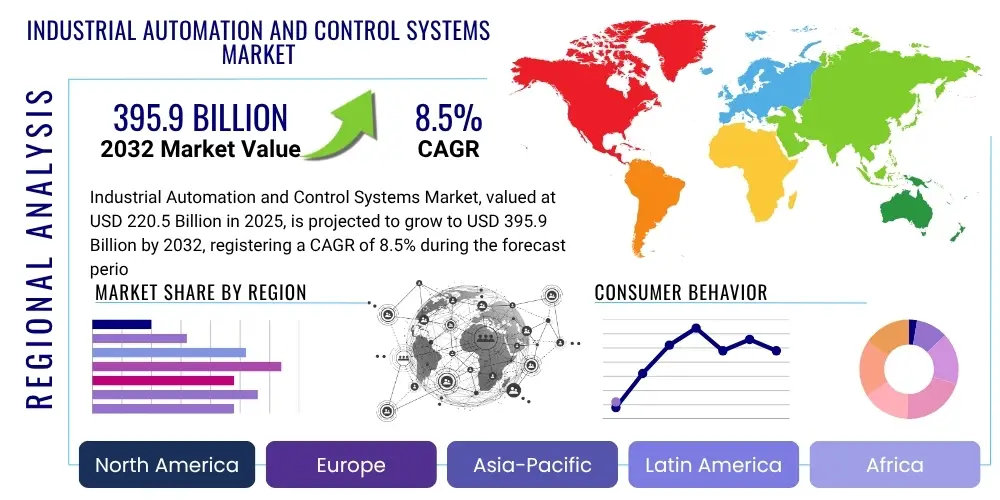

Industrial Automation and Control Systems Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428890 | Date : Oct, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Industrial Automation and Control Systems Market Size

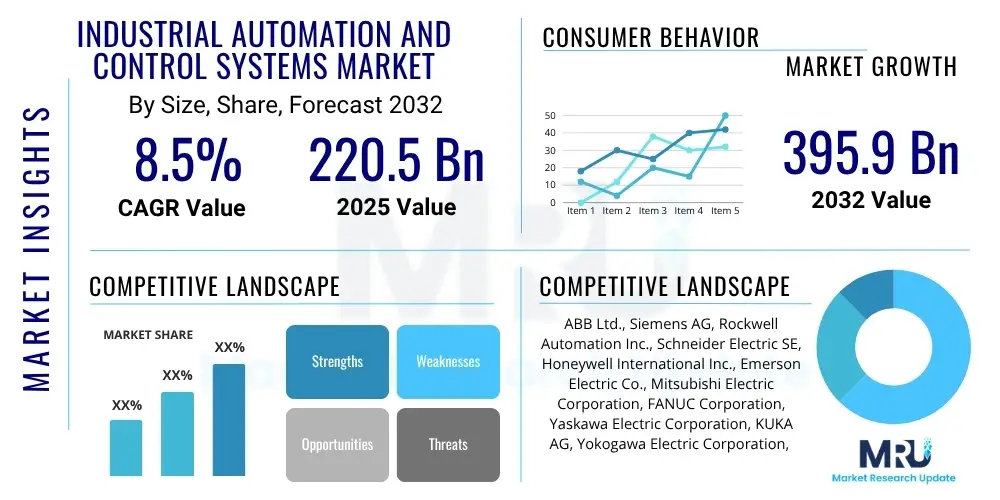

The Industrial Automation and Control Systems Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2025 and 2032. The market is estimated at USD 220.5 Billion in 2025 and is projected to reach USD 395.9 Billion by the end of the forecast period in 2032.

Industrial Automation and Control Systems Market introduction

The Industrial Automation and Control Systems (IACS) market encompasses a wide array of technologies and solutions designed to automate and control various industrial processes and operations, enhancing efficiency, safety, and productivity across diverse sectors. These systems are crucial for modern manufacturing and production, allowing for precision control, data acquisition, and optimized resource utilization. The core product description includes a spectrum of components such as Distributed Control Systems (DCS), Supervisory Control and Data Acquisition (SCADA) systems, Programmable Logic Controllers (PLCs), Human Machine Interfaces (HMIs), Manufacturing Execution Systems (MES), and various types of industrial robots and sensors. These technologies work in concert to manage everything from discrete manufacturing tasks to continuous process operations.

Major applications for IACS are widespread, spanning critical industries such as automotive, food and beverage, oil and gas, pharmaceuticals, chemicals, power generation, and water and wastewater treatment. In the automotive sector, automation ensures precision assembly and quality control, while in process industries like oil and gas, it facilitates safe and efficient extraction, refining, and distribution. The benefits derived from implementing these systems are substantial, including significant reductions in operational costs, improved product quality and consistency, enhanced worker safety by minimizing human exposure to hazardous environments, and ultimately, increased overall production throughput and efficiency. The ability to collect and analyze real-time data also empowers businesses to make more informed decisions, leading to continuous process improvement.

The driving factors propelling the growth of the IACS market are multifaceted. The relentless push towards Industry 4.0 and smart manufacturing initiatives worldwide is a primary catalyst, necessitating greater integration of IT and operational technology (OT). The increasing adoption of the Industrial Internet of Things (IIoT) across manufacturing floors, coupled with the demand for energy-efficient production processes, further fuels market expansion. Additionally, the rising labor costs in many developed economies incentivize businesses to invest in automation to maintain competitiveness, while stringent regulatory requirements for operational safety and environmental compliance also mandate the deployment of advanced control systems. These factors collectively create a robust demand environment for IACS solutions.

Industrial Automation and Control Systems Market Executive Summary

The Industrial Automation and Control Systems market is currently experiencing dynamic growth, characterized by significant business trends that reflect a global shift towards optimized and intelligent manufacturing. A major trend is the accelerating adoption of digital transformation initiatives, including the integration of Artificial Intelligence (AI) and Machine Learning (ML) into control processes for predictive maintenance, quality control, and autonomous operations. Cybersecurity has emerged as a paramount concern, driving investment in robust security solutions for operational technology (OT) networks. Furthermore, there is a growing emphasis on sustainability and energy efficiency, pushing manufacturers to implement automation systems that reduce waste and optimize energy consumption. The market is also seeing a move towards modular, flexible, and customized automation solutions to cater to evolving production demands and smaller batch sizes, reflecting an increasing need for adaptability in complex industrial environments.

From a regional perspective, the Asia Pacific region stands out as a dominant and rapidly expanding market, primarily due to extensive industrialization, significant government support for manufacturing growth, and a large consumer base. Countries like China, India, and South Korea are leading this surge with heavy investments in smart factories and advanced automation technologies. North America continues to be a strong market, driven by high technological adoption rates, significant R&D spending, and a focus on upgrading existing infrastructure with cutting-edge solutions. Europe, particularly Germany and the Nordic countries, emphasizes advanced manufacturing concepts under Industry 4.0, coupled with a strong regulatory push for environmental compliance and operational efficiency. These regional dynamics highlight diverse drivers, from greenfield investments in emerging economies to brownfield modernization in mature markets.

Segmentation trends within the IACS market reveal distinct patterns of growth and evolution. Process automation, which includes industries such as oil and gas, chemicals, and pharmaceuticals, remains a foundational and substantial segment, driven by the continuous need for precise control over complex operations. Discrete automation, encompassing sectors like automotive, electronics, and food and beverage, is experiencing rapid growth due to the rising demand for mass customization and flexible production lines. Within components, industrial robots are witnessing a surge in adoption across various industries for their ability to enhance speed, accuracy, and safety. Software segments, including MES and SCADA, are also expanding significantly, reflecting the increasing importance of data analytics, real-time monitoring, and intelligent decision-making in modern industrial settings. The service segment, particularly focused on system integration, maintenance, and cybersecurity, is also growing rapidly as companies seek expert support for complex deployments.

AI Impact Analysis on Industrial Automation and Control Systems Market

Users frequently inquire about the transformative potential of Artificial Intelligence within the Industrial Automation and Control Systems market, often focusing on its ability to enhance operational efficiency, enable predictive capabilities, and manage complex data streams. Key concerns revolve around the practical integration of AI with existing legacy systems, the cybersecurity risks introduced by AI-driven networks, and the implications for the human workforce in increasingly automated environments. There is also significant interest in understanding the tangible return on investment (ROI) from AI implementation, particularly regarding maintenance cost reductions, quality improvements, and optimization of resource utilization. Expectations are high for AI to deliver more autonomous, adaptive, and intelligent industrial operations, moving beyond traditional automation to truly smart factories that can self-diagnose, self-optimize, and even self-correct in real-time.

- AI enables highly accurate predictive maintenance by analyzing sensor data to anticipate equipment failures, minimizing downtime and maintenance costs.

- AI-driven autonomous control systems optimize production processes in real-time, adjusting parameters for maximum efficiency, quality, and energy savings.

- Enhanced quality control through AI-powered visual inspection systems capable of detecting minute defects faster and more accurately than human operators.

- Improved cybersecurity postures in operational technology (OT) environments through AI-based anomaly detection and threat response mechanisms.

- Optimized resource management, including energy consumption, raw material usage, and waste reduction, through intelligent AI algorithms.

- Facilitation of digital twin technology, allowing for real-time simulation and optimization of industrial processes and asset performance.

- Empowerment of human operators with AI-driven insights and decision support tools, enhancing their capabilities rather than replacing them entirely.

DRO & Impact Forces Of Industrial Automation and Control Systems Market

The Industrial Automation and Control Systems market is profoundly influenced by a complex interplay of drivers, restraints, opportunities, and impactful forces that shape its growth trajectory and adoption rates. A primary driver is the accelerating global trend towards Industry 4.0 and smart manufacturing, which mandates the integration of advanced automation, IoT, and data analytics to create interconnected and intelligent production environments. The increasing demand for operational efficiency, higher productivity, and improved product quality across diverse industries further fuels investment in automation solutions. Additionally, rising labor costs in developed and emerging economies, coupled with a focus on enhancing worker safety by automating hazardous tasks, significantly propel market growth. Stringent regulatory requirements for environmental protection and quality standards also necessitate the deployment of sophisticated control systems to ensure compliance and minimize waste.

Despite these strong drivers, the market faces notable restraints. High initial capital investment is a significant barrier for many small and medium-sized enterprises (SMEs), making the adoption of advanced automation technologies challenging. The growing complexity of integrating new automation systems with existing legacy infrastructure can be costly and time-consuming, requiring specialized expertise. Furthermore, the increasing connectivity of industrial systems elevates cybersecurity risks, making robust protection a critical and expensive consideration. A persistent shortage of skilled personnel capable of deploying, maintaining, and managing advanced automation and control systems also hinders market expansion, requiring significant investment in training and talent development. These challenges necessitate strategic planning and substantial financial commitment from adopting organizations.

Opportunities for growth in the IACS market are abundant and diverse. The continuous evolution and integration of Artificial Intelligence (AI) and Machine Learning (ML) within automation promises to unlock new levels of predictive capabilities, autonomous operations, and process optimization. The potential for customized and flexible manufacturing, enabled by advanced robotics and modular control systems, allows industries to cater to niche markets and fluctuating consumer demands more effectively. Emerging economies, undergoing rapid industrialization and infrastructure development, represent significant untapped markets for IACS solutions, particularly in greenfield projects. Additionally, the retrofitting and modernization of existing industrial plants with advanced automation offer substantial growth prospects, as older facilities seek to improve efficiency and competitiveness. The increasing demand for remote monitoring and control, especially amplified by global events, also presents a strong opportunity for cloud-based and secure remote access solutions.

Segmentation Analysis

The Industrial Automation and Control Systems market is extensively segmented to reflect the diverse applications, technologies, and components that comprise this complex industry. This segmentation provides a granular view of market dynamics, allowing stakeholders to understand specific growth areas and technological preferences. Key segmentation categories typically include component type, automation type, end-use industry, and function, each revealing unique market characteristics and growth drivers. Understanding these segments is crucial for strategic planning, product development, and market entry decisions, as different industries and applications demand tailored automation solutions. The interplay between these segments also highlights the cross-functional nature of modern industrial operations, where hardware, software, and services converge to create integrated automation ecosystems.

- Component:

- Industrial Robots

- Control Systems

- Distributed Control System (DCS)

- Supervisory Control and Data Acquisition (SCADA)

- Programmable Logic Controller (PLC)

- Human Machine Interface (HMI)

- Manufacturing Execution System (MES)

- Industrial Safety Systems

- Sensors

- Actuators

- Field Devices

- Communication Protocols (Industrial Ethernet, Wireless)

- Industrial Software (CAD/CAM, ERP, Asset Performance Management)

- Services (Consulting, System Integration, Maintenance, Training)

- Type:

- Process Automation

- Discrete Automation

- Industry:

- Automotive

- Food and Beverage

- Oil and Gas

- Pharmaceuticals and Biotechnology

- Chemicals

- Power Generation and Utilities

- Metals and Mining

- Water and Wastewater Treatment

- Electronics and Semiconductors

- Packaging

- Aerospace and Defense

- Function:

- Operations Management

- Field Device Control

- Enterprise Resource Planning (ERP) Integration

- Quality Control and Inspection

- Predictive Maintenance

Value Chain Analysis For Industrial Automation and Control Systems Market

The value chain for the Industrial Automation and Control Systems market is intricate, encompassing various stages from raw material sourcing to end-user implementation and ongoing support. At the upstream stage, the value chain begins with raw material suppliers providing essential components such as metals, plastics, and electronic materials. This then progresses to specialized component manufacturers who produce microprocessors, sensors, actuators, industrial cameras, communication modules, and power supply units. Software developers also play a crucial upstream role, creating the operating systems, algorithms, and application-specific programs that form the intelligence layer of automation systems. These diverse suppliers and manufacturers form the foundational backbone, ensuring the availability of high-quality, specialized parts necessary for building complex industrial automation solutions.

The midstream of the value chain involves the design, assembly, and manufacturing of integrated automation solutions. This includes the development and production of programmable logic controllers (PLCs), distributed control systems (DCS), supervisory control and data acquisition (SCADA) units, human machine interfaces (HMIs), and various types of industrial robots. System integrators are a critical link in this stage, responsible for combining different hardware and software components from various vendors into a cohesive, functional system tailored to specific industrial requirements. They bridge the gap between component manufacturers and end-users, ensuring seamless interoperability and optimal performance. This stage also includes the development of industrial software platforms and cybersecurity solutions vital for protecting operational technology (OT) networks.

The downstream segment primarily focuses on the distribution, installation, and post-sales support of IACS. Distribution channels are varied, including direct sales from major automation vendors to large industrial clients, as well as indirect channels through a network of distributors, resellers, and value-added resellers (VARs) who cater to smaller businesses or specific regional markets. Once systems are sold, installation, commissioning, and ongoing maintenance services become paramount. This includes preventive maintenance, troubleshooting, upgrades, and providing training to operators. After-sales support, including technical assistance and spare parts supply, ensures the longevity and efficient operation of the installed systems. The strong presence of both direct and indirect channels allows for broad market reach and caters to diverse customer needs, from large-scale project implementations to ongoing operational support.

Industrial Automation and Control Systems Market Potential Customers

The potential customer base for Industrial Automation and Control Systems is incredibly broad and diverse, spanning virtually every sector that relies on precision, efficiency, and scale in its operations. At its core, any industrial entity seeking to optimize production processes, reduce operational costs, enhance safety, and improve product quality is a prospective buyer. This includes a wide array of manufacturing facilities that range from heavy industries to light assembly. Companies across the automotive sector are significant customers, utilizing automation for everything from robotic welding and painting to assembly line control and quality inspection. The food and beverage industry leverages automation for consistent product formulation, packaging, and supply chain management, ensuring hygiene and regulatory compliance.

Process industries form another critical segment of potential customers. This includes the vast oil and gas sector, where automation is essential for upstream exploration, midstream transportation, and downstream refining, ensuring safety in hazardous environments and optimizing resource extraction. Similarly, chemical manufacturers rely on advanced control systems for precise temperature, pressure, and flow management in complex reactions. Power generation and utility companies utilize IACS for efficient grid management, power plant operations, and renewable energy integration. The pharmaceutical and biotechnology industries require stringent automation for sterile processing, batch consistency, and regulatory traceability in drug manufacturing and research.

Beyond these major sectors, other significant end-users include metals and mining operations that employ automation for material handling, processing, and safety in challenging environments. Water and wastewater treatment plants depend on control systems for efficient filtration, chemical dosing, and environmental compliance. The electronics and semiconductor industries use highly precise automation for microchip manufacturing and component assembly. Furthermore, companies in the packaging industry, logistics and warehousing, and even specialized sectors like aerospace and defense, all represent substantial potential customers for tailored industrial automation and control solutions, as they continually seek to streamline operations and enhance competitiveness through technological advancement.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 220.5 Billion |

| Market Forecast in 2032 | USD 395.9 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., Siemens AG, Rockwell Automation Inc., Schneider Electric SE, Honeywell International Inc., Emerson Electric Co., Mitsubishi Electric Corporation, FANUC Corporation, Yaskawa Electric Corporation, KUKA AG, Yokogawa Electric Corporation, Omron Corporation, Dassault Systèmes SE, Bosch Rexroth AG, Eaton Corporation plc, GE Digital, Advantech Co., Ltd., Cognex Corporation, Endress+Hauser Group Services AG, Fuji Electric Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Automation and Control Systems Market Key Technology Landscape

The Industrial Automation and Control Systems market is characterized by a rapidly evolving technological landscape, driven by the relentless pursuit of greater efficiency, intelligence, and connectivity in industrial operations. At the forefront of this evolution is the Industrial Internet of Things (IIoT), which forms the backbone of interconnected smart factories by enabling devices, sensors, and machines to collect and exchange data in real-time. This pervasive connectivity is complemented by advancements in cloud computing and edge computing, allowing for both centralized, scalable data processing and localized, low-latency decision-making, crucial for critical industrial applications. These foundational technologies facilitate the seamless integration of various components within an automation system, enhancing overall operational visibility and control.

Artificial Intelligence (AI) and Machine Learning (ML) are increasingly becoming integral to modern IACS, moving beyond traditional control logic to enable predictive analytics, adaptive control, and autonomous operations. AI algorithms are used for pattern recognition in sensor data, facilitating predictive maintenance by identifying potential equipment failures before they occur, thereby minimizing costly downtime. Machine learning also optimizes process parameters in real-time, improving product quality, reducing waste, and enhancing energy efficiency. Furthermore, the development of digital twin technology, which creates virtual replicas of physical assets and processes, allows for simulation, analysis, and optimization in a risk-free environment, leading to more informed operational strategies and improved system design and performance before physical deployment.

The role of advanced robotics continues to expand, with collaborative robots (cobots) and mobile robots becoming more prevalent across industries, working alongside human operators or autonomously navigating factory floors for material handling and assembly tasks. Cybersecurity solutions are no longer an afterthought but a critical component of the IACS technology landscape, protecting interconnected OT networks from sophisticated cyber threats and ensuring operational integrity. Big data analytics tools are essential for extracting actionable insights from the vast amounts of data generated by automated systems, supporting continuous improvement and strategic decision-making. Lastly, the adoption of 5G connectivity is poised to revolutionize industrial communication, offering ultra-low latency, high bandwidth, and massive device connectivity, which will unlock new possibilities for real-time control, remote operations, and highly distributed automation architectures.

Regional Highlights

- North America: This region is a leading adopter of advanced industrial automation technologies, driven by a strong focus on enhancing manufacturing competitiveness, significant investments in research and development, and a growing emphasis on digital transformation initiatives. The presence of key technology providers and early adoption of Industry 4.0 concepts, particularly in the automotive, aerospace, and oil and gas sectors, contribute to its robust market position.

- Europe: European countries, especially Germany, are at the forefront of the Industry 4.0 movement, characterized by a strong push for smart factories, sustainable manufacturing practices, and stringent regulatory frameworks for quality and environmental compliance. The region benefits from a highly skilled workforce and government-backed initiatives promoting automation and digitalization, particularly in the automotive, machinery, and pharmaceutical industries.

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market for Industrial Automation and Control Systems, primarily fueled by rapid industrialization, extensive manufacturing activities, and substantial government investments in infrastructure development. Countries like China, India, Japan, and South Korea are key contributors, driven by expanding consumer markets, increasing labor costs, and a strong drive for technological modernization across diverse sectors including electronics, automotive, and chemicals.

- Latin America: This region is experiencing steady growth in IACS adoption, mainly driven by investments in natural resource processing industries such as mining, oil and gas, and agriculture. Efforts to modernize aging infrastructure and improve operational efficiencies, coupled with increasing foreign investments in manufacturing, are contributing to market expansion, albeit at a slower pace compared to APAC.

- Middle East and Africa (MEA): The MEA region is witnessing significant investments in industrial automation, particularly in the oil and gas sector, which remains a cornerstone of its economy. There is also a growing push towards economic diversification and the development of smart cities and advanced manufacturing capabilities, creating new opportunities for IACS solutions. However, political instability and a nascent technological infrastructure in some areas can present challenges.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Automation and Control Systems Market.- ABB Ltd.

- Siemens AG

- Rockwell Automation Inc.

- Schneider Electric SE

- Honeywell International Inc.

- Emerson Electric Co.

- Mitsubishi Electric Corporation

- FANUC Corporation

- Yaskawa Electric Corporation

- KUKA AG

- Yokogawa Electric Corporation

- Omron Corporation

- Dassault Systèmes SE

- Bosch Rexroth AG

- Eaton Corporation plc

- GE Digital

- Advantech Co., Ltd.

- Cognex Corporation

- Endress+Hauser Group Services AG

- Fuji Electric Co., Ltd.

Frequently Asked Questions

What is industrial automation and why is it important?

Industrial automation involves using control systems, such as computers or robots, and information technologies to handle different processes and machinery in an industry to replace human intervention. It is crucial for enhancing efficiency, reducing operational costs, improving safety, and ensuring consistency and quality in production.

How is Industry 4.0 impacting the Industrial Automation and Control Systems market?

Industry 4.0 is profoundly impacting the market by driving the integration of advanced automation with digital technologies like IoT, AI, and cloud computing. This fosters smart factories capable of real-time data exchange, self-optimization, and autonomous operations, leading to higher productivity and flexible manufacturing.

What are the primary challenges facing the adoption of industrial automation?

Key challenges include the high initial investment required for advanced systems, the complexity of integrating new automation with existing legacy infrastructure, significant cybersecurity risks for interconn

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager