Hot Runner Temperature Controller Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428017 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Hot Runner Temperature Controller Market Size

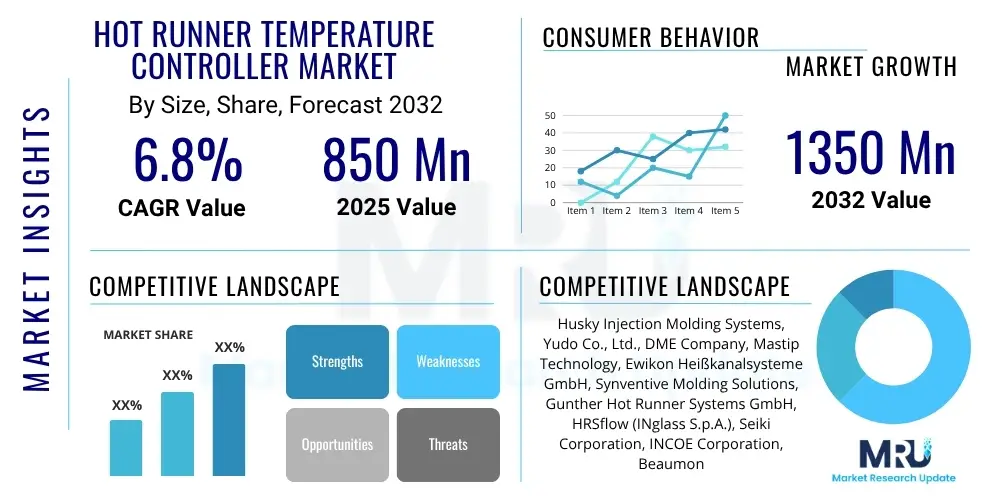

The Hot Runner Temperature Controller Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 850 million in 2025 and is projected to reach USD 1350 million by the end of the forecast period in 2032. This growth trajectory is underpinned by the increasing demand for high-precision injection molding, reduced material waste, and enhanced operational efficiency across various industrial sectors. The market expansion is further propelled by technological advancements in control systems and the expanding adoption of automated manufacturing processes.

Hot Runner Temperature Controller Market introduction

Hot runner temperature controllers are sophisticated electronic devices meticulously engineered to maintain precise temperature profiles within the manifold and nozzle systems of hot runner molds used in plastic injection molding. These controllers are paramount in ensuring the consistent melt quality of thermoplastic materials, preventing premature solidification, and guaranteeing optimal flow into the mold cavity. Their primary function is to eliminate cold slugs, reduce gate vestiges, and enable direct gating onto the part, thereby significantly enhancing part quality and aesthetic appeal. The technology is critical for producing parts with tight tolerances and complex geometries, which are increasingly required across numerous industries.

The product range encompasses various configurations, from single-zone controllers for simpler applications to multi-zone systems capable of managing dozens or even hundreds of individual heating zones. This versatility allows manufacturers to tailor temperature control solutions to the specific demands of their molds and materials. Major applications span a broad spectrum of industries, including automotive for interior and exterior components, medical for precision devices and disposables, packaging for thin-wall containers and closures, and electronics for intricate housings and connectors. The controllers are instrumental in achieving high-volume production with unparalleled consistency.

The benefits derived from employing advanced hot runner temperature controllers are substantial, including improved part quality, characterized by superior surface finish and dimensional stability; reduced cycle times due to faster material flow and elimination of sprue removal; significant material savings by eliminating runners; and reduced post-processing requirements. These advantages collectively contribute to lower manufacturing costs and increased profitability. Driving factors for market growth include the escalating demand for high-quality plastic products, the relentless pursuit of automation and efficiency in manufacturing, the imperative to optimize material usage, and the burgeoning adoption of sophisticated injection molding techniques for complex part designs. Furthermore, the push towards Industry 4.0 integration and smart manufacturing practices is fostering innovation in controller technology, leading to more intelligent and networked systems.

Hot Runner Temperature Controller Market Executive Summary

The Hot Runner Temperature Controller Market is experiencing robust expansion driven by several key business trends, regional shifts, and advancements across various market segments. Business trends indicate a strong focus on enhancing manufacturing competitiveness through automation, precision, and waste reduction. Companies are increasingly investing in sophisticated control systems to meet stringent quality standards and achieve higher production throughput. The demand for customized solutions, particularly for complex and high-value parts in sectors like automotive and medical, is pushing manufacturers to offer more flexible and adaptable temperature control technologies. Furthermore, the global drive towards sustainable manufacturing practices is amplifying the adoption of hot runner systems that minimize material waste, thereby reinforcing the market's growth trajectory.

Regional trends reveal a dynamic landscape, with Asia Pacific emerging as a dominant force due to the rapid expansion of its manufacturing base, particularly in countries like China, India, and Southeast Asian nations. This region benefits from significant investments in automotive, electronics, and consumer goods production, which are primary end-users of hot runner technology. Europe continues to be a hub for innovation, with a strong emphasis on precision engineering and advanced manufacturing techniques, driving the adoption of high-end, multi-zone controllers. North America demonstrates consistent growth, propelled by technological advancements and the demand for advanced manufacturing solutions in its diverse industrial landscape. Emerging markets in Latin America and the Middle East & Africa are also showing promising growth as industrialization efforts intensify and local manufacturing capabilities expand.

Segment trends highlight a significant shift towards multi-zone temperature controllers, which offer superior control over complex mold designs and a wider range of materials, enabling manufacturers to produce intricate parts with higher accuracy. Closed-loop control systems are gaining traction due to their enhanced precision and ability to provide real-time feedback and adjustments, leading to more consistent part quality. In terms of applications, the automotive sector remains a major consumer, followed closely by the medical and packaging industries, both of which require high-volume production of defect-free components. The continuous evolution of materials science and advanced polymer formulations further necessitates more precise and adaptable temperature control, ensuring that the market for hot runner temperature controllers remains vibrant and innovative.

AI Impact Analysis on Hot Runner Temperature Controller Market

Common user questions regarding the impact of AI on the Hot Runner Temperature Controller Market frequently revolve around how artificial intelligence can enhance existing control precision, predict potential system failures, and optimize overall injection molding processes. Users are keen to understand if AI integration can lead to further reductions in cycle times, improvements in part quality consistency, and more efficient energy consumption. There is also significant interest in the potential for AI to facilitate proactive maintenance, intelligent diagnostics, and seamless integration within broader Industry 4.0 frameworks, ultimately seeking to achieve fully autonomous and self-optimizing hot runner systems. Concerns often include the complexity of implementation, data security, and the return on investment for such advanced technologies, driving a demand for clear demonstrations of value and practical applications.

The integration of artificial intelligence is poised to revolutionize the Hot Runner Temperature Controller Market by moving beyond traditional PID control to more adaptive and predictive methodologies. AI algorithms can analyze vast datasets of historical molding parameters, temperature fluctuations, and part quality outcomes to identify complex correlations and patterns that are imperceptible to conventional systems. This analytical capability allows controllers to anticipate thermal variations and adjust heating profiles preemptively, leading to unprecedented levels of temperature stability and consistency across all zones. Such foresight minimizes defects, reduces scrap rates, and ensures that every molded part adheres to the highest quality specifications, regardless of external disturbances or material property variations. The ability to learn and adapt from continuous operation makes hot runner systems more resilient and efficient, ultimately increasing the overall effectiveness of the injection molding process.

Furthermore, AI-driven solutions are enabling a paradigm shift from reactive maintenance to predictive maintenance within hot runner systems. By continuously monitoring sensor data from heating elements, thermocouples, and power consumption, AI models can detect subtle anomalies and trends indicative of impending component failure. This capability allows manufacturers to schedule maintenance proactively, replacing parts before they cause unplanned downtime and costly production interruptions. The implications extend to optimizing energy consumption, as AI can fine-tune heating cycles and power delivery based on real-time needs, preventing overheating and reducing unnecessary energy expenditure. The vision is for hot runner temperature controllers to become integral components of smart factories, communicating seamlessly with other manufacturing equipment and enterprise systems to create a fully optimized, self-regulating production environment that maximizes efficiency and minimizes human intervention.

- Predictive Analytics for Thermal Stability: AI algorithms analyze historical temperature data and operational parameters to predict and proactively adjust heating profiles, ensuring optimal and consistent melt temperature.

- Real-time Adaptive Control: AI enables controllers to learn from ongoing processes and adapt temperature settings in real time to compensate for material variations, ambient conditions, and machine fluctuations, thereby enhancing part quality.

- Enhanced Fault Detection and Diagnostics: AI models can identify subtle anomalies in sensor readings that indicate impending issues with heating elements, thermocouples, or wiring, allowing for predictive maintenance and minimizing downtime.

- Process Optimization and Self-Correction: AI can autonomously fine-tune molding parameters by correlating temperature data with part quality metrics, leading to optimized cycle times, reduced scrap rates, and improved overall efficiency.

- Energy Efficiency Maximization: Intelligent algorithms can optimize power consumption by ensuring heating elements operate only when necessary and at the most efficient levels, reducing energy waste and operational costs.

- Integration with Industry 4.0 and Smart Manufacturing: AI facilitates seamless communication and data exchange between hot runner controllers and other smart factory components, enabling holistic process management and autonomous production lines.

- Personalized Parameter Generation: AI can assist in automatically generating optimal temperature profiles for new materials or complex mold designs based on material properties and desired part specifications, accelerating setup times.

DRO & Impact Forces Of Hot Runner Temperature Controller Market

The Hot Runner Temperature Controller Market is dynamically shaped by a confluence of drivers, restraints, opportunities, and various impact forces that collectively dictate its growth trajectory and evolutionary path. The primary drivers fueling market expansion include the escalating global demand for high-quality, defect-free plastic components across diverse industries such as automotive, medical, and packaging. Manufacturers are increasingly prioritizing precision and consistency in injection molding processes to meet stringent product specifications and reduce post-processing costs. Furthermore, the imperative to minimize material waste and optimize production cycles, driven by both economic considerations and sustainability goals, strongly encourages the adoption of hot runner systems and their sophisticated temperature controllers. The ongoing trend of automation in manufacturing, coupled with the rising complexity of plastic part designs, further necessitates advanced control mechanisms capable of managing intricate thermal profiles with utmost accuracy, thereby acting as a significant market impetus.

Despite the compelling drivers, the market faces several notable restraints. The initial high capital investment associated with acquiring and implementing advanced hot runner systems, including multi-zone temperature controllers, can be a deterrent for small and medium-sized enterprises (SMEs) with limited budgets. The technical complexity involved in setting up, operating, and maintaining these sophisticated systems requires specialized knowledge and skilled personnel, which can pose a challenge in regions with a shortage of trained technicians. Moreover, the integration of hot runner systems with existing injection molding machines and enterprise manufacturing systems can sometimes present compatibility issues, requiring significant customization and integration efforts. The perception of longer lead times for custom hot runner solutions and the potential for higher maintenance costs in comparison to traditional cold runner systems also act as restraining factors, influencing investment decisions among potential adopters.

Opportunities for growth are abundant and strategically position the market for future expansion. The rapid industrialization and burgeoning manufacturing sectors in emerging economies, particularly in Asia Pacific, Latin America, and the Middle East & Africa, present vast untapped markets for hot runner temperature controllers. These regions are witnessing increased foreign direct investment in manufacturing and a rising demand for high-quality plastic goods. The continuous evolution of smart manufacturing technologies, including Industry 4.0, IoT, and AI, offers significant opportunities for integrating more intelligent, connected, and predictive control features into hot runner systems, leading to enhanced performance and new value propositions. Furthermore, the development of specialized controllers for processing advanced engineering plastics and bio-based polymers, which often require highly precise and stable thermal management, represents a niche yet high-growth segment. The increasing focus on custom-designed hot runner solutions tailored to specific application requirements also opens avenues for market participants to differentiate their offerings and capture premium market segments.

The market is also influenced by several impact forces. Technological advancements, particularly in sensor technology, microprocessors, and communication protocols, are continually driving innovation, leading to more accurate, reliable, and user-friendly temperature controllers. Economic cycles and global manufacturing output directly affect the demand for injection molding machinery and, consequently, hot runner systems, with downturns potentially leading to deferred investments. Regulatory standards pertaining to product quality, safety, and environmental impact in industries like medical and food packaging necessitate the use of highly controlled and repeatable manufacturing processes, thereby boosting the demand for advanced hot runner temperature control. Competitive intensity among market players drives continuous product development and pricing strategies, while the availability and cost of raw materials for both the hot runner systems and the plastic products being molded also exert significant influence on market dynamics and overall profitability.

Segmentation Analysis

The Hot Runner Temperature Controller Market is meticulously segmented across various dimensions to provide a comprehensive understanding of its structure, dynamics, and growth potential. This segmentation allows for targeted analysis of market opportunities, competitive landscapes, and evolving customer preferences, enabling stakeholders to make informed strategic decisions. The market can be broadly categorized by product type, control technology, application, and end-user, each revealing distinct growth patterns and demand drivers. Understanding these segments is crucial for identifying key growth areas and developing tailored solutions to meet specific industry needs. The intricate nature of injection molding processes and the diverse requirements of different plastic materials necessitate a highly differentiated approach to temperature control, underscoring the importance of this granular market segmentation.

- By Product Type:

- Single Zone Controllers: These are typically used for simpler molds with fewer heating zones or smaller production runs where a single temperature profile is sufficient. They are cost-effective and easy to operate.

- Multi-Zone Controllers: Designed for complex molds with multiple heating zones, offering independent control over each zone. This enables precise temperature gradients and individual nozzle control, critical for intricate parts and advanced engineering plastics.

- Small Multi-Zone (e.g., 2-12 zones)

- Medium Multi-Zone (e.g., 13-48 zones)

- Large Multi-Zone (e.g., 49+ zones)

- By Control Technology:

- Open-Loop Control: Basic control systems where the output is determined by the input signal without feedback. Less precise but more economical for certain applications.

- Closed-Loop Control (PID, Fuzzy Logic, etc.): Advanced systems that utilize feedback from thermocouples to continuously adjust heating power, maintaining highly precise and stable temperatures. This is crucial for high-quality and consistent production.

- By Application:

- Automotive: Interior components (dashboards, door panels), exterior components (grilles, bumpers), lighting systems, connectors. Requires high aesthetic quality and durability.

- Medical: Syringes, IV components, surgical instruments, diagnostic parts, pharmaceutical packaging. Demands extreme precision, material purity, and regulatory compliance.

- Packaging: Thin-wall containers, caps, closures, preforms, food packaging. Focus on high-speed production, material efficiency, and consistent quality.

- Electronics: Connectors, switches, housings for consumer electronics, automotive electronics, and industrial equipment. Requires precision for small, intricate parts.

- Consumer Goods: Household appliances, toys, sports equipment, personal care products. Emphasis on aesthetic finish, cost-effectiveness, and high-volume production.

- Construction: Pipes, fittings, profiles, and various building components made from plastics.

- Others: Aerospace, industrial tools, agricultural components, etc.

- By End-User:

- OEMs (Original Equipment Manufacturers): Companies that integrate hot runner systems into new injection molding machines or develop custom hot runner solutions.

- Tier 1 & Tier 2 Suppliers: Manufacturers producing components for larger OEMs, particularly prevalent in the automotive industry.

- Custom Molders: Companies offering contract manufacturing services for various industries, often requiring flexible and adaptable hot runner solutions.

- In-House Manufacturing Units: Companies that have their own injection molding facilities for producing parts for their own products.

Value Chain Analysis For Hot Runner Temperature Controller Market

The value chain for the Hot Runner Temperature Controller Market is a complex network involving multiple stages, from raw material sourcing to the final end-user application, highlighting the interdependencies among various stakeholders. The upstream segment of the value chain is dominated by suppliers of critical components and raw materials. This includes manufacturers of high-grade electronic components such as microcontrollers, power transistors, and sensor technologies like thermocouples and resistance temperature detectors (RTDs). Furthermore, suppliers of specialized metals and alloys for heating elements, wiring, and structural enclosures play a crucial role. The quality and reliability of these upstream components directly impact the performance, durability, and cost-effectiveness of the final temperature controller unit. Strategic relationships with these suppliers are essential for ensuring a stable supply chain and maintaining competitive pricing for the finished product. Innovation at this stage, particularly in advanced materials and miniaturized electronics, often dictates the technological progress of the entire market, allowing for more compact, efficient, and precise controllers.

Moving downstream, the value chain encompasses the manufacturing and assembly of the hot runner temperature controllers. This stage involves sophisticated design, engineering, and quality control processes to integrate various components into a cohesive and functional system. Manufacturers of hot runner temperature controllers leverage their expertise in electrical engineering, thermal dynamics, and software development to produce units that meet stringent industry standards and customer requirements. Following manufacturing, the distribution channel plays a pivotal role in delivering these products to end-users. This involves both direct and indirect sales channels. Direct sales are often utilized for large-scale customers, complex integrated systems, or when extensive technical support and customization are required. This approach allows manufacturers to build direct relationships with clients, offering personalized service and tailored solutions. It also provides immediate feedback on product performance and market needs, fostering continuous improvement and innovation.

Conversely, indirect sales channels involve distributors, agents, and system integrators who act as intermediaries, particularly for reaching a broader customer base, including smaller businesses or those in geographically dispersed regions. These partners often provide local sales support, technical assistance, and sometimes integrate hot runner temperature controllers into complete molding solutions. The choice of distribution strategy depends on market penetration goals, customer segment characteristics, and the level of technical complexity involved. Ultimately, the hot runner temperature controllers reach the end-users, which are primarily injection molding companies across diverse industries such as automotive, medical, packaging, and electronics. These end-users integrate the controllers into their injection molding machines to produce a wide array of plastic parts. Effective collaboration and communication throughout this entire value chain are critical for ensuring product quality, timely delivery, and sustained market growth. Each stage adds value, from the technological advancements in components to the efficient distribution and end-user application, collectively contributing to the market's overall efficiency and competitive posture.

Hot Runner Temperature Controller Market Potential Customers

The Hot Runner Temperature Controller Market serves a diverse and expansive base of potential customers, primarily comprised of entities engaged in plastic injection molding across various industrial sectors. These customers are fundamentally driven by the need for precision, efficiency, and quality in their manufacturing processes. The largest segment of potential customers includes injection molding companies, which range from large-scale contract manufacturers producing millions of parts annually to smaller, specialized molders catering to niche markets. These companies are constantly seeking solutions that can enhance their competitiveness by reducing cycle times, minimizing material waste, improving part consistency, and lowering overall production costs. Their demand for advanced temperature controllers is directly correlated with the increasing complexity of part designs, the use of advanced engineering polymers, and the stringent quality standards imposed by end-product industries.

Beyond general injection molders, specific industry verticals represent significant customer segments. The automotive industry is a major consumer, encompassing automotive manufacturers (OEMs) and their Tier 1 and Tier 2 suppliers who produce components like interior trim, exterior grilles, lighting lenses, and under-hood parts. The medical device industry also represents a high-value customer segment, including manufacturers of medical disposables, diagnostic components, and surgical instruments, where extreme precision, material purity, and consistent quality are paramount due to regulatory requirements and critical application areas. Similarly, the packaging industry, particularly for food and beverage containers, closures, and thin-wall packaging, relies heavily on hot runner systems for high-speed, high-volume production with minimal material consumption. These customers prioritize controllers that ensure rapid cycle times, excellent repeatability, and superior surface finishes to meet consumer expectations and market demands for efficiency.

Furthermore, the electronics industry, which produces intricate housings, connectors, and internal components for consumer electronics, industrial equipment, and telecommunications, requires precise temperature control for molding small, complex, and often delicate parts. Other emerging customer segments include manufacturers in the construction sector for plastic pipes and fittings, and the consumer goods industry for a wide array of household items, toys, and sports equipment. In addition to direct end-users, mold makers and hot runner system integrators also represent critical potential customers as they often purchase controllers as part of a complete hot runner package or integrate them into custom mold solutions for their clients. The continuous evolution of these industries, coupled with their increasing reliance on advanced plastic components, ensures a sustained and growing demand for sophisticated hot runner temperature controllers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 850 million |

| Market Forecast in 2032 | USD 1350 million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Husky Injection Molding Systems, Yudo Co., Ltd., DME Company, Mastip Technology, Ewikon Heißkanalsysteme GmbH, Synventive Molding Solutions, Gunther Hot Runner Systems GmbH, HRSflow (INglass S.p.A.), Seiki Corporation, INCOE Corporation, Beaumont Technologies Inc., CACO Pacific Corporation, EWIKON, Gammaflux, Athena Automation Ltd., Hottip, Mokon, Mold-Masters (Milacron), Polimold, PSG Plastic Systems GmbH, Thermoplay S.p.A., Cold Shot Chillers |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hot Runner Temperature Controller Market Key Technology Landscape

The Hot Runner Temperature Controller Market is characterized by a continuously evolving technology landscape, driven by the relentless pursuit of higher precision, greater efficiency, and enhanced user-friendliness in injection molding processes. At the core of these advancements is the sophisticated application of control algorithms, with PID (Proportional-Integral-Derivative) control remaining a cornerstone for maintaining stable temperatures. However, modern controllers are increasingly integrating more advanced control strategies, such as Fuzzy Logic and even rudimentary neural networks, to handle non-linearities and disturbances more effectively, leading to superior temperature stability and quicker response times. These advanced algorithms enable controllers to adapt to varying material characteristics and mold conditions, ensuring consistent melt quality throughout the production run and minimizing potential defects.

Beyond core algorithms, the technological landscape is significantly influenced by hardware innovations and connectivity features. Modern hot runner temperature controllers typically feature high-resolution touch-screen interfaces, providing intuitive operation, comprehensive data visualization, and simplified parameter adjustments. The incorporation of advanced sensor technology, particularly high-accuracy thermocouples and improved noise reduction circuitry, ensures more reliable and precise temperature readings, which are critical inputs for effective control. Furthermore, multi-zone control capabilities have become standard, allowing for independent and precise temperature management of numerous heating zones within a single mold. This is indispensable for molding complex parts with varying wall thicknesses or requiring sequential filling, enabling optimal flow balance and preventing material degradation.

The rise of Industry 4.0 and smart manufacturing paradigms is profoundly shaping the future of hot runner temperature controllers. This includes the integration of remote monitoring and control functionalities, allowing operators to oversee and adjust processes from anywhere, thereby enhancing operational flexibility and reducing the need for constant on-site supervision. Connectivity features such as Ethernet, USB, and various industrial communication protocols (e.g., OPC UA, Modbus) facilitate seamless data exchange with supervisory control and data acquisition (SCADA) systems, manufacturing execution systems (MES), and enterprise resource planning (ERP) systems. This enables comprehensive process data logging, real-time analytics, and predictive maintenance capabilities. Moreover, the focus on energy efficiency is driving the development of controllers with advanced power management features, such as intelligent energy-saving modes and precise power modulation, which reduce overall energy consumption and contribute to more sustainable manufacturing operations. These technological advancements collectively ensure that hot runner temperature controllers remain at the forefront of injection molding innovation, continually enhancing productivity and part quality.

Regional Highlights

- North America: This region is characterized by a mature industrial base and a strong emphasis on advanced manufacturing, particularly in the automotive, medical device, and aerospace sectors. The demand for high-precision hot runner temperature controllers is driven by stringent quality requirements, the adoption of complex mold designs, and the continuous pursuit of automation and efficiency. There is a significant focus on integrating smart factory solutions and leveraging technologies such as IoT and AI to optimize production processes. Innovation in materials science and customized molding solutions further fuels market growth, with a preference for high-performance multi-zone controllers and closed-loop systems that offer superior control and data analytics capabilities.

- Europe: Europe is a global leader in precision engineering and advanced manufacturing, making it a critical market for hot runner temperature controllers. Countries like Germany, Italy, and Switzerland are at the forefront of injection molding technology, with a strong demand for high-end, customized hot runner systems. The region's robust automotive industry, coupled with its thriving medical and packaging sectors, drives the need for controllers that ensure exceptional part quality, consistency, and energy efficiency. There is a significant emphasis on R&D, leading to continuous innovation in control algorithms, user interfaces, and remote diagnostic capabilities. Sustainability initiatives and strict environmental regulations also influence product development, pushing for more energy-efficient and waste-reducing hot runner solutions.

- Asia Pacific (APAC): The APAC region stands as the largest and fastest-growing market for hot runner temperature controllers, propelled by rapid industrialization, burgeoning manufacturing sectors, and increasing foreign direct investment. China, India, Japan, and South Korea are key contributors, with massive production volumes in automotive, electronics, consumer goods, and packaging. The demand is characterized by a mix of cost-effective, reliable controllers for high-volume production and sophisticated multi-zone systems for increasingly complex and high-value applications. The region's expanding middle class and growing consumer purchasing power are driving an increased demand for high-quality plastic products, subsequently boosting the adoption of advanced hot runner technology. Investments in infrastructure and manufacturing capabilities continue to accelerate market expansion.

- Latin America: This region is an emerging market for hot runner temperature controllers, with countries like Brazil and Mexico leading the industrial growth. The market is primarily driven by the expansion of the automotive and packaging industries, which are undergoing modernization and adopting more efficient manufacturing processes. There is a growing awareness of the benefits of hot runner technology in terms of material savings and improved part quality. While demand for advanced multi-zone controllers is increasing, particularly for export-oriented production, the market also sees significant uptake of robust and easy-to-use single-zone and basic multi-zone controllers. Economic stability and governmental support for industrial development are key factors influencing market growth.

- Middle East and Africa (MEA): The MEA region is witnessing steady growth in the hot runner temperature controller market, fueled by increasing investments in industrial diversification, particularly in the packaging, automotive, and construction sectors. Countries like Saudi Arabia, UAE, and South Africa are developing their manufacturing capabilities, leading to a greater demand for advanced plastic processing equipment. The market is still in its nascent stages compared to more developed regions, but the growing local production of consumer goods and industrial components is creating new opportunities. There is a strong focus on acquiring reliable and durable hot runner solutions that can withstand challenging operating conditions and contribute to cost-effective production.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hot Runner Temperature Controller Market.- Husky Injection Molding Systems

- Yudo Co., Ltd.

- DME Company

- Mastip Technology

- Ewikon Heißkanalsysteme GmbH

- Synventive Molding Solutions

- Gunther Hot Runner Systems GmbH

- HRSflow (INglass S.p.A.)

- Seiki Corporation

- INCOE Corporation

- Beaumont Technologies Inc.

- CACO Pacific Corporation

- EWIKON

- Gammaflux

- Athena Automation Ltd.

- Hottip

- Mokon

- Mold-Masters (Milacron)

- Polimold

- PSG Plastic Systems GmbH

- Thermoplay S.p.A.

- Cold Shot Chillers

Frequently Asked Questions

What is a hot runner temperature controller and why is it essential?

A hot runner temperature controller is an electronic device used in plastic injection molding to precisely regulate the temperature of the hot runner manifold and nozzles. It is essential for maintaining consistent melt quality, preventing material degradation, reducing cycle times, eliminating waste, and ensuring high-quality, defect-free plastic parts by keeping the plastic molten until it enters the mold cavity.

How do hot runner temperature controllers contribute to improved part quality?

Hot runner temperature controllers improve part quality by ensuring a stable and uniform melt temperature throughout the injection process. This prevents cold slugs, reduces gate vestiges, minimizes flow imbalances, and enhances dimensional stability and surface finish, leading to fewer defects and more consistent, high-quality molded parts.

What are the key benefits of using multi-zone hot runner temperature controllers?

Multi-zone hot runner temperature controllers offer independent temperature control for multiple heating zones within a mold. This provides superior precision for complex geometries, allows for processing diverse materials, optimizes flow balance, and enables sequential filling, leading to enhanced part quality, reduced scrap, and greater production flexibility.

How does AI impact the future of hot runner temperature control?

AI is set to revolutionize hot runner temperature control by enabling predictive analytics for thermal stability, real-time adaptive adjustments, enhanced fault detection, and process optimization. AI-driven systems can learn from data, anticipate issues, improve energy efficiency, and integrate seamlessly with Industry 4.0 environments for truly intelligent and autonomous molding operations.

Which industries are the primary adopters of hot runner temperature controllers?

The primary adopters of hot runner temperature controllers are industries requiring high-precision and high-volume plastic injection molding. These include the automotive sector for various components, the medical device industry for critical parts, the packaging industry for containers and closures, and the electronics sector for intricate housings and connectors.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager