Hydraulic Hoist Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427688 | Date : Oct, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Hydraulic Hoist Market Size

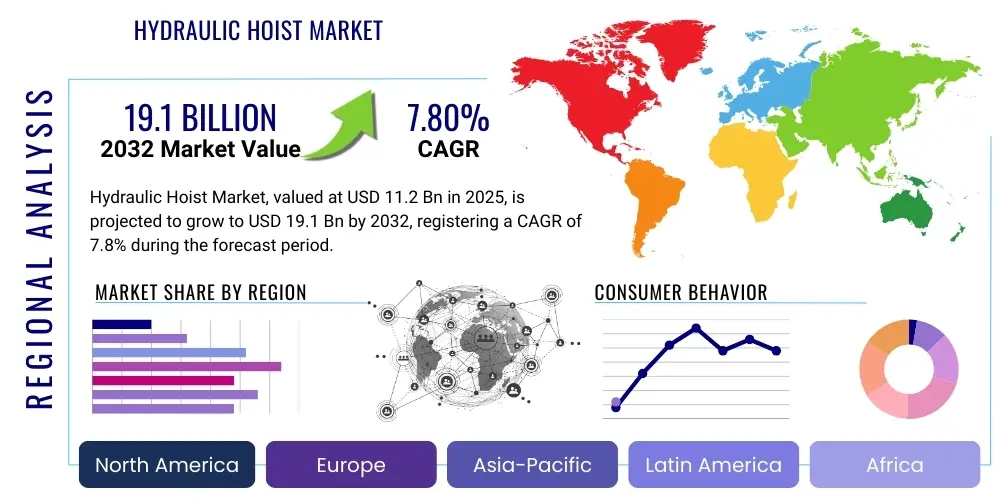

The Hydraulic Hoist Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at USD 11.2 Billion in 2025 and is projected to reach USD 19.1 Billion by the end of the forecast period in 2032. This robust expansion is primarily driven by escalating demand from critical end-use industries, including construction, manufacturing, and logistics, all of which increasingly rely on efficient and powerful lifting solutions for heavy material handling. Global infrastructure development projects, coupled with a surge in industrialization in emerging economies, are creating significant opportunities for market participants.

The consistent growth trajectory of the hydraulic hoist market reflects ongoing technological advancements aimed at enhancing operational efficiency, safety, and durability. Manufacturers are continually innovating to offer solutions that meet stringent regulatory standards and diverse application requirements. Furthermore, the increasing adoption of automation in industrial processes and the expanding scope of material handling operations across various sectors are pivotal factors contributing to the markets upward trend. This projected growth underscores the essential role hydraulic hoists play in modern industrial and commercial landscapes, enabling complex lifting tasks with precision and reliability.

Hydraulic Hoist Market introduction

A hydraulic hoist is a mechanical device designed to lift and lower heavy loads using hydraulic power. Its fundamental operation relies on Pascals principle, where a small force applied to a fluid in a confined space generates a much larger force. These systems typically consist of a hydraulic pump, cylinders, valves, and fluid reservoirs, all meticulously engineered to provide controlled and powerful lifting capabilities. Hydraulic hoists are indispensable across numerous industrial and commercial settings due to their remarkable strength, precise control, and inherent stability, making them a preferred choice for heavy-duty applications where safety and efficiency are paramount.

The major applications of hydraulic hoists span a wide spectrum of industries. In the construction sector, they are vital for lifting structural components, heavy machinery, and construction materials on job sites. The automotive industry utilizes them extensively in repair shops and assembly lines for vehicle lifting and component installation. Manufacturing facilities integrate hydraulic hoists for moving heavy molds, raw materials, and finished goods within production environments. Furthermore, they are crucial in logistics and warehousing for efficient loading and unloading of cargo, in marine applications for ship maintenance and port operations, and in mining for equipment servicing and material handling in harsh conditions.

The benefits associated with hydraulic hoists are multifaceted, including their superior lifting capacity, precise control, and inherent safety features. They are known for their robust construction and durability, ensuring a long operational lifespan even under arduous conditions. Key driving factors propelling the markets expansion include the escalating global investment in infrastructure development, particularly in developing economies, and the rapid pace of urbanization which necessitates advanced construction equipment. Additionally, the growing emphasis on automation in industrial processes, the increasing demand for material handling solutions, and the stringent regulatory focus on workplace safety are significantly contributing to the sustained growth and adoption of hydraulic hoists across a diverse range of end-user industries.

Hydraulic Hoist Market Executive Summary

The Hydraulic Hoist Market is currently experiencing dynamic business trends characterized by significant technological innovation, strategic collaborations, and a strong emphasis on sustainability and operational efficiency. Market players are increasingly investing in research and development to integrate advanced control systems, IoT capabilities, and energy-efficient hydraulic components into their product offerings. This push towards smarter, more connected hoist systems is driven by end-user demand for enhanced productivity, reduced downtime, and improved safety standards. Furthermore, consolidation activities, including mergers and acquisitions, are shaping the competitive landscape, allowing companies to expand their product portfolios and geographical reach, thereby capitalizing on emerging market opportunities.

Regionally, the market exhibits varied growth patterns with Asia-Pacific leading in terms of market share and growth potential, propelled by rapid industrialization, massive infrastructure projects, and a booming manufacturing sector, particularly in countries like China and India. North America and Europe, while mature markets, demonstrate steady growth driven by the adoption of advanced hoist technologies, stringent safety regulations, and continuous modernization of existing industrial infrastructure. Latin America and the Middle East & Africa are emerging as significant growth hubs, fueled by increasing investment in construction, oil and gas, and mining sectors. These regional dynamics reflect diverse economic landscapes and varying stages of industrial development, influencing both demand and technological adoption rates.

Segment-wise, the hydraulic hoist market is witnessing notable trends across different product types, lifting capacities, and end-use applications. There is a growing demand for telescopic and articulate boom hoists due to their versatility and reach in construction and utility applications. In terms of lifting capacity, the mid-range capacity segment (5-15 tons) continues to dominate, catering to a broad array of industrial and commercial needs, while the heavy-duty segment is gaining traction with large-scale infrastructure projects. The construction and manufacturing industries remain the primary end-users, but significant growth is also observed in logistics, marine, and automotive sectors, driven by evolving material handling requirements and the need for specialized lifting solutions. These segmentation trends highlight a market that is continually adapting to specific industry demands and technological advancements.

AI Impact Analysis on Hydraulic Hoist Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Hydraulic Hoist Market frequently center on its potential to revolutionize operational efficiency, safety protocols, and predictive maintenance strategies. Common questions reveal a strong interest in how AI can integrate with Internet of Things (IoT) sensors to provide real-time data analysis, enabling proactive identification of potential system failures before they occur. Users are keen to understand the practical applications of AI in optimizing hoist usage, managing complex lifting tasks, and extending the lifespan of critical equipment, thereby minimizing costly downtime and maximizing productivity in demanding industrial environments.

Furthermore, user questions often delve into the specific benefits AI can offer in terms of enhanced worker safety and compliance with stringent industry regulations. There is significant curiosity about AIs role in monitoring operational parameters, detecting anomalies, and even facilitating autonomous or semi-autonomous lifting operations to reduce human error. However, users also express concerns regarding the financial investment required for AI implementation, the complexity of integrating advanced AI systems into existing legacy infrastructure, and the cybersecurity implications of connecting hoists to broader digital networks. Addressing these multifaceted concerns and highlighting tangible returns on investment are crucial for widespread adoption.

The overarching expectation among users is that AI will transform hydraulic hoist management from a reactive maintenance model to a proactive, data-driven approach. This includes the anticipation of AI-powered analytics providing insights into optimal load distribution, energy consumption, and scheduled maintenance intervals, leading to significant cost savings and improved operational reliability. The market anticipates that AI will not only make hoists smarter and more efficient but also contribute to a safer working environment by continuously monitoring performance and predicting potential hazards, thereby fostering a new era of intelligent lifting solutions that are both highly performant and secure.

- Predictive Maintenance: AI algorithms analyze sensor data to forecast component failures, scheduling maintenance proactively and reducing unplanned downtime.

- Operational Optimization: AI enhances hoist efficiency by optimizing lifting paths, speed, and load distribution, leading to reduced energy consumption and faster cycle times.

- Enhanced Safety: AI-powered vision systems and sensors detect potential hazards, monitor operator performance, and prevent overload situations, significantly improving workplace safety.

- Autonomous Operation: AI facilitates the development of semi-autonomous or fully autonomous hoists, particularly for repetitive tasks or hazardous environments, minimizing human intervention.

- Remote Diagnostics: AI enables remote monitoring and diagnosis of hoist issues, allowing for quicker troubleshooting and maintenance without on-site presence.

- Data-driven Decision Making: AI processes vast amounts of operational data to provide insights into hoist performance, utilization, and asset management strategies.

- Energy Efficiency: AI optimizes hydraulic pump control and motor operation based on real-time load requirements, leading to significant reductions in energy consumption.

DRO & Impact Forces Of Hydraulic Hoist Market

The Hydraulic Hoist Market is significantly driven by a confluence of factors, prominently including the robust expansion of the global construction industry, fueled by urbanization, infrastructure development initiatives, and residential and commercial construction booms worldwide. Concurrently, the growth in manufacturing and automotive sectors, particularly in emerging economies, necessitates efficient and reliable material handling solutions, directly boosting demand for hydraulic hoists. The increasing emphasis on workplace safety and ergonomics, coupled with stringent regulatory standards, also acts as a key driver, pushing industries to invest in modern, high-performance hoists that minimize manual labor risks and comply with safety mandates.

However, the market faces several restraints that could impede its growth. The high initial capital investment required for purchasing and installing advanced hydraulic hoist systems can be a barrier for small and medium-sized enterprises (SMEs). Additionally, the complexity associated with maintaining these sophisticated systems, which require specialized technical expertise and regular servicing, can add to operational costs. Economic downturns or geopolitical instabilities can lead to reduced industrial activity and construction projects, directly impacting market demand. Furthermore, the rising cost of raw materials, such as steel and hydraulic fluids, and fluctuating energy prices can increase production costs for manufacturers, potentially leading to higher product prices and dampening market growth.

Opportunities within the hydraulic hoist market are abundant, primarily stemming from the rapid technological advancements focusing on automation, digitalization, and the integration of smart technologies like IoT and AI for enhanced operational efficiency and predictive maintenance. The growing demand for customized hoist solutions tailored to specific industry needs, particularly in niche applications, presents a lucrative avenue for innovation. Moreover, the expanding market in developing regions, characterized by ongoing industrialization and infrastructure projects, offers significant growth potential for manufacturers. The key impact forces influencing this market include global economic stability, government investments in infrastructure, environmental regulations promoting energy-efficient and sustainable solutions, and rapid technological innovation. These forces collectively shape market dynamics, influencing demand, supply chain resilience, and the competitive landscape for hydraulic hoist manufacturers and service providers globally.

Segmentation Analysis

The Hydraulic Hoist Market is comprehensively segmented to address the diverse requirements and applications across various industries, offering a granular view of market dynamics and opportunities. This segmentation primarily categorizes the market based on product type, lifting capacity, application, and end-user industry, reflecting the specialized needs of different operational environments. Understanding these distinct segments is crucial for market players to develop targeted strategies, innovate product offerings, and efficiently allocate resources to capitalize on specific growth areas. Each segment represents unique challenges and opportunities, driven by varying operational demands, regulatory landscapes, and technological preferences.

Segmentation by product type typically includes hydraulic cylinder hoists, telescopic hoists, and underbody hoists, each designed for specific lifting mechanisms and operational flexibilities. Lifting capacity segmentation distinguishes between light-duty (e.g., up to 5 tons), medium-duty (e.g., 5-15 tons), and heavy-duty (e.g., above 15 tons) hoists, catering to the varying weight requirements of different tasks. Application-based segmentation covers a broad spectrum, from general material handling and vehicle lifts to industrial lifting in manufacturing plants and specialized use in marine or mining operations. This detailed breakdown ensures that manufacturers can align their product development with the precise performance specifications demanded by their target customers.

Furthermore, segmentation by end-user industry highlights the markets penetration across major sectors such as construction, manufacturing, automotive, logistics & warehousing, marine, and mining. Each of these industries presents distinct operational environments, safety standards, and investment patterns, thereby influencing the demand for specific types of hydraulic hoists. For instance, the construction sector often requires robust, high-capacity hoists for outdoor use, while the automotive industry prioritizes precision and safety for vehicle maintenance. Analyzing these segments provides invaluable insights into market size, growth rates, competitive intensity, and the emerging needs of different customer bases, enabling strategic decision-making for sustainable growth and market leadership.

- By Product Type:

- Hydraulic Cylinder Hoists

- Telescopic Hoists

- Underbody Hoists

- Articulating Boom Hoists

- Scissor Hoists

- By Lifting Capacity:

- Up to 5 Tons

- 5-15 Tons

- 15-30 Tons

- Above 30 Tons

- By Application:

- Material Handling

- Vehicle Lifts

- Industrial Lifting

- Loading/Unloading

- Specialized Equipment Maintenance

- By End-User Industry:

- Construction

- Manufacturing

- Automotive

- Logistics & Warehousing

- Marine

- Mining & Quarrying

- Waste Management

- Agriculture

Hydraulic Hoist Market Value Chain Analysis

The value chain of the Hydraulic Hoist Market begins with extensive upstream activities, primarily involving the sourcing of raw materials such as high-grade steel, cast iron, aluminum alloys, and specialized hydraulic fluids and components. Manufacturers establish robust relationships with suppliers of hydraulic pumps, cylinders, valves, seals, and control systems, ensuring the quality and reliability of these foundational elements. Research and development plays a critical upstream role, focusing on innovations in hydraulic system design, material science, and control technologies to enhance hoist performance, energy efficiency, and compliance with evolving safety standards. This phase is crucial for ensuring the foundational quality and technological edge of the final product.

Moving downstream, the value chain encompasses the manufacturing, assembly, and rigorous testing of hydraulic hoists, followed by their distribution to end-users. The manufacturing process involves precision engineering, fabrication, welding, and painting, adhering to strict quality control measures throughout each stage. Once manufactured, the hoists are transported through various distribution channels, which can be broadly categorized into direct and indirect routes. This downstream segment also includes essential after-sales services such as installation, maintenance, repair, and the supply of spare parts, which are critical for ensuring customer satisfaction and the long-term operational efficiency of the hoists in diverse industrial settings.

Distribution channels in the Hydraulic Hoist Market are typically a hybrid of direct and indirect approaches. Direct channels involve manufacturers selling directly to large industrial clients, government agencies, or major construction firms, often through dedicated sales teams that provide customized solutions and extensive technical support. Indirect channels leverage a network of authorized distributors, dealers, and system integrators who market and sell hoists to a broader base of small and medium-sized businesses, automotive workshops, and specialized contractors. These indirect partners often provide localized sales, installation, and maintenance services, enhancing market reach and customer convenience. The growing prominence of e-commerce platforms is also influencing the distribution of hoist components and accessories, offering an additional avenue for sales and increasing market accessibility.

Hydraulic Hoist Market Potential Customers

The primary potential customers for hydraulic hoists are diverse and span across numerous heavy-industry and service-oriented sectors, all requiring robust and reliable lifting capabilities. At the forefront are construction companies, which extensively utilize hydraulic hoists for lifting large structural beams, prefabricated concrete panels, heavy machinery, and various building materials on job sites. Similarly, manufacturing plants, particularly those involved in heavy machinery, automotive assembly, and metal fabrication, are key end-users, requiring hoists for moving raw materials, positioning components on assembly lines, and transporting finished products within their facilities, underscoring the demand for high-capacity, durable lifting solutions.

Beyond these core industries, the automotive sector, encompassing repair workshops, dealerships, and specialized service centers, represents a substantial customer base, primarily for vehicle lifts used in maintenance, inspection, and repair operations. The logistics and warehousing industry also constitutes a significant segment of potential customers, relying on hydraulic hoists for efficient loading and unloading of heavy cargo from trucks, ships, and trains, as well as for stacking and organizing goods within storage facilities. These applications demand hoists that can withstand continuous operation, offer precise control, and integrate seamlessly into existing material handling workflows, ensuring quick turnaround times and operational fluidity.

Further extending the customer landscape are the marine industry, including shipyards, ports, and offshore platforms, where hydraulic hoists are essential for ship construction, maintenance, and handling large components, and the mining and quarrying sectors, which employ heavy-duty hoists for equipment maintenance, material extraction, and personnel lifting in challenging environments. Waste management and recycling facilities also utilize hydraulic hoists for handling bulky refuse and processing materials. The common thread among all these potential customers is the critical need for safe, efficient, and precise lifting solutions to manage heavy or cumbersome loads, emphasizing reliability, durability, and operational safety as paramount purchasing criteria when evaluating hydraulic hoist systems.

Hydraulic Hoist Market Key Technology Landscape

The Hydraulic Hoist Market is continuously evolving through significant technological advancements aimed at enhancing performance, efficiency, and safety. A central aspect of this landscape is the development of more advanced hydraulic systems, featuring energy-efficient pumps that reduce power consumption and advanced valve technologies that provide finer control over lifting and lowering speeds. Innovations in cylinder design, including multi-stage telescopic cylinders, allow for greater reach and lifting height while maintaining a compact retracted size. Furthermore, the integration of high-pressure hydraulic components made from robust, lightweight materials is increasing the strength-to-weight ratio of hoists, enabling higher capacities without excessive bulk.

A pivotal technological trend is the pervasive integration of smart sensors and IoT (Internet of Things) capabilities into hydraulic hoist systems. These sensors monitor critical operational parameters such as load weight, hydraulic pressure, temperature, and extension angles in real-time. This data is then transmitted to central monitoring systems or cloud platforms, enabling predictive maintenance, remote diagnostics, and performance analytics. By leveraging IoT, operators and maintenance teams can anticipate potential failures, schedule preventive maintenance, and optimize hoist utilization, significantly reducing downtime and extending the equipments operational lifespan. This digital transformation is fundamentally changing how hoists are managed and maintained, shifting towards more proactive and data-driven approaches.

The emerging technology landscape also includes the adoption of advanced control systems, often incorporating Artificial Intelligence (AI) and machine learning algorithms. These intelligent control systems can optimize lifting operations, improve precision, and enhance safety by analyzing operational data and making real-time adjustments. Furthermore, theres a growing emphasis on modular designs that facilitate easier customization and faster assembly, alongside the development of eco-friendly hydraulic fluids that minimize environmental impact. Robotics and automation are also beginning to play a role, with some high-end hoists featuring automated positioning and load handling capabilities, especially in controlled industrial environments, signaling a future where hydraulic hoists are not just powerful lifting tools but also intelligent, integrated components of automated workflows.

Regional Highlights

The global Hydraulic Hoist Market exhibits diverse regional dynamics, influenced significantly by localized economic conditions, the pace of industrialization, infrastructure development projects, and stringent regulatory environments. Each region presents unique growth opportunities and challenges, with varying levels of technological adoption and market maturity. Understanding these regional specificities is crucial for market players to tailor their strategies, product offerings, and distribution networks effectively, ensuring resonance with local demands and regulatory compliance. The demand for hydraulic hoists is intrinsically linked to the health of the construction, manufacturing, and logistics sectors within each geographical area.

- Asia-Pacific: This region dominates the market, driven by rapid industrialization, massive infrastructure development projects (e.g., Chinas Belt and Road Initiative, Indias Smart Cities Mission), and booming construction and manufacturing sectors. Countries like China, India, Japan, and South Korea are key contributors due to high investment in urban development, automotive production, and general industrial expansion.

- North America: Characterized by a mature market with high adoption rates of advanced hydraulic hoist technologies. Growth is fueled by continuous investment in infrastructure upgrades, robust residential and commercial construction, and a strong automotive and logistics industry. The United States and Canada are leading markets, with an increasing focus on safety standards and automation.

- Europe: A well-established market with a strong emphasis on precision engineering, stringent safety regulations, and sustainable solutions. Demand is driven by the automotive industry, manufacturing sector, and ongoing modernization of infrastructure. Countries such as Germany, the UK, France, and Italy are significant contributors, focusing on energy efficiency and technological advancements.

- Latin America: An emerging market with considerable growth potential, primarily driven by infrastructure development projects, mining activities, and growing industrialization in key economies. Brazil and Mexico are leading the demand, supported by expanding construction and resource extraction sectors.

- Middle East & Africa: This region is witnessing substantial growth due to significant investments in construction, real estate, and energy infrastructure (e.g., Saudi Arabias Vision 2030, UAEs Expo 2020 projects). South Africa and the UAE are prominent markets, fueled by mega-project developments and diversification of economies beyond oil.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hydraulic Hoist Market. The competitive landscape is characterized by a mix of global industry giants and specialized regional manufacturers, all striving for technological leadership and market expansion. These companies are continuously investing in research and development to introduce innovative and energy-efficient hydraulic hoist solutions, while also focusing on strategic partnerships, mergers, and acquisitions to strengthen their market position and expand their global footprint. Key differentiators often include product durability, lifting capacity, advanced control systems, after-sales support, and compliance with international safety standards, reflecting a highly competitive and innovation-driven environment.- Columbus McKinnon Corporation

- Kito Corporation

- Konecranes

- Terex Corporation (Genie)

- Palfinger AG

- Liebherr Group

- Tadano Ltd.

- JLG Industries (Oshkosh Corporation)

- Altec Industries

- Hyva Group

- Load Lifter Manufacturing Ltd.

- Effer S.p.A. (CTP S.p.A.)

- Stellar Industries Inc.

- Fassi Gru S.p.A.

- Hiab (Cargotec Corporation)

- Manitowoc Company, Inc.

- Zoomlion Heavy Industry Science and Technology Co., Ltd.

- XCMG Construction Machinery Co., Ltd.

- LiuGong Machinery Co., Ltd.

- Sany Group Co., Ltd.

Frequently Asked Questions

What is a hydraulic hoist and how does it fundamentally operate?

A hydraulic hoist is a lifting device that utilizes the power of pressurized hydraulic fluid to generate mechanical force, enabling it to lift or lower heavy loads with precision and control. It operates on Pascals principle, where a small force applied to a fluid in a confined system transmits pressure equally throughout, resulting in a larger force capable of moving heavy objects.

What are the primary industries and applications for hydraulic hoists?

Hydraulic hoists are primarily used in industries such as construction for material handling, manufacturing for assembly lines and machinery movement, automotive for vehicle lifting and repair, and logistics for efficient loading and unloading of heavy cargo. They are also crucial in marine, mining, and waste management sectors due to their robust lifting capabilities.

How is Artificial Intelligence (AI) impacting the hydraulic hoist market?

AI is transforming the hydraulic hoist market by enabling predictive maintenance, optimizing operational efficiency through data analysis, and enhancing safety features. It allows for real-time monitoring, remote diagnostics, and even supports autonomous operations, leading to reduced downtime, improved reliability, and smarter asset management.

What factors significantly influence the cost and selection of a hydraulic hoist?

Key factors influencing the cost and selection of a hydraulic hoist include its lifting capacity, specific product type (e.g., telescopic, underbody), technological features (e.g., smart controls, IoT integration), material quality, and the manufacturers brand reputation. Customization requirements, installation complexity, and after-sales service availability also play a crucial role.

What are the critical maintenance considerations for ensuring the longevity and safety of hydraulic hoists?

Critical maintenance considerations for hydraulic hoists involve regular inspection of hydraulic fluid levels and quality, timely checking for leaks in hoses and seals, ensuring adequate lubrication of moving parts, and verifying the structural integrity of components. Adherence to manufacturer-recommended service schedules and prompt replacement of worn parts are paramount for operational safety and extended lifespan.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager