Industrial Humidifier Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430218 | Date : Nov, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Industrial Humidifier Market Size

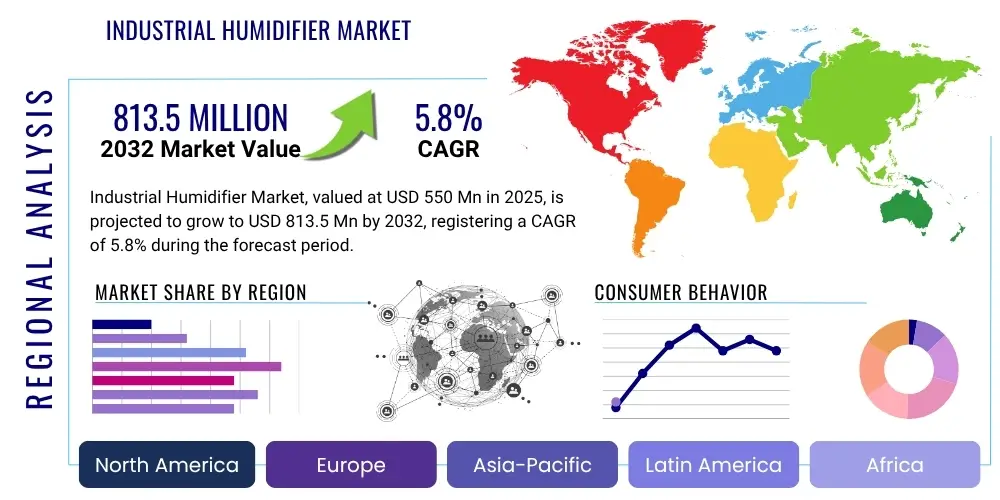

The Industrial Humidifier Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 550 Million in 2025 and is projected to reach USD 813.5 Million by the end of the forecast period in 2032.

Industrial Humidifier Market introduction

The Industrial Humidifier Market encompasses a specialized segment within the broader HVAC and industrial equipment sector, focusing on maintaining optimal humidity levels in diverse commercial and industrial environments. Industrial humidifiers are crucial devices designed to add moisture to the air in large-scale settings, which is essential for various manufacturing processes, preservation of goods, and ensuring health and comfort for personnel. These systems prevent issues such as static electricity buildup, material shrinkage, product damage, and respiratory problems that arise from excessively dry air. The market's significance stems from its direct impact on product quality, operational efficiency, and workplace safety across a multitude of industries.

Products within this market range from sophisticated steam humidifiers, which inject sterile steam directly into the air, to energy-efficient ultrasonic and evaporative systems that generate fine mists or naturally add moisture through water evaporation. Each type offers distinct advantages based on application requirements, energy consumption, and maintenance considerations. Major applications span critical sectors including pharmaceuticals, data centers, textile manufacturing, printing, food processing, agriculture, and healthcare facilities. In these environments, precise humidity control is not merely a comfort factor but a fundamental necessity for process integrity, equipment longevity, and compliance with stringent industry standards. For instance, in data centers, humidification prevents electrostatic discharge which can damage sensitive electronic equipment, while in textile manufacturing, it maintains fabric pliability and reduces thread breakage.

The primary benefits derived from industrial humidification include enhanced product quality, reduced material waste, improved operational efficiency, and a more comfortable and safer working environment. By mitigating static electricity, preserving sensitive materials, and optimizing environmental conditions, these systems contribute significantly to cost savings and higher output. The market is propelled by several driving factors, notably the escalating demand from industries requiring precise environmental control, the increasing adoption of automated manufacturing processes, and a heightened awareness of energy efficiency and sustainable solutions. Additionally, stringent regulatory requirements in sectors like pharmaceuticals and food processing for environmental control further accelerate market expansion, compelling industries to invest in advanced humidification technologies to meet compliance standards and uphold product integrity.

Industrial Humidifier Market Executive Summary

The Industrial Humidifier Market is experiencing robust growth driven by evolving business trends, significant regional expansion, and diversification across various industrial segments. A key business trend shaping the market is the increasing focus on energy efficiency and sustainability. Industrial operators are prioritizing humidification systems that offer lower operational costs through reduced energy consumption and minimal water waste, leading to a surge in demand for evaporative and ultrasonic humidifiers. Furthermore, the integration of smart technologies, such as IoT-enabled sensors and predictive maintenance capabilities, is becoming standard, allowing for real-time monitoring and optimized performance. This shift towards intelligent solutions enhances operational efficiency and reduces downtime, making advanced humidifiers more attractive to end-users seeking greater control and reliability.

Regionally, the Asia Pacific (APAC) market is poised for significant expansion, fueled by rapid industrialization, burgeoning manufacturing sectors, and increasing investments in infrastructure development, particularly in countries like China, India, and Southeast Asian nations. This growth is accompanied by a rising demand for controlled environments in industries such as electronics, textiles, and pharmaceuticals. North America and Europe, while mature markets, continue to demonstrate steady growth, largely due to stringent regulatory standards concerning indoor air quality and process control, as well as a strong emphasis on upgrading existing facilities with more advanced and energy-efficient systems. Latin America and the Middle East and Africa regions are also showing potential, driven by growing industrial bases and increasing awareness of the benefits of precise humidity control.

In terms of segment trends, the market is witnessing a strong preference for ultrasonic humidifiers due to their high energy efficiency, quiet operation, and ability to produce very fine mist without heating, making them ideal for sensitive applications like data centers and healthcare. Steam humidifiers, despite higher energy consumption, remain critical for applications requiring sterile humidification, such as hospitals and pharmaceutical cleanrooms, where bacterial contamination is a significant concern. The application segment is seeing robust growth in data centers, where precise humidity control is essential to prevent static electricity and maintain equipment integrity. Additionally, the pharmaceutical and food processing industries continue to be major consumers, driven by strict quality control and preservation requirements. Overall, the market is characterized by innovation, with manufacturers continually developing more efficient, intelligent, and application-specific humidification solutions.

AI Impact Analysis on Industrial Humidifier Market

Common user questions regarding AI's impact on the Industrial Humidifier Market frequently revolve around how artificial intelligence can enhance efficiency, optimize operational costs, improve predictive maintenance, and integrate with existing smart building management systems. Users are keen to understand if AI can make humidification processes more adaptive and responsive to real-time environmental changes, thereby reducing energy consumption and extending equipment lifespan. There is also significant interest in AI's role in data analysis, allowing for precise control and anomaly detection to prevent failures or suboptimal performance. The overarching expectation is that AI will transform industrial humidification from a reactive maintenance task into a proactive, intelligent, and highly optimized operational component, addressing concerns about energy waste, downtime, and the consistency of environmental conditions.

- AI-driven predictive maintenance: Algorithms analyze operational data from sensors to forecast potential equipment failures, enabling proactive servicing and reducing unexpected downtime.

- Optimized energy consumption: AI systems continuously adjust humidifier output based on real-time environmental conditions, external weather data, and anticipated operational needs, minimizing energy use.

- Enhanced precision control: Machine learning models improve the accuracy of humidity control by learning from historical data and adapting to dynamic environmental factors, ensuring optimal conditions for sensitive processes.

- Integration with Building Management Systems (BMS): AI facilitates seamless communication and coordination between humidifiers and other HVAC components, creating a unified and highly efficient climate control ecosystem.

- Remote monitoring and control: AI-powered platforms enable operators to monitor humidifier performance and adjust settings from any location, improving responsiveness and operational flexibility.

- Automated fault detection and diagnostics: AI can quickly identify operational anomalies, diagnose issues, and even suggest corrective actions, significantly streamlining troubleshooting processes.

- Data-driven insights and reporting: AI analyzes vast amounts of operational data, providing valuable insights into performance trends, efficiency metrics, and compliance adherence, supporting informed decision-making.

- Adaptive learning for diverse applications: AI algorithms can learn and adapt to the specific humidity requirements of different industrial processes, tailoring performance for optimal results in varied settings.

- Improved resource management: AI helps optimize water usage and other consumables by ensuring humidifiers operate at peak efficiency and avoid unnecessary output.

- Enhanced cybersecurity: AI can monitor humidifier network activity for unusual patterns, identifying and mitigating potential cyber threats to connected smart systems.

DRO & Impact Forces Of Industrial Humidifier Market

The Industrial Humidifier Market is shaped by a complex interplay of drivers, restraints, opportunities, and broader impact forces that collectively dictate its growth trajectory and evolutionary path. Key drivers include the escalating demand for stringent environmental control across diverse industrial sectors, necessitated by the need to maintain product quality, ensure operational efficiency, and comply with increasingly strict regulatory standards. The expansion of manufacturing, pharmaceutical, food processing, and data center industries globally directly fuels the adoption of advanced humidification solutions. Furthermore, a growing awareness of the adverse effects of dry air on human health and sensitive materials, coupled with a push for energy-efficient industrial practices, significantly contributes to market acceleration. Technological advancements leading to more precise, reliable, and energy-efficient humidification systems are also powerful growth catalysts.

However, the market faces several restraints that could impede its full potential. The high initial capital investment required for purchasing and installing industrial humidification systems can be a barrier for small and medium-sized enterprises (SMEs), particularly in developing regions. Additionally, the ongoing maintenance costs associated with water treatment, component replacement, and energy consumption can add to operational expenditures. A lack of comprehensive awareness among some end-users regarding the long-term benefits and return on investment of optimal humidity control may also hinder adoption. The availability of alternative, less expensive, albeit less effective, humidity control methods or basic air conditioning units could divert potential customers, although these often fail to meet stringent industrial requirements. Moreover, complex installation procedures and the need for specialized technical expertise for maintenance pose challenges.

Despite these restraints, significant opportunities abound within the Industrial Humidifier Market. Emerging economies in Asia Pacific, Latin America, and the Middle East and Africa present untapped potential due to rapid industrialization and growing infrastructure development, fostering new application areas. The development of smart, IoT-enabled humidification systems that offer remote monitoring, predictive maintenance, and seamless integration with building management systems represents a major technological opportunity, appealing to industries focused on automation and operational intelligence. Furthermore, the increasing focus on sustainable and green building initiatives creates demand for energy-efficient and environmentally friendly humidification solutions. Niche applications, such as specialized environmental control in cannabis cultivation facilities, museums, and art galleries, are also opening new revenue streams. The continuous evolution of manufacturing processes and the proliferation of advanced technologies will require even more precise atmospheric control, presenting a constant opportunity for innovation and market expansion. The impact forces affecting the market include technological innovation, which drives the development of more efficient and intelligent systems; changing regulatory landscapes that impose new standards for air quality and process control; global economic conditions influencing industrial investments; and environmental concerns pushing for eco-friendly solutions and reduced resource consumption. These forces collectively steer the market towards greater sophistication and broader adoption.

Segmentation Analysis

The Industrial Humidifier Market is comprehensively segmented based on various attributes including type, application, component, and region, allowing for a detailed understanding of its dynamics and growth prospects across different sectors. This segmentation helps in identifying specific market trends, competitive landscapes, and consumer preferences, offering crucial insights for manufacturers, suppliers, and investors. Each segment represents a distinct facet of the market, driven by unique requirements and technological considerations. The diverse range of industrial needs dictates the proliferation of different humidifier types and their specialized applications, contributing to the market's robust structure and varied offerings.

- By Type

- Steam Humidifiers

- Ultrasonic Humidifiers

- Evaporative Humidifiers

- Atomizing Humidifiers

- Hybrid Humidifiers

- By Application

- Manufacturing

- Data Centers

- Healthcare & Pharmaceuticals

- Food & Beverage

- Textile

- Printing

- Agriculture

- Wood & Paper

- Others (e.g., Museums, Art Galleries, Cold Storage)

- By Component

- Humidistats & Sensors

- Control Systems

- Water Treatment Systems

- Fans & Blowers

- Distribution Systems (Ducting, Nozzles)

- Heaters & Boilers (for Steam Types)

- Pumps & Valves

- Electrical Components

- Enclosures & Casings

- Filters & Membranes

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Industrial Humidifier Market

The value chain for the Industrial Humidifier Market is a complex network involving multiple stages, from the procurement of raw materials to the final installation and after-sales service. It begins with upstream activities, where suppliers provide essential raw materials and components. This includes metals such as stainless steel for casings and internal components, various plastics for nozzles and tanks, electronic components like circuit boards, microcontrollers, and sensors for control systems, and specialized materials for water treatment and filtration. Additionally, heating elements for steam humidifiers, ultrasonic transducers, and sophisticated fan and pump systems are sourced from a diverse array of specialized manufacturers. The quality and availability of these upstream inputs directly influence the manufacturing cost, reliability, and performance of the final humidification units, making strong supplier relationships crucial for market players.

The core of the value chain involves the manufacturing and assembly of industrial humidifiers. This stage includes design and engineering, component fabrication, assembly, quality control, and rigorous testing. Manufacturers leverage advanced production techniques to ensure product durability, energy efficiency, and compliance with industry standards. After manufacturing, the products move through various distribution channels to reach end-users. These channels can be direct, where manufacturers sell directly to large industrial clients or through their own sales teams and subsidiaries, offering customized solutions and comprehensive support. Indirect channels involve a network of authorized distributors, wholesalers, and system integrators who facilitate sales, provide local support, and often integrate humidifiers into larger HVAC or building management systems. Online platforms and specialized industrial equipment marketplaces are also gaining traction as effective means for product dissemination, especially for standardized units and replacement parts.

Downstream activities encompass the installation, commissioning, maintenance, and after-sales services, which are critical for customer satisfaction and long-term product performance. Installers, often specialized HVAC contractors or system integrators, ensure the correct setup and integration of humidifiers within complex industrial environments. Post-installation, ongoing maintenance, including routine cleaning, filter replacement, and calibration, is essential to prevent downtime and extend equipment life. After-sales support, including technical assistance, spare parts supply, and warranty services, forms a vital part of the customer relationship, contributing to brand loyalty and repeat business. The entire value chain is characterized by a strong emphasis on specialized knowledge, technical expertise, and a robust service infrastructure to support the intricate demands of industrial applications. Effective management of this value chain enables companies to deliver high-quality products, optimize operational costs, and maintain a competitive edge in the market.

Industrial Humidifier Market Potential Customers

The Industrial Humidifier Market serves a broad spectrum of potential customers, primarily end-users and buyers from various industrial and commercial sectors where precise environmental control is paramount. These customers are typically businesses and organizations that operate facilities requiring specific humidity levels to protect sensitive equipment, maintain product integrity, ensure process efficiency, or provide optimal conditions for human health and comfort. The diversity of these applications means that the customer base is highly fragmented, ranging from large multinational corporations with extensive manufacturing operations to specialized laboratories and cultural institutions. Understanding the specific needs and pain points of each customer group is critical for market players to develop targeted products and services that deliver optimal value.

Key potential customers include entities in the manufacturing sector, particularly those involved in textiles, printing, wood processing, and electronics, where humidity control prevents static electricity, material shrinkage, and damage to components. Data centers represent a rapidly growing customer segment, as they require stable humidity to prevent electrostatic discharge that can corrupt data and damage expensive servers. Healthcare and pharmaceutical companies are crucial buyers, using industrial humidifiers in hospitals, laboratories, and cleanrooms to maintain sterile environments, control airborne contaminants, and ensure the efficacy of sensitive drugs and materials. The food and beverage industry utilizes humidification to preserve product freshness, prevent spoilage, and maintain quality during processing and storage, especially for items like baked goods, produce, and aged meats.

Furthermore, agricultural operations, such as greenhouses and indoor farming facilities, rely on industrial humidifiers to create optimal growing conditions for various crops, enhancing yield and quality. Museums, art galleries, and archives are also significant customers, requiring precise humidity control to preserve valuable artifacts, documents, and artworks from deterioration caused by fluctuating moisture levels. Other potential customers include educational institutions with specialized laboratories, commercial buildings seeking to improve indoor air quality and occupant comfort, and cold storage facilities where controlled humidity prevents frost buildup and product desiccation. Each of these customer groups has distinct requirements regarding humidifier capacity, precision, energy efficiency, and integration capabilities, driving innovation and customization within the industrial humidifier market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 550 Million |

| Market Forecast in 2032 | USD 813.5 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Condair Group AG, Dri-Steem Corporation, Hygromatik GmbH, H. IKEUCHI & CO., LTD., Neptronic (S.A.M.I. Inc.), Carel Industries S.p.A., Vapac Limited (Airedale International Air Conditioning Ltd.), STULZ GmbH, Armstrong International, Inc., Spirax Sarco Engineering plc, Nortec Humidity Inc., Fisair SA, Cummins Inc. (formerly Aircool), Munters Group AB, Walter Meier AG, Carrier Global Corporation, Johnson Controls International plc, Trane Technologies plc, Parker Hannifin Corporation, Honeywell International Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Humidifier Market Key Technology Landscape

The Industrial Humidifier Market is characterized by a dynamic and evolving technology landscape, with manufacturers continually integrating advanced solutions to enhance efficiency, precision, and connectivity. At the forefront are technologies aimed at optimizing energy consumption and reducing operational costs. This includes the development of highly efficient ultrasonic transducers that produce fine mist with minimal energy input, as well as sophisticated evaporative media that maximize water absorption and evaporation rates. Precision control is paramount, leading to widespread adoption of advanced sensors and humidistats that offer real-time monitoring of humidity levels, temperature, and other environmental parameters. These sensors, often integrated with microprocessors, allow for highly accurate and responsive adjustments, maintaining conditions within extremely tight tolerances.

Connectivity and smart integration represent another critical aspect of the technological landscape. The Internet of Things (IoT) plays a transformative role, enabling industrial humidifiers to connect to central building management systems (BMS) and cloud platforms. This allows for remote monitoring, control, and data logging, providing operators with unprecedented visibility and control over their humidification processes. Predictive maintenance capabilities, often powered by AI and machine learning algorithms, analyze operational data from connected devices to anticipate potential failures, schedule proactive servicing, and minimize downtime. This shift from reactive to proactive maintenance significantly improves operational reliability and extends the lifespan of equipment, aligning with broader industry trends towards smart factories and automated industrial environments.

Furthermore, technologies focusing on water quality management are crucial, given that untreated water can lead to mineral buildup, equipment damage, and bacterial growth. This involves the integration of advanced water purification systems, such as reverse osmosis, deionization, and UV sterilization, to ensure that the water used for humidification is pure and sterile. Materials science also contributes, with the use of corrosion-resistant components and advanced coatings extending product durability and performance in harsh industrial settings. The collective advancement in these technological areas not only enhances theifiers' performance and efficiency but also broadens their application scope, making them indispensable tools for maintaining optimal environmental conditions across a diverse range of industries.

Regional Highlights

- North America: This region is a mature market driven by stringent indoor air quality regulations, robust healthcare and pharmaceutical sectors, and significant investments in data centers. The adoption of advanced, energy-efficient, and smart humidification systems is high, fueled by technological innovation and a strong focus on operational efficiency. The presence of major market players and a well-developed industrial infrastructure further supports market growth.

- Europe: Similar to North America, Europe is characterized by a strong emphasis on environmental standards, industrial automation, and energy conservation. Countries like Germany, the UK, and France show high demand from manufacturing, printing, and healthcare industries. Regulatory frameworks like the EU's energy efficiency directives encourage the adoption of modern, sustainable humidification solutions.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market due to rapid industrialization, expanding manufacturing bases (especially in electronics, textiles, and automotive), and increasing foreign investments in countries such as China, India, Japan, and South Korea. Rising awareness of product quality control and occupational health, coupled with economic growth, fuels demand for industrial humidifiers across various sectors.

- Latin America: This region is an emerging market with gradual growth, driven by expanding industrial activities in countries like Brazil, Mexico, and Argentina. Investments in infrastructure and manufacturing modernization are creating new opportunities for industrial humidifier adoption, particularly in food processing, pharmaceuticals, and agriculture.

- Middle East & Africa (MEA): The MEA region presents significant growth potential, particularly in the Middle East, owing to large-scale infrastructure projects, expansion of data centers, and investments in diversified economies away from oil dependency. The extreme climatic conditions often necessitate advanced humidification solutions for environmental control, especially in sectors like healthcare, hospitality, and specialized manufacturing.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Humidifier Market.- Condair Group AG

- Dri-Steem Corporation

- Hygromatik GmbH

- H. IKEUCHI & CO., LTD.

- Neptronic (S.A.M.I. Inc.)

- Carel Industries S.p.A.

- Vapac Limited (Airedale International Air Conditioning Ltd.)

- STULZ GmbH

- Armstrong International, Inc.

- Spirax Sarco Engineering plc

- Nortec Humidity Inc.

- Fisair SA

- Cummins Inc. (formerly Aircool)

- Munters Group AB

- Walter Meier AG

- Carrier Global Corporation

- Johnson Controls International plc

- Trane Technologies plc

- Parker Hannifin Corporation

- Honeywell International Inc.

Frequently Asked Questions

What are the primary drivers for the Industrial Humidifier Market's growth?

The market's growth is primarily driven by increasing industrialization, stringent quality control requirements in manufacturing and healthcare, rising demand from data centers, and a growing emphasis on energy efficiency and worker comfort in industrial environments.

What types of industrial humidifiers are available and what are their main applications?

Key types include steam, ultrasonic, evaporative, atomizing, and hybrid humidifiers. Steam types are ideal for sterile environments like pharmaceuticals and hospitals, ultrasonic for energy efficiency in data centers and printing, and evaporative for general manufacturing and textile industries.

How does AI impact the Industrial Humidifier Market?

AI significantly impacts the market by enabling predictive maintenance, optimizing energy consumption through smart controls, enhancing precision humidity regulation, and facilitating seamless integration with existing building management systems for improved operational efficiency.

Which geographical region is expected to show the highest growth in the Industrial Humidifier Market?

The Asia Pacific (APAC) region is anticipated to exhibit the highest growth, driven by rapid industrial expansion, increasing manufacturing activities, and significant infrastructure development in countries like China and India.

What are the main benefits of implementing industrial humidification systems?

Implementing industrial humidification systems offers numerous benefits, including improved product quality, prevention of static electricity damage to sensitive equipment, enhanced worker comfort and health, reduced material waste, and optimized operational efficiency in various industrial processes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager