Hydrogen Generator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429506 | Date : Nov, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Hydrogen Generator Market Size

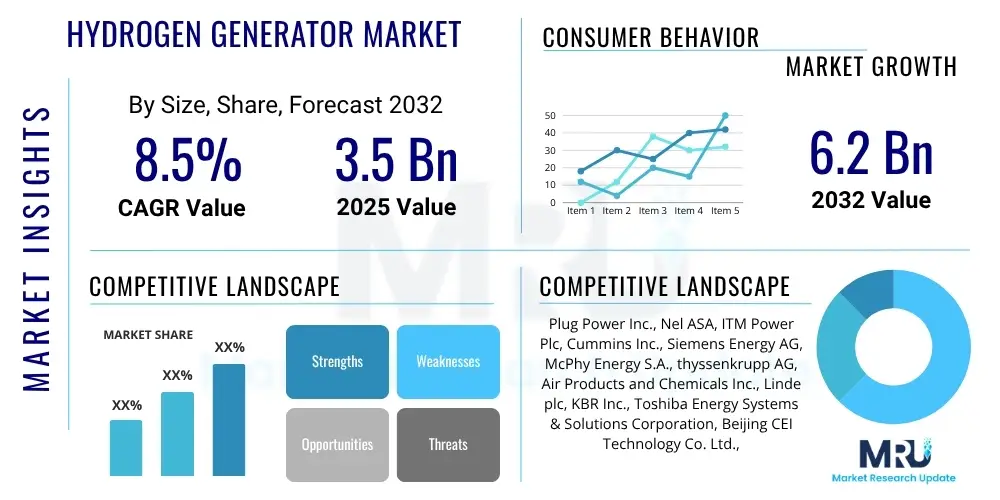

The Hydrogen Generator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2025 and 2032. The market is estimated at USD 3.5 Billion in 2025 and is projected to reach USD 6.2 Billion by the end of the forecast period in 2032.

Hydrogen Generator Market introduction

The hydrogen generator market encompasses the global industry involved in the production of hydrogen gas through various methods, predominantly electrolysis of water and steam methane reforming. These devices are pivotal in the emerging hydrogen economy, offering a clean energy alternative to fossil fuels and serving critical industrial applications. Hydrogen generators produce high-purity hydrogen on-site, eliminating the need for transportation and storage of compressed gas, thereby enhancing safety and operational efficiency.

Hydrogen generators offer numerous benefits, including reduced carbon emissions when powered by renewable energy, energy independence, and versatility in applications ranging from fuel cells to industrial processes. Major applications span across industrial feedstock in chemical and refining sectors, power generation and grid balancing, fuel for transportation (fuel cell electric vehicles), and metallurgy. The market is significantly driven by global decarbonization goals, increasing investments in renewable energy infrastructure, and supportive government policies aimed at fostering green hydrogen production and adoption.

The core product in this market is the hydrogen generator, primarily classified by the technology it employs, such as Alkaline Electrolyzers, Proton Exchange Membrane (PEM) Electrolyzers, and Solid Oxide Electrolyzer Cells (SOEC). Each technology presents distinct advantages in terms of efficiency, purity, cost, and operational flexibility. As the demand for clean energy solutions intensifies, the role of hydrogen generators in enabling a sustainable future becomes increasingly prominent, facilitating the transition away from carbon-intensive energy sources.

Hydrogen Generator Market Executive Summary

The Hydrogen Generator Market is experiencing robust growth, propelled by a global shift towards clean energy and stringent environmental regulations. Business trends indicate a surge in strategic partnerships, venture capital investments in green hydrogen projects, and a focus on scaling up electrolyzer manufacturing capacities to meet anticipated demand. Technological advancements aimed at reducing production costs and enhancing efficiency are paramount, driving innovation across the value chain. Key players are diversifying their portfolios, integrating renewable energy sources directly with electrolysis units, and expanding their geographical footprint to capitalize on emerging regional opportunities.

Regional trends highlight Europe and North America as frontrunners, largely due to ambitious green hydrogen targets, substantial government subsidies, and existing industrial infrastructure. The Asia Pacific region is also emerging as a significant market, driven by industrial demand from countries like China, India, and Japan, coupled with growing investments in renewable energy. Segments trends reveal a strong dominance of alkaline and PEM electrolyzers, with SOEC technology gaining traction for its high efficiency at elevated temperatures, particularly in industrial settings. The market is also witnessing a shift towards larger capacity on-site hydrogen generation solutions, reflecting the increasing scale of industrial and energy sector applications. Furthermore, the transportation sector, particularly heavy-duty vehicles and maritime shipping, is poised to become a significant end-user segment, fueled by advancements in fuel cell technology and hydrogen refueling infrastructure development.

AI Impact Analysis on Hydrogen Generator Market

Common user questions regarding AI's impact on the Hydrogen Generator Market often revolve around how artificial intelligence can enhance efficiency, reduce operational costs, optimize energy consumption, and improve the safety and reliability of hydrogen production processes. Users are keen to understand AI's role in predictive maintenance for electrolyzers, intelligent integration with renewable energy sources for optimal green hydrogen generation, and the overall smart management of hydrogen value chains. There is also interest in AI-driven process optimization to achieve higher purity and yield, as well as its application in designing more efficient generator components.

- AI optimizes electrolyzer efficiency by predicting optimal operating parameters based on real-time data, renewable energy availability, and electricity prices.

- Predictive maintenance schedules for hydrogen generators are enhanced by AI algorithms, reducing downtime and operational costs by anticipating equipment failures.

- Smart grid integration facilitated by AI allows hydrogen generators to act as flexible loads, balancing supply and demand from intermittent renewable energy sources.

- AI-driven process control ensures consistent hydrogen purity and optimizes reaction conditions, leading to higher yields and reduced waste.

- Enhanced safety protocols are developed and monitored through AI, detecting anomalies and potential hazards in hydrogen production and storage systems.

- AI aids in the design and engineering of next-generation hydrogen generator components, accelerating material discovery and optimizing system architecture for improved performance.

DRO & Impact Forces Of Hydrogen Generator Market

The Hydrogen Generator Market is significantly influenced by a complex interplay of drivers, restraints, and opportunities, all contributing to its evolving impact forces. Key drivers include the urgent global imperative for decarbonization and the transition to cleaner energy sources, directly fueling demand for green hydrogen. Supportive government policies, such as tax credits, subsidies, and ambitious national hydrogen strategies, particularly in regions like Europe and North America, are instrumental in accelerating market growth. Furthermore, the decreasing cost of renewable energy, especially solar and wind, makes green hydrogen production increasingly economically viable, thereby strengthening the market's foundation.

However, the market faces notable restraints. The initial high capital expenditure (CAPEX) required for hydrogen generation facilities, particularly for advanced electrolyzer technologies, remains a significant barrier for many potential investors. Concerns regarding hydrogen storage, transportation, and distribution infrastructure, which is currently nascent in many regions, also impede widespread adoption. Safety perceptions associated with hydrogen, despite advancements in handling technologies, continue to be a challenge. Additionally, competition from established fossil fuel industries and the fluctuating prices of natural gas can impact the economic competitiveness of hydrogen derived from SMR without Carbon Capture and Storage (CCS).

Opportunities for market expansion are abundant, driven by emerging applications in heavy-duty transport (maritime, aviation), grid energy storage, and industrial decarbonization beyond traditional sectors. The potential for hydrogen to serve as an energy carrier for renewable energy surpluses and to facilitate international energy trade opens vast new avenues. Impact forces include rapid technological advancements in electrolyzer efficiency and durability, geopolitical shifts affecting energy security, and evolving carbon pricing mechanisms, which collectively shape the market's trajectory and competitive landscape. The increasing corporate sustainability commitments and ESG (Environmental, Social, and Governance) investment trends also exert considerable influence on market development.

Segmentation Analysis

The Hydrogen Generator Market is comprehensively segmented to provide a detailed understanding of its diverse components and growth dynamics. These segmentations allow for a granular analysis of market trends, competitive landscapes, and strategic opportunities across various technologies, applications, capacities, end-uses, and geographical regions. Understanding these distinct segments is crucial for stakeholders to tailor their product offerings, investment strategies, and market penetration approaches effectively. The market's structure reflects the evolving demands of different industries and the continuous innovation in hydrogen production technologies.

- By Technology

- Alkaline Electrolyzer

- Proton Exchange Membrane (PEM) Electrolyzer

- Solid Oxide Electrolyzer Cell (SOEC)

- Other Technologies (e.g., Anion Exchange Membrane (AEM) Electrolyzer)

- By Application

- Industrial Feedstock (Chemicals, Refineries, Metals & Metallurgy, Electronics)

- Fueling Stations (Vehicles, Forklifts)

- Power Generation & Grid Injection

- Energy Storage

- Others (e.g., Glass Manufacturing, Food Processing)

- By Capacity

- Small-Scale (0-100 Nm3/hr)

- Medium-Scale (101-1000 Nm3/hr)

- Large-Scale (>1000 Nm3/hr)

- By End-Use Industry

- Chemical & Petrochemical

- Oil & Gas

- Power & Utilities

- Automotive & Transportation

- Metals

- Electronics

- Food & Beverage

- Pharmaceuticals

- Other Industries

- By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Value Chain Analysis For Hydrogen Generator Market

The value chain for the Hydrogen Generator Market begins with upstream activities focused on raw material procurement and component manufacturing. This includes sourcing essential materials like catalysts (platinum, iridium), membranes (Nafion for PEM), electrodes, and structural components for electrolyzers. Specialized manufacturers produce power electronics, compressors, purification units, and control systems crucial for the functionality of hydrogen generation systems. Key players in this stage are typically chemical companies, material science firms, and specialized engineering component suppliers, whose innovation directly impacts the efficiency and cost-effectiveness of the final product.

Midstream activities involve the actual assembly and integration of these components into complete hydrogen generator units, along with system testing and quality assurance. This stage is dominated by the core hydrogen generator manufacturers who design, produce, and often install the electrolysis or reforming systems. Following this, downstream activities focus on the installation, operation, and maintenance of these generators at end-user sites. This includes connecting the generators to water sources, electricity grids (especially renewable energy sources), and hydrogen storage or distribution infrastructure.

Distribution channels for hydrogen generators are typically multifaceted. Direct sales are common for large-scale industrial projects where manufacturers engage directly with major industrial gas companies, chemical plants, or utility providers. For smaller to medium-scale applications, indirect channels through specialized distributors, engineering, procurement, and construction (EPC) contractors play a crucial role. EPC firms often integrate hydrogen generation solutions into larger industrial or energy projects, providing a comprehensive solution to the end-user. The choice of channel often depends on the project's scale, complexity, and the geographic reach of the manufacturer, with after-sales support and technical services forming a vital part of the overall value proposition.

Hydrogen Generator Market Potential Customers

The Hydrogen Generator Market caters to a diverse range of potential customers and end-users, reflecting hydrogen's versatile applications across various industrial and energy sectors. Large industrial gas companies are primary buyers, as they utilize hydrogen as a critical feedstock or for commercial distribution. The oil and gas industry, particularly refineries, represents another significant customer segment, employing hydrogen for hydrotreating and hydrocracking processes. Chemical manufacturers, especially those producing ammonia, methanol, and specialty chemicals, are also key consumers, relying on hydrogen for their synthesis processes.

Beyond traditional industrial users, the power and utilities sector is emerging as a crucial customer base, driven by the need for energy storage, grid balancing, and decarbonizing power generation through fuel cells or hydrogen co-firing. The automotive and transportation industry, including manufacturers of fuel cell electric vehicles (FCEVs), hydrogen fueling station operators, and developers of hydrogen-powered heavy-duty vehicles, maritime vessels, and even aircraft, are increasingly adopting hydrogen generators. Furthermore, the electronics industry uses high-purity hydrogen for semiconductor manufacturing, while the metals industry utilizes it for annealing and welding processes. Renewable energy developers are also significant customers, integrating hydrogen generators with wind and solar farms to produce green hydrogen for storage or grid injection, aligning with global decarbonization efforts.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 3.5 Billion |

| Market Forecast in 2032 | USD 6.2 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Plug Power Inc., Nel ASA, ITM Power Plc, Cummins Inc., Siemens Energy AG, McPhy Energy S.A., thyssenkrupp AG, Air Products and Chemicals Inc., Linde plc, KBR Inc., Toshiba Energy Systems & Solutions Corporation, Beijing CEI Technology Co. Ltd., Green Hydrogen Systems A/S, Electrochaea GmbH, Sumitomo Corporation, Ballard Power Systems Inc., Hyundai Mobis, FuelCell Energy Inc., Hysata, Sunfire GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hydrogen Generator Market Key Technology Landscape

The Hydrogen Generator Market is characterized by a dynamic and evolving technology landscape, primarily dominated by various forms of electrolysis for green hydrogen production, alongside conventional methods like steam methane reforming (SMR) which are increasingly being paired with carbon capture and storage (CCS) for blue hydrogen. Electrolysis technologies, which split water into hydrogen and oxygen using electricity, are at the forefront of decarbonization efforts. Alkaline electrolyzers are mature, cost-effective for large-scale production, and durable, though they operate at lower current densities. Proton Exchange Membrane (PEM) electrolyzers offer higher efficiency, faster response times, and compactness, making them suitable for integration with intermittent renewable energy sources, albeit with higher capital costs due to expensive catalyst materials.

Solid Oxide Electrolyzer Cells (SOEC) represent a rapidly advancing technology that operates at high temperatures (500-850°C), resulting in higher electrical efficiency when waste heat from industrial processes or nuclear power plants is available. This high-temperature operation allows for a more efficient use of energy, as less electrical energy is required to break water molecules. Other emerging electrolysis technologies include Anion Exchange Membrane (AEM) electrolyzers, which aim to combine the advantages of alkaline and PEM systems by using non-precious metals and operating at moderate temperatures. Beyond electrolysis, research and development are also ongoing in areas like biomass gasification and photoelectrochemical (PEC) water splitting, though these are at earlier stages of commercialization.

Innovation is also focused on improving the overall system efficiency, reducing the balance of plant costs, and enhancing the durability and lifespan of generator components. Advancements in materials science are crucial for developing more robust membranes, efficient catalysts, and corrosion-resistant electrodes. Digitalization and automation, often incorporating AI and machine learning, are increasingly integrated into hydrogen generator systems for real-time monitoring, predictive maintenance, and optimized operational control, further driving the efficiency and economic viability of hydrogen production. These technological developments collectively pave the way for more widespread and cost-effective hydrogen generation, supporting the global energy transition.

Regional Highlights

North America is a pivotal region in the Hydrogen Generator Market, largely driven by the United States' Inflation Reduction Act (IRA), which offers significant tax credits for green hydrogen production. This policy framework is stimulating substantial investment in electrolysis capacity, particularly for large-scale projects integrated with renewable energy. Canada also demonstrates strong commitment with its national hydrogen strategy, focusing on leveraging its abundant hydropower to become a global leader in clean hydrogen. The region's robust industrial base and growing demand for decarbonization in sectors like transportation and heavy industry further solidify its market position.

Europe stands as a global leader in hydrogen initiatives, propelled by the European Green Deal and ambitious targets to deploy large-scale electrolyzer capacity. Countries like Germany, France, and the Netherlands are investing heavily in green hydrogen projects, establishing hydrogen valleys, and developing extensive pipeline infrastructure for distribution. The region's focus on energy independence and stringent emissions reduction targets are primary drivers, fostering a competitive landscape for hydrogen generator manufacturers and driving technological innovation, particularly in PEM and SOEC technologies. Supportive regulatory frameworks and strong public-private partnerships are accelerating deployment.

The Asia Pacific region is rapidly emerging as a significant market, primarily due to the massive industrial demand from countries like China, India, Japan, and South Korea. China, with its vast manufacturing capabilities and ambitious renewable energy expansion, is investing heavily in both electrolyzer production and large-scale green hydrogen projects. Japan and South Korea are focusing on hydrogen as a key pillar for their energy security and decarbonization goals, particularly in fuel cell electric vehicles and power generation. Australia, with its abundant solar and wind resources, is positioning itself as a major exporter of green hydrogen, leading to significant investments in large-scale electrolysis plants. These regional dynamics highlight diverse approaches but a unified goal towards hydrogen adoption.

- North America: Driven by US Inflation Reduction Act incentives and Canada's hydrogen strategy, focusing on green hydrogen production and industrial decarbonization.

- Europe: Leading the global charge with ambitious green hydrogen targets, substantial investments in electrolysis, and extensive infrastructure development, particularly in Germany, France, and the Netherlands.

- Asia Pacific: High industrial demand from China, India, Japan, and South Korea; significant investments in manufacturing capacity and green hydrogen export projects, notably in Australia.

- Latin America: Emerging market with strong potential for green hydrogen production due to abundant renewable resources, particularly in Chile and Brazil.

- Middle East and Africa (MEA): Significant investments in large-scale green hydrogen projects, leveraging vast solar and wind resources, especially in Saudi Arabia and the UAE.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hydrogen Generator Market.- Plug Power Inc.

- Nel ASA

- ITM Power Plc

- Cummins Inc.

- Siemens Energy AG

- McPhy Energy S.A.

- thyssenkrupp AG

- Air Products and Chemicals Inc.

- Linde plc

- KBR Inc.

- Toshiba Energy Systems & Solutions Corporation

- Beijing CEI Technology Co. Ltd.

- Green Hydrogen Systems A/S

- Electrochaea GmbH

- Sumitomo Corporation

- Ballard Power Systems Inc.

- Hyundai Mobis

- FuelCell Energy Inc.

- Hysata

- Sunfire GmbH

Frequently Asked Questions

What is a hydrogen generator?

A hydrogen generator is a device or system designed to produce hydrogen gas, typically through the process of electrolysis (splitting water into hydrogen and oxygen using electricity) or steam methane reforming (reacting natural gas with steam). These systems enable on-site hydrogen production for various industrial, energy, and transportation applications.

How does a hydrogen generator work?

Most modern hydrogen generators operate via electrolysis, where an electrical current passes through water (H2O), breaking it down into hydrogen (H2) at the cathode and oxygen (O2) at the anode. Different types of electrolyzers, like alkaline, PEM, and SOEC, use varying electrolytes and operating conditions to facilitate this reaction efficiently.

What are the primary applications of hydrogen generators?

Hydrogen generators serve diverse applications including providing industrial feedstock for chemical manufacturing (e.g., ammonia, methanol), refining processes (hydrotreating), power generation and grid balancing, fueling stations for fuel cell electric vehicles (FCEVs), and energy storage solutions by converting excess renewable electricity into storable hydrogen.

What are the main types of hydrogen generator technologies?

The primary technologies include Alkaline Electrolyzers, known for their maturity and cost-effectiveness; Proton Exchange Membrane (PEM) Electrolyzers, favored for their efficiency and dynamic response; and Solid Oxide Electrolyzer Cells (SOEC), which offer high efficiency at elevated temperatures. Each type has specific advantages depending on the application and energy source.

What factors are driving the growth of the hydrogen generator market?

Market growth is largely driven by global decarbonization goals, the increasing adoption of renewable energy sources, supportive government policies and incentives for clean hydrogen production, decreasing costs of renewable electricity, and the expanding demand for hydrogen across various industrial, energy, and transportation sectors as a clean fuel and feedstock.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Onsite Hydrogen Generator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Hydrogen Generator Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Water Electrolysis, Ammonia Electrolysis, Others), By Application (Electricity Industry, Chemical Industry, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager