Hybrid Printing System Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429832 | Date : Nov, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Hybrid Printing System Market Size

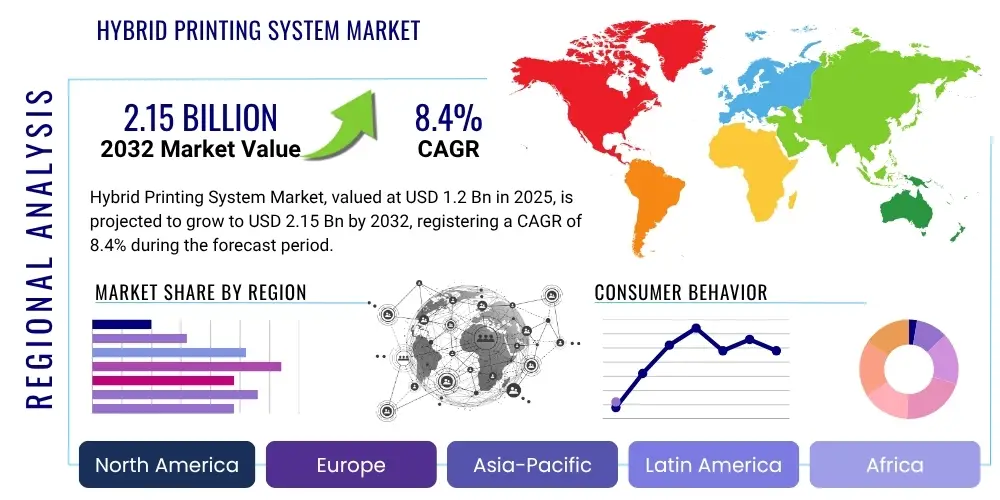

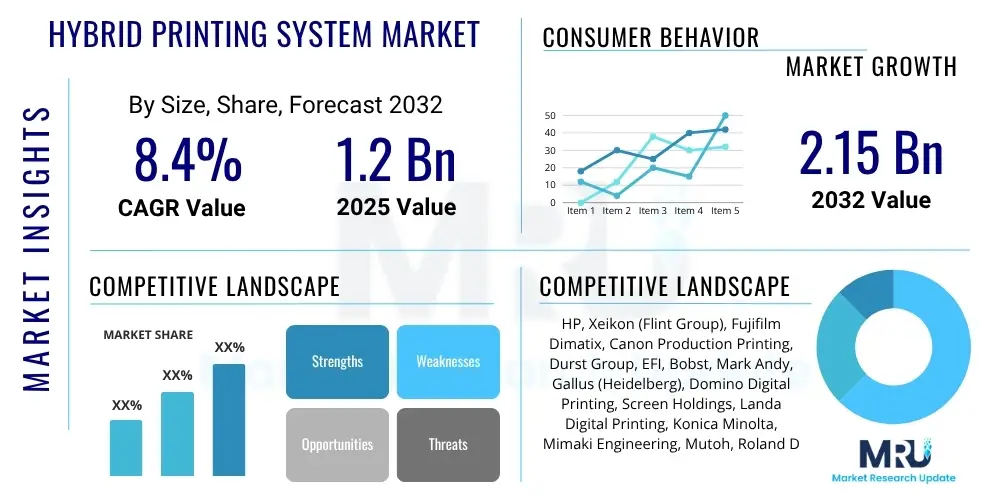

The Hybrid Printing System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.4% between 2025 and 2032. The market is estimated at $1.2 Billion in 2025 and is projected to reach $2.15 Billion by the end of the forecast period in 2032.

Hybrid Printing System Market introduction

The Hybrid Printing System market is at the forefront of print technology innovation, integrating the strengths of both conventional analog and advanced digital printing methods into a single, cohesive workflow. This sophisticated approach enables manufacturers and print service providers to achieve unparalleled versatility, combining the high-speed and cost-efficiency of analog processes for long runs with the personalization, flexibility, and rapid turnaround of digital techniques for shorter, variable data tasks. The ability to leverage the benefits of each technology within one streamlined system addresses the evolving demands of various industries for custom designs, quick market responsiveness, and reduced waste, driving significant interest and investment in this sector. The market is propelled by a growing demand for customized and short-run printing, particularly in the packaging, labels, and commercial printing segments, where brand differentiation and agility are paramount.

Hybrid printing systems typically involve the integration of technologies such as flexography, offset, or gravure with digital inkjet capabilities. This convergence allows for base color printing, special effects, and embellishments to be handled by the analog unit, while variable data, personalization, and intricate digital details are added by the integrated inkjet modules. The product range within this market includes a diverse array of presses, from compact label presses to large-format industrial systems, all designed to offer seamless transitions between printing methods. Major applications span across critical sectors including flexible packaging, corrugated board, folding cartons, textiles, commercial brochures, and direct mail, where the blend of quality, speed, and customization is highly valued. The inherent benefits of these systems, such as enhanced productivity, expanded creative possibilities, and improved supply chain efficiency, make them an attractive solution for businesses looking to optimize their printing operations and meet complex customer specifications.

Driving factors for the Hybrid Printing System market include the accelerating trend towards mass customization and personalization in consumer goods, which necessitates flexible and agile printing solutions. Furthermore, the increasing pressure on brands to achieve faster time-to-market for new products and promotional campaigns is pushing print providers to adopt technologies that can deliver both speed and quality. Economic factors such as the reduction of inventory costs through print-on-demand capabilities, coupled with growing environmental concerns fostering the adoption of more efficient and less wasteful printing processes, further fuel market expansion. The continuous advancements in digital inkjet technology, including improved printhead resolution, wider color gamuts, and faster drying inks, are also critical enablers for the widespread adoption and enhanced performance of hybrid printing solutions across a multitude of industrial and commercial applications.

Hybrid Printing System Market Executive Summary

The Hybrid Printing System market is undergoing a transformative period, characterized by several key business trends including a strong emphasis on automation and software integration to optimize workflows and reduce manual intervention. Industry consolidation, through mergers and acquisitions, is evident as major players seek to expand their technological portfolios and market reach, fostering innovation and competitive dynamics. There is a discernible shift towards more sustainable printing solutions, with manufacturers developing systems that consume less energy, utilize eco-friendly inks, and minimize material waste, aligning with global environmental regulations and consumer preferences. Furthermore, the increasing adoption of cloud-based platforms for data management and remote monitoring is enhancing operational efficiency and providing valuable insights into production processes, supporting a more data-driven approach to printing operations. This evolution is enabling print businesses to offer higher value-added services and maintain profitability in an increasingly competitive landscape.

Regionally, the Hybrid Printing System market exhibits diverse growth patterns and levels of maturity. Asia Pacific continues to emerge as a dominant force, fueled by rapid industrialization, burgeoning e-commerce sectors, and substantial investments in manufacturing infrastructure, particularly in countries like China and India. This region benefits from a large consumer base demanding a wide array of customized products, driving the need for advanced printing solutions. North America remains a significant market, characterized by early adoption of innovative technologies, strong research and development capabilities, and a high demand for personalized packaging and commercial print. Europe, with its mature industrial base and stringent environmental regulations, shows sustained growth driven by the need for efficient, high-quality, and sustainable printing practices, with a particular focus on industrial and label applications. Latin America and the Middle East & Africa regions are experiencing steady growth, propelled by expanding consumer markets and increasing industrialization, albeit at a slower pace compared to the leading regions.

Segmentation trends within the Hybrid Printing System market highlight the pronounced growth in the packaging sector, encompassing labels, flexible packaging, and corrugated board, due to the escalating demand for unique branding and intricate designs that hybrid systems can deliver efficiently. The commercial printing segment, although facing some digital disruption, leverages hybrid solutions for personalized marketing collateral, books, and promotional materials, benefiting from their versatility and economic efficiency for varied run lengths. Industrial printing applications, including textiles, decorative surfaces, and electronics, are also witnessing significant expansion, driven by the ability of hybrid systems to print on diverse substrates with high precision and durability. In terms of technology, the integration of advanced inkjet solutions with traditional presses is a key driver, alongside the increasing demand for sophisticated workflow software and automation components that streamline the entire printing process, from pre-press to finishing, thereby enhancing overall productivity and cost-effectiveness for print service providers.

AI Impact Analysis on Hybrid Printing System Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize the efficiency, quality, and cost-effectiveness of hybrid printing systems. Key themes revolve around AI's ability to automate complex decision-making processes, enhance predictive maintenance, optimize color consistency across diverse print runs and substrates, and enable hyper-personalization at scale. There is considerable interest in AI's role in improving operational insights, reducing waste, and streamlining the entire workflow from design to finish, essentially pushing the boundaries of what is possible in combining analog and digital printing. Concerns often surface regarding the initial investment required for AI integration, the complexity of data management, and the potential impact on human labor, alongside expectations for significantly higher throughput, superior print quality, and a more responsive production environment.

- Predictive maintenance: AI algorithms analyze machine performance data to forecast potential failures, enabling proactive maintenance and minimizing downtime.

- Automated quality control: AI-powered vision systems detect print defects in real time, ensuring consistent output quality and reducing material waste.

- Workflow optimization: AI can intelligently schedule jobs, optimize print paths, and manage material flow, enhancing overall production efficiency and throughput.

- Color management and consistency: AI systems learn and adapt to various substrates and ink properties, maintaining accurate color reproduction across analog and digital modules.

- Personalization and variable data printing: AI facilitates the seamless integration and processing of variable data, enabling mass customization and personalized print products efficiently.

- Supply chain optimization: AI can forecast demand, manage inventory for inks and substrates, and optimize logistics, contributing to cost savings and faster delivery.

- Energy efficiency: AI algorithms monitor and adjust system parameters to reduce energy consumption during operation, supporting sustainable printing practices.

DRO & Impact Forces Of Hybrid Printing System Market

The Hybrid Printing System market is significantly shaped by a dynamic interplay of drivers, restraints, and opportunities, all influenced by various impact forces. A primary driver is the escalating demand for customized and personalized print products across diverse industries, from packaging to commercial printing, compelling businesses to adopt flexible and efficient printing technologies. The inherent ability of hybrid systems to combine the speed and cost-effectiveness of analog methods with the versatility and variable data capabilities of digital printing makes them ideal for meeting these evolving market needs. Additionally, the continuous advancements in digital inkjet technology, offering higher resolutions, faster speeds, and broader material compatibility, further bolster the appeal and capabilities of hybrid presses. Furthermore, the increasing focus on reducing waste and improving sustainability within the printing industry encourages the adoption of these systems, which can optimize material usage and minimize makeready times. Operational efficiency gains and faster time-to-market for products are also powerful incentives for investment in hybrid printing solutions.

Despite the strong growth drivers, the market faces notable restraints. The substantial initial capital investment required for hybrid printing systems can be a significant barrier for many small to medium-sized print service providers, limiting their adoption. The technical complexity of integrating disparate analog and digital technologies, along with the need for specialized software and highly skilled operators, presents another challenge. Finding and retaining talent proficient in operating and maintaining these advanced systems remains a concern, contributing to higher operational costs. Moreover, the lack of standardized workflows and the complexities associated with color management across different print technologies can impede seamless production and sometimes lead to inconsistencies. Furthermore, the ongoing rapid evolution of technology demands continuous investment in upgrades, which adds to the long-term cost of ownership, potentially deterring some potential adopters from investing in these sophisticated solutions.

Opportunities for growth in the Hybrid Printing System market are abundant and varied. The expansion into new industrial printing applications, such as direct-to-object printing, functional printing for electronics, and advanced textile decoration, presents significant untapped potential. Emerging markets, particularly in Asia Pacific and Latin America, offer vast opportunities as industrialization and consumer demand for high-quality, customized products grow rapidly. The development of smart packaging, incorporating features like augmented reality codes and track-and-trace functionalities, is another promising area where hybrid systems excel due to their ability to print variable data alongside high-quality graphics. Innovations in sustainable inks and substrates, coupled with the increasing adoption of cloud-based platforms for workflow management and data analytics, are creating new avenues for efficiency and value creation. These opportunities, coupled with the inherent advantages of hybrid systems, are poised to drive sustained market expansion and technological advancement in the coming years, particularly as market forces continue to push for greater efficiency, flexibility, and customization.

Segmentation Analysis

The Hybrid Printing System market is meticulously segmented to provide a comprehensive understanding of its diverse components and application areas. This segmentation allows for targeted analysis of market dynamics, growth drivers, and competitive landscapes across different technological approaches, end-use industries, and product components. By categorizing the market based on various parameters, stakeholders can identify specific niches, assess market maturity, and forecast future trends more accurately. This detailed breakdown highlights the varying demands and adoption rates of hybrid printing technologies across different sectors, reflecting the adaptability and versatility of these advanced systems in meeting specialized production requirements.

The market is primarily segmented by printing process, which differentiates between the specific analog and digital combinations employed, such as flexo-digital, offset-digital, or screen-digital systems. Each combination offers distinct advantages tailored to specific production needs and substrate types. Another critical segmentation is by application, delineating the primary industries where hybrid systems are deployed, including packaging (labels, flexible, corrugated), commercial printing, and industrial printing (textiles, decorative, functional). Furthermore, the market is categorized by end-use industry, providing insights into specific verticals like food and beverage, pharmaceuticals, cosmetics, and electronics, which all have unique regulatory and aesthetic requirements. Finally, a component-based segmentation, separating hardware, software, and services, allows for an analysis of technological advancements and value-added offerings within the ecosystem, revealing the integral role of integrated solutions in driving market growth.

- By Printing Process

- Flexo-Digital Hybrid

- Offset-Digital Hybrid

- Gravure-Digital Hybrid

- Screen-Digital Hybrid

- Other Combinations

- By Application

- Packaging Printing

- Labels

- Flexible Packaging

- Folding Cartons

- Corrugated Packaging

- Commercial Printing

- Books and Magazines

- Direct Mail

- Brochures and Flyers

- Industrial Printing

- Textile Printing

- Decorative Printing (e.g., laminates)

- Functional Printing (e.g., electronics, automotive)

- Ceramic Printing

- By End-Use Industry

- Food and Beverage

- Pharmaceuticals

- Cosmetics and Personal Care

- Electronics

- Automotive

- Textiles and Apparel

- Advertising and Marketing

- Others

- By Component

- Hardware (Presses, Digital Print Engines, Finishing Units)

- Software (Workflow Management, RIP, Color Management)

- Services (Installation, Maintenance, Training, Consulting)

Value Chain Analysis For Hybrid Printing System Market

The value chain for the Hybrid Printing System market is complex, encompassing various stages from raw material sourcing to end-user delivery, highlighting the intricate network of suppliers, manufacturers, integrators, and service providers. At the upstream end, the chain begins with the manufacturers of core components and raw materials crucial for both analog and digital printing technologies. This includes suppliers of specialized printheads for inkjet systems, ink and coating manufacturers (aqueous, UV, solvent, LED-curable inks), substrate producers (papers, films, foils, textiles), and manufacturers of advanced automation and robotics systems that integrate into the presses. These upstream players are fundamental in providing the foundational technologies and materials that dictate the performance, quality, and versatility of the final hybrid printing solutions, requiring extensive research and development to innovate and meet evolving market demands for speed, resolution, and sustainability.

Midstream, the value chain involves the design, manufacturing, and assembly of the hybrid printing presses themselves. This stage is dominated by major printing press manufacturers who integrate various analog and digital modules, alongside sophisticated control systems and software for seamless operation. These manufacturers often work closely with component suppliers to develop customized solutions that optimize performance and efficiency. Downstream, the value chain extends to the distribution channels and end-users. Distribution typically occurs through a combination of direct sales, where manufacturers sell directly to large print service providers or brand owners, and indirect channels, involving a network of distributors, agents, and system integrators. These intermediaries play a crucial role in reaching a broader customer base, offering localized support, sales expertise, and often providing installation and initial training services, particularly in regions where manufacturers may not have a direct presence. System integrators are especially vital for custom configurations and ensuring compatibility with existing production environments.

The primary end-users or buyers of hybrid printing systems are diverse and span across multiple industries. They include large commercial printing houses seeking greater flexibility for varied print jobs, packaging converters aiming to produce personalized labels and flexible packaging, and industrial manufacturers looking to print directly onto products or specialized materials. Brand owners, particularly in the consumer goods, pharmaceutical, and cosmetics sectors, are also increasingly investing in or influencing the adoption of hybrid systems to ensure brand consistency, facilitate quick market launches, and implement innovative packaging designs. The indirect channels often provide value-added services such as financing options, extended warranty programs, and ongoing technical support, forming a critical link in ensuring customer satisfaction and long-term relationships. This multifaceted value chain underscores the collaborative nature of the hybrid printing market, where innovation and efficiency at each stage contribute to the overall success and market penetration of these advanced printing solutions.

Hybrid Printing System Market Potential Customers

Potential customers for Hybrid Printing Systems represent a broad spectrum of industries, all seeking enhanced flexibility, efficiency, and customization capabilities in their printing operations. A primary group consists of large and medium-sized commercial printing houses, which regularly handle a diverse range of print jobs, from high-volume marketing materials to short-run personalized publications. These customers benefit immensely from hybrid systems' ability to efficiently manage varied print runs, reduce setup times, and offer a wider array of embellished products, thereby expanding their service offerings and competitive edge in a demanding market. The versatility of hybrid presses allows them to cater to the evolving needs of clients who require both the economies of scale from analog processes and the agility of digital printing for variable data and short-batch production, leading to increased profitability and client satisfaction.

Another significant segment of potential customers includes packaging manufacturers and converters specializing in labels, flexible packaging, folding cartons, and corrugated boxes. With the global surge in e-commerce and the increasing consumer demand for personalized and aesthetically appealing product packaging, these entities are constantly seeking ways to differentiate brands and respond quickly to market trends. Hybrid systems enable them to achieve high-quality graphics and special effects with analog components, while simultaneously integrating variable data for serialization, traceability, or custom branding through digital inkjet. This capability is particularly crucial for industries like food and beverage, pharmaceuticals, and cosmetics, where product differentiation, regulatory compliance, and rapid design iterations are paramount. The efficiency and flexibility offered by hybrid solutions directly translate into quicker product launches and reduced waste in their highly competitive sectors.

Beyond traditional printing and packaging, a growing number of industrial manufacturers are becoming key potential customers for hybrid printing systems. This includes companies in textiles, automotive, electronics, and decorative laminate industries. For textile manufacturers, hybrid systems offer the ability to combine traditional screen printing for bulk color application with digital printing for intricate patterns and custom designs on fabrics, reducing lead times and enabling on-demand production. In the electronics sector, hybrid systems are used for functional printing, combining conventional methods for conductive inks with digital for circuit board patterning or flexible electronics. The broad application versatility and the ability to print on diverse substrates with precision make hybrid systems invaluable for these industrial applications, driving innovation and expanding manufacturing capabilities across various advanced manufacturing sectors seeking to integrate print functionality or enhance product aesthetics in novel ways.

Report Attributes Report Details Market Size in 2025 $1.2 Billion Market Forecast in 2032 $2.15 Billion Growth Rate 8.4% CAGR Historical Year 2019 to 2023 Base Year 2024 Forecast Year 2025 - 2032 DRO & Impact Forces - Drivers: Growing demand for customization, increased operational efficiency, faster time to market, advancements in digital print technology.

- Restraints: High initial investment costs, technical complexity, scarcity of skilled labor, standardization challenges.

- Opportunities: Expansion into new industrial applications, smart packaging, emerging markets, sustainable printing solutions.

- Impact Forces: Technological shifts, economic conditions, regulatory environment, consumer trends, competitive intensity.

Segments Covered - By Printing Process (Flexo-Digital Hybrid, Offset-Digital Hybrid, Gravure-Digital Hybrid, Screen-Digital Hybrid, Other Combinations)

- By Application (Packaging Printing: Labels, Flexible Packaging, Folding Cartons, Corrugated Packaging; Commercial Printing: Books and Magazines, Direct Mail, Brochures and Flyers; Industrial Printing: Textile Printing, Decorative Printing, Functional Printing, Ceramic Printing)

- By End-Use Industry (Food and Beverage, Pharmaceuticals, Cosmetics and Personal Care, Electronics, Automotive, Textiles and Apparel, Advertising and Marketing, Others)

- By Component (Hardware, Software, Services)

Key Companies Covered HP, Xeikon (Flint Group), Fujifilm Dimatix, Canon Production Printing, Durst Group, EFI, Bobst, Mark Andy, Gallus (Heidelberg), Domino Digital Printing, Screen Holdings, Landa Digital Printing, Konica Minolta, Mimaki Engineering, Mutoh, Roland DG, Koenig & Bauer, Agfa, SPGPrints, Sisma Regions Covered North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) Enquiry Before Buy Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy Hybrid Printing System Market Key Technology Landscape

The Hybrid Printing System market is characterized by a rapidly evolving technology landscape, where continuous innovation drives performance enhancements, efficiency gains, and broader application possibilities. At its core, the advancement of digital inkjet technology is paramount. This includes the development of high-resolution printheads capable of faster firing frequencies and wider print swaths, leading to increased production speeds and superior image quality. Furthermore, the diversification of ink chemistries—such as UV-curable, aqueous, solvent-based, and LED-curable inks—enables hybrid systems to print on an expansive array of substrates, from traditional paper and film to challenging materials like metal, glass, and various textiles. These ink innovations also contribute to improved durability, color gamut, and environmental compliance, addressing specific industry needs and regulatory requirements across diverse end-use sectors.

Beyond the fundamental printing components, workflow automation software plays a critical role in seamlessly integrating analog and digital processes within a hybrid system. These sophisticated software solutions manage job queues, optimize print layouts, handle variable data printing (VDP), and ensure accurate color matching across different print technologies. The increasing adoption of Internet of Things (IoT) sensors and connectivity within hybrid presses allows for real-time monitoring of machine performance, predictive maintenance, and remote diagnostics, significantly reducing downtime and improving operational efficiency. Robotics and advanced automation systems are also being increasingly incorporated, especially for automated material handling, loading, and unloading, further streamlining the production process and minimizing manual intervention, thereby enhancing throughput and reducing labor costs. This integration transforms individual machines into intelligent, interconnected production hubs.

Another crucial aspect of the technology landscape involves advanced data analytics and cloud computing platforms. These technologies collect and analyze vast amounts of production data, offering insights into operational bottlenecks, material consumption, and print quality, enabling continuous process optimization. Cloud-based solutions facilitate remote access, data sharing, and software updates, creating a more agile and responsive printing environment. Furthermore, sophisticated color management systems are essential for achieving consistent brand colors and visual fidelity when combining different printing methods, ensuring that digital embellishments perfectly align with conventionally printed elements. The convergence of these advanced technologies not only enhances the capabilities of hybrid printing systems but also positions them as intelligent manufacturing solutions capable of meeting the complex demands of modern production environments, fostering greater efficiency, flexibility, and sustainability throughout the entire print value chain and enabling new levels of innovation in various application areas.

Regional Highlights

- North America: This region is characterized by early adoption of advanced printing technologies and a strong emphasis on innovation. The market here is driven by the robust demand for personalized packaging, premium labels, and short-run commercial print jobs. High R&D investments, particularly in the United States, contribute to the continuous development and integration of cutting-edge hybrid printing solutions. Established infrastructure and a mature industrial base ensure a steady growth trajectory, with a focus on high-value applications and automation to address labor costs.

- Europe: Europe represents a mature yet highly dynamic market for hybrid printing systems, propelled by stringent environmental regulations and a strong commitment to sustainable manufacturing practices. Countries like Germany, Italy, and the UK are leaders in industrial printing, packaging, and label production, driving demand for efficient, high-quality, and environmentally friendly hybrid solutions. The region benefits from significant investments in smart factories and Industry 4.0 initiatives, fostering the integration of advanced automation and digital workflows within hybrid printing operations.

- Asia Pacific (APAC): The APAC region is the fastest-growing market, primarily due to rapid industrialization, burgeoning e-commerce sectors, and increasing disposable incomes, which fuel consumer demand for diverse and customized products. Countries such as China, India, Japan, and South Korea are key growth engines, benefiting from massive production capacities and a competitive manufacturing landscape. The expansion of the packaging industry, driven by food and beverage, pharmaceuticals, and consumer electronics, is a major contributor to the widespread adoption of hybrid printing systems across the region.

- Latin America: This region is experiencing steady growth in the hybrid printing system market, mainly influenced by the expanding consumer goods sector and increasing foreign investments in manufacturing. Countries like Brazil and Mexico are leading the adoption, driven by the rising demand for sophisticated packaging and labels, particularly in the food and beverage and personal care industries. Economic development and a growing middle class contribute to the overall market expansion, with a focus on improving production efficiency and reducing import dependencies through localized manufacturing.

- Middle East and Africa (MEA): The MEA market for hybrid printing systems is in an nascent stage but shows promising growth potential. Infrastructure development projects, diversification of economies away from oil, and increasing consumer spending are contributing factors. Countries in the GCC region are investing in advanced manufacturing capabilities, including printing technologies, to support various industries. While adoption is slower compared to other regions, the increasing need for localized production and high-quality packaging presents significant opportunities for future market expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hybrid Printing System Market.- HP Inc.

- Xeikon (Flint Group)

- Fujifilm Dimatix Inc.

- Canon Production Printing (formerly Océ)

- Durst Group AG

- EFI (Electronics For Imaging)

- Bobst Group SA

- Mark Andy Inc.

- Gallus Ferd. Rüesch AG (Heidelberg Group)

- Domino Digital Printing Solutions

- Screen Holdings Co., Ltd.

- Landa Digital Printing

- Konica Minolta Inc.

- Mimaki Engineering Co., Ltd.

- Mutoh Industries Ltd.

- Roland DG Corporation

- Koenig & Bauer AG

- Agfa-Gevaert N.V.

- SPGPrints B.V.

- Sisma S.p.A.

Frequently Asked Questions

What is a hybrid printing system?

A hybrid printing system integrates two or more printing technologies, typically combining a conventional analog process like flexography or offset with a digital inkjet module, into a single press. This combination allows for the benefits of both worlds, such as high-speed analog production and digital flexibility for variable data and personalization.

What are the main benefits of hybrid printing?

Hybrid printing offers numerous benefits including enhanced versatility for varied print runs, improved cost-efficiency for short-to-medium runs, accelerated time-to-market, superior print quality with diverse embellishments, and capabilities for mass customization and personalization. It also aids in reducing waste and optimizing production workflows.

Which industries primarily use hybrid printing?

Hybrid printing systems are primarily utilized in the packaging industry (labels, flexible packaging, corrugated boxes), commercial printing (marketing materials, books, direct mail), and various industrial applications such as textile printing, decorative printing, and functional printing for electronics.

What role does AI play in hybrid printing?

AI significantly enhances hybrid printing by enabling predictive maintenance, automating quality control, optimizing complex workflows, ensuring consistent color management, and facilitating highly personalized print jobs. It contributes to greater efficiency, reduced downtime, and improved overall output quality.

What are the future trends in the hybrid printing market?

Future trends in the hybrid printing market include increased adoption of advanced automation and robotics, deeper integration of AI and machine learning for predictive analytics, a growing focus on sustainable printing solutions, expansion into new industrial applications like smart packaging, and continued innovation in ink and substrate technologies to broaden application possibilities.

- Packaging Printing

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager