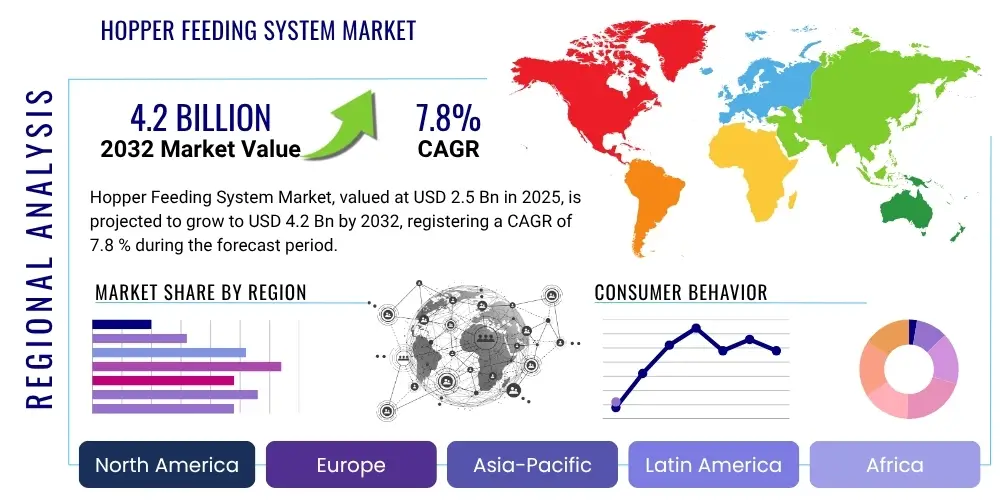

Hopper Feeding System Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427962 | Date : Oct, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Hopper Feeding System Market Size

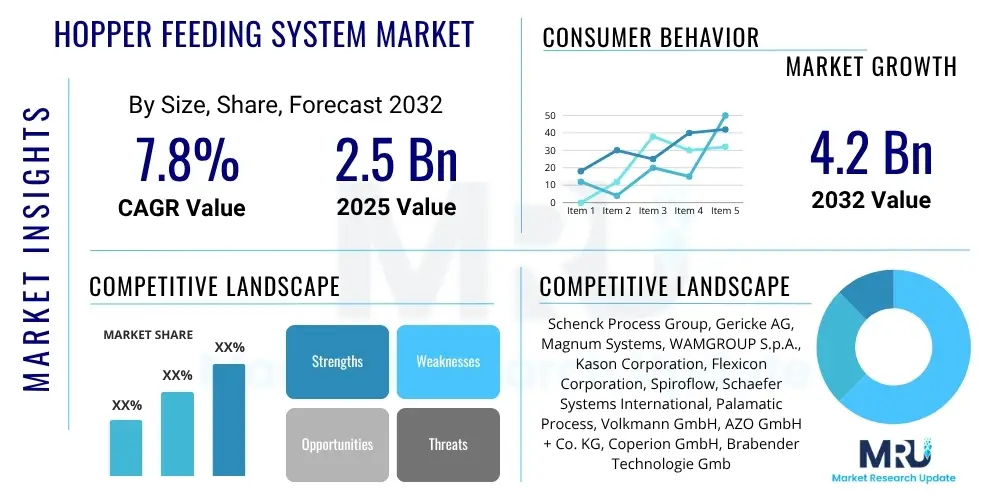

The Hopper Feeding System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at USD 2.5 Billion in 2025 and is projected to reach USD 4.2 Billion by the end of the forecast period in 2032. This growth is underpinned by increasing automation across various industrial sectors, particularly in manufacturing, processing, and packaging, where efficient material handling is crucial for optimizing operational workflows and reducing labor costs. The demand for precise and consistent material delivery systems is rising, especially with the expansion of high-volume production lines and the need to handle diverse types of bulk materials, ranging from fine powders to granules and flakes. Technological advancements in sensor integration, control systems, and modular designs are further contributing to the market's expansion, enhancing the adaptability and performance of hopper feeding solutions across a broader spectrum of applications.

Hopper Feeding System Market introduction

The Hopper Feeding System Market encompasses the design, manufacturing, and distribution of equipment used for the controlled and automated feeding of bulk materials into processing or packaging lines. These systems are essential components in numerous industrial applications, facilitating the seamless transfer of raw materials, intermediates, or finished products from storage hoppers to subsequent stages of production. A Hopper Feeding System typically consists of a hopper (storage vessel), a feeder mechanism (such as vibratory, screw, belt, or rotary feeders), and a control system to regulate material flow, ensuring accuracy and consistency. Product descriptions vary widely based on material properties (e.g., density, abrasiveness, flow characteristics), desired feed rates, and integration requirements. Major applications span industries like food and beverage, pharmaceuticals, chemicals, plastics, mining, construction, and agriculture, where they are deployed for tasks such as batching ingredients, dosing additives, conveying materials, and filling containers. The primary benefits of implementing these systems include enhanced production efficiency, improved process accuracy, reduced material waste, minimized human error, increased operational safety by limiting manual handling, and significant labor cost savings. Key driving factors propelling market growth include the global trend towards industrial automation and digitalization, stringent quality control standards necessitating precise material handling, the expansion of manufacturing capacities in developing economies, and the continuous innovation in feeder technologies to accommodate challenging materials and complex process requirements. These systems are critical enablers for modern, lean manufacturing principles, ensuring uninterrupted material supply and optimizing overall plant throughput.

Hopper Feeding System Market Executive Summary

The Hopper Feeding System Market is undergoing substantial transformation, driven by a confluence of evolving business trends, significant regional developments, and dynamic segment-specific shifts. Business trends indicate a strong move towards integrated and intelligent material handling solutions, with manufacturers increasingly seeking systems that offer real-time monitoring, predictive maintenance capabilities, and seamless integration with broader enterprise resource planning (ERP) systems. The emphasis is on improving supply chain resilience, reducing operational bottlenecks, and achieving higher levels of production flexibility. Companies are investing in automation to counter labor shortages and to ensure consistent product quality, especially in industries facing stringent regulatory oversight. Regional trends highlight robust growth in Asia Pacific, propelled by rapid industrialization, burgeoning manufacturing sectors, and substantial investments in infrastructure development, particularly in countries like China, India, and Southeast Asian nations. North America and Europe continue to be significant markets, characterized by demand for advanced, high-precision systems and a strong focus on sustainable manufacturing practices. Latin America, the Middle East, and Africa are emerging as promising regions due to growing industrialization and the adoption of modern processing technologies. Segment trends reveal increasing demand for gravimetric feeders due to their superior accuracy in dosing and batching, which is crucial for high-value applications in pharmaceuticals and specialized chemicals. The food and beverage sector remains a dominant application segment, driven by high production volumes and the need for hygienic material handling solutions. Furthermore, there is a growing interest in modular and customizable hopper feeding systems that can be easily adapted to various production scales and material types, offering greater versatility and future-proofing for industrial operations. These overarching trends collectively underscore a market characterized by continuous innovation, strategic regional expansion, and a persistent drive towards operational excellence through advanced material handling technologies.

AI Impact Analysis on Hopper Feeding System Market

Common user questions regarding AI's impact on the Hopper Feeding System Market frequently revolve around how artificial intelligence can enhance operational efficiency, predictive maintenance, and overall system autonomy. Users are keenly interested in understanding if AI can lead to more precise material dosing, reduce downtime, and adapt to changing material characteristics in real-time. There are also inquiries about the potential for AI-driven systems to integrate seamlessly with existing smart factory infrastructures and contribute to a more sustainable manufacturing environment by optimizing resource utilization. Concerns often include the complexity and cost of implementing AI solutions, data security, and the need for specialized personnel to manage these advanced systems. Overall, the prevailing expectation is that AI will revolutionize the intelligence and responsiveness of hopper feeding operations, moving them from merely automated to truly autonomous and adaptive, ultimately driving significant improvements in productivity, reliability, and cost-effectiveness across industrial applications.

- Enhanced Predictive Maintenance: AI algorithms analyze sensor data from feeders (vibration, motor load, temperature) to predict equipment failures, allowing for proactive maintenance and minimizing unscheduled downtime.

- Optimized Material Flow Control: AI systems can dynamically adjust feeder speeds and parameters based on real-time material characteristics (e.g., humidity, density variations) and downstream demand, ensuring consistent and precise dosing.

- Improved Anomaly Detection: AI identifies unusual patterns in operational data, flagging potential issues like blockages, wear, or inconsistent material supply before they escalate into major problems.

- Autonomous System Adaptation: AI-powered feeders can learn and adapt to changing production recipes, batch sizes, and environmental conditions without manual recalibration, enhancing flexibility and efficiency.

- Data-Driven Process Optimization: AI integrates with other factory systems to provide holistic insights into material consumption, production rates, and overall equipment effectiveness (OEE), facilitating continuous improvement.

- Enhanced Safety and Quality Control: AI vision systems can monitor material quality and detect foreign objects or inconsistencies in real-time, improving product integrity and worker safety by reducing human interaction with hazardous materials.

- Reduced Waste and Energy Consumption: By optimizing feed rates and minimizing overfeeding or underfeeding, AI contributes to significant reductions in material waste and optimizes energy usage in feeding operations.

DRO & Impact Forces Of Hopper Feeding System Market

The Hopper Feeding System Market is profoundly influenced by a complex interplay of drivers, restraints, opportunities, and broader impact forces that shape its growth trajectory and competitive landscape. Key drivers include the escalating global demand for industrial automation across diverse sectors, driven by the need to enhance operational efficiency, reduce labor costs, and improve production consistency. The stringent regulatory requirements for product quality, especially in food and beverage, pharmaceuticals, and chemicals, mandate precise and controlled material handling, thereby accelerating the adoption of advanced feeding systems. Furthermore, the expansion of manufacturing industries in emerging economies and the increasing complexity of materials being processed (e.g., nano-materials, challenging powders) necessitate sophisticated and reliable feeding solutions. However, the market faces significant restraints, primarily the high initial capital investment required for installing advanced automated feeding systems, which can be a barrier for small and medium-sized enterprises (SMEs). The technical complexity associated with integrating these systems into existing production lines, along with the need for specialized maintenance and skilled labor, also poses challenges. Moreover, fluctuations in raw material prices for system components and intense market competition from established players and new entrants exert pressure on pricing and profit margins. Despite these restraints, substantial opportunities exist for market expansion. The growing trend towards Industry 4.0 and the integration of IoT, AI, and data analytics into material handling systems present avenues for innovation and value creation, allowing for predictive maintenance, real-time optimization, and enhanced system autonomy. The increasing demand for customizable and modular feeding solutions that can adapt to varying production requirements and product types offers significant growth potential. Furthermore, the focus on sustainable manufacturing practices and the development of energy-efficient and waste-reducing feeding technologies open new market niches. Impact forces such as global economic stability, geopolitical factors affecting supply chains, technological advancements, and evolving environmental regulations collectively influence investment decisions and market dynamics, shaping the strategic priorities of manufacturers and end-users within the Hopper Feeding System Market.

Segmentation Analysis

The Hopper Feeding System market is broadly segmented to reflect the diverse applications, material types, operational requirements, and technological advancements prevalent across various industrial sectors. This comprehensive segmentation allows for a detailed analysis of market trends, identification of niche opportunities, and strategic planning for manufacturers and suppliers. The market is typically segmented by the type of feeder mechanism employed, the nature of the material being handled, the specific industrial application, the end-use industry utilizing these systems, and the level of automation integrated within the feeding process. Each segment presents unique characteristics in terms of demand drivers, technological preferences, and growth potential, necessitating tailored approaches for market penetration and product development. Understanding these distinct segments is crucial for stakeholders to effectively target specific customer needs and address varying operational challenges within the expansive landscape of material handling.

- By Feeder Type:

- Vibratory Feeders

- Screw Feeders (Single Screw, Twin Screw)

- Belt Feeders

- Rotary Feeders (Rotary Valve, Rotary Airlock)

- Loss-in-Weight Feeders (Gravimetric)

- Gain-in-Weight Feeders (Gravimetric)

- Volumetric Feeders

- By Material Handled:

- Powders (Fine, Coarse)

- Granules

- Pellets

- Flakes

- Aggregates

- Irregular Shapes

- Corrosive Materials

- Abrasive Materials

- By Application:

- Batching & Blending

- Dosing & Metering

- Conveying & Transferring

- Filling & Packaging

- Sorting & Separating

- By End-Use Industry:

- Food & Beverage (Dairy, Bakery, Confectionery, Beverages)

- Pharmaceuticals (API, Excipients)

- Chemicals (Polymers, Fertilizers, Specialty Chemicals)

- Plastics & Rubber

- Mining & Metallurgy (Ores, Minerals)

- Construction (Cement, Aggregates)

- Packaging

- Agriculture (Grains, Feed)

- Ceramics & Glass

- Pulp & Paper

- By Operation Mode:

- Continuous Feeding

- Batch Feeding

- By Capacity:

- Low Capacity (< 100 kg/hr)

- Medium Capacity (100 kg/hr - 1000 kg/hr)

- High Capacity (> 1000 kg/hr)

- By Automation Level:

- Manual/Semi-Automatic

- Fully Automatic

Value Chain Analysis For Hopper Feeding System Market

The value chain for the Hopper Feeding System Market is an intricate network that begins with the sourcing of raw materials and extends through to the final deployment and post-sales support, illustrating the sequential activities that add value to the end product. The upstream analysis involves critical activities such as the procurement of various raw materials including specialized metals (stainless steel, carbon steel), plastics, electronics, and control components like sensors, motors, and programmable logic controllers (PLCs). Suppliers in this stage focus on providing high-quality, durable, and cost-effective materials that meet specific industrial standards and operational demands, such as corrosion resistance for hygienic applications or abrasion resistance for handling heavy aggregates. Manufacturing and assembly constitute the core of the value chain, where components are engineered, fabricated, and integrated into complete feeding systems. This stage involves significant R&D investments in designing efficient feeder mechanisms, developing advanced control software, and ensuring robust construction for various industrial environments. Downstream analysis encompasses the distribution, installation, and end-user application of hopper feeding systems. Distribution channels are varied, including direct sales from manufacturers to large industrial clients, through a network of specialized distributors and resellers who provide localized sales and technical support, or via integrators who incorporate these systems into larger plant automation projects. Direct distribution allows for stronger customer relationships and customized solutions, while indirect channels offer broader market reach and regional expertise. Post-sales services, including installation, commissioning, training, maintenance, and spare parts supply, are crucial for customer satisfaction and long-term value generation. The effectiveness of the distribution channel directly impacts market penetration and customer accessibility. The entire value chain is characterized by a high degree of specialization and the need for strong collaboration between different stakeholders to ensure efficiency, quality, and responsiveness to market demands. Supply chain resilience and technological innovation at each stage are paramount for competitive advantage in this market.

Hopper Feeding System Market Potential Customers

The Hopper Feeding System Market serves a diverse and expansive customer base across a multitude of industrial sectors, all united by the common need for efficient, precise, and reliable bulk material handling. Potential customers, or end-users/buyers of these sophisticated systems, primarily include manufacturing and processing facilities that handle powders, granules, pellets, and other bulk solids as part of their production processes. In the food and beverage industry, major players such as large-scale bakeries, confectionery manufacturers, dairy processing plants, and beverage producers represent significant buyers, utilizing hopper feeders for accurate ingredient batching, mixing, and packaging. Pharmaceutical companies, from active pharmaceutical ingredient (API) manufacturers to dosage formulators, rely heavily on these systems for precise dosing of delicate and high-value compounds, adhering to strict regulatory standards. The chemical industry, encompassing producers of plastics, polymers, fertilizers, and specialty chemicals, constitutes another substantial customer segment, requiring robust feeders for handling corrosive, abrasive, or hazardous materials. Furthermore, mining and metallurgy operations employ heavy-duty feeding systems for raw ore, minerals, and aggregates, while construction material manufacturers use them for cement, sand, and gravel. Other key end-users include companies in the plastics processing, ceramics, glass, pulp and paper, and agricultural sectors, all seeking to optimize their material transfer, reduce manual labor, enhance safety, and ensure consistent product quality. The demand is not limited to large corporations; increasingly, small and medium-sized enterprises (SMEs) are investing in more automated feeding solutions to scale operations and improve competitive positioning, driving a broader market penetration for various types of hopper feeding systems designed for specific capacity and material requirements. The continuous evolution of manufacturing technologies and the persistent drive for operational excellence ensure a sustained and expanding pool of potential customers for this critical industrial equipment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 2.5 Billion |

| Market Forecast in 2032 | USD 4.2 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Schenck Process Group, Gericke AG, Magnum Systems, WAMGROUP S.p.A., Kason Corporation, Flexicon Corporation, Spiroflow, Schaefer Systems International, Palamatic Process, Volkmann GmbH, AZO GmbH + Co. KG, Coperion GmbH, Brabender Technologie GmbH & Co. KG, Tecweigh, Hapman, National Bulk Equipment, Inc. (NBE), Gough Engineering, Applied Process Equipment, Inc., B.A.G. Corp., Process Equipment & Automation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hopper Feeding System Market Key Technology Landscape

The Hopper Feeding System Market is characterized by a dynamic and evolving technological landscape, driven by the continuous pursuit of higher precision, greater efficiency, enhanced reliability, and seamless integration with broader industrial automation systems. At the core, mechanical feeder technologies such as vibratory, screw, belt, and rotary feeders continue to be refined, with advancements focusing on optimizing material contact surfaces for improved flow characteristics, reduced wear, and easier cleaning, particularly crucial for hygienic applications. Material science innovations play a critical role, leading to the development of specialized coatings and construction materials that enhance abrasion resistance, corrosion protection, and anti-stick properties for challenging bulk solids. A significant technological shift is the pervasive integration of advanced sensor technologies, including load cells for highly accurate gravimetric feeding (loss-in-weight and gain-in-weight systems), proximity sensors for material level detection, and flow meters to monitor material throughput in real-time. These sensors provide the data backbone for intelligent control systems. Control systems are rapidly advancing, moving beyond basic Programmable Logic Controllers (PLCs) to incorporate sophisticated Human-Machine Interfaces (HMIs) that offer intuitive operation and extensive diagnostic capabilities. The advent of Industry 4.0 and the Industrial Internet of Things (IIoT) has revolutionized this landscape, enabling hopper feeding systems to connect, communicate, and exchange data with other plant equipment and cloud-based platforms. This connectivity facilitates remote monitoring, predictive maintenance through AI and machine learning algorithms that analyze operational data for early fault detection, and real-time process optimization. Furthermore, modular design principles are gaining traction, allowing for greater flexibility and scalability of feeding systems, making them easily configurable for various capacities and material types. Robotics and automation are also increasingly being integrated, particularly in downstream processes like automated container filling or precise ingredient dispensing. The development of advanced software for simulation and digital twinning allows for the virtual testing and optimization of feeder designs and operational parameters before physical implementation, significantly reducing development time and costs. These technological advancements collectively contribute to more intelligent, responsive, and adaptable hopper feeding solutions, meeting the demanding requirements of modern industrial environments and driving the market towards greater automation and data-driven operational excellence.

Regional Highlights

- North America: A mature market characterized by high adoption of automated systems, significant investment in R&D for advanced feeding technologies, and stringent safety and quality regulations. The region sees strong demand from pharmaceuticals, food & beverage, and plastics industries, with a focus on precision and efficiency.

- Europe: Similar to North America, Europe exhibits a high level of automation and advanced manufacturing capabilities. Demand is driven by strict environmental regulations, emphasis on energy efficiency, and a strong presence of pharmaceutical, chemical, and food processing industries. Germany, Italy, and the UK are key contributors.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, expanding manufacturing sectors, and increasing foreign direct investment. Countries like China, India, Japan, and South Korea are witnessing substantial growth due to booming construction, automotive, food processing, and electronics industries, along with a growing shift towards automation.

- Latin America: An emerging market experiencing steady growth, primarily driven by expanding mining, agriculture, food processing, and construction sectors. Brazil and Mexico are leading the adoption of modern hopper feeding systems, aiming to improve productivity and reduce operational costs.

- Middle East and Africa (MEA): This region is characterized by ongoing industrialization and infrastructure development projects, particularly in Saudi Arabia, UAE, and South Africa. Growing investments in food & beverage, construction, and petrochemical industries are creating new opportunities for hopper feeding system suppliers, albeit from a smaller base.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hopper Feeding System Market.

- Schenck Process Group

- Gericke AG

- Magnum Systems

- WAMGROUP S.p.A.

- Kason Corporation

- Flexicon Corporation

- Spiroflow

- Schaefer Systems International

- Palamatic Process

- Volkmann GmbH

- AZO GmbH + Co. KG

- Coperion GmbH

- Brabender Technologie GmbH & Co. KG

- Tecweigh

- Hapman

- National Bulk Equipment, Inc. (NBE)

- Gough Engineering

- Applied Process Equipment, Inc.

- B.A.G. Corp.

- Process Equipment & Automation

Frequently Asked Questions

Analyze common user questions about the Hopper Feeding System market and generate a concise list of summarized FAQs reflecting key topics and concerns.

What is a hopper feeding system and its primary function in industrial processes?

A hopper feeding system is an automated material handling solution designed to store bulk materials in a hopper and then precisely feed them at a controlled rate into a subsequent processing or packaging line. Its primary function is to ensure a continuous, consistent, and accurate supply of materials, optimizing production efficiency, reducing waste, and improving product quality.

Which industries are the primary end-users of hopper feeding systems?

Hopper feeding systems are critical in a wide range of industries including food and beverage, pharmaceuticals, chemicals, plastics, mining, construction, and agriculture. They are essential wherever bulk powders, granules, pellets, or aggregates need to be accurately dosed, conveyed, or blended in a manufacturing or processing environment.

What are the key benefits of implementing automated hopper feeding solutions?

Implementing automated hopper feeding solutions offers numerous benefits, such as significantly enhanced production efficiency and throughput, improved accuracy and consistency in material dosing, reduced labor costs, minimized material waste, increased operational safety by limiting manual handling, and better adherence to stringent quality control standards.

How do technological advancements like AI and IoT impact the hopper feeding system market?

AI and IoT are profoundly impacting the market by enabling advanced capabilities like predictive maintenance, real-time material flow optimization, and autonomous system adaptation. These technologies facilitate seamless integration with smart factory environments, enhance data-driven process control, improve system reliability, and contribute to overall operational intelligence and efficiency.

What types of materials can be handled by hopper feeding systems, and how is this accounted for in design?

Hopper feeding systems are engineered to handle a diverse range of materials, including fine powders, coarse granules, pellets, flakes, and even irregular shapes. System design accounts for material properties such as density, abrasiveness, corrosiveness, and flow characteristics by selecting appropriate feeder mechanisms (e.g., vibratory for difficult powders, screw for consistent flow), construction materials, and specialized coatings to ensure optimal performance and longevity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager