Human Machine Interface Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430298 | Date : Nov, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Human Machine Interface Market Size

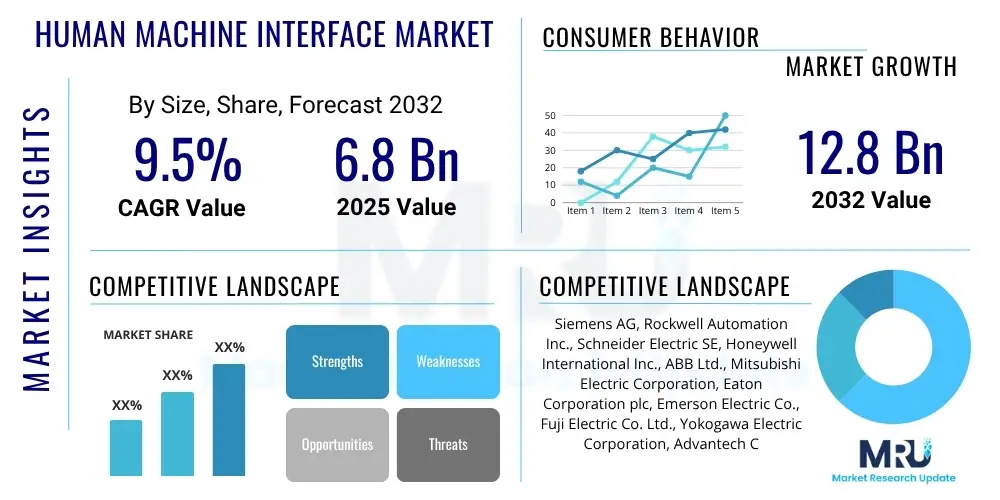

The Human Machine Interface Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2025 and 2032. The market is estimated at USD 6.8 Billion in 2025 and is projected to reach USD 12.8 Billion by the end of the forecast period in 2032.

Human Machine Interface Market introduction

The Human Machine Interface (HMI) market encompasses technologies and devices that facilitate communication and interaction between human operators and industrial machinery, systems, or processes. An HMI serves as a digital dashboard, providing a visual representation of a control system and enabling operators to monitor real-time data, manage operations, and input commands. These interfaces range from simple push-button panels to sophisticated touchscreens, industrial PCs, and integrated software solutions, all designed to enhance operational efficiency, ensure safety, and optimize process control across various sectors. The primary goal of HMI is to simplify complex operational data and machine control into an intuitive and user-friendly format.

HMI products are diverse, including panel-mount HMIs, industrial PCs with HMI software, web-based HMIs, and mobile HMI applications. Major applications span discrete manufacturing, process industries, automotive, energy and power, oil and gas, healthcare, and building automation. The benefits of deploying HMI solutions are numerous, including improved decision-making through enhanced data visualization, reduced operational errors, increased productivity, and superior system diagnostics. Key driving factors propelling the HMI market include the escalating adoption of Industry 4.0 initiatives, the proliferation of the Industrial Internet of Things (IIoT), the growing demand for automation across industries, and the continuous focus on improving user experience and operational safety.

Human Machine Interface Market Executive Summary

The Human Machine Interface market is currently experiencing robust growth, driven by significant shifts in business, regional, and segment trends. Business trends highlight a strong inclination towards integrated, intelligent, and cloud-connected HMI solutions, enabling remote monitoring and enhanced data analytics. There is a continuous push for more intuitive and adaptive interfaces that leverage advanced graphics and user-centric designs to minimize operator training and error. Furthermore, cybersecurity concerns are fostering the development of more secure HMI platforms, making them resilient against sophisticated threats and ensuring data integrity and system reliability in critical industrial environments.

Regionally, the Asia Pacific market is demonstrating exceptional growth, primarily fueled by the rapid industrialization, massive manufacturing base, and substantial investments in automation technologies, particularly in countries like China, India, and Japan. North America and Europe continue to be innovation hubs, characterized by early adoption of advanced HMI technologies, stringent regulatory compliance, and a strong emphasis on smart factory initiatives and digitalization. Segment trends indicate the enduring dominance of panel-based HMIs due to their ruggedness and reliability, while industrial PC-based and software-only HMI solutions are witnessing accelerated adoption, driven by their flexibility, scalability, and enhanced processing capabilities. The convergence of HMI with SCADA and MES systems is also a prominent trend, offering comprehensive control and management solutions.

AI Impact Analysis on Human Machine Interface Market

Common user questions regarding AI's impact on the Human Machine Interface market frequently revolve around how artificial intelligence can enhance usability, intelligence, and predictive capabilities within HMI systems. Users are keen to understand if AI will make HMIs more intuitive, capable of anticipating operator needs, or provide more actionable insights. The overarching themes include the potential for AI to transform HMIs into proactive decision-support tools, moving beyond mere data visualization to intelligent operational guidance and predictive maintenance. Concerns also include the complexity of integrating AI, potential data privacy issues, and the need for new skillsets among operators to fully leverage AI-powered interfaces.

AI's influence is poised to revolutionize HMI by embedding intelligence directly into the interface, offering significant advancements in operational efficiency and user experience. This includes enabling HMIs to learn from operator behavior, adapt interfaces dynamically, and provide context-aware information. The integration of AI facilitates predictive analytics, allowing HMIs to forecast potential equipment failures or operational inefficiencies, thereby enabling proactive intervention rather than reactive troubleshooting. Furthermore, AI-powered HMIs can process vast amounts of data from various sources, presenting operators with consolidated, prioritized, and easily digestible information, significantly enhancing decision-making capabilities. This transformative impact leads to more resilient, efficient, and user-friendly industrial environments.

- Enhanced predictive maintenance capabilities through machine learning algorithms that analyze operational data to anticipate equipment failures.

- Adaptive and personalized user interfaces that learn operator preferences and workflow patterns, dynamically adjusting displays and controls.

- Natural Language Processing (NLP) integration for voice commands and intelligent assistants, enabling hands-free operation and faster data retrieval.

- Advanced anomaly detection and diagnostic support, allowing HMIs to identify unusual patterns and suggest corrective actions in real-time.

- Improved data visualization through AI-driven insights, presenting complex information in more intuitive and actionable formats.

- Automated decision support and recommendation systems to optimize processes and improve operational efficiency.

DRO & Impact Forces Of Human Machine Interface Market

The Human Machine Interface (HMI) market is shaped by a complex interplay of drivers, restraints, opportunities, and broader impact forces. Key drivers include the widespread adoption of Industry 4.0 and smart factory initiatives globally, which necessitate advanced interfaces for managing increasingly automated and interconnected systems. The proliferation of the Industrial Internet of Things (IIoT) mandates sophisticated HMIs capable of aggregating and visualizing data from countless sensors and devices. Furthermore, the relentless pursuit of operational efficiency, enhanced worker safety, and improved productivity across diverse industries is compelling organizations to invest in modern HMI solutions that offer intuitive control and comprehensive data insights. The growing demand for remote monitoring and control capabilities, especially in hazardous or geographically dispersed operations, also significantly propels market growth.

Despite the strong growth drivers, several restraints challenge the HMI market. The initial high cost of implementing advanced HMI systems, including hardware, software, and integration services, can be a significant barrier for small and medium-sized enterprises (SMEs). The complexity associated with integrating new HMI solutions into legacy systems, coupled with the need for specialized technical expertise for installation, configuration, and maintenance, also acts as a deterrent. Moreover, the increasing threat of cyberattacks targeting industrial control systems poses substantial cybersecurity risks to HMI platforms, necessitating continuous investment in robust security measures and raising concerns among potential adopters regarding data integrity and system vulnerability. Maintaining compatibility with diverse industrial protocols and ensuring seamless interoperability remains an ongoing challenge.

Opportunities for market expansion are abundant, particularly in emerging economies undergoing rapid industrialization and technological modernization. The advent of augmented reality (AR) and virtual reality (VR) technologies presents a significant opportunity for developing more immersive and interactive HMI experiences, offering new paradigms for operator training and remote assistance. The integration of artificial intelligence (AI) and machine learning (ML) capabilities within HMI platforms for predictive analytics, adaptive interfaces, and intelligent decision support represents a transformative growth avenue. Furthermore, the growing demand for mobile and cloud-based HMIs, which offer unprecedented flexibility and accessibility for operators, is creating new market niches. The focus on developing sustainable and energy-efficient operations also opens doors for HMIs that can monitor and optimize resource consumption.

Segmentation Analysis

The Human Machine Interface market is comprehensively segmented to provide a detailed understanding of its diverse components and applications. This segmentation allows for targeted analysis of market dynamics, identifies key growth areas, and informs strategic decision-making for businesses operating within or looking to enter the HMI space. The market can be broadly categorized by component, type, technology, and end-use industry, reflecting the varied needs and preferences across different industrial environments. Each segment possesses distinct characteristics, market drivers, and competitive landscapes, contributing uniquely to the overall market ecosystem. Understanding these distinctions is crucial for developing effective product strategies and market penetration plans.

The component segment differentiates between hardware and software, recognizing the foundational physical elements versus the operating and application logic. The type segmentation typically categorizes HMIs based on their form factor and computational power, such as panel-mount HMIs, industrial PCs, and dedicated HMI software. Technology-based segmentation highlights the underlying interaction methods, including touch-based, gesture-based, and voice-controlled interfaces, along with emerging technologies like augmented reality. Finally, end-use industry segmentation dissects the market by the major sectors deploying HMI solutions, offering insights into industry-specific requirements and adoption rates. This multi-dimensional approach to segmentation ensures a holistic view of the HMI market, enabling stakeholders to pinpoint specific opportunities and challenges.

- By Component

- Hardware

- Software

- By Type

- Panel-Mount HMI

- Industrial PC (IPC)-based HMI

- HMI Software (Standalone and Integrated)

- Video and Graphic HMI

- Mobile HMI

- By Technology

- Touchscreen

- Keypad

- Gesture Recognition

- Voice Recognition

- Biometrics

- Augmented Reality (AR)/Virtual Reality (VR)

- By End-use Industry

- Automotive

- Manufacturing (Discrete and Process)

- Oil and Gas

- Chemicals and Petrochemicals

- Food and Beverages

- Packaging

- Energy and Power

- Healthcare and Pharmaceuticals

- Water and Wastewater Management

- Building Automation

- Metals and Mining

- Pulp and Paper

- Others (e.g., Aerospace and Defense, Marine)

Value Chain Analysis For Human Machine Interface Market

The value chain for the Human Machine Interface (HMI) market is a complex ecosystem involving various stages from raw material sourcing to end-user deployment and post-sales support. At the upstream end, the chain begins with component suppliers providing essential hardware elements such as semiconductors, microcontrollers, displays (LCD, OLED), touch sensors, industrial enclosures, and connectivity modules. These suppliers are critical for the functionality and quality of HMI devices. The manufacturing phase then involves assembling these components into complete HMI units, often incorporating specialized industrial-grade materials and robust designs to withstand harsh operating environments. This stage includes sophisticated circuit board design, software integration, and rigorous quality testing.

Further along the value chain, HMI manufacturers develop and integrate proprietary software platforms, operating systems, and application tools that enable data visualization, control logic, and connectivity features. Downstream activities involve system integrators, value-added resellers (VARs), and engineering firms who specialize in customizing HMI solutions for specific industrial applications and integrating them into existing plant architectures, often alongside SCADA or MES systems. Distribution channels play a vital role in market reach; these can be direct sales forces for large enterprises and strategic accounts, or indirect channels through a network of distributors, resellers, and channel partners who provide local support, sales, and training to a broader customer base. Post-sales services, including technical support, maintenance, and software updates, are crucial for customer satisfaction and long-term relationships.

Human Machine Interface Market Potential Customers

The Human Machine Interface (HMI) market serves a broad and diverse spectrum of potential customers across nearly every industrial and commercial sector that relies on machinery, automation, and data-driven operations. End-users and buyers of HMI solutions primarily include manufacturing companies in both discrete and process industries, seeking to enhance production efficiency, monitor real-time processes, and improve worker safety. This encompasses sectors such as automotive, where HMIs are critical for assembly line control and quality assurance; food and beverages, for recipe management and batch control; and pharmaceuticals, for stringent process monitoring and regulatory compliance.

Beyond traditional manufacturing, potential customers extend to the energy and power sector for managing grid operations and renewable energy facilities, the oil and gas industry for upstream, midstream, and downstream process control, and the water and wastewater management sector for remote monitoring of treatment plants. Healthcare providers utilize HMIs in medical equipment and facility management. Additionally, the building automation sector employs HMIs for intelligent control of HVAC, lighting, and security systems. Essentially, any organization aiming to optimize operational control, improve data visibility, reduce manual intervention, and foster more intuitive interaction between human operators and complex machinery represents a potential customer for HMI solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 6.8 Billion |

| Market Forecast in 2032 | USD 12.8 Billion |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, Rockwell Automation Inc., Schneider Electric SE, Honeywell International Inc., ABB Ltd., Mitsubishi Electric Corporation, Eaton Corporation plc, Emerson Electric Co., Fuji Electric Co. Ltd., Yokogawa Electric Corporation, Advantech Co. Ltd., Kontron AG, Exor International S.p.A., Pro-face by Schneider Electric, Weidmueller Interface GmbH & Co. KG, Beckhoff Automation GmbH & Co. KG, GE Digital, Red Lion Controls Inc., Capstone Technology, Maple Systems Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Human Machine Interface Market Key Technology Landscape

The Human Machine Interface (HMI) market is continually evolving, driven by advancements in various underlying technologies aimed at making human-machine interaction more intuitive, efficient, and robust. A cornerstone of this landscape is the widespread adoption of advanced touchscreen technology, including multi-touch and projected capacitive touch (PCT) displays, which offer superior responsiveness, durability, and clarity compared to traditional resistive touchscreens. These are often coupled with high-resolution graphics engines and industrial-grade operating systems (such as Windows Embedded, Linux, or proprietary RTOS) optimized for real-time control and data visualization in demanding industrial environments. The integration of powerful processors, like ARM-based or Intel x86 architectures, provides the computational horsepower needed for complex HMI applications and data processing at the edge.

Beyond touch-based interaction, the technology landscape is expanding to include more natural and hands-free control methods. Gesture recognition, utilizing cameras or specialized sensors, enables operators to control systems without physical contact, which is particularly beneficial in cleanroom environments or when operators are wearing gloves. Voice control, leveraging sophisticated natural language processing (NLP) and speech-to-text engines, is gaining traction for hands-free operation and faster command execution, especially in situations where visual interaction is limited or unsafe. The rise of cloud computing and mobile technologies has also led to the development of web-based and mobile HMIs, allowing for remote monitoring, control, and data access from smartphones, tablets, and wearable devices, significantly enhancing operational flexibility and accessibility.

Furthermore, the convergence of HMI with emerging technologies such as Augmented Reality (AR) and Virtual Reality (VR) is transforming how operators interact with machinery. AR-enabled HMIs can overlay digital information directly onto physical equipment, providing contextual data, maintenance instructions, or performance metrics in real-time, thereby improving troubleshooting and training. Virtual Reality HMIs offer immersive simulation environments for operator training and complex system design review. The integration of Artificial Intelligence (AI) and Machine Learning (ML) capabilities is also becoming pivotal, enabling HMIs to offer predictive analytics, adaptive interfaces, and intelligent decision support, moving beyond mere data display to proactive operational guidance. Lastly, robust communication protocols, including Ethernet/IP, Profinet, Modbus, and OPC UA, are essential for seamless integration of HMIs with programmable logic controllers (PLCs), distributed control systems (DCS), and other industrial equipment, ensuring reliable data exchange and interoperability across the plant floor and enterprise systems.

Regional Highlights

- North America: This region is a significant market for HMI due to early adoption of advanced manufacturing technologies, substantial investments in industrial automation, and a strong emphasis on research and development. The presence of key market players and a robust automotive industry further contribute to its dominance.

- Europe: Europe represents a mature market with a high degree of industrial automation, particularly in Germany's "Industrie 4.0" initiatives. Strict regulatory standards, a focus on energy efficiency, and a well-established automotive and process manufacturing sector drive HMI adoption.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market, primarily fueled by rapid industrialization, expansion of manufacturing facilities, and increasing government investments in smart factory projects in countries like China, India, Japan, and South Korea. The region's large industrial base and growing demand for automation solutions are key drivers.

- Latin America: This region is an emerging market for HMI, driven by increasing industrial investments in countries such as Brazil and Mexico, particularly in the oil and gas, mining, and automotive sectors. Modernization of infrastructure and manufacturing facilities contributes to steady growth.

- Middle East and Africa (MEA): MEA is witnessing significant growth in HMI adoption, mainly due to investments in oil and gas, infrastructure development, and diversification of economies away from oil dependency. The need for efficient process control and monitoring in large-scale industrial projects is a key factor.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Human Machine Interface Market.- Siemens AG

- Rockwell Automation Inc.

- Schneider Electric SE

- Honeywell International Inc.

- ABB Ltd.

- Mitsubishi Electric Corporation

- Eaton Corporation plc

- Emerson Electric Co.

- Fuji Electric Co. Ltd.

- Yokogawa Electric Corporation

- Advantech Co. Ltd.

- Kontron AG

- Exor International S.p.A.

- Pro-face by Schneider Electric

- Weidmueller Interface GmbH & Co. KG

- Beckhoff Automation GmbH & Co. KG

- GE Digital

- Red Lion Controls Inc.

- Capstone Technology

- Maple Systems Inc.

Frequently Asked Questions

What is a Human Machine Interface (HMI)?

A Human Machine Interface (HMI) is a user interface or dashboard that connects a person to a machine, system, or device. It provides a graphical representation of the industrial control system, allowing operators to monitor, control, and visualize processes in real-time, thereby facilitating interaction between humans and complex machinery. HMIs convert intricate data into easily understandable visual information, enhancing operational efficiency and safety across various industrial applications.

What are the primary benefits of using HMI in industrial settings?

The primary benefits of using HMIs in industrial settings include improved operational efficiency, reduced human errors, enhanced data visualization for better decision-making, and increased worker safety. HMIs provide real-time data access, enable proactive problem-solving through alerts and diagnostics, simplify complex control tasks, and facilitate remote monitoring and control, all contributing to optimized production processes and reduced downtime.

How is Artificial Intelligence (AI) impacting the HMI market?

Artificial Intelligence (AI) is significantly impacting the HMI market by enabling more intuitive, adaptive, and predictive interfaces. AI integration allows HMIs to learn operator behaviors, provide context-aware information, facilitate predictive maintenance, and offer intelligent decision support through advanced analytics and anomaly detection. This transforms HMIs into proactive tools that enhance operational intelligence and user experience, moving beyond mere data display to intelligent guidance.

What are the key growth drivers for the Human Machine Interface market?

Key growth drivers for the HMI market include the widespread adoption of Industry 4.0 and Industrial Internet of Things (IIoT) initiatives, the increasing demand for automation across diverse industries, and the continuous focus on improving operational efficiency and worker safety. The demand for advanced data visualization, remote monitoring capabilities, and enhanced user experience also significantly propels market expansion.

Which industries are the major end-users of HMI solutions?

Major end-users of HMI solutions span a wide range of industries, including manufacturing (both discrete and process), automotive, oil and gas, energy and power, food and beverages, healthcare and pharmaceuticals, and water and wastewater management. These sectors heavily rely on HMIs to monitor, control, and optimize their production processes, machinery, and facility operations, ensuring efficiency, quality, and compliance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Automotive Human Machine Interface (HMI) Market Size Report By Type (Instrument Cluster, Infotainment & Telematics), By Application (Economic Passenger Cars, Mid-Price Passenger Cars, Luxury Passenger Cars), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Human Machine Interface (HMI) Enclosures Market Statistics 2025 Analysis By Application (Industrial, Commercial), By Type (Plastic Material, Aluminium Material, Stainless Steel Material), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Programmable Industrial Automation Market Statistics 2025 Analysis By Application (Oil & Gas, Machine Manufacturing, Electrical & Electronics, Aerospace & Defense, Chemical, Pharmaceuticals, Automotive & Transportation, Other), By Type (Programmable Automation Controller (PAC), Supervisory control and data acquisition (SCADA), Programmable Logic Controller (PLC), Human Machine Interface (HMI)), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Touch Based Human Machine Interface (HMI) Market Statistics 2025 Analysis By Application (Industrial, Commercial), By Type (Resistive, Capacitive, Surface Acoustic Wave), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Industrial Automation Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Distributed Control System (DCS), Programmable Logic Control System (PLC), Machine Vision System, Manufacturing Execution System (MES), Human Machine Interface (HMI), Supervisory Control and Data Acquisition (SCADA), Product Lifecycle Management (PLM), Plant Asset Management, Computer Numerical Control (CNC) routers, Electronic Control Units (ECU), Others), By Application (Automation and Transportation, Metals and Mining, Oil and Gas, Pulp and Paper, Hydro power, Energy and Power System, Chemical, Material and Food, Measurement and Instrumentation), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager