monitoring and diagnostic systems, augmented by AI, provide operators and maintenance teams with critical, actionable insights into homogenizer performance and health from virtually any location. This capability streamlines troubleshooting processes, optimizes operational oversight for multi-site facilities, and ensures rapid response to potential issues, improving overall productivity.

DRO & Impact Forces Of Homogenizer Market

The Homogenizer Market is intricately shaped by a complex interplay of drivers, restraints, opportunities, and broader impact forces that collectively dictate its growth trajectory and competitive dynamics. Key drivers include the relentless growth of the global processed and packaged food and beverage sector, which inherently relies on homogenization to achieve desired textures, prevent phase separation, and extend product shelf life. The concurrent expansion of the pharmaceutical and biotechnology industries further fuels market demand, driven by an increasing need for stable drug emulsions, precise vaccine formulations, advanced cell disruption techniques for protein extraction, and the development of sophisticated gene therapies. Moreover, continuous technological advancements, such as the emergence of more energy-efficient models, higher capacity homogenizers, and systems capable of achieving nano-scale particle reduction, play a pivotal role in accelerating adoption across diverse industrial landscapes. The intrinsic benefits of homogenization, encompassing superior product quality, enhanced bioavailability, and consistent batch uniformity, firmly establish it as an indispensable process in modern manufacturing.

Despite these significant growth drivers, the market faces several notable restraints that could potentially impede its expansion. A primary barrier is the substantial initial capital investment required for acquiring advanced homogenizer equipment, particularly for high-pressure and specialized systems. This high entry cost, coupled with ongoing operational expenses, including energy consumption, wear-part replacement, and specialized maintenance, can be prohibitive for small and medium-sized enterprises (SMEs) or startups. Furthermore, the stringent regulatory landscape, particularly within the highly scrutinized pharmaceutical and food sectors (ee.g., FDA, EMA, USDA regulations), mandates rigorous validation, documentation, and adherence to Good Manufacturing Practices (GMP). These compliance requirements add layers of complexity, time, and cost to equipment deployment and sustained operation, posing challenges for manufacturers to meet evolving standards.

Nonetheless, the Homogenizer Market is rich with promising opportunities that could unlock significant growth potential. Emerging economies, particularly those within the Asia Pacific, Latin America, and Middle East & Africa regions, represent vast untapped markets with rapidly industrializing food processing and pharmaceutical sectors, coupled with rising disposable incomes and changing consumer preferences for processed goods. The increasing global consumer preference for natural, organic, and plant-based products is also creating a niche demand for homogenizers capable of processing delicate ingredients while preserving their nutritional integrity and sensory characteristics. Additionally, advancements in "green" homogenization techniques, focusing on reduced energy consumption, water usage, and waste generation, offer a pathway for market differentiation and alignment with global sustainability goals. The development of highly customizable, modular, and intelligent homogenizer systems that can seamlessly integrate into existing production lines and adapt to diverse product specifications and varying production scales represents a significant growth avenue, enhancing operational flexibility and overall efficiency for end-users, thus shaping the long-term strategic outlook for market participants.

Segmentation Analysis

The Homogenizer Market is meticulously segmented across various dimensions to offer a granular and comprehensive understanding of its intricate structure, diverse applications, technological spectrum, and operational scales. This multi-faceted segmentation is a crucial analytical tool, enabling market participants to identify precise growth drivers, discern emerging opportunities, pinpoint competitive advantages, and strategically position their offerings within specific niches. For manufacturers, a deep dive into these segments facilitates product development tailored to exact customer requirements, while for investors, it provides clarity on high-potential investment avenues. Moreover, end-users benefit from this structured analysis by being able to select the most appropriate homogenization solutions that align perfectly with their processing needs, ensuring optimal product quality, process efficiency, and cost-effectiveness.

- By Type

- High Pressure Homogenizers: These remain the dominant type, characterized by their robustness and versatility in achieving fine particle sizes. They are widely utilized in critical applications across the dairy, food processing, and pharmaceutical industries due to their consistent performance.

- Low Pressure Homogenizers: Typically employed for less viscous materials or as an initial pre-treatment stage in multi-step processing, offering a cost-effective solution for less demanding applications or when coarser dispersions are acceptable.

- Ultrasonic Homogenizers: Gaining significant traction in advanced applications such as biotechnology, nanotechnology, and specialized chemical synthesis. They excel in achieving very fine, often nano-scale, particle sizes and are effective for cell disruption and difficult-to-emulsify substances.

- Mechanical Homogenizers (e.g., Rotor-Stator, Valve Homogenizers): Broadly used for primary mixing, emulsification, and dispersion in various industries, offering a balance of efficiency and cost for a wide range of product viscosities.

- By Application

- Food and Beverage: Encompasses extensive use in dairy products (milk, yogurt, ice cream), fruit juices, sauces, dressings, confectionery, and the rapidly growing segment of plant-based beverages and infant formulas.

- Pharmaceutical and Biotechnology: Critical for preparing stable drug emulsions, suspensions, vaccines, liposomal formulations, cell disruption for biologics extraction, and gene therapy vectors, where precision and sterility are paramount.

- Cosmetics and Personal Care: Essential for creating stable and aesthetically appealing creams, lotions, shampoos, conditioners, perfumes, and various makeup bases, ensuring smooth texture and extended shelf life.

- Chemical: Utilized in the production of paints, coatings, inks, polymers, lubricants, and agricultural chemicals, where particle size control directly impacts product performance, stability, and appearance.

- Others: Includes applications in research and development laboratories, specialty chemicals, waste treatment, and advanced material science.

- By Capacity

- Laboratory Scale: Designed for small batch processing, crucial for fundamental research, formulation development, quality control, and testing of new products and processes.

- Pilot Scale: Intermediate volumes used for process optimization, scale-up studies, and producing small commercial batches, bridging the gap between lab and full-scale production.

- Industrial Scale: High-volume production systems engineered for continuous, large-scale commercial manufacturing, built for durability, efficiency, and throughput.

- By Technology

- Dynamic Homogenizers: Involve moving parts that create high shear and turbulence, such as conventional valve homogenizers, which are highly effective and widely adopted.

- Static Homogenizers: Utilize fixed internal geometries or baffles to generate shear and mixing without moving parts, often used for less intense homogenization or as inline mixers.

Value Chain Analysis For Homogenizer Market

The value chain for the Homogenizer Market commences at the upstream segment with the procurement of critical raw materials and specialized components, which are foundational to the quality and longevity of the final equipment. This initial stage involves suppliers providing high-grade stainless steel, typically AISI 316L, essential for contact parts to ensure hygiene and corrosion resistance, particularly in food and pharmaceutical applications. Furthermore, advanced ceramic materials like tungsten carbide or zirconia are sourced for wear-resistant components such as valves, seats, and plungers, which endure extreme pressures and abrasive forces. Precision electronics for control systems, robust motors and pumps for power, and specialized seals and gaskets for leak prevention also form vital upstream inputs. The performance, reliability, and ultimately the market competitiveness of homogenizer manufacturers are heavily reliant on establishing strong, reliable relationships with these high-quality component suppliers and implementing stringent quality assurance protocols at this foundational stage.

Mid-stream in the value chain, after manufacturing and assembly, the homogenizers move into the distribution phase, which is characterized by a blend of direct and indirect channels designed to optimize market reach and customer engagement. Direct distribution typically involves the manufacturer's own dedicated sales force, technical support teams, and service engineers, especially for complex, large-scale industrial systems that require bespoke installation, commissioning, and ongoing maintenance. This direct approach ensures close customer relationships and tailored solutions. Indirect channels encompass a network of authorized distributors, regional agents, and value-added resellers who provide localized market access, immediate technical assistance, and often integrate homogenizers into broader processing lines for specific industries. Additionally, Original Equipment Manufacturers (OEMs) may incorporate homogenizer units or core components into their larger, integrated processing equipment, expanding market penetration by offering complete system solutions. The efficacy of these diverse distribution networks is crucial for efficient market penetration, responsive customer service, and timely delivery across various geographical regions.

The downstream segment culminates with the end-users, or potential customers, who are the ultimate beneficiaries of homogenization technology across a wide array of industries. This includes major players in the food and beverage industry, pharmaceutical companies, biotechnology firms, cosmetic manufacturers, and specialized chemical producers. The effectiveness of the entire value chain is fundamentally measured by its ability to deliver the most suitable homogenizer solution, coupled with comprehensive pre-sales consultation, seamless installation, thorough operator training, and robust post-sales technical support, including spare parts availability and preventative maintenance services. An integrated and customer-centric approach throughout this value chain fosters long-term relationships, enhances customer satisfaction, and significantly contributes to the sustained growth and reputation of homogenizer manufacturers in a highly competitive global market.

Homogenizer Market Potential Customers

The Homogenizer Market serves a broad and strategically important base of potential customers, primarily comprising end-users and buyers across various industrial sectors who have a critical need for precise particle size reduction and dispersion capabilities in their manufacturing processes. These customers are motivated by a core set of operational imperatives: the necessity to significantly enhance product stability, achieve desired textural properties and sensory attributes, improve the bioavailability of active ingredients, extend the shelf life of perishable goods, and ensure consistent, batch-to-batch product quality. The indispensable role that homogenizers play in addressing these crucial requirements positions them as essential capital equipment for entities ranging from large, multinational corporations with extensive production lines to specialized research and development laboratories and innovative startups focusing on novel material formulations.

Within the expansive food and beverage industry, major buyers include global dairy processors, large-scale juice manufacturers, producers of a diverse range of sauces, dressings, and condiments, as well as companies specializing in the rapidly growing segments of plant-based milk alternatives, infant nutrition, and functional beverages. These organizations leverage homogenizers to prevent fat separation in milk, create smooth and uniform textures in dairy products like yogurt and ice cream, stabilize emulsions in fruit juices and cream liqueurs, and ensure the consistent quality of various culinary preparations. In the highly regulated pharmaceutical and biotechnology sectors, the customer base is equally significant, encompassing leading drug manufacturers, vaccine producers, and cutting-edge biotech research firms. Here, homogenizers are critical for preparing highly stable drug suspensions and emulsions, facilitating controlled drug release, achieving efficient cell lysis for protein and DNA extraction, and producing liposomal drug delivery systems and gene therapy vectors, where precision, sterility, and regulatory compliance are non-negotiable.

Furthermore, manufacturers in the global cosmetic and personal care industry represent another substantial segment of potential customers, employing homogenizers extensively to create stable, aesthetically pleasing, and functionally effective creams, lotions, serums, shampoos, and makeup products. The consistency and stability achieved through homogenization are vital for product appeal and shelf life in this consumer-driven market. Similarly, the chemical industry relies heavily on homogenizers for producing high-quality paints, coatings, inks, polymers, lubricants, and specialized agricultural chemicals, where precise control over particle size directly impacts product performance, application characteristics, and overall appearance. Additionally, academic research institutions, university laboratories, and contract manufacturing organizations (CMOs) constitute a specialized segment of customers, requiring laboratory and pilot-scale homogenizers for new product development, process optimization, and small-batch production. The diverse and exacting requirements across these varied industries necessitate a highly flexible, adaptable, and technologically advanced portfolio of homogenizer solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 2.15 Billion |

| Market Forecast in 2032 | USD 3.45 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | FBF Italia S.p.A., GEA Group Aktiengesellschaft, SPX FLOW Inc., Niro Soavi (GEA Group), Alfa Laval AB, Avestin Inc., PHARMALAB, Bertoli S.r.l., Krones AG, Microfluidics International Corporation (IDEX Corporation), Sonic Corporation, Bosch Packaging Technology (Syntegon Technology GmbH), FrymaKoruma AG, Netzsch-Feinmahltechnik GmbH, IKA Works GmbH & Co. KG, Homogenizing Systems Inc., Shanghai Jinzhu Homogenizer Co., Ltd., Sevanan Corporation, APV (SPX FLOW Inc.), Rossi & Catelli (Tetra Pak). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Homogenizer Market Key Technology Landscape

The Homogenizer Market's technological landscape is characterized by a relentless pursuit of innovation, focusing on enhancing processing efficiency, achieving finer particle sizes with greater precision, and increasing the overall versatility of equipment. Within high-pressure homogenization, which remains a foundational technology, ongoing advancements are seen in critical areas such as valve design. Manufacturers are continually developing and refining multi-stage valve systems, including two-stage, three-stage, and even more complex geometries, which not only improve energy efficiency by optimizing pressure drop but also achieve a tighter and more uniform particle size distribution, crucial for applications requiring ultra-fine emulsions. Furthermore, the integration of advanced materials, such as high-performance ceramics (e.g., silicon nitride, zirconia) and specialized alloys, for components like plungers, valves, and seats, significantly extends equipment lifespan, reduces wear and tear, and enables the processing of increasingly abrasive, corrosive, or high-viscosity materials while adhering to stringent sanitary and aseptic standards.

A significant transformative trend shaping the market is the accelerating integration of automation, digitalization, and smart technologies into homogenizer systems. Modern homogenizers are now routinely equipped with sophisticated Programmable Logic Controllers (PLCs), intuitive Human Machine Interfaces (HMIs), and an array of intelligent sensors for real-time, continuous monitoring and precise control of critical operational parameters, including pressure, temperature, flow rate, and energy consumption. This level of automation ensures unparalleled process repeatability, significantly minimizes human error, and greatly facilitates compliance with rigorous international regulatory standards such as FDA, cGMP, and HACCP. The advent of remote diagnostic capabilities, cloud connectivity, and integration into broader Industrial Internet of Things (IIoT) platforms further enables preventative maintenance scheduling, predictive analytics for potential equipment failures, and optimized operational uptime, directly contributing to higher Overall Equipment Effectiveness (OEE) and reduced total cost of ownership.

Beyond high-pressure systems, the market is also witnessing considerable technological advancements in other homogenization methods. Ultrasonic homogenization, for instance, is seeing developments in more robust sonication probes, cavitation chamber designs, and scalable reactor configurations, making these systems more effective and suitable for industrial-scale applications requiring nano-scale emulsions or high-efficiency cell disruption in biotech. Microfluidization, another cutting-edge technology, employs precisely engineered micro-channels to generate extremely high shear rates, enabling the production of highly stable emulsions and dispersions with exceptionally narrow particle size distributions, particularly valuable for pharmaceutical and advanced material applications. Overall, the technology landscape is rapidly evolving towards more intelligent, highly energy-efficient, versatile, and sustainable homogenizers capable of meeting the increasingly complex and specialized demands of diverse end-use industries, while simultaneously prioritizing operational flexibility, reduced resource consumption, and enhanced product quality control.

Regional Highlights

- North America: This region represents a mature and technologically advanced market for homogenizers, characterized by stringent regulatory standards, particularly within the pharmaceutical and food processing industries. High adoption rates of advanced processing technologies, substantial R&D investments in biotechnology, and a strong emphasis on automation and energy efficiency drive consistent demand. The United States and Canada are key contributors, leading in innovation and the demand for high-quality, stable consumer and medical products.

- Europe: Similar to North America, Europe demonstrates robust demand for sophisticated homogenizers, underpinned by a highly developed food and beverage industry, a well-established and innovation-driven pharmaceutical manufacturing sector, and a strong regional focus on sustainability and energy-efficient processing solutions. Countries such as Germany, France, and the UK are prominent contributors to market growth, driven by both domestic demand and export capabilities of high-quality homogenized products.

- Asia Pacific (APAC): APAC stands out as the fastest-growing and largest market for homogenizers globally, experiencing significant expansion propelled by rapid industrialization, burgeoning economies, and rapidly increasing consumer populations, especially in key countries like China, India, and Japan. The burgeoning food processing sector, expanding dairy industry, and escalating pharmaceutical and biotechnology investments in this region are formidable demand drivers, often seeking both cost-effective and high-performance homogenization solutions.

- Latin America: This region presents considerable growth potential for the Homogenizer Market, primarily due to increasing investments in its burgeoning food processing and pharmaceutical industries. Countries such as Brazil and Mexico are witnessing a notable modernization of their manufacturing capabilities and are experiencing a growing demand for advanced homogenization equipment to cater to an expanding middle class and evolving consumer preferences for processed and packaged goods.

- Middle East and Africa (MEA): As an emerging market, MEA is experiencing gradual but steady growth in industrialization, particularly within the food processing, dairy, and personal care sectors. Increased disposable incomes, alongside a discernible shift in consumer preferences towards processed and packaged goods, are fueling the demand for homogenization equipment. While market penetration is still in its nascent stages compared to more developed regions, the ongoing economic diversification and infrastructure development indicate significant future growth prospects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Homogenizer Market.- FBF Italia S.p.A.

- GEA Group Aktiengesellschaft

- SPX FLOW Inc.

- Niro Soavi (GEA Group)

- Alfa Laval AB

- Avestin Inc.

- PHARMALAB

- Bertoli S.r.l.

- Krones AG

- Microfluidics International Corporation (IDEX Corporation)

- Sonic Corporation

- Bosch Packaging Technology (Syntegon Technology GmbH)

- FrymaKoruma AG

- Netzsch-Feinmahltechnik GmbH

- IKA Works GmbH & Co. KG

- Homogenizing Systems Inc.

- Shanghai Jinzhu Homogenizer Co., Ltd.

- Sevanan Corporation

- APV (SPX FLOW Inc.)

- Rossi & Catelli (Tetra Pak)

Frequently Asked Questions

What is a homogenizer primarily used for?

A homogenizer is a mechanical device primarily used to reduce the particle or droplet size within a liquid mixture, thereby creating a stable and uniform emulsion, dispersion, or suspension. This process is crucial for preventing phase separation, improving texture, and enhancing product consistency across various industrial applications.

How does homogenization improve product quality in the food industry?

In the food industry, homogenization significantly improves product quality by stabilizing emulsions in dairy products (like milk, yogurt), preventing fat separation, enhancing mouthfeel, increasing viscosity for sauces and dressings, and extending the shelf life of various beverages and food items, leading to a more appealing and consistent consumer experience.

What are the main types of homogenizers available in the market?

The main types of homogenizers include high-pressure homogenizers, which utilize extreme pressure and shear forces; ultrasonic homogenizers, employing high-frequency sound waves for cavitation; and mechanical homogenizers, such as rotor-stator mixers or valve homogenizers, each tailored for different material properties and desired levels of particle size reduction.

Which industries heavily rely on homogenizers for their operations?

Homogenizers are heavily relied upon by a diverse set of industries including the food and beverage sector (dairy, juices, plant-based products), pharmaceutical and biotechnology industries (drug emulsions, vaccines, cell disruption), cosmetics and personal care manufacturers (creams, lotions), and various chemical industries (paints, coatings, polymers).

What are the latest technological advancements observed in homogenizer technology?

Recent technological advancements in homogenizer technology include the integration of advanced automation and digital control systems, the application of AI for real-time process optimization and predictive maintenance, development of highly energy-efficient designs, utilization of advanced materials for enhanced durability and sanitation, and the introduction of modular and scalable solutions to meet varied production needs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Homogenizer Mixers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Homogenizer Mixers Market Statistics 2025 Analysis By Application (Dairy, Food, Cosmetic, Chemical, Pharmaceutical, Biotech products), By Type (Bench-top, Handheld), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager