Hoppers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430696 | Date : Nov, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Hoppers Market Size

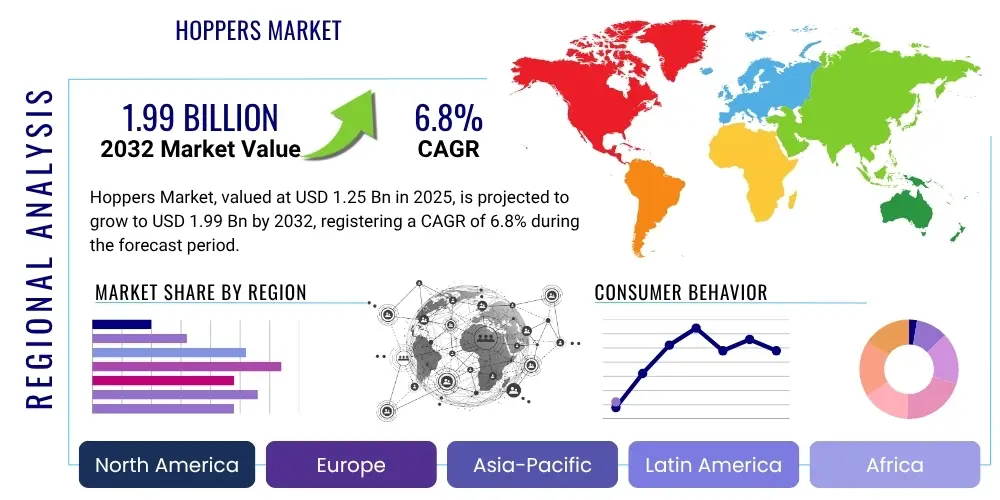

The Hoppers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at $1.25 billion in 2025 and is projected to reach $1.99 billion by the end of the forecast period in 2032.

Hoppers Market introduction

Hoppers are fundamental and ubiquitous components within a vast array of industrial processes, serving as essential equipment for the efficient storage, controlled feeding, and seamless transfer of bulk materials. These versatile containers are expertly designed, typically featuring a distinctive funnel-shaped bottom that facilitates a predictable and continuous discharge of various substances, including granular products, fine powders, or lumpy aggregates. Their core utility lies in enabling a steady and uninterrupted flow of materials at critical junctures within a production line, spanning from the initial reception of raw ingredients to the final stages of packaging finished goods. The sophisticated design of modern hoppers can be extensively customized to accommodate diverse material characteristics, specific volumetric capacities, and unique operational demands, often incorporating advanced features such as integrated vibration mechanisms to prevent bridging, agitators for uniform mixing, and specialized internal coatings to enhance material flow and mitigate caking or adhesion issues.

The applications for hoppers are incredibly broad and permeate numerous critical industries globally. In the agricultural sector, hoppers are indispensable for the bulk storage of grains, seeds, and animal feed, as well as for precise dispensing in planting and feeding systems. The construction industry relies heavily on hoppers for managing and distributing aggregates, cement, and other building materials on-site, contributing to efficient project execution. In mining and quarrying operations, hoppers are crucial for handling vast quantities of ore, crushed rock, and minerals, ensuring continuous processing. Furthermore, the food and beverage industry utilizes specialized sanitary hoppers for ingredients such as flour, sugar, and spices, while the chemicals and pharmaceuticals manufacturing sectors employ them for accurate dosing and containment of various powders and granules. Each application demands specific design considerations to optimize performance and adhere to industry standards.

The inherent benefits of employing hoppers in industrial settings are substantial and directly contribute to improved operational performance and profitability. These advantages include significantly enhanced operational efficiency through the automation of material handling tasks, leading to reduced manual labor and accelerated processing times. Hoppers also contribute to improved workplace safety by minimizing direct human interaction with potentially hazardous materials and reducing the risk of spillage. Material wastage is considerably reduced due to the precise and controlled dispensing capabilities, which also aids in better inventory management. Ultimately, hohoppers play a pivotal role in optimizing overall production flow and throughput, making them indispensable assets in modern industrial infrastructure. The continuous expansion of global manufacturing capabilities, alongside the increasing emphasis on automation and stringent quality control, serves as the primary driving force behind the sustained growth and innovation within the Hoppers Market, ensuring their continued relevance and demand across industrial landscapes worldwide.

Hoppers Market Executive Summary

The Hoppers Market is currently undergoing a period of robust expansion, propelled by an intricate interplay of evolving business trends, significant regional economic shifts, and a dynamic landscape of segment-specific advancements. A predominant business trend involves the escalating integration of automation and digitalization across various manufacturing and processing industries. This pivotal shift is generating substantial demand for "smart hoppers" equipped with advanced Internet of Things (IoT) sensors, capable of real-time material level monitoring, temperature and pressure sensing, and sophisticated data analytics for predictive maintenance. Additionally, there is a marked trend towards the customization and modularization of hopper designs, enabling manufacturers to offer highly flexible solutions tailored to precise industrial specifications, thereby maximizing operational efficiency and adaptability within diverse production environments. Furthermore, a growing emphasis on sustainability is influencing material selection and manufacturing processes, driving interest in hoppers constructed from recycled or environmentally friendly materials, and those engineered for enhanced energy efficiency.

From a regional perspective, the market is demonstrating vigorous growth, particularly within the rapidly industrializing economies of the Asia Pacific (APAC) region. Countries like China, India, and various Southeast Asian nations are experiencing accelerated urbanization, unprecedented infrastructure development, and substantial expansion in sectors such as construction, mining, food processing, and general manufacturing, all of which are vigorously fueling the demand for a diverse range of hoppers. North America and Europe, as mature markets, continue to contribute significantly through technological innovation, strict adherence to advanced safety and environmental regulations, and ongoing investments in upgrading existing industrial facilities with state-of-the-art material handling technologies. Latin America and the Middle East & Africa (MEA) are also emerging as key growth areas, spurred by investments in resource extraction, the expansion of agricultural capacities, and the development of new manufacturing hubs, indicating a pervasive global need for efficient and modernized bulk material management solutions across all geographies.

Within the various market segments, a clear trend is emerging towards the development and adoption of highly specialized hoppers designed to address unique and often challenging material handling requirements. This includes the growing demand for hoppers fabricated from corrosion-resistant or abrasion-resistant materials for aggressive chemical or mining environments, as well as those engineered to meet stringent sanitary standards for the food and pharmaceutical industries, where hygiene and product integrity are paramount. The increasing prevalence of weighing hoppers, which offer precise batching and mixing capabilities, is significantly enhancing quality control and minimizing material waste in critical processes. Moreover, the incorporation of advanced features such as sophisticated dust suppression systems and intrinsically safe or explosion-proof designs for hazardous environments is becoming a standard expectation, reflecting a market that is continually evolving towards more functional, safer, and highly specialized equipment solutions tailored to the ever-increasing complexity of industrial operations.

AI Impact Analysis on Hoppers Market

User inquiries regarding the transformative impact of Artificial Intelligence (AI) on the Hoppers Market frequently converge on themes centered around optimizing operational efficiency, minimizing costly downtime, and significantly enhancing safety protocols within bulk material handling processes. A recurring interest lies in understanding the practical applications of AI for predictive maintenance of hopper systems, allowing for proactive intervention before failures occur. Furthermore, users are keen to explore how AI can intelligently optimize material flow and discharge rates, ensure highly accurate real-time inventory management, and elevate quality control during precise batching and mixing operations. The overarching expectation is for AI to deliver tangible benefits, such as substantial cost reductions, improved throughput, and the capacity to manage complex material behaviors with unprecedented precision, thereby transforming routine, reactive maintenance into a data-driven, predictive activity that extends equipment lifespan and maximizes asset utilization.

- AI-driven predictive maintenance algorithms analyze sensor data from hoppers to forecast potential equipment failures with high accuracy, drastically reducing unplanned downtime and associated maintenance costs.

- Optimized material flow through AI algorithms dynamically adjusts discharge gates and vibrators, preventing bridging and ratholing, ensuring consistent material delivery and improving processing efficiency.

- Real-time inventory management capabilities enhanced by AI provide precise insights into material levels within hoppers, optimizing procurement, preventing stockouts, and streamlining supply chain logistics.

- AI-powered vision systems integrated with hoppers can detect foreign objects or material anomalies during loading, significantly improving product purity and overall quality control in sensitive applications.

- Automated calibration and self-adjusting mechanisms, guided by AI, enhance the precision of weighing and batching hoppers, ensuring accurate ingredient ratios and reducing material waste in critical formulations.

- Enhanced safety protocols are developed and enforced through AI by continuously monitoring operational parameters, identifying deviations, and issuing immediate alerts for potential hazards or unsafe conditions.

- Adaptive control systems utilizing AI intelligently adjust hopper operations based on real-time changes in material characteristics, environmental factors, or downstream process demands, maintaining optimal performance automatically.

DRO & Impact Forces Of Hoppers Market

The Hoppers Market is strategically shaped by a complex interplay of powerful driving forces, significant inherent restraints, compelling emerging opportunities, and broader overarching impact forces that collectively dictate its trajectory and future growth prospects. Among the primary drivers fueling market expansion is the relentless pace of industrialization observed across developing nations globally, which necessitates robust material handling infrastructure for new manufacturing plants and processing facilities. Concurrently, there is a pervasive global imperative for greater automation in manufacturing and logistics sectors, aimed at substantially reducing labor costs, increasing operational efficiency, and enhancing safety standards. Moreover, colossal investments in infrastructure development worldwide, encompassing roads, ports, and urban centers, inherently require extensive bulk material handling solutions, further propelling the demand for diverse hopper systems. The increasing sophistication and variability of materials requiring specialized handling, coupled with a growing emphasis on minimizing waste and ensuring precise material flow, additionally contribute to the market's robust growth, underscoring the indispensable role hoppers play in modern industrial ecosystems.

Despite these potent growth drivers, the Hoppers Market also navigates several notable restraints that can potentially temper its expansion. A significant barrier to entry or adoption, particularly for smaller enterprises or those with limited capital, is the substantial initial capital investment required for acquiring high-capacity, custom-engineered, or technologically advanced hopper systems. Beyond the upfront cost, operational complexities, including the imperative for rigorous routine maintenance, meticulous cleaning protocols, and strict adherence to industry-specific material handling best practices, contribute to the total cost of ownership, which can be considerable. Furthermore, the increasing stringency of environmental regulations pertaining to dust emission control, material containment, and workplace safety, especially in sensitive industries, often necessitates the development and adoption of more advanced and, consequently, more expensive hopper designs. This regulatory compliance, while crucial, can act as a limiting factor in market adoption across certain regions or for specific applications, creating additional challenges for manufacturers and end-users alike. Economic downturns, geopolitical instabilities, or significant slowdowns in global industrial production can also directly diminish the demand for new capital equipment, including hoppers.

Amidst these challenges, the Hoppers Market is replete with significant opportunities for astute market players. The burgeoning field of smart hoppers, intricately integrated with advanced IoT sensors and Artificial Intelligence capabilities, presents lucrative avenues for innovation, promising unparalleled enhancements in operational efficiency, predictive maintenance, and intelligent material management. This technological frontier offers manufacturers a competitive edge through differentiated product offerings. Furthermore, the increasing demand for customization and modularity in hopper design, enabling greater adaptability to an expansive array of industrial needs and processes, represents a powerful growth area. The global focus on sustainability is also catalyzing demand for hoppers constructed from recycled or environmentally benign materials, and those engineered for superior energy efficiency, opening new market segments. Lastly, the strategic expansion into untapped and rapidly developing emerging markets, particularly in regions undergoing substantial industrial and agricultural transformation, offers immense growth potential for manufacturers willing to innovate, adapt their product offerings to local requirements, and navigate diverse economic landscapes, ensuring continued market evolution and expansion.

Segmentation Analysis

The Hoppers Market is meticulously segmented to effectively cater to the highly diverse and evolving needs of various industries, precisely reflecting the expansive spectrum of materials handled, the myriad operational environments encountered, and the specific functional requirements that drive industrial processes. This comprehensive segmentation framework is instrumental in deeply understanding prevailing market dynamics, accurately identifying nascent niche opportunities, and strategically developing highly tailored product offerings that resonate with specific client demands. The primary classifications within this market include segmentation based on the specific type of hopper, the intrinsic material utilized in its construction, its precise application across an array of end-use industries, and its volumetric capacity, which directly dictates its suitability for both small-scale and large-scale industrial operations. Each distinct segment addresses unique operational challenges and requirements, ranging from basic material storage solutions to highly advanced, integrated, and controlled feeding systems, thereby unequivocally underscoring the remarkable versatility and increasingly specialized nature of contemporary hopper technology within the global industrial landscape.

Further, more granular sub-segmentation within these broad categories allows for an even more profound and nuanced market analysis, enabling distinctions between, for instance, highly flexible mobile units and robust fixed installations, or between hoppers specifically engineered for fine powders versus those designed for larger, more abrasive granules. The judicious choice of construction material for a hopper is critically important, with a spectrum of options available: stainless steel is often preferred for hygiene-sensitive applications such as in food and pharmaceutical processing, carbon steel is widely employed for general industrial use due to its strength and cost-effectiveness, and specialized plastics or composites are utilized for handling corrosive substances, with each material choice profoundly impacting the hopper's durability, overall cost, and suitability for its intended environment. Similarly, the diverse range of applications, from the ultra-precise dosing demanded in pharmaceutical manufacturing to the extremely robust material handling required in arduous mining operations, each mandates specific design considerations and specialized engineering to optimize performance and longevity under unique operational stresses.

The market's inherent capability to consistently cater to this extensive array of varied requirements eloquently underscores its profound maturity and continuous drive towards innovation. The escalating demand for highly specialized solutions, such as hoppers seamlessly integrated with sophisticated weighing systems for unparalleled accuracy, or those incorporating advanced dust suppression technologies for environmental compliance and worker safety, signifies a definitive and transformative shift towards more intelligent, functional, and environmentally responsible hopper designs. This detailed segmentation framework not only provides invaluable insights for comprehensive market research but also critically informs the entire product development lifecycle, ensuring that manufacturers are consistently creating and delivering cutting-edge solutions that directly address specific industrial pain points, align perfectly with evolving operational standards, and meet the dynamic demands of the global industrial economy, thus solidifying the market's trajectory towards sustained growth and technological advancement.

- By Type:

- Fixed Hoppers (Stationary installations for continuous material flow)

- Mobile Hoppers (Portable units for flexible material transfer)

- Dust Hoppers (Designed for dust collection and filtration systems)

- Silo Hoppers (Large-capacity hoppers integrated with silos for long-term storage)

- Weigh Hoppers (Equipped with load cells for precise material batching and weighing)

- Bag Dump Hoppers (Facilitate ergonomic and dust-controlled emptying of bags)

- Bulk Bag Hoppers/Dischargers (Used for controlled discharge of Flexible Intermediate Bulk Containers - FIBCs)

- Live Bottom Hoppers (Feature agitators or vibrating mechanisms for difficult-to-flow materials)

- Dewatering Hoppers (Designed for separating liquids from solids)

- Metering Hoppers (Provide controlled and consistent feeding rates)

- By Material:

- Carbon Steel Hoppers (Economical, high strength, suitable for general industrial use)

- Stainless Steel Hoppers (Corrosion-resistant, hygienic, ideal for food, pharma, and chemical industries)

- Plastic Hoppers (Lightweight, corrosion-resistant, often for specific chemicals or food applications)

- Fiberglass Hoppers (Corrosion-resistant, good for certain chemical storage, often lightweight)

- Polyethylene Hoppers (UV resistant, chemical resistant, used in outdoor and corrosive environments)

- Aluminum Hoppers (Lightweight, corrosion-resistant, typically for smaller applications or specific material needs)

- Lined Hoppers (Steel hoppers with specialized liners for abrasion or chemical resistance)

- By Application/End-Use Industry:

- Agriculture & Farming Hoppers (Grain storage, feed dispensing, fertilizer handling)

- Construction Hoppers (Aggregate storage, cement, sand, concrete batching plants)

- Mining & Quarrying Hoppers (Ore, crushed rock, minerals handling at extraction and processing sites)

- Food & Beverage Processing Hoppers (Ingredients storage, sugar, flour, spices, sanitary applications)

- Chemical Processing Hoppers (Powders, granules, corrosive substances storage and transfer)

- Pharmaceutical Hoppers (API handling, excipients, sterile environments, precise dosing)

- Manufacturing Hoppers (e.g., Plastics pellets, rubber crumbs, metalworking chips, industrial components)

- Waste Management Hoppers (Recyclables, municipal solid waste, industrial waste sorting and processing)

- Logistics & Transportation Hoppers (Bulk material loading/unloading at ports, terminals, railway yards)

- Packaging Industry Hoppers (Feeding packaging machines with various materials)

- Water Treatment Hoppers (Chemicals for water purification)

- By Capacity:

- Small Capacity Hoppers (Typically less than 1 cubic meter, for laboratory or small batch processes)

- Medium Capacity Hoppers (Ranging from 1 to 5 cubic meters, common in smaller manufacturing lines)

- Large Capacity Hoppers (Exceeding 5 cubic meters, for bulk storage in large industrial facilities, silos, or mines)

- Custom/Modular Capacity Hoppers (Designed to specific project needs, often scalable)

Value Chain Analysis For Hoppers Market

The value chain within the Hoppers Market represents a meticulously structured sequence of interconnected activities, commencing from the foundational sourcing of raw materials and culminating in the final delivery of sophisticated hopper systems, comprehensive installation, and critical after-sales support to the end-user. Upstream analysis predominantly focuses on the initial and highly crucial stages, primarily involving a diverse network of raw material suppliers who provide essential inputs. These inputs range from various grades of robust steel, including both carbon and stainless variants, to specialized plastics and advanced composite materials, alongside a myriad of critical components such as precision-engineered motors, sophisticated sensors, intricate pneumatic systems, and advanced control units. Concurrently, specialized engineering and design firms play an indispensable upstream role, contributing significantly to the innovation of hopper designs, conducting advanced material flow simulations to optimize performance, and rigorously analyzing structural integrity, all of which are paramount for ensuring optimal operational performance, longevity, and adherence to stringent safety standards. Stringent quality control measures implemented at this nascent stage are pivotal for guaranteeing the durability and flawless functionality of the final product, thereby proactively mitigating potentially costly issues that could arise in later downstream phases.

Midstream activities encompass the core processes of manufacturing, precise assembly, and seamless integration of these diverse components into fully functional and often highly customized hopper systems. This intensive phase typically involves advanced precision fabrication techniques, specialized welding processes, a variety of critical surface treatments (such as polishing, coating, or painting), and the expert installation of sophisticated ancillary equipment. Such equipment commonly includes vibratory feeders, specialized agitators, integrated load cells for weighing, and advanced conveying mechanisms. Manufacturers frequently specialize in particular types of hoppers or cater exclusively to specific industries, thereby cultivating deep expertise in areas like ultra-hygienic design for food processing applications or exceptional abrasion resistance for demanding mining environments. Throughout this phase, rigorous testing protocols and comprehensive quality assurance procedures are meticulously implemented to verify that the manufactured hoppers not only meet but often exceed specified performance criteria, comply with all relevant regulatory standards, and consistently fulfill the elevated expectations of discerning customers, ensuring product reliability and operational excellence before their progression to the subsequent stage of the value chain.

Downstream analysis critically encompasses the multifaceted aspects of distribution, strategic sales, and comprehensive post-sales services, all of which are vital for sustained market presence and customer loyalty. Distribution channels for hoppers are varied and strategically tailored, ranging from direct sales engagements between manufacturers and clients, particularly for large-scale, custom-engineered projects that demand close collaborative partnerships, to an extensive network of specialized distributors who offer localized support, maintain crucial inventory, and facilitate faster delivery times across broader geographic markets. The increasing prominence of online B2B platforms is also revolutionizing distribution, offering enhanced reach and efficiency. Crucially, after-sales services—including professional installation, meticulous commissioning, routine maintenance schedules, reliable spare parts supply, and responsive technical support—are paramount for ensuring high levels of customer satisfaction, maximizing the long-term operational performance of the equipment, and ultimately fostering robust, enduring customer relationships. These comprehensive downstream activities significantly contribute to the overall value proposition, reinforcing the manufacturer's commitment to product excellence and ongoing client support throughout the hopper's lifecycle.

Hoppers Market Potential Customers

Potential customers for the Hoppers Market originate from an exceptionally wide and diverse spectrum of industries and operate across various scales, from small-batch operations to massive industrial complexes. They are invariably united by a fundamental and critical need for efficient, highly reliable, and intrinsically safe solutions for handling bulk materials. These end-users or buyers primarily operate in sectors where granular, powdered, or lumpy materials must be meticulously stored, precisely transferred, accurately weighed, or consistently fed into subsequent processing lines. Their overarching objective is to meticulously streamline their intricate production processes, significantly minimize material waste and associated costs, profoundly enhance workplace safety for their personnel, and diligently ensure unwavering compliance with stringent industry-specific regulations and quality standards. Consequently, hoppers are not merely pieces of equipment but rather indispensable, integral components of their core operational infrastructure. The inherent diversity of these potential customers naturally necessitates an extensive array of hopper designs and features, ranging from rudimentary storage bins to highly sophisticated, fully automated, and seamlessly integrated feeding systems that cater to their unique demands.

Prominent and significant customer segments include vast industrial facilities such as sprawling manufacturing plants engaged in the production of plastics, specialty chemicals, and high-value pharmaceuticals. In these environments, the paramount importance of precise dosing, the absolute necessity of preventing contamination, and rigorous material integrity controls are non-negotiable requirements that hoppers are engineered to fulfill. The construction and mining industries represent colossal consumers of hoppers, requiring exceptionally robust and durable systems for managing and distributing massive volumes of aggregates, cement, various types of ore, and other raw materials at every stage of their complex projects, from extraction to final processing. Furthermore, large-scale agricultural enterprises are heavy users, deploying hoppers for the bulk storage and controlled distribution of essential commodities such as grains, seeds, and animal feed, where both immense capacity and unwavering durability are critical design considerations to withstand demanding outdoor conditions and heavy usage cycles. Concurrently, the highly sensitive food and beverage industry profoundly relies on specialized, sanitary-grade hoppers for processing ingredients like flour, sugar, and coffee beans, in which impeccable hygiene, ease of cleaning, and the absolute prevention of cross-contamination are paramount to ensure product quality and consumer safety.

Beyond these colossal industrial sectors, a substantial and growing customer base also exists within smaller businesses and highly specialized operations. This includes, but is not limited to, feed mills requiring precise ingredient mixing, concrete batching plants demanding accurate aggregate delivery, advanced waste management facilities for sorting and processing various refuse streams, and even large-scale logistics hubs that necessitate highly efficient systems for the rapid loading and unloading of bulk goods during transportation. The escalating global demand for enhanced automation, rigorous process optimization, and superior operational efficiency across all these aforementioned segments further solidifies their status as crucial potential customers. This is because hoppers directly and significantly contribute to achieving these critical operational goals by consistently providing controlled and predictable material flow, and by enabling seamless integration with broader, sophisticated automated systems. Therefore, a deep and nuanced understanding of the specific material characteristics, environmental conditions, and unique operational requirements of each customer type is absolutely vital for manufacturers to effectively tailor their innovative hopper solutions and maintain a competitive edge in this dynamic market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $1.25 billion |

| Market Forecast in 2032 | $1.99 billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | AZO GmbH + Co. KG, Schenck Process Holding GmbH, Coperion GmbH, Spiroflow Ltd., Palamatic Process Inc., Flexicon Corporation, Hapman Corporation, WAMGroup S.p.A., Müller Group (J. Müller GmbH), Volkmann GmbH, Daxner International GmbH, Gericke AG, Donaldson Company, Inc., Vibra Screw Inc., Material Transfer & Storage Inc., National Bulk Equipment, Inc. (NBE), Haver & Boecker Niagara, Conair Group, Cyclonaire Corporation, Kason Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hoppers Market Key Technology Landscape

The Hoppers Market is currently experiencing a profound transformation, driven by a rapidly evolving technological landscape that is keenly focused on achieving unprecedented levels of efficiency, precision, and safety in all aspects of bulk material handling. At the forefront of this evolution is the pervasive integration of advanced Internet of Things (IoT) sensors. These sophisticated sensors empower hoppers with real-time monitoring capabilities, providing critical data on material levels, internal temperature, pressure differentials, and precise flow rates. This continuous stream of data is absolutely invaluable for accurate inventory management, proactively preventing costly overfilling or disruptive underfilling events, and ensuring an uninterrupted supply of materials to downstream processes, thereby minimizing operational interruptions and significantly enhancing overall production fluidity and predictability across the entire industrial value chain.

Central to the modernization of hopper technology is the widespread adoption of sophisticated automation systems. These encompass a broad range of solutions, including fully automated loading and unloading mechanisms, robotic integration for ultra-precise material placement and handling, and advanced pneumatic or mechanical conveying systems that seamlessly operate in conjunction with hoppers to establish truly integrated and continuous material transfer solutions. Furthermore, the implementation of intelligent control systems, frequently incorporating state-of-the-art Programmable Logic Controllers (PLCs) and intuitive Human-Machine Interfaces (HMIs), provides operators with unparalleled, user-friendly control and comprehensive visualization of all hopper operations. This allows for efficient remote monitoring, precise adjustments, and data-driven decision-making, which collectively contribute significantly to reducing manual labor requirements, enhancing workplace safety by minimizing human exposure to potentially hazardous materials, and drastically increasing the speed, consistency, and reliability of material handling operations within complex industrial environments.

Further pushing the boundaries of innovation are advancements in predictive analytics and cutting-edge artificial intelligence (AI) algorithms. These powerful tools leverage the vast datasets collected from IoT sensors to accurately forecast potential maintenance needs, intelligently optimize material discharge rates based on real-time process demands, and even dynamically adapt hopper operations to varying material characteristics or fluctuating environmental conditions. Specialized material flow optimization software, often utilizing advanced computational fluid dynamics (CFD) simulations, is employed to meticulously design optimal hopper geometries that proactively prevent common issues such as bridging, ratholing, and segregation of materials, thereby guaranteeing a consistent and predictable material flow. Additionally, the adoption of advanced manufacturing techniques, including highly efficient modular design principles and the utilization of intrinsically corrosion-resistant or abrasion-resistant materials, fundamentally improves the durability, extends the operational lifespan, and significantly enhances the adaptability of hoppers, making them more versatile, cost-effective, and sustainable solutions for an even wider array of demanding industrial applications globally.

Regional Highlights

- North America: This region is characterized by highly mature industrial sectors, a pioneering spirit in the widespread adoption of advanced automation technologies, and the enforcement of exceptionally stringent safety and environmental standards. Consequently, there is a significant and sustained demand for sophisticated, high-efficiency hoppers that often integrate advanced IoT capabilities and intelligent automation features. The food processing, pharmaceutical, and general manufacturing sectors, in particular, exhibit strong growth. The primary regional focus is directed towards the continuous upgrading of existing industrial infrastructure and the meticulous optimization of current material handling processes to achieve increased productivity, enhanced product quality, and substantial reductions in operational costs across various industries.

- Europe: Echoing trends observed in North America, Europe maintains a robust emphasis on advanced manufacturing techniques, a strong commitment to sustainability initiatives, and strict adherence to a comprehensive framework of regulatory compliance. The European market specifically demands hoppers engineered for superior precision, exceptional energy efficiency, and unwavering conformity to rigorous environmental and hygiene standards. Key industrial players in countries such as Germany, Italy, and the United Kingdom are at the forefront of technological innovation, driving the adoption of highly specialized hoppers tailored for the discerning chemical, pharmaceutical, and automotive industries, reflecting a market that values high-performance and regulatory adherence.

- Asia Pacific (APAC): The APAC region is unequivocally projected to be the fastest-growing market globally for hoppers, a trajectory fueled by unprecedented rates of rapid industrialization, extensive urbanization, and colossal infrastructure development projects unfolding across powerhouse economies like China and India, as well as dynamic Southeast Asian nations. This expansive growth translates into immense demand for a diverse range of hoppers across critical sectors including construction, mining, agriculture, and manufacturing. Significant investments in establishing new industrial capacities and expanding existing production lines are serving as the pivotal drivers stimulating vigorous market expansion throughout the entire region, reflecting a period of intense industrial growth.

- Latin America: This region demonstrates steady and consistent market growth, principally driven by its inherently robust agricultural sector, extensive resource extraction activities (particularly mining), and steadily expanding manufacturing capabilities. There is a discernible and increasing demand for highly durable and cost-effective hoppers, with a growing interest in adopting semi-automated and efficient material handling solutions designed to significantly improve productivity across large-scale operations. Brazil and Mexico stand out as key, influential markets within Latin America, spearheading regional demand due to their diverse industrial bases and ongoing infrastructure developments, further propelling the hoppers market forward.

- Middle East and Africa (MEA): The MEA region is experiencing accelerated market growth, primarily propelled by strategic efforts towards economic diversification away from traditional oil revenues, coupled with numerous ambitious infrastructure mega-projects, and the progressive development of indigenous manufacturing bases. Consequently, the demand for hoppers is robustly increasing across the construction, mining, food processing, and petrochemical industries. Substantial investments in establishing new industrial parks and advanced processing facilities are actively stimulating market expansion, with a particular emphasis on sourcing and deploying highly robust, reliable, and technologically appropriate material handling equipment capable of enduring challenging operational environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hoppers Market.- AZO GmbH + Co. KG (Germany)

- Schenck Process Holding GmbH (Germany)

- Coperion GmbH (Germany)

- Spiroflow Ltd. (United Kingdom)

- Palamatic Process Inc. (USA)

- Flexicon Corporation (USA)

- Hapman Corporation (USA)

- WAMGroup S.p.A. (Italy)

- Müller Group (J. Müller GmbH) (Germany)

- Volkmann GmbH (Germany)

- Daxner International GmbH (Austria)

- Gericke AG (Switzerland)

- Donaldson Company, Inc. (USA)

- Vibra Screw Inc. (USA)

- Material Transfer & Storage Inc. (USA)

- National Bulk Equipment, Inc. (NBE) (USA)

- Haver & Boecker Niagara (Germany/Canada)

- Conair Group (USA)

- Cyclonaire Corporation (USA)

- Kason Corporation (USA)

Frequently Asked Questions

What is a hopper and its primary function in industrial settings?

A hopper is a large, often funnel-shaped container specifically designed for the temporary storage and controlled, efficient discharge of various bulk materials, including powders, granules, and aggregates. Its primary function is to facilitate the seamless and continuous flow of these materials into or out of a processing or conveying system, thereby ensuring uninterrupted industrial operations, optimizing throughput, and preventing material handling bottlenecks within a production line.

Which industries are the major users of hoppers, and why are they critical?

Hoppers are indispensable across a wide range of industries such as agriculture (for storing and dispensing grains, seeds, animal feeds), construction (for managing cement, sand, aggregates), mining (for handling ore, minerals), food and beverage processing (for ingredients like flour, sugar), chemical manufacturing, pharmaceuticals, and general manufacturing. They are critical because they enable precise material handling, enhance operational efficiency, reduce labor costs, and improve safety by controlling the flow of bulk materials, which is essential for consistent product quality and production continuity.

How do smart hoppers with AI and IoT capabilities benefit industrial operations and enhance efficiency?

Smart hoppers, integrated with advanced AI and IoT (Internet of Things) capabilities, revolutionize industrial operations by offering a multitude of benefits. These include real-time, accurate material level monitoring, which optimizes inventory management; AI-driven predictive maintenance, which significantly reduces costly downtime; intelligent optimization of material flow for consistent discharge rates; and enhanced safety protocols through continuous monitoring and automated alerts. These features collectively lead to greater operational efficiency, substantial cost savings, improved product quality, and extended equipment lifespan, transforming traditional material handling into a data-driven, proactive process.

What are the different types of hoppers available in the market, and how do they differ in application?

The market offers a diverse array of hopper types, each tailored for specific applications. Key types include fixed hoppers for stationary storage; mobile hoppers for flexible, transportable material transfer; weigh hoppers, which are equipped with load cells for ultra-precise material batching; dust hoppers, designed to integrate with dust collection and filtration systems; silo hoppers for large-scale, long-term bulk storage; and specialized designs like bag dump hoppers for ergonomic emptying of sacks, and live bottom hoppers with agitators for difficult-to-flow materials. These variations cater to different material characteristics, operational scales, and industrial process requirements, ensuring optimal performance.

What critical factors should be considered when selecting a hopper for a specific industrial application?

When selecting a hopper, several critical factors must be thoroughly evaluated to ensure optimal performance and suitability. These include the precise type and characteristics of the material to be handled (e.g., abrasive, corrosive, cohesive, hazardous), the required volumetric capacity and desired flow rate, stringent hygiene requirements (especially for food and pharmaceutical industries), the environmental conditions of the operating site (e.g., temperature, humidity, outdoor exposure), available physical space, the allocated budget, and the necessity for integrated features such as weighing systems, vibratory agitators, specialized liners, or advanced dust suppression mechanisms. A comprehensive assessment of these factors ensures the selection of a hopper that meets all operational demands, complies with regulations, and provides long-term value.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager