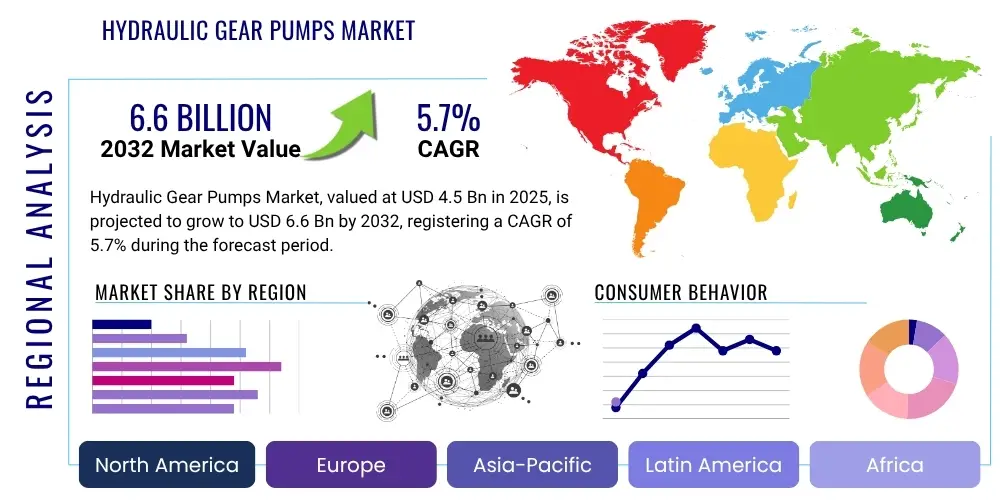

Hydraulic Gear Pumps Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431207 | Date : Nov, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Hydraulic Gear Pumps Market Size

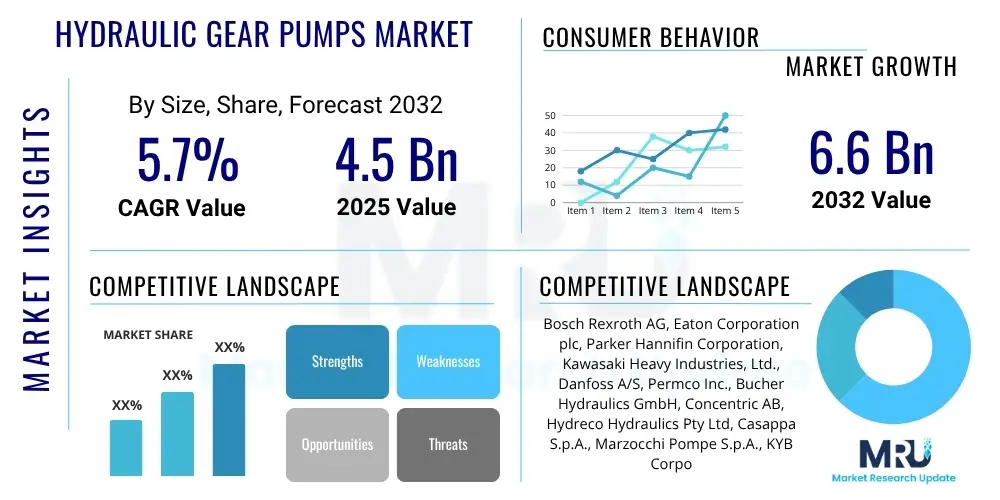

The Hydraulic Gear Pumps Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.7% between 2025 and 2032. The market is estimated at USD 4.5 Billion in 2025 and is projected to reach USD 6.6 Billion by the end of the forecast period in 2032.

Hydraulic Gear Pumps Market introduction

Hydraulic gear pumps are fundamental components within hydraulic systems, responsible for converting mechanical energy into hydraulic energy by displacing fluid. These robust and compact positive displacement pumps are widely utilized across various industries due to their simplicity, reliability, and cost-effectiveness. Their design typically involves meshing gears that create a vacuum at the inlet, drawing fluid into the pump, and then forcing it out through the outlet as the gears rotate, generating continuous flow. This mechanical action is crucial for powering a multitude of applications where controlled force and motion are required.

The product, a hydraulic gear pump, effectively handles a wide range of fluid viscosities and operates under varying pressure conditions, making it highly versatile. Major applications span industrial machinery such as presses, machine tools, and manufacturing automation, as well as mobile equipment like excavators, loaders, and agricultural tractors. Furthermore, they are integral to material handling systems, power steering units, and diverse construction equipment, providing the necessary hydraulic power for critical operations. The enduring demand for these pumps stems from their inherent benefits, including high power density, predictable performance, and relatively low maintenance requirements compared to more complex pump types.

Key driving factors for the hydraulic gear pumps market include the accelerating pace of global industrialization and infrastructure development, particularly in emerging economies. The increasing demand for automation in manufacturing processes and the mechanization of agriculture further stimulate market growth. Additionally, ongoing advancements in hydraulic system efficiency and the development of new, more robust materials contribute significantly to the expansion of this essential market segment.

Hydraulic Gear Pumps Market Executive Summary

The Hydraulic Gear Pumps Market is characterized by dynamic business trends driven by technological advancements, evolving application demands, and a heightened focus on efficiency and sustainability. Key business trends include the miniaturization of pump designs for compact equipment, the integration of smart technologies for enhanced control and monitoring, and a growing emphasis on energy-efficient solutions to meet stringent environmental regulations. Manufacturers are increasingly investing in research and development to produce pumps capable of operating at higher pressures and with improved volumetric efficiency, catering to the sophisticated needs of modern machinery. Furthermore, the aftermarket segment continues to present significant opportunities, driven by the need for maintenance, repair, and replacement of existing hydraulic systems globally.

Regionally, the market exhibits varied growth trajectories. Asia Pacific stands as the dominant and fastest-growing region, propelled by rapid industrial expansion, extensive infrastructure projects, and robust manufacturing activities in countries like China and India. North America and Europe represent mature markets, characterized by stable demand from established industries and a strong focus on advanced, high-performance, and environmentally compliant hydraulic solutions. Latin America, the Middle East, and Africa are emerging as promising markets, driven by investments in mining, construction, and agricultural sectors, indicating future growth potential as economic development progresses and mechanization increases.

Segmentation trends highlight the continued dominance of external gear pumps due to their simplicity and cost-effectiveness, although internal gear pumps are gaining traction in applications requiring quieter operation and higher efficiency. Fixed displacement pumps maintain a larger market share, yet variable displacement pumps are seeing increased adoption in specialized applications demanding precise flow control and energy savings. The construction, agriculture, and material handling sectors remain the largest end-use segments, consistently driving demand for reliable hydraulic power. The market is also experiencing a shift towards modular and integrated hydraulic systems, influencing pump design and manufacturing processes to offer more comprehensive solutions to end-users.

AI Impact Analysis on Hydraulic Gear Pumps Market

Common user questions regarding AI's impact on the Hydraulic Gear Pumps Market frequently revolve around how artificial intelligence can enhance operational efficiency, extend equipment lifespan, and contribute to predictive maintenance strategies. Users are keen to understand the potential for AI to optimize pump performance by analyzing real-time operating data, anticipate failures before they occur, and facilitate more precise control over hydraulic systems. There is also significant interest in the concept of "smart pumps" that integrate AI for autonomous adjustments and diagnostics, ultimately leading to reduced downtime and lower operational costs. The overarching themes reflect a strong expectation for AI to transform hydraulic systems from reactive maintenance models to proactive, intelligent operations, ensuring higher reliability and sustained productivity.

AI's influence is expected to lead to a significant paradigm shift in the design, operation, and maintenance of hydraulic gear pumps. By integrating AI algorithms with sensor data from pumps and hydraulic systems, manufacturers can develop predictive maintenance platforms that monitor various parameters such as pressure, temperature, flow rate, and vibration. This allows for the early detection of anomalies, enabling timely intervention and preventing catastrophic failures, thereby drastically reducing unplanned downtime and maintenance expenses. Furthermore, AI can optimize pump performance by dynamically adjusting operational parameters based on real-time load and environmental conditions, leading to improved energy efficiency and prolonged component life. This level of optimization is crucial for industries striving for higher productivity and lower environmental footprints.

Beyond operational enhancements, AI is poised to impact the design and manufacturing phases of hydraulic gear pumps. Generative design powered by AI can explore thousands of design iterations to create pumps that are lighter, more durable, and more efficient than conventionally designed counterparts. This can lead to breakthroughs in material usage and internal geometries, pushing the boundaries of what is possible in pump engineering. Additionally, AI-driven automation in manufacturing processes can improve production quality, reduce waste, and accelerate time-to-market for new pump models. The cumulative effect of these AI applications will be a more resilient, intelligent, and optimized hydraulic gear pump ecosystem, providing substantial competitive advantages to adopters.

- Predictive maintenance enablement through real-time data analysis and anomaly detection.

- Optimized pump performance via dynamic adjustment of operating parameters for energy efficiency.

- Development of smart hydraulic systems with autonomous control and diagnostic capabilities.

- AI-driven generative design for lighter, more durable, and highly efficient pump components.

- Enhanced quality control and waste reduction in manufacturing processes through AI automation.

- Reduced operational costs and unplanned downtime due to proactive system management.

DRO & Impact Forces Of Hydraulic Gear Pumps Market

The Hydraulic Gear Pumps Market is significantly influenced by a complex interplay of Drivers, Restraints, and Opportunities, which collectively shape its growth trajectory and competitive landscape. Key drivers include the robust growth in the construction and mining sectors globally, necessitating reliable and powerful hydraulic machinery. The increasing mechanization in agriculture, especially in developing economies, further fuels the demand for gear pumps in tractors and harvesting equipment. Additionally, the expansion of manufacturing industries and material handling applications, coupled with a rising emphasis on automation and operational efficiency across various industrial segments, consistently propels market expansion. The inherent simplicity, durability, and cost-effectiveness of gear pumps compared to other hydraulic pump types also serve as fundamental demand accelerators.

However, the market faces several restraints that could impede its growth. Fluctuations in raw material prices, particularly steel and other metals, can directly impact manufacturing costs and product pricing, leading to potential margin erosion for manufacturers. Economic slowdowns or geopolitical instabilities in key industrial regions can dampen investment in new machinery and infrastructure, thereby reducing demand for hydraulic components. The emergence of alternative hydraulic technologies, such as piston pumps for very high-pressure applications, or vane pumps for quieter operation, presents competitive challenges. Furthermore, increasingly stringent environmental regulations regarding noise emissions, energy consumption, and fluid leakage compel manufacturers to invest heavily in R&D for compliant and sustainable solutions, potentially increasing costs and complexity.

Despite these challenges, significant opportunities exist for market players. The ongoing trend towards industrial automation and the integration of IoT and smart technologies into hydraulic systems offer avenues for developing advanced, intelligent gear pumps with enhanced monitoring and control capabilities. Expansion into untapped or rapidly industrializing emerging markets, particularly in Southeast Asia, Africa, and parts of Latin America, presents substantial growth prospects. Moreover, the development of eco-friendly hydraulic fluids and the design of pumps optimized for these new fluids open doors for innovation and market differentiation. The impact forces within the market, including the bargaining power of buyers who demand customized and efficient solutions, and the bargaining power of suppliers who provide critical components and raw materials, continually shape pricing and supply chain dynamics. The threat of substitutes and new entrants encourages continuous innovation and competitive pricing, while the intensity of rivalry among established players drives advancements in technology and service offerings.

Segmentation Analysis

The Hydraulic Gear Pumps Market is comprehensively segmented across various parameters to provide a detailed understanding of its dynamics and opportunities. These segments are primarily based on the type of pump, operating pressure, displacement mechanism, and the diverse applications and end-use industries they serve. This granular segmentation allows for targeted market analysis, identifying high-growth areas and specific customer needs within the broader hydraulic sector. Understanding these segments is crucial for manufacturers to tailor their product offerings, develop effective market strategies, and allocate resources efficiently to capitalize on emerging trends and demands across different vertical markets.

- By Type

- External Gear Pumps

- Internal Gear Pumps

- By Operating Pressure

- Low Pressure (Up to 500 psi)

- Medium Pressure (501 psi to 2000 psi)

- High Pressure (Above 2000 psi)

- By Displacement

- Fixed Displacement Pumps

- Variable Displacement Pumps

- By Application

- Industrial Applications (Machine Tools, Presses, Injection Molding, Power Units)

- Mobile Applications (Construction Equipment, Agricultural Machinery, Material Handling, Forestry Equipment, Mining Equipment)

- By End-Use Industry

- Construction

- Agriculture

- Manufacturing

- Material Handling

- Mining

- Automotive

- Marine

- Oil and Gas

- By Sales Channel

- OEM (Original Equipment Manufacturer)

- Aftermarket

Value Chain Analysis For Hydraulic Gear Pumps Market

The value chain for the Hydraulic Gear Pumps Market begins with upstream activities involving the sourcing and processing of raw materials and the manufacturing of essential components. This phase includes suppliers of high-grade metals such as cast iron, aluminum, and various alloys crucial for pump casings and gears, as well as manufacturers providing precision bearings, seals, shafts, and other internal components. Quality and cost-effectiveness at this stage are paramount, as they directly influence the final product's performance and price point. Strong supplier relationships and effective procurement strategies are vital for ensuring a consistent supply of materials that meet stringent quality standards and regulatory requirements.

Moving further along the value chain, the manufacturing and assembly phase involves the design, machining, assembly, and rigorous testing of the hydraulic gear pumps. This stage often incorporates advanced manufacturing techniques, including CNC machining and automated assembly lines, to achieve high precision and consistency. Following production, the distribution channel plays a critical role in bringing the pumps to market. This includes both direct and indirect sales approaches. Direct sales involve manufacturers selling directly to Original Equipment Manufacturers (OEMs) who integrate the pumps into their machinery (e.g., construction vehicles, agricultural equipment) or to large industrial end-users with specific project requirements. This channel allows for close collaboration and customization.

Indirect sales channels primarily involve a network of distributors, wholesalers, and value-added resellers. These intermediaries provide market reach, local presence, technical support, and often stock inventory, making pumps readily available to a broader range of smaller OEMs, MRO (Maintenance, Repair, and Operations) clients, and individual buyers. Downstream activities involve the integration of these pumps into larger hydraulic systems by OEMs and system integrators, as well as after-sales services such as maintenance, repair, and provision of spare parts, which are critical for customer satisfaction and long-term market presence. The efficiency and optimization of each link in this value chain directly impact product quality, market accessibility, and overall profitability for all stakeholders.

Hydraulic Gear Pumps Market Potential Customers

Potential customers for the Hydraulic Gear Pumps Market primarily consist of Original Equipment Manufacturers (OEMs) across various heavy industries, who integrate these pumps as core components into their machinery and equipment. This includes leading manufacturers of construction machinery such as excavators, bulldozers, and loaders, where reliable hydraulic power is indispensable for operational efficiency and safety. Agricultural equipment manufacturers, producing tractors, harvesters, and irrigation systems, represent another significant segment of OEM buyers, driven by the ongoing global need for food production and farm mechanization. The industrial sector, encompassing manufacturers of machine tools, presses, material handling equipment, and general industrial machinery, also forms a substantial customer base, seeking robust and cost-effective hydraulic solutions for diverse applications.

Beyond the initial equipment manufacturing, the aftermarket segment constitutes another vital group of potential customers. This includes MRO (Maintenance, Repair, and Operations) departments within large industrial facilities, independent repair shops, and end-users who require replacement pumps or spare parts for existing machinery. These buyers prioritize product availability, durability, and compatibility to minimize downtime and extend the operational life of their equipment. System integrators, who design and build customized hydraulic systems for specific industrial or mobile applications, also represent key purchasers, often requiring specialized or high-performance gear pumps to meet unique project specifications.

Furthermore, government and public sector entities investing in infrastructure development, such as road construction, dam projects, and utility maintenance, often procure equipment that relies heavily on hydraulic gear pumps. The marine industry, with its demand for pumps in steering systems, winches, and auxiliary machinery, and the mining sector, requiring robust pumps for heavy-duty earthmoving and material extraction, also contribute significantly to the customer landscape. The diversity of these end-user segments underscores the broad applicability and sustained demand for hydraulic gear pumps in both new equipment installations and ongoing operational support.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.5 Billion |

| Market Forecast in 2032 | USD 6.6 Billion |

| Growth Rate | 5.7% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bosch Rexroth AG, Eaton Corporation plc, Parker Hannifin Corporation, Kawasaki Heavy Industries, Ltd., Danfoss A/S, Permco Inc., Bucher Hydraulics GmbH, Concentric AB, Hydreco Hydraulics Pty Ltd, Casappa S.p.A., Marzocchi Pompe S.p.A., KYB Corporation, Nachi-Fujikoshi Corp., Roquet Hydraulics, Linde Hydraulics GmbH & Co. KG, Voith GmbH & Co. KGaA, Walvoil S.p.A., Hema Endustri A.S., Atos S.p.A., Poclain Hydraulics S.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hydraulic Gear Pumps Market Key Technology Landscape

The Hydraulic Gear Pumps Market is continuously evolving with significant advancements in its core technology landscape, driven by the demand for improved efficiency, durability, and environmental compliance. One critical aspect is the development of advanced material science, utilizing high-strength alloys and specialized coatings for gears and casings. These materials enhance resistance to wear, corrosion, and cavitation, thereby extending the pump's operational life and improving performance in harsh operating conditions. Precision manufacturing techniques, including advanced machining and heat treatment processes, are also crucial for achieving the tight tolerances required for optimal volumetric and mechanical efficiency, minimizing internal leakage and maximizing power output.

Furthermore, technological innovations focus on noise reduction and vibration dampening, crucial for applications in enclosed environments and to meet stricter regulatory standards. This involves optimizing gear tooth profiles, integrating specialized dampening materials, and refining housing designs. Another significant trend is the integration of smart technologies and sensorization. Hydraulic gear pumps are increasingly being equipped with embedded sensors that monitor critical parameters such as pressure, temperature, flow rate, and rotational speed. These sensors, coupled with IoT connectivity, enable real-time data acquisition and transmission, forming the basis for predictive maintenance, remote diagnostics, and condition monitoring systems.

The development of more energy-efficient pump designs is also a key technological imperative. This includes innovations in porting geometry to optimize fluid flow, advanced bearing designs to reduce friction, and the exploration of variable displacement mechanisms for gear pumps, though traditionally fixed. Modular and compact designs are gaining traction, allowing for easier integration into complex hydraulic systems and contributing to the overall miniaturization of equipment. Additionally, research into new hydraulic fluids, including synthetic and biodegradable options, is influencing pump material compatibility and design, pushing towards more sustainable and eco-friendly hydraulic solutions across various industries.

Regional Highlights

- North America: A mature market characterized by stable demand from established industries like construction, agriculture, and manufacturing. The region emphasizes technological innovation, high-performance solutions, and adherence to stringent environmental regulations. Significant investments in infrastructure and modernization of industrial machinery contribute to sustained demand, with a focus on smart and efficient hydraulic systems.

- Europe: Similar to North America, Europe is a well-established market driven by advanced manufacturing, automotive, and agricultural sectors. Strong regulatory frameworks concerning emissions and energy efficiency push for continuous innovation in pump design and materials. Germany, Italy, and the UK are key contributors, known for their precision engineering and high-quality hydraulic component manufacturing.

- Asia Pacific (APAC): The largest and fastest-growing market globally, propelled by rapid industrialization, urbanization, and infrastructure development, particularly in China, India, Japan, and South Korea. Extensive growth in construction, mining, and agricultural activities, coupled with burgeoning manufacturing sectors, drives substantial demand for hydraulic gear pumps. The region also benefits from lower manufacturing costs and increasing adoption of automation.

- Latin America: An emerging market experiencing growth due to increasing investments in mining, construction, and agricultural sectors. Brazil and Mexico are leading markets within the region, driven by resource extraction and expanding industrial bases. The demand is often for robust and cost-effective solutions capable of operating in challenging environments.

- Middle East and Africa (MEA): A developing market characterized by significant investments in oil and gas infrastructure, construction projects, and agricultural mechanization. Countries like Saudi Arabia, UAE, and South Africa are key players, with a growing demand for durable hydraulic equipment to support large-scale industrial and infrastructure initiatives. The region presents considerable long-term growth potential as economic diversification continues.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hydraulic Gear Pumps Market.- Bosch Rexroth AG

- Eaton Corporation plc

- Parker Hannifin Corporation

- Kawasaki Heavy Industries, Ltd.

- Danfoss A/S

- Permco Inc.

- Bucher Hydraulics GmbH

- Concentric AB

- Hydreco Hydraulics Pty Ltd

- Casappa S.p.A.

- Marzocchi Pompe S.p.A.

- KYB Corporation

- Nachi-Fujikoshi Corp.

- Roquet Hydraulics

- Linde Hydraulics GmbH & Co. KG

- Voith GmbH & Co. KGaA

- Walvoil S.p.A.

- Hema Endustri A.S.

- Atos S.p.A.

- Poclain Hydraulics S.A.

Frequently Asked Questions

What is a hydraulic gear pump and how does it function?

A hydraulic gear pump is a positive displacement pump that uses the meshing of gears to pump fluid. As the gears rotate, they create a vacuum at the inlet, drawing fluid in, and then trap and force the fluid through the pump's outlet, generating continuous flow and pressure.

What are the primary applications of hydraulic gear pumps?

Hydraulic gear pumps are widely used in industrial machinery like presses, machine tools, and material handling equipment, as well as in mobile applications such as construction equipment, agricultural tractors, and mining machinery, providing power for various operations.

What are the main types of hydraulic gear pumps?

The two main types are external gear pumps, which use two external gears meshing together, and internal gear pumps, which feature an internally meshing gear pair (a smaller gear inside a larger one), each offering distinct advantages for different applications.

What benefits do hydraulic gear pumps offer?

Hydraulic gear pumps are known for their simplicity, robust design, compact size, cost-effectiveness, and reliable performance across a range of pressures and fluid viscosities, making them suitable for numerous industrial and mobile hydraulic systems.

How is AI impacting the hydraulic gear pumps market?

AI is impacting the market through predictive maintenance, optimizing pump performance via real-time data analysis, enabling smart control systems, and enhancing pump design and manufacturing processes for greater efficiency and durability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager