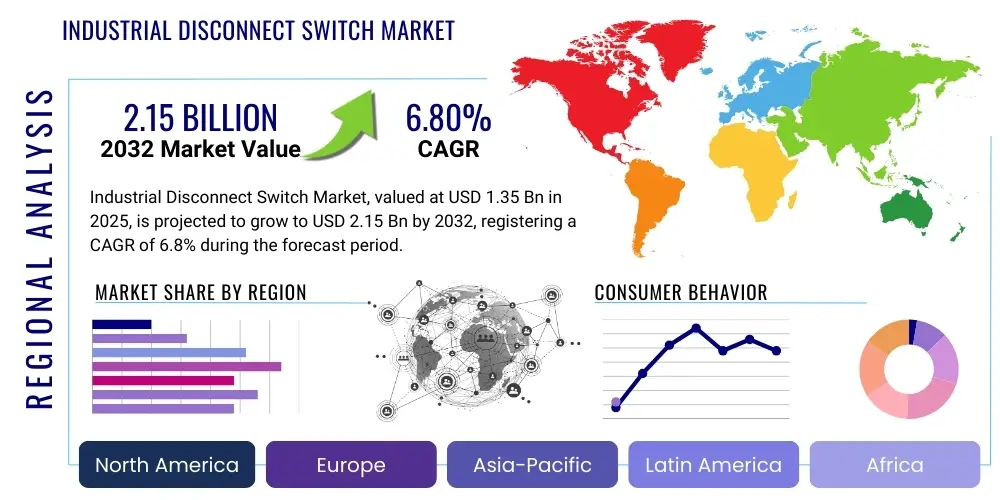

Industrial Disconnect Switch Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427734 | Date : Oct, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Industrial Disconnect Switch Market Size

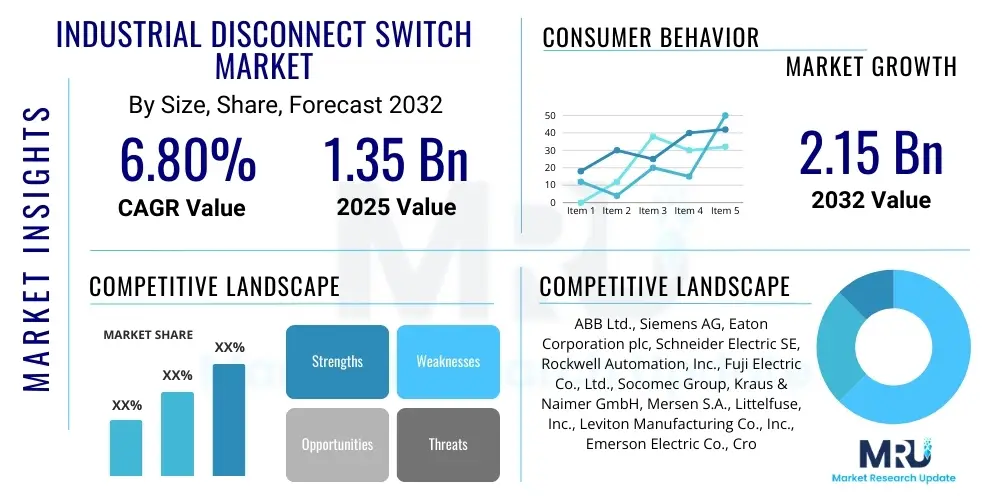

The Industrial Disconnect Switch Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 1.35 billion in 2025 and is projected to reach USD 2.15 billion by the end of the forecast period in 2032.

Industrial Disconnect Switch Market introduction

The Industrial Disconnect Switch Market encompasses devices designed to safely isolate electrical circuits in industrial settings, ensuring the complete shutdown of power for maintenance, repair, or emergency situations. These critical components are fundamental for operational safety, preventing electrical shocks and equipment damage. Disconnect switches are essentially manual power switches that break or make an electrical circuit, often visible to confirm the open circuit state.

The primary applications of industrial disconnect switches span across various heavy industries, including manufacturing plants, power generation facilities, oil and gas refineries, chemical processing units, and mining operations. They are indispensable for motor control centers, machinery isolation, and main service entrances, providing a clear and reliable means to de-energize equipment. Benefits include enhanced worker safety, compliance with stringent electrical codes, increased equipment longevity by preventing overloads, and facilitating efficient maintenance procedures without risking continuous power flow.

Key driving factors for market growth include the escalating global demand for industrial automation, which necessitates robust safety mechanisms, and the increasing stringency of workplace safety regulations worldwide. Furthermore, rapid industrialization in emerging economies, coupled with significant investments in infrastructure development and renewable energy projects, continues to fuel the adoption of these essential safety devices, ensuring reliable and secure electrical distribution within complex industrial environments.

Industrial Disconnect Switch Market Executive Summary

The Industrial Disconnect Switch Market is currently experiencing dynamic shifts driven by evolving industrial landscapes and technological advancements. Key business trends include a growing emphasis on smart disconnect solutions integrated with IoT for enhanced monitoring and remote control, a rising demand for specialized switches catering to harsh environmental conditions, and an increased focus on energy efficiency. Manufacturers are innovating to offer more compact, modular, and customizable solutions, addressing the diverse needs of various industrial sectors while optimizing installation and operational costs. Strategic partnerships and mergers and acquisitions are also prevalent as companies seek to expand their product portfolios and geographical reach.

Regionally, Asia-Pacific is projected to exhibit the highest growth, propelled by rapid industrialization, burgeoning manufacturing sectors, and substantial investments in infrastructure development, particularly in countries like China, India, and Southeast Asian nations. North America and Europe, while mature markets, continue to demonstrate steady growth, primarily driven by stringent safety regulations, the modernization of existing industrial facilities, and the adoption of advanced technologies for operational efficiency. The Middle East and Africa, along with Latin America, are emerging as significant markets due to increasing investments in oil and gas, mining, and renewable energy projects, necessitating robust electrical safety infrastructure.

Segment-wise, the market is witnessing significant traction in the fused disconnect switch segment due to their inherent overcurrent protection capabilities, essential for safeguarding expensive industrial machinery. The low voltage segment continues to dominate in terms of volume, driven by widespread applications across various industrial settings, while the medium and high voltage segments are poised for considerable growth with expanding power generation and distribution networks. End-use industries such as power generation, manufacturing, and oil & gas remain the largest contributors, reflecting the critical role of disconnect switches in their operational safety and continuity. The trend towards sustainable and eco-friendly products also influences material choices and manufacturing processes within the segment.

AI Impact Analysis on Industrial Disconnect Switch Market

The integration of Artificial Intelligence (AI) is poised to significantly transform the Industrial Disconnect Switch Market, primarily by enhancing predictive maintenance, optimizing operational efficiency, and bolstering safety protocols. Users frequently inquire about how AI can improve the reliability and longevity of these critical components, mitigate potential failures, and reduce downtime. There is also considerable interest in AIs role in enabling smart grid functionalities, remote diagnostics, and automated fault detection, addressing concerns about complex installations and the need for continuous monitoring in increasingly autonomous industrial environments. Cybersecurity implications of connected AI-driven systems are also a key user concern.

AIs influence extends to providing real-time data analysis from sensors integrated into disconnect switches, allowing for anomaly detection and proactive maintenance scheduling. This capability minimizes unexpected outages, thereby improving overall system reliability and asset utilization. Furthermore, AI algorithms can analyze historical performance data and environmental factors to predict the remaining useful life of switches, facilitating more informed replacement decisions and preventing catastrophic failures. The technology is also expected to contribute to more adaptive and responsive safety systems, where disconnect switches can be automatically activated or deactivated based on AI-driven risk assessments, moving towards a more intelligent and autonomous industrial safety framework.

- Enhanced predictive maintenance and fault detection through real-time data analysis.

- Optimized operational efficiency via remote monitoring and AI-driven control of disconnect actions.

- Improved safety by predicting potential failures and enabling proactive intervention.

- Integration with smart grid systems for intelligent energy management and load balancing.

- Development of self-diagnosing disconnect switches capable of reporting their status.

- Reduced downtime and maintenance costs through condition-based monitoring.

- Potential for automated compliance checks and reporting based on operational data.

DRO & Impact Forces Of Industrial Disconnect Switch Market

The Industrial Disconnect Switch Market is shaped by a complex interplay of drivers, restraints, opportunities, and broader impact forces. Key drivers include the global push for industrial automation and modernization, leading to increased demand for reliable electrical safety equipment. Stringent safety regulations and industrial standards, such as those set by OSHA, IEC, and NFPA, mandate the use of disconnect switches, thereby underpinning market growth. Additionally, the expansion of manufacturing sectors in emerging economies, coupled with significant investments in renewable energy infrastructure and smart grid projects, further propels the adoption of these essential devices, ensuring safe and efficient power isolation.

However, the market also faces several restraints. The high initial investment cost associated with advanced disconnect switches, particularly for specialized applications or high-voltage systems, can deter smaller enterprises. The technical complexity involved in the installation, integration, and maintenance of these switches, especially for smart or networked systems, poses challenges, requiring specialized expertise. Furthermore, intense price competition among manufacturers and the potential for product commoditization in certain segments can exert downward pressure on profit margins, compelling companies to focus on differentiation through innovation and value-added services.

Opportunities for market expansion are significant, driven by the increasing adoption of IoT and AI in industrial settings, which allows for the development of smart, connected disconnect switches offering remote monitoring, diagnostics, and predictive maintenance capabilities. The growing demand for sustainable and energy-efficient solutions encourages innovation in materials and designs that reduce energy consumption and environmental impact. Expansion into untapped emerging markets, particularly in sectors undergoing rapid industrialization or infrastructure development, presents lucrative growth avenues. Strategic partnerships and collaborations for offering integrated solutions, combining disconnect switches with other electrical control components, also represent a key opportunity to capture a larger market share and provide comprehensive offerings to end-users.

Segmentation Analysis

The Industrial Disconnect Switch Market is broadly segmented based on several critical parameters, including type, voltage, end-use industry, and mounting type. This detailed segmentation allows for a granular understanding of market dynamics, specific product demands, and regional adoption patterns. Each segment addresses distinct operational requirements and safety considerations within diverse industrial environments, reflecting the versatile nature and application range of these indispensable electrical components.

- By Type: Fused Disconnect Switches, Non-Fused Disconnect Switches.

- By Voltage: Low Voltage (Up to 1 kV), Medium Voltage (1 kV to 36 kV), High Voltage (Above 36 kV).

- By End-Use Industry: Manufacturing, Power Generation & Utilities, Oil & Gas, Mining, Chemical & Petrochemical, Food & Beverage, Data Centers, Infrastructure, Others.

- By Mounting Type: Panel Mounted, Wall Mounted, Enclosed, DIN Rail Mounted.

Industrial Disconnect Switch Market Value Chain Analysis

The value chain of the Industrial Disconnect Switch Market begins with upstream activities involving the procurement of raw materials and components. This stage includes sourcing metals like copper, aluminum, and steel, as well as plastics, ceramics, and advanced composite materials for housing and insulating parts. Key component suppliers provide contactors, fuses, operating mechanisms, and advanced electronic modules for smart switches. The quality and availability of these materials directly impact the manufacturing process and the final products performance and cost-effectiveness. Establishing robust relationships with reliable suppliers is crucial for maintaining production continuity and controlling input costs, especially with fluctuating commodity prices.

Midstream activities encompass the manufacturing, assembly, and testing of the disconnect switches. This involves precision machining, molding, welding, and intricate assembly processes to ensure the devices meet stringent performance and safety standards. Manufacturers invest heavily in R&D to develop innovative designs, improve arc quenching capabilities, enhance modularity, and integrate smart features like IoT connectivity. Rigorous quality control and testing are performed to comply with international certifications such as IEC, UL, and CE, guaranteeing reliability and safety. Manufacturing efficiency and economies of scale play a significant role in determining the competitiveness of products in this stage.

Downstream activities involve the distribution, sales, installation, and after-sales services. Distribution channels are typically a mix of direct sales to large industrial clients and OEMs, and indirect sales through a network of distributors, wholesalers, and electrical contractors. These channels are crucial for reaching a broad customer base and providing localized support. Post-sale services include installation assistance, maintenance, repair, and technical support, which are vital for customer satisfaction and long-term relationships. The efficiency of the distribution network and the responsiveness of service teams significantly influence customer perception and market penetration, ensuring that the disconnect switches are correctly applied and maintained throughout their operational lifecycle.

Industrial Disconnect Switch Market Potential Customers

The Industrial Disconnect Switch Market serves a diverse range of potential customers, primarily entities that operate or maintain complex electrical systems within industrial and commercial environments. These end-users prioritize safety, operational efficiency, and compliance with electrical standards. Key sectors include heavy manufacturing, where machinery isolation is paramount for worker safety during maintenance, and the power generation industry, including conventional, nuclear, and renewable energy plants, which require reliable circuit isolation for grid stability and personnel protection during equipment servicing and upgrades.

Another significant customer segment comprises the oil and gas industry, both upstream and downstream, where explosion-proof and robust disconnect switches are essential for safe operations in hazardous environments. Mining and chemical processing industries similarly demand highly durable and specialized switches capable of withstanding corrosive atmospheres and extreme conditions while ensuring the safe shutdown of critical equipment. Additionally, utility companies, data centers, and large commercial establishments such as hospitals and airports represent crucial buyers, relying on disconnect switches for their main power distribution systems and emergency power cut-off mechanisms, ensuring continuity and safety in their critical operations.

The construction and infrastructure development sectors also represent growing customer bases, as new factories, power plants, and public infrastructure projects necessitate the installation of new electrical distribution systems. OEMs (Original Equipment Manufacturers) of industrial machinery and control panels are also significant purchasers, integrating disconnect switches as standard safety features within their products. The increasing adoption of smart factory concepts and industrial IoT solutions further broadens the customer base, as these technologies often require advanced disconnect switches with integrated communication capabilities for remote monitoring and control, catering to a future-oriented industrial landscape.

Industrial Disconnect Switch Market Key Technology Landscape

The Industrial Disconnect Switch Market is continually evolving with technological advancements aimed at enhancing safety, reliability, and operational intelligence. A significant trend is the integration of Internet of Things (IoT) capabilities, enabling disconnect switches to become smart devices. These IoT-enabled switches are equipped with sensors that monitor parameters such as current, voltage, temperature, and even arc flash events in real-time. This data is then transmitted to a central system or cloud platform for analysis, facilitating remote monitoring, predictive maintenance, and automated fault detection, significantly reducing manual inspection needs and improving response times to potential issues.

Another crucial technological development focuses on improving arc quenching capabilities and overall safety mechanisms. Advanced designs incorporate faster breaking mechanisms and superior contact materials to minimize arc duration during circuit interruption, thereby reducing the risk of arc flash incidents and enhancing operator safety. Furthermore, the development of modular and compact designs allows for easier installation, retrofitting, and space optimization in crowded industrial panels. Features like visible blade contacts provide clear indication of the switchs open status, adding an extra layer of visual safety assurance for maintenance personnel, particularly in critical applications.

The market is also witnessing innovations in robust enclosure technologies and materials, specifically designed to withstand harsh industrial environments, including corrosive atmospheres, extreme temperatures, and hazardous locations. Explosion-proof and dust-ignition-proof certifications are becoming standard requirements for switches deployed in industries such as oil & gas and chemical processing. Moreover, the integration of advanced communication protocols (e.g., Modbus, Ethernet/IP) allows for seamless integration into broader industrial control systems and SCADA networks, paving the way for more interconnected and intelligent electrical distribution systems. These technological strides collectively aim to make disconnect switches more secure, efficient, and integral to modern industrial automation.

Regional Highlights

- Asia-Pacific: Dominates the market due to rapid industrialization, extensive manufacturing sector growth, and significant infrastructure development, especially in China, India, and Southeast Asian countries. High investments in power generation and renewable energy projects further drive demand.

- North America: A mature market characterized by stringent safety regulations, the modernization of aging industrial infrastructure, and a strong focus on industrial automation and smart factory initiatives. High adoption of advanced and smart disconnect switches.

- Europe: Exhibits steady growth, propelled by robust industrial safety standards, emphasis on renewable energy integration, and technological advancements. Germany, France, and the UK are key contributors, focusing on energy efficiency and smart grid solutions.

- Middle East & Africa: Emerging market with substantial growth potential, driven by large-scale investments in oil & gas exploration, infrastructure development, and industrial diversification initiatives. Demand for robust and specialized switches is high due to harsh operating conditions.

- South America: Growing market, primarily influenced by mining activities, expansion of utility infrastructure, and industrial development in countries like Brazil and Argentina. Focus on improving electrical safety and operational efficiency in industrial plants.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Disconnect Switch Market.- ABB Ltd.

- Siemens AG

- Eaton Corporation plc

- Schneider Electric SE

- Rockwell Automation, Inc.

- Fuji Electric Co., Ltd.

- Socomec Group

- Kraus & Naimer GmbH

- Mersen S.A.

- Littelfuse, Inc.

- Leviton Manufacturing Co., Inc.

- Emerson Electric Co.

- Crompton Greaves Consumer Electricals Limited

- Chint Group

- Terasaki Electric Co., Ltd.

Frequently Asked Questions

What is an industrial disconnect switch and why is it crucial?

An industrial disconnect switch is a critical electrical safety device used to completely isolate a circuit or piece of equipment from its power source. It is crucial because it allows for safe maintenance, repair, and inspection by ensuring that machinery is fully de-energized, thereby protecting personnel from electrical shock and preventing damage to equipment. These switches provide a visible means of circuit opening, enhancing safety protocols in industrial environments and ensuring compliance with occupational safety regulations.

What are the primary types of industrial disconnect switches?

The primary types of industrial disconnect switches include fused and non-fused variants. Fused disconnect switches incorporate fuses to provide overcurrent protection in addition to isolation, safeguarding equipment from surges and faults. Non-fused disconnect switches, conversely, offer only circuit isolation without built-in overcurrent protection, relying on upstream protective devices. Further classifications can be made by voltage level (low, medium, high) and mounting type (panel, wall, enclosed), each designed for specific application requirements and operational environments.

How is industrial automation driving the demand for disconnect switches?

Industrial automation drives the demand for disconnect switches by increasing the complexity and interconnectedness of machinery, which necessitates robust and reliable safety mechanisms. As factories become more automated with advanced robotics and production lines, the frequency of maintenance and the potential for electrical faults increase. Disconnect switches are essential for safely isolating individual automated components or entire sections of production lines, enabling technicians to work without the risk of accidental startup or live circuits, thus ensuring uninterrupted and safe automated operations and protecting high-value equipment.

What role does IoT and AI play in the evolution of disconnect switches?

IoT and AI are transforming disconnect switches by enabling them to become smart, connected devices that offer enhanced monitoring, control, and predictive capabilities. IoT integration allows switches to transmit real-time data on their operational status, current loads, and environmental conditions to central systems. AI algorithms then analyze this data to predict potential failures, optimize maintenance schedules, and identify anomalies, thereby preventing unexpected downtime and improving overall reliability. This technological evolution moves disconnect switches beyond simple isolation tools into intelligent components of a smart industrial ecosystem, contributing to advanced safety and operational efficiency.

What are the key growth opportunities in the Industrial Disconnect Switch Market?

Key growth opportunities in the Industrial Disconnect Switch Market stem from several factors. The expanding renewable energy sector, including solar and wind farms, necessitates specialized disconnect switches for safe system integration and maintenance. Additionally, the increasing focus on smart grid infrastructure and energy efficiency solutions creates demand for advanced, connected switches. Untapped markets in developing economies with rapidly growing industrial bases present significant expansion potential. Furthermore, the continuous modernization of existing industrial facilities and the adoption of more stringent safety regulations globally drive consistent demand for new and upgraded disconnect switch technologies, encouraging innovation in design and functionality.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Fused Industrial Disconnect Switch Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Non-Fused Industrial Disconnect Switch Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager