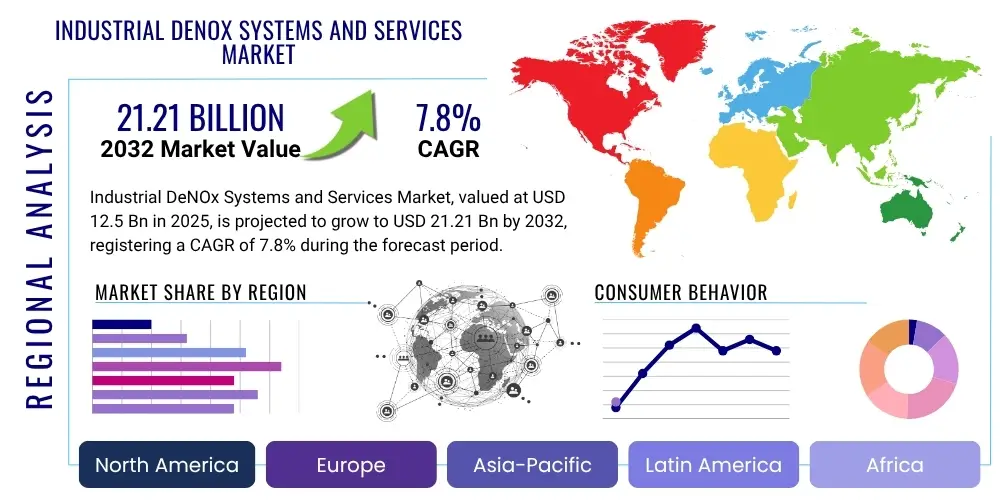

Industrial DeNOx Systems and Services Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429550 | Date : Nov, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Industrial DeNOx Systems and Services Market Size

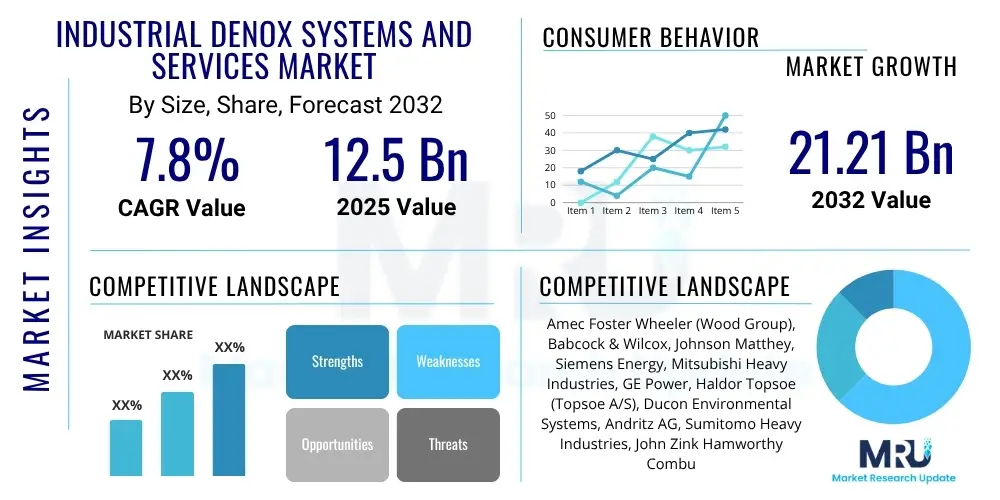

The Industrial DeNOx Systems and Services Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at USD 12.5 Billion in 2025 and is projected to reach USD 21.21 Billion by the end of the forecast period in 2032.

Industrial DeNOx Systems and Services Market introduction

The Industrial DeNOx Systems and Services Market encompasses technologies and solutions designed to reduce nitrogen oxide (NOx) emissions generated by various industrial processes. Nitrogen oxides are hazardous air pollutants contributing to acid rain, smog, and respiratory issues. DeNOx systems are critical for environmental compliance and public health, especially in heavy industries. These systems typically involve chemical processes to convert NOx into harmless nitrogen and water.

Major applications for DeNOx systems include power generation facilities (coal, gas, and biomass fired power plants), cement production plants, glass manufacturing, iron and steel industries, chemical processing, and oil refineries. The market offers a range of technologies such as Selective Catalytic Reduction (SCR), Selective Non-Catalytic Reduction (SNCR), and Low NOx Burners, each tailored to specific industrial requirements regarding temperature, flue gas composition, and desired efficiency. These systems are essential for industries to meet stringent air quality standards imposed by environmental protection agencies globally.

The primary benefits of implementing industrial DeNOx systems include significant reduction in harmful NOx emissions, compliance with evolving environmental regulations, improved air quality, and enhanced corporate social responsibility. The driving factors for this market are predominantly stringent environmental policies and regulations worldwide aimed at curbing air pollution, increasing industrialization and energy consumption, and growing awareness regarding the adverse health effects of air pollutants. Additionally, technological advancements leading to more efficient and cost-effective DeNOx solutions further propel market growth.

Industrial DeNOx Systems and Services Market Executive Summary

The Industrial DeNOx Systems and Services Market is experiencing robust growth, driven primarily by escalating global environmental concerns and tightening regulatory frameworks. Business trends indicate a strong demand for advanced Selective Catalytic Reduction (SCR) technologies due to their high efficiency in NOx removal, alongside a growing retrofit market for existing industrial facilities seeking to upgrade their emissions control systems. Manufacturers are focusing on developing more durable catalysts and integrated solutions that offer enhanced performance, lower operational costs, and ease of maintenance. The industry is also witnessing an increase in partnerships and collaborations aimed at innovation and market expansion, particularly in emerging industrial hubs.

Regionally, Asia Pacific is anticipated to dominate the market share, fueled by rapid industrial expansion, increasing energy demand, and a growing emphasis on environmental protection, especially in countries like China and India. Europe and North America continue to be significant markets, primarily driven by stringent emission standards and the demand for upgrades and services for their aging industrial infrastructure. Latin America, the Middle East, and Africa are showing promising growth, as new industrial projects in these regions increasingly incorporate advanced DeNOx solutions from the outset to meet evolving local and international standards.

Segment-wise, the power generation and cement industries remain the largest end-users of DeNOx systems, given their substantial NOx emissions. The SCR technology segment is expected to maintain its leadership position due to superior efficiency and widespread adoption across diverse applications. Furthermore, the services segment, including installation, maintenance, and consulting, is projected to expand significantly as industries seek expert support to ensure optimal performance and compliance of their DeNOx installations. The overarching trend points towards integrated, data-driven solutions that offer both emission reduction and operational efficiency.

AI Impact Analysis on Industrial DeNOx Systems and Services Market

User inquiries frequently revolve around how Artificial Intelligence (AI) can revolutionize the efficiency, cost-effectiveness, and operational stability of Industrial DeNOx Systems. Common questions include the potential for AI to optimize catalyst performance, predict maintenance needs, and enable real-time adjustments for fluctuating industrial loads. Users are keen to understand if AI can reduce the consumption of reducing agents like ammonia or urea, minimize downtime, and ensure consistent compliance with emission limits. The prevailing expectation is that AI will introduce a new era of smart, adaptive, and highly efficient DeNOx solutions, moving beyond traditional static operational models to dynamic, data-driven control systems.

- AI enables predictive maintenance of DeNOx systems, anticipating component failures and optimizing service schedules, thereby minimizing downtime.

- Real-time optimization of reagent injection (e.g., ammonia or urea) based on flue gas analysis and operational conditions, improving NOx removal efficiency.

- Enhanced process control and fault detection capabilities, allowing for quicker identification and resolution of operational anomalies.

- Advanced data analytics for performance monitoring, identifying trends, and providing insights for long-term system improvements.

- Development of autonomous or semi-autonomous DeNOx operations, reducing the need for continuous human intervention.

- Improved compliance reporting and environmental performance tracking through automated data collection and analysis.

- Potential for energy consumption optimization within DeNOx processes by intelligently controlling fan speeds, heaters, and other auxiliary equipment.

- Facilitates the development of smarter, more responsive catalyst management strategies, extending catalyst lifespan.

DRO & Impact Forces Of Industrial DeNOx Systems and Services Market

The Industrial DeNOx Systems and Services Market is significantly shaped by a confluence of drivers, restraints, and opportunities, all influenced by various impact forces. The primary drivers are the increasing stringency of global environmental regulations aimed at controlling air pollution, particularly NOx emissions, which compel industries to invest in or upgrade their DeNOx systems. Rapid industrialization and urbanization, especially in developing economies, contribute to higher energy demands and consequently increased emissions, further boosting the need for effective DeNOx solutions. Additionally, growing public awareness regarding the adverse health effects of air pollutants exerts pressure on industries and governments to adopt cleaner technologies. The pursuit of greater energy efficiency and sustainability goals within industries also motivates the adoption of optimized DeNOx technologies.

However, the market faces several restraints. The high capital expenditure associated with installing advanced DeNOx systems, particularly SCR, can be a significant barrier for smaller industries or those with tight budget constraints. Operational costs, including the continuous consumption of reducing agents (like ammonia or urea) and catalyst replacement, also contribute to the overall economic burden. Technological complexities in designing and integrating DeNOx systems into diverse industrial setups, along with the need for skilled labor for operation and maintenance, pose additional challenges. Furthermore, the availability and cost fluctuations of critical raw materials for catalysts can impact manufacturing costs and market stability.

Despite these restraints, ample opportunities exist for market expansion. The growing demand for retrofitting existing industrial plants with modern DeNOx technologies presents a substantial market segment, especially in regions with older industrial infrastructure. Emerging economies offer significant growth potential as they ramp up industrial production and concurrently strengthen their environmental protection policies. Research and development in advanced catalyst materials with improved efficiency and longer lifespans, as well as the integration of digital technologies like IoT and AI for performance optimization, open new avenues for market players. The trend towards cleaner energy production and waste-to-energy solutions also creates new demand for sophisticated emission control systems.

Segmentation Analysis

The Industrial DeNOx Systems and Services Market is extensively segmented to reflect the diverse technologies, end-use applications, and service requirements across various industrial sectors. This segmentation provides a granular view of market dynamics, enabling a more precise analysis of trends, opportunities, and competitive landscapes. Understanding these segments is crucial for stakeholders to tailor their product offerings, marketing strategies, and investment decisions, addressing specific needs of different industrial clients and regional regulatory environments. The market is primarily categorized by the type of technology employed, the specific industries utilizing these systems, and the range of services offered alongside the core equipment.

- By Technology:

- Selective Catalytic Reduction (SCR)

- Selective Non-Catalytic Reduction (SNCR)

- Low NOx Burners

- Others (e.g., Flue Gas Recirculation, Over Fire Air, Wet Scrubbers, Adsorption)

- By End-Use Industry:

- Power Generation (Coal, Gas, Biomass)

- Cement

- Glass

- Iron and Steel

- Chemical

- Refineries

- Waste-to-Energy

- Marine

- Other Industrial Boilers

- By Services:

- Installation and Commissioning

- Maintenance and Repair

- Consulting and Engineering

- Operations and Monitoring

- Catalyst Management and Recycling

Value Chain Analysis For Industrial DeNOx Systems and Services Market

The value chain for the Industrial DeNOx Systems and Services Market encompasses several critical stages, from the sourcing of raw materials to the end-use and post-sales support, illustrating the flow of value creation. At the upstream end, the chain begins with suppliers of essential raw materials and components. This includes manufacturers of catalyst materials (such as titanium dioxide, vanadium pentoxide, tungsten oxides, zeolite), suppliers of reducing agents (ammonia, urea), and producers of specialized components like reactors, heat exchangers, blowers, pumps, control systems, and sensors. These upstream activities are crucial for the quality and cost-effectiveness of the final DeNOx systems.

Midstream activities involve the design, engineering, and manufacturing of the DeNOx systems themselves. This stage is dominated by specialized engineering firms and equipment manufacturers who integrate various components and technologies (SCR reactors, SNCR injection systems, Low NOx burners) into complete, functional solutions. This often involves extensive R&D to improve efficiency, reduce emissions, and optimize system footprint. The distribution channel then facilitates the delivery of these systems and related services to end-users. This typically involves a combination of direct sales from manufacturers, a network of distributors, and collaborations with Engineering, Procurement, and Construction (EPC) contractors who integrate DeNOx solutions into larger industrial projects.

Downstream activities focus on the installation, commissioning, operation, and maintenance of the DeNOx systems at the client's site. This involves specialized service providers who ensure proper setup, system optimization, troubleshooting, and ongoing performance monitoring. Post-sales services, including technical support, spare parts supply, and catalyst replacement or regeneration, are vital for ensuring long-term system efficiency and regulatory compliance. Direct channels involve manufacturers selling and servicing their systems directly to large industrial clients, while indirect channels utilize third-party distributors, system integrators, and EPC firms to reach a broader customer base, particularly for complex or geographically dispersed projects.

Industrial DeNOx Systems and Services Market Potential Customers

The potential customers for Industrial DeNOx Systems and Services span a wide array of heavy industrial sectors that generate significant nitrogen oxide (NOx) emissions as a byproduct of their operations. These end-users are driven by the necessity to comply with environmental regulations, improve air quality, and enhance their operational sustainability. The diversity of industrial processes means that DeNOx solutions must often be customized to suit specific flue gas compositions, temperature profiles, and spatial constraints.

Key segments of end-users include thermal power generation plants, which often burn coal, natural gas, or biomass, resulting in substantial NOx output. Cement manufacturers are another major customer group, as their kiln operations are a significant source of these pollutants. Similarly, the glass manufacturing industry, with its high-temperature furnaces, requires robust DeNOx solutions. Iron and steel mills, chemical processing plants involved in the production of nitric acid or fertilizers, and petroleum refineries also represent large markets due to their complex and emissions-intensive processes. Furthermore, waste-to-energy facilities and marine vessels, which face increasingly strict emissions standards, are emerging as important customer bases for advanced DeNOx technologies.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 12.5 Billion |

| Market Forecast in 2032 | USD 21.21 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Amec Foster Wheeler (Wood Group), Babcock & Wilcox, Johnson Matthey, Siemens Energy, Mitsubishi Heavy Industries, GE Power, Haldor Topsoe (Topsoe A/S), Ducon Environmental Systems, Andritz AG, Sumitomo Heavy Industries, John Zink Hamworthy Combustion, KBR Inc., Yara International, Thermax Limited, Veolia, Fuel Tech Inc., CRI Catalyst Company, Cormetech Inc., BASF SE, CECO Environmental |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial DeNOx Systems and Services Market Key Technology Landscape

The technological landscape of the Industrial DeNOx Systems and Services Market is characterized by a blend of established and emerging solutions, all aimed at effectively mitigating nitrogen oxide emissions. The most prevalent technology is Selective Catalytic Reduction (SCR), which involves injecting a reducing agent (typically anhydrous ammonia, aqueous ammonia, or urea) into the flue gas stream in the presence of a catalyst. The catalyst facilitates a chemical reaction that converts NOx into harmless nitrogen gas and water vapor at relatively lower temperatures, offering high removal efficiencies and making it a preferred choice for stringent emission control requirements across various industries.

Another significant technology is Selective Non-Catalytic Reduction (SNCR), which also uses a reducing agent but operates at higher temperatures (typically 850°C to 1100°C) without the need for a catalyst. While SNCR generally offers lower NOx reduction efficiencies compared to SCR, its lower capital cost and simpler installation make it suitable for certain applications. Low NOx Burners represent a primary combustion modification technique that reduces NOx formation at the source by optimizing the combustion process, such as staging air or fuel, thereby lowering flame temperatures and oxygen availability in the primary combustion zone. These are often used as a primary control measure, sometimes in conjunction with post-combustion DeNOx systems for even greater reduction.

Beyond these core technologies, the market is increasingly integrating advanced monitoring and control systems, including continuous emissions monitoring systems (CEMS) to track performance in real-time. Emerging technologies focus on improving catalyst durability, developing novel catalyst materials with enhanced resistance to poisoning, and exploring non-thermal plasma or electron beam technologies for niche applications. Furthermore, the adoption of digital solutions like IoT sensors, big data analytics, and Artificial Intelligence (AI) is transforming the operational efficiency of DeNOx systems, enabling predictive maintenance, dynamic process optimization, and smart reagent management to ensure sustained compliance and reduce operational costs.

Regional Highlights

- North America: This region is characterized by mature industrial sectors and some of the world's most stringent environmental regulations, particularly those set by the U.S. Environmental Protection Agency (EPA). The market here is driven by the need for compliance, upgrades of aging infrastructure, and a focus on advanced, efficient DeNOx solutions. Strong R&D capabilities and technological innovation further support market growth.

- Europe: Driven by ambitious climate targets and comprehensive directives such as the Industrial Emissions Directive (IED), Europe represents a significant market. Countries like Germany, the UK, and France show high adoption rates, with a strong emphasis on sustainable practices and circular economy principles. The region is a leader in developing innovative catalyst technologies and integrated emission control solutions.

- Asia Pacific (APAC): Expected to be the fastest-growing region, APAC's market expansion is fueled by rapid industrialization, increasing energy demand, and growing environmental awareness in major economies like China and India. Government initiatives to combat severe air pollution, coupled with significant investments in new industrial capacities, are accelerating the adoption of DeNOx systems.

- Latin America: This region presents emerging opportunities as industrial sectors, particularly in mining, oil and gas, and power generation, expand. While regulations are evolving, there is a growing recognition of the need for advanced emission control, driving demand for new installations and retrofits in countries like Brazil and Mexico.

- Middle East and Africa (MEA): The MEA region is experiencing industrial diversification and growth, particularly in petrochemicals, power, and manufacturing. With new industrial projects being commissioned, there is an increasing demand for DeNOx systems to meet developing environmental standards and ensure sustainable industrial development.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial DeNOx Systems and Services Market.- Amec Foster Wheeler (Wood Group)

- Babcock & Wilcox

- Johnson Matthey

- Siemens Energy

- Mitsubishi Heavy Industries

- GE Power

- Haldor Topsoe (Topsoe A/S)

- Ducon Environmental Systems

- Andritz AG

- Sumitomo Heavy Industries

- John Zink Hamworthy Combustion

- KBR Inc.

- Yara International

- Thermax Limited

- Veolia

- Fuel Tech Inc.

- CRI Catalyst Company

- Cormetech Inc.

- BASF SE

- CECO Environmental

Frequently Asked Questions

What are industrial DeNOx systems?

Industrial DeNOx systems are technologies designed to remove harmful nitrogen oxides (NOx) from the exhaust gases of various industrial processes, playing a crucial role in air pollution control and environmental compliance.

What is the primary difference between SCR and SNCR technologies?

Selective Catalytic Reduction (SCR) utilizes a catalyst at lower temperatures (200-450°C) to convert NOx, offering higher efficiency. Selective Non-Catalytic Reduction (SNCR) operates at higher temperatures (850-1100°C) without a catalyst but typically achieves lower NOx removal rates.

Which industries are the largest consumers of DeNOx systems?

The largest consumers are industries with high NOx emissions, including power generation (coal, gas, biomass), cement manufacturing, glass production, iron and steel mills, chemical processing, and oil refining.

What are the main drivers for the growth of the DeNOx market?

Key drivers include increasingly stringent environmental regulations globally, rapid industrialization and urbanization leading to higher emissions, and growing public awareness regarding the adverse health impacts of air pollution.

How is Artificial Intelligence (AI) impacting DeNOx system operations?

AI is enhancing DeNOx systems by enabling real-time process optimization, predictive maintenance, precise reagent injection, and intelligent fault detection, leading to improved efficiency, reduced operational costs, and consistent regulatory compliance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager