Hot Mix Asphalt Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427802 | Date : Oct, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Hot Mix Asphalt Market Size

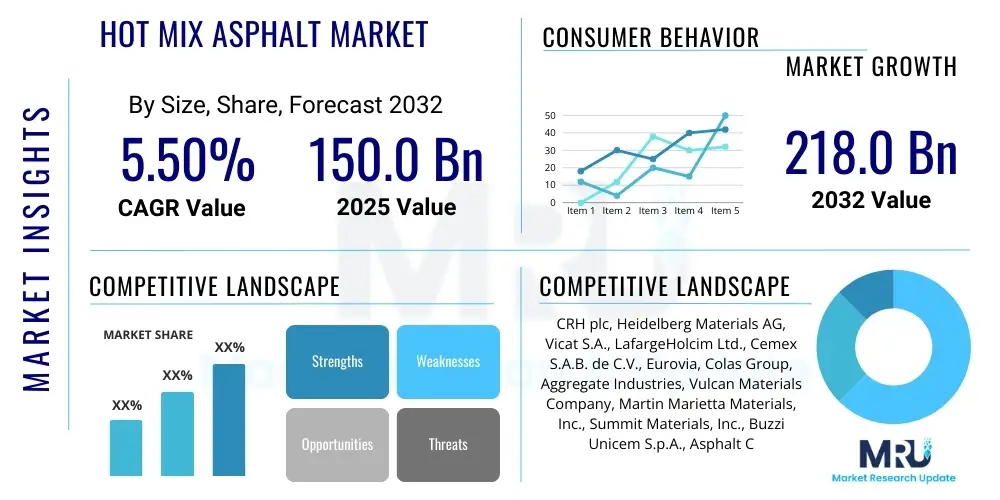

The Hot Mix Asphalt Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.5% between 2025 and 2032. The market is estimated at USD 150.0 billion in 2025 and is projected to reach USD 218.0 billion by the end of the forecast period in 2032.

Hot Mix Asphalt Market introduction

The Hot Mix Asphalt (HMA) market encompasses the production, distribution, and application of a blend of aggregate, bitumen, and filler, heated and mixed at elevated temperatures to produce a durable paving material. This material is primarily utilized in the construction and maintenance of roads, highways, airports, and other large-scale infrastructure projects requiring robust and long-lasting surfaces. Its widespread adoption stems from its superior performance characteristics, including high load-bearing capacity, weather resistance, and ability to be recycled, making it an essential component of modern transportation networks.

Major applications for Hot Mix Asphalt extend across various sectors. Road construction and rehabilitation constitute the largest segment, addressing the continuous need for new infrastructure development and the repair of existing roadways degraded by traffic and environmental factors. Beyond public roads, HMA is extensively used for airport runways and taxiways, where it must withstand extreme loads and constant use. Commercial and residential paving, including parking lots, driveways, and sports courts, also represent significant application areas, valued for HMAs smooth finish and relatively quick installation process. The versatility and established performance of HMA ensure its foundational role in global construction.

The benefits associated with Hot Mix Asphalt are numerous, contributing to its sustained market demand. These include its high durability and resistance to wear, effective waterproofing properties, and excellent skid resistance, enhancing safety for motorists. Furthermore, HMA offers a smooth, quiet riding surface, contributing to reduced noise pollution. Key driving factors propelling market growth include increasing government investments in infrastructure development, rapid urbanization, and a growing emphasis on maintaining and upgrading existing transportation networks. The ease of production and relatively cost-effective application methods also continue to fuel its market expansion globally.

Hot Mix Asphalt Market Executive Summary

The Hot Mix Asphalt market is experiencing dynamic shifts, driven by persistent infrastructure demands and evolving material science. Business trends indicate a strong focus on sustainability, with increasing adoption of recycled asphalt pavement (RAP) and warm mix asphalt (WMA) technologies to reduce energy consumption and greenhouse gas emissions. Companies are investing in advanced production techniques, such as continuous mix plants and enhanced quality control systems, to improve product consistency and efficiency. Furthermore, the market is witnessing consolidation among major players, alongside the emergence of specialized firms offering innovative asphalt solutions and paving services. This competitive landscape fosters technological advancements and encourages operational optimization across the value chain, leading to a more efficient and environmentally conscious industry.

Regionally, the market exhibits varied growth trajectories, heavily influenced by economic development and government infrastructure spending. Asia Pacific, particularly China and India, is a dominant force, driven by rapid urbanization and extensive road network expansion projects. North America and Europe demonstrate mature markets, characterized by significant investment in maintenance, rehabilitation, and the upgrade of aging infrastructure, alongside a strong emphasis on sustainable paving practices. Latin America and the Middle East & Africa are emerging as high-growth regions, propelled by industrialization, new urban development, and increasing connectivity needs. Each region presents unique challenges and opportunities, including varying regulatory landscapes, climate conditions, and material availability, all impacting market dynamics and strategic investments.

Segment trends highlight a sustained demand across different application areas. The road construction and paving segment remains the largest consumer of HMA, underscoring its indispensable role in transportation infrastructure. The increasing demand for specialty asphalt mixes, such as stone mastic asphalt (SMA) for enhanced durability and porous asphalt for improved drainage, indicates a trend towards performance-based solutions tailored for specific environmental and traffic conditions. Recycled asphalt materials are gaining significant traction due to environmental mandates and cost efficiencies, while the adoption of additive technologies to improve asphalt performance and longevity is also on the rise. These segmentation shifts reflect an industry moving towards greater specialization, efficiency, and environmental responsibility in response to global demands for robust and sustainable infrastructure.

AI Impact Analysis on Hot Mix Asphalt Market

Users frequently inquire about how artificial intelligence can transform the Hot Mix Asphalt market, expressing concerns about potential job displacement versus the benefits of increased efficiency and predictive maintenance. Key themes revolve around optimizing material design, improving construction project management, and enhancing quality control throughout the HMA lifecycle. There is considerable interest in AIs capability to analyze vast datasets from sensors, drones, and historical performance records to provide actionable insights. Expectations are high for AI to reduce material waste, lower operational costs, and contribute to more sustainable and longer-lasting asphalt pavements, thereby addressing critical industry challenges related to resource efficiency and infrastructure longevity.

The integration of AI in the Hot Mix Asphalt market promises a paradigm shift, moving from traditional, reactive approaches to proactive, data-driven decision-making. AI algorithms can process complex variables such as aggregate properties, bitumen characteristics, and environmental conditions to precisely design optimal asphalt mixes tailored for specific project requirements. This goes beyond conventional methods by identifying subtle patterns and correlations that human analysis might miss, leading to superior material performance and reduced material consumption. Furthermore, AI-powered systems can simulate various mix designs under different stress conditions, allowing for virtual testing and refinement before actual production, which significantly reduces prototyping costs and time.

Beyond material design, AIs influence extends deeply into the operational aspects of HMA production and application. Predictive analytics, driven by AI, can forecast equipment maintenance needs, minimizing downtime and optimizing production schedules. In the field, AI-enabled sensors and drone technology can monitor paving operations in real-time, ensuring uniform compaction, accurate layer thickness, and optimal temperature control. This level of precision not only enhances the quality and longevity of pavements but also contributes to greater safety on construction sites by identifying potential hazards. The long-term impact includes more resilient infrastructure, reduced lifecycle costs, and a more sustainable industry footprint.

- Optimized Mix Design: AI algorithms analyze material properties and environmental data to create custom asphalt mixes, reducing material waste and enhancing pavement performance.

- Predictive Maintenance: AI-driven analytics forecast equipment failures in HMA plants and paving machinery, minimizing unplanned downtime and optimizing operational efficiency.

- Real-time Quality Control: AI-powered sensors and drones monitor paving conditions, ensuring optimal compaction, temperature, and material distribution during application.

- Supply Chain Optimization: AI improves logistics for raw material procurement and HMA delivery, reducing transportation costs and improving project timelines.

- Automated Inspection & Assessment: AI analyzes imagery from drones and ground sensors to detect pavement defects early, enabling proactive repair and maintenance strategies.

- Enhanced Safety: AI systems monitor construction sites for potential hazards, alerting personnel to risks and improving overall worker safety during HMA operations.

- Environmental Impact Reduction: AI optimizes energy consumption in HMA production and identifies opportunities for greater use of recycled materials, contributing to sustainability goals.

DRO & Impact Forces Of Hot Mix Asphalt Market

The Hot Mix Asphalt market is shaped by a confluence of driving forces, inherent restraints, and emerging opportunities, all interacting to create dynamic impact forces. Driving factors primarily include robust governmental investments in infrastructure development, particularly in developing economies, aimed at upgrading road networks and expanding transportation capacities. Rapid urbanization trends globally necessitate continuous construction of new roads, highways, and commercial paving projects. Additionally, the increasing demand for repair and maintenance of aging infrastructure in developed nations provides a constant baseline for market activity. Technological advancements in HMA formulations and application techniques, enhancing durability and sustainability, further bolster demand. These drivers collectively push market expansion and innovation.

However, the market also faces significant restraints. Fluctuations in crude oil prices directly impact the cost of bitumen, a primary component of HMA, leading to price volatility and affecting project budgets. Environmental regulations, particularly those concerning emissions from HMA production plants and the use of virgin aggregates, impose stringent compliance requirements and can increase operational costs. The availability of raw materials, such as suitable aggregates, can be geographically constrained, influencing regional pricing and supply chain logistics. Furthermore, the emergence of alternative paving materials, though currently niche, poses a long-term competitive threat that could potentially fragment market share.

Opportunities within the Hot Mix Asphalt market are largely driven by the pursuit of sustainable and efficient solutions. The increasing adoption of Warm Mix Asphalt (WMA) and Cold Mix Asphalt (CMA) technologies offers avenues for reducing energy consumption and greenhouse gas emissions, aligning with global environmental objectives. The recycling of asphalt pavement (RAP) and reclaimed asphalt shingles (RAS) presents significant cost savings and environmental benefits, creating a circular economy model for the industry. Innovations in asphalt additives, such as polymers and crumb rubber, enhance pavement performance and extend service life, opening new market segments for specialized products. These opportunities empower market players to differentiate offerings and meet evolving demands for eco-friendly and high-performance infrastructure materials.

- Drivers:

- Increasing government investments in infrastructure development and expansion globally.

- Rapid urbanization and growing need for road networks, airports, and commercial paving.

- Aging infrastructure in developed countries requiring extensive repair and rehabilitation.

- Technological advancements improving HMA performance, durability, and sustainability.

- Demand for efficient and robust paving solutions for high-traffic areas.

- Restraints:

- Volatility in crude oil prices directly impacting bitumen costs and project budgets.

- Stringent environmental regulations regarding emissions and material sourcing.

- Limited availability of high-quality virgin aggregates in certain regions.

- Seasonal nature of construction activities affecting demand and production cycles.

- Competition from alternative paving materials and construction methods.

- Opportunities:

- Growing adoption of Warm Mix Asphalt (WMA) and Cold Mix Asphalt (CMA) for energy savings.

- Increased use of Recycled Asphalt Pavement (RAP) and Reclaimed Asphalt Shingles (RAS).

- Development of high-performance asphalt additives and modifiers to enhance pavement life.

- Emergence of smart city initiatives driving demand for durable and sensor-integrated roads.

- Expansion into niche applications requiring specialized asphalt formulations.

Segmentation Analysis

The Hot Mix Asphalt market is critically segmented to understand its diverse dynamics and address specific industry needs effectively. These segmentations are typically based on material type, application, and end-user, providing a granular view of market demand and supply. Analyzing these distinct categories helps identify growth pockets, competitive landscapes, and strategic entry points for market participants. The varied requirements across different types of infrastructure projects and the evolving preferences for sustainable and performance-driven materials significantly influence how these segments perform and grow over time, highlighting the industrys continuous adaptation to technological advancements and environmental considerations.

- By Type:

- Dense-Graded Asphalt: The most common type, characterized by a well-graded aggregate blend, suitable for high-traffic pavements.

- Stone Matrix Asphalt (SMA): Known for high stone content and rich asphalt binder, offering excellent rutting resistance and durability, especially for heavy traffic.

- Porous Asphalt: Designed with a high void content to allow water to drain through, reducing surface water and enhancing skid resistance.

- Open-Graded Asphalt: Contains fewer fines than dense-graded, providing good drainage and reduced spray from tires.

- Warm Mix Asphalt (WMA): Produced at lower temperatures than conventional HMA, reducing energy consumption and emissions.

- Recycled Asphalt Pavement (RAP): Asphalt mix incorporating a significant percentage of reclaimed asphalt materials, promoting sustainability.

- By Application:

- Road Construction & Paving: Primary application for highways, urban roads, and rural routes.

- Airport Paving: Used for runways, taxiways, and aprons due to high load-bearing requirements.

- Commercial & Residential Paving: Includes parking lots, driveways, sidewalks, and sports courts.

- Specialty Applications: Such as bridge decks, port facilities, and industrial areas requiring specific performance characteristics.

- By End-User:

- Government & Public Sector: Major consumers for public infrastructure projects (roads, airports).

- Commercial Sector: Includes private developers for commercial complexes, retail spaces, and industrial parks.

- Residential Sector: For private driveways, residential roads, and community developments.

Hot Mix Asphalt Market Value Chain Analysis

The Hot Mix Asphalt market value chain is a complex network involving several key stages, from the extraction of raw materials to the final application of the asphalt product. Upstream activities begin with the sourcing and processing of aggregates, such as crushed stone, sand, and gravel, which are mined or quarried. Simultaneously, crude oil refining yields bitumen, the binding agent. These raw materials are then transported to asphalt mixing plants, where they undergo heating, drying, and precise blending to produce the hot mix asphalt. The efficiency and cost-effectiveness of these upstream processes significantly impact the overall profitability and environmental footprint of the final product, demanding robust supply chain management and quality control measures.

Midstream activities primarily involve the manufacturing of hot mix asphalt at fixed or portable asphalt plants. These facilities are crucial for ensuring the correct proportioning and heating of aggregates and bitumen, along with any additives, to achieve specific mix designs. Energy consumption and emission control are critical considerations at this stage, with advancements in Warm Mix Asphalt (WMA) and continuous production technologies enhancing efficiency and reducing environmental impact. Quality assurance and control, including material testing and mix design verification, are paramount to ensure the HMA meets required specifications for strength, durability, and performance, which is vital for the integrity of subsequent infrastructure projects.

Downstream activities encompass the transportation of the hot mix asphalt from the plant to the construction site, followed by its application and compaction. This stage requires specialized equipment, including insulated trucks for transport to maintain temperature, and paving machines (finishers) for laying the asphalt evenly. Rollers are then used for compaction to achieve the desired density and surface finish. Distribution channels can be direct, where HMA producers own and operate paving crews, or indirect, involving sales to third-party contractors. The success of the downstream process relies on timely delivery, skilled labor, and precise execution to ensure the long-term performance and quality of the paved surface. Customer satisfaction and project longevity are directly tied to the effectiveness of these final value chain steps.

Hot Mix Asphalt Market Potential Customers

The primary potential customers for Hot Mix Asphalt are entities engaged in large-scale infrastructure development and maintenance projects, driven by a continuous need for durable and high-performance paving materials. Government agencies, including federal, state, and municipal departments of transportation, represent the largest segment of end-users. These bodies are responsible for the planning, funding, and oversight of public road networks, highways, bridges, and airport runways. Their procurement decisions are often influenced by long-term performance, cost-effectiveness over the assets lifecycle, and increasingly, by environmental sustainability mandates that favor recycled content and energy-efficient production methods.

Beyond the public sector, the commercial and industrial sectors also constitute significant end-users. This includes private developers and construction companies undertaking projects such as shopping centers, industrial parks, logistics hubs, and large parking facilities. For these customers, factors such as installation speed, pavement longevity, and aesthetic appeal play a crucial role in material selection. They often seek solutions that minimize disruption to business operations and provide robust surfaces capable of withstanding heavy vehicular traffic and adverse weather conditions. The demand from these segments is closely tied to economic growth, urban expansion, and commercial investment activities.

Other notable customer segments include airport authorities, private property owners, and specialized contractors focusing on niche applications. Airport authorities require HMA for runways, taxiways, and aprons, where stringent specifications for load-bearing capacity and resistance to jet fuel are paramount. Private property owners may procure HMA for driveways, private roads, or recreational surfaces, prioritizing durability and aesthetic integration. Furthermore, construction companies specializing in civil engineering, railways, and port infrastructure also represent potential buyers, seeking customized asphalt solutions for their specific project requirements. These diverse customer bases underscore the pervasive need for HMA across various facets of modern infrastructure development.

Hot Mix Asphalt Market Key Technology Landscape

The technology landscape for the Hot Mix Asphalt market is continuously evolving, driven by demands for increased efficiency, enhanced pavement performance, and reduced environmental impact. Core technologies revolve around the asphalt mixing plants themselves, which have transitioned from batch plants to more sophisticated continuous drum mix plants. Modern plants incorporate advanced burner systems, precise aggregate weighing, and automated control systems to optimize fuel consumption, minimize emissions, and ensure consistent mix quality. Innovations in plant design focus on modularity for easier relocation, improved dust collection systems, and the integration of technologies that facilitate higher percentages of recycled asphalt pavement (RAP) in the mix, contributing to a circular economy model.

Beyond production, significant technological advancements are observed in asphalt binder modification and mix design. Polymer-modified bitumen (PMB) is increasingly used to enhance the elastic and viscoelastic properties of asphalt, leading to improved resistance to rutting, cracking, and fatigue, particularly in high-traffic or extreme climate conditions. The development of various additives, such as anti-stripping agents, adhesion promoters, and rejuvenators for recycled asphalt, further extends pavement life and performance. Furthermore, the rise of Warm Mix Asphalt (WMA) technologies, employing foaming techniques or chemical additives, allows for production and paving at lower temperatures. This significantly reduces energy consumption and lowers greenhouse gas emissions, aligning with global sustainability objectives and offering considerable environmental benefits compared to traditional HMA.

The application and monitoring of Hot Mix Asphalt also leverage advanced technologies. Intelligent compaction systems, integrated with vibratory rollers, use GPS and sensor data to provide real-time feedback on compaction levels, ensuring uniform density and preventing over-compaction or under-compaction. Pavement management systems (PMS) utilize data analytics to assess pavement conditions, predict deterioration, and optimize maintenance schedules, extending the service life of roads and reducing long-term costs. Drone technology equipped with thermal imaging and high-resolution cameras is being used for pre-construction site analysis and post-paving quality assessment, ensuring uniform temperature distribution and identifying potential issues. These integrated technologies collectively enhance the efficiency, quality, and longevity of asphalt pavements, representing a progressive shift in infrastructure development practices.

Regional Highlights

- North America: A mature market characterized by significant government spending on infrastructure repair and rehabilitation. Strong emphasis on sustainable practices, including recycled asphalt pavement (RAP) and warm mix asphalt (WMA), alongside innovations in polymer-modified binders for enhanced durability in diverse climates.

- Europe: Driven by strict environmental regulations and a focus on circular economy principles, leading to high adoption of WMA and RAP. Investments in smart road technologies and advanced pavement management systems are prevalent, particularly in Germany, the UK, and France.

- Asia Pacific: The fastest-growing market, propelled by rapid urbanization, extensive road network expansion in countries like China and India, and significant infrastructure investments. Emerging economies in Southeast Asia are also contributing substantially to demand for new HMA infrastructure.

- Latin America: Experiencing growth due to increasing industrialization and development of new trade routes and urban centers. Investments in basic infrastructure are rising, creating a demand for cost-effective and durable HMA solutions.

- Middle East & Africa: Marked by large-scale construction projects, particularly in the GCC countries, driven by economic diversification and smart city initiatives. High demand for HMA to withstand extreme temperatures and heavy loads, often utilizing specialized mix designs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hot Mix Asphalt Market.- CRH plc

- Heidelberg Materials AG

- Vicat S.A.

- LafargeHolcim Ltd.

- Cemex S.A.B. de C.V.

- Eurovia (Vinci Construction)

- Colas Group

- Aggregate Industries (Holcim Group)

- Vulcan Materials Company

- Martin Marietta Materials, Inc.

- Summit Materials, Inc.

- Buzzi Unicem S.p.A.

- Asphalt Construction Company, Inc.

- Dynasol (Repsol)

- Pavement Recycling Systems, Inc.

Frequently Asked Questions

What is Hot Mix Asphalt and its primary use?

Hot Mix Asphalt (HMA) is a combination of aggregate, bitumen, and filler, mixed at high temperatures to create a durable paving material. Its primary use is in the construction and maintenance of roads, highways, airport runways, and other essential infrastructure requiring robust and long-lasting surfaces.

How is the Hot Mix Asphalt market addressing environmental concerns?

The HMA market is actively addressing environmental concerns through the adoption of Warm Mix Asphalt (WMA) technologies, which reduce energy consumption and emissions. Additionally, increased utilization of Recycled Asphalt Pavement (RAP) and other reclaimed materials significantly lowers the demand for virgin resources and minimizes waste.

What factors are driving the growth of the Hot Mix Asphalt market?

Key drivers include substantial government investments in infrastructure development, rapid global urbanization leading to increased road construction, and the ongoing need for maintenance and rehabilitation of aging transportation networks. Technological advancements in HMA formulations also enhance durability and performance, further stimulating demand.

What role does Artificial Intelligence play in the Hot Mix Asphalt industry?

Artificial Intelligence is transforming the HMA industry by optimizing mix designs for superior performance, enabling predictive maintenance for production equipment, and enhancing real-time quality control during paving operations. AI also aids in supply chain efficiency and environmental impact reduction, leading to more sustainable and efficient infrastructure projects.

Which regions are key contributors to the Hot Mix Asphalt market?

North America and Europe are significant mature markets driven by maintenance and sustainable practices. Asia Pacific, particularly China and India, represents the fastest-growing region due to extensive infrastructure expansion. Latin America and the Middle East & Africa are emerging markets with increasing investments in new development.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager