Industrial Metaverse Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428015 | Date : Oct, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Industrial Metaverse Market Size

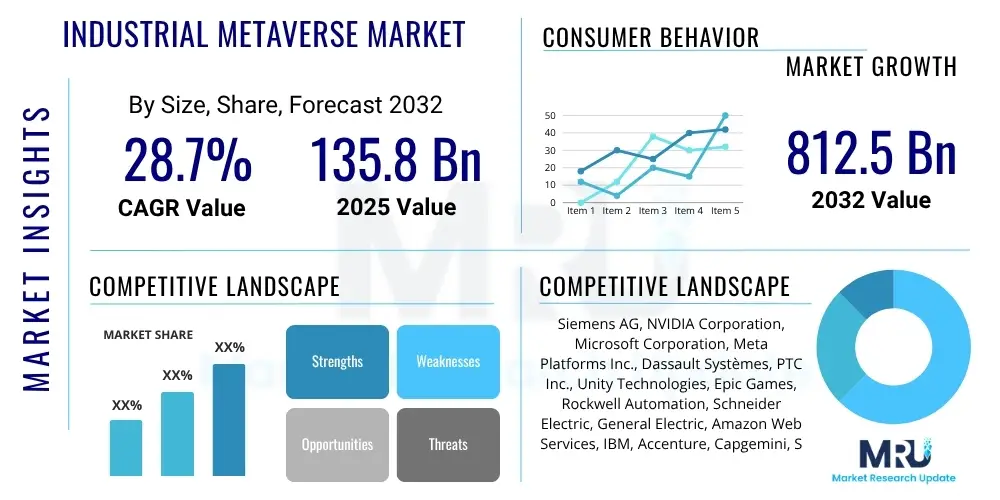

The Industrial Metaverse Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 28.7% between 2025 and 2032. The market is estimated at USD 135.8 Billion in 2025 and is projected to reach USD 812.5 Billion by the end of the forecast period in 2032. This substantial growth trajectory reflects the accelerating integration of advanced digital technologies within industrial sectors, driven by the pursuit of enhanced operational efficiency, remote collaboration capabilities, and immersive training solutions. The convergence of artificial intelligence, extended reality, digital twin technology, and high-speed connectivity is fundamentally transforming how industries design, operate, and maintain complex systems, paving the way for unprecedented innovation and value creation across the global economy.

Industrial Metaverse Market introduction

The Industrial Metaverse represents a paradigm shift, extending the physical industrial world into persistent, interconnected virtual environments. This sophisticated digital twin of industrial operations allows for real-time monitoring, predictive maintenance, collaborative design, and immersive training, revolutionizing processes from product conceptualization to lifecycle management. It encompasses a rich ecosystem of technologies including augmented reality (AR), virtual reality (VR), mixed reality (MR), artificial intelligence (AI), machine learning (ML), the Internet of Things (IoT), and high-fidelity 3D modeling, all synergistically working to create a truly immersive and interactive industrial workspace. The core objective is to enhance productivity, optimize resource utilization, and foster innovation by blurring the lines between the physical and digital realms.

Major applications of the Industrial Metaverse span across various critical sectors. In manufacturing, it facilitates virtual factory simulations, predictive analytics for machinery, and remote assistance for technicians. The healthcare industry leverages it for surgical planning, medical training, and collaborative diagnostics. Logistics and supply chain management benefit from optimized route planning, warehouse visualization, and real-time asset tracking. Energy and utilities sectors employ it for monitoring complex infrastructure, simulating grid performance, and ensuring operational safety in hazardous environments. Furthermore, education and training utilize the platform for highly realistic and interactive skill development, reducing the need for costly physical prototypes and enabling learning in simulated high-stakes scenarios.

The benefits derived from adopting the Industrial Metaverse are extensive and transformative. Companies can achieve significant cost reductions by minimizing travel for inspections and maintenance, optimizing resource allocation, and detecting potential failures before they occur. It enhances operational efficiency through real-time data insights and AI-driven optimizations. Furthermore, it accelerates product development cycles by enabling rapid prototyping and collaborative design reviews in virtual spaces. Improved safety is another critical advantage, as hazardous tasks can be practiced in a safe, simulated environment, and remote operations reduce human exposure to risks. The driving factors behind this market surge include the growing demand for digital transformation, the imperative for remote work and collaboration post-pandemic, advancements in AR/VR hardware, the proliferation of IoT devices generating vast amounts of data, and the increasing maturity of cloud and edge computing infrastructures that support these complex, data-intensive applications.

Industrial Metaverse Market Executive Summary

The Industrial Metaverse Market is experiencing rapid expansion, propelled by significant business trends towards digital twins, Industry 4.0 adoption, and the increasing demand for remote operational capabilities. Enterprises are aggressively investing in immersive technologies to gain competitive advantages, enhance operational resilience, and create more efficient, sustainable, and adaptive industrial ecosystems. This shift is characterized by strategic partnerships between technology providers and industrial giants, focused on developing integrated platforms that merge physical and digital realities. The market's growth is further fueled by the imperative for advanced analytics and AI-driven insights, which transform raw data from connected industrial assets into actionable intelligence, driving predictive maintenance, process optimization, and intelligent decision-making across the value chain. Sustainability initiatives also play a role, as virtual simulations can optimize energy consumption and resource use, contributing to greener industrial practices.

Regional trends indicate North America and Europe as leading adopters, largely due to strong technological infrastructure, significant R&D investments, and a high concentration of advanced manufacturing and technology firms. These regions are pioneering sophisticated Industrial Metaverse applications in aerospace, automotive, and healthcare. The Asia Pacific region is demonstrating the fastest growth, driven by rapid industrialization, government-led digital transformation initiatives in countries like China, Japan, and South Korea, and a burgeoning manufacturing sector eager to embrace cutting-edge technologies. Latin America, the Middle East, and Africa are emerging markets, with increasing investments in smart city projects, resource extraction industries, and efforts to diversify economies through technological advancements. These regions are poised for substantial growth as infrastructure improves and awareness of the Industrial Metaverse's benefits penetrates local industries.

Segmentation trends highlight several key areas of growth and innovation. By component, software and services are expected to dominate, as they represent the ongoing development, integration, and maintenance of complex virtual environments. Hardware, though crucial, will see innovation focused on more ergonomic and powerful AR/VR devices. In terms of technology, Digital Twin and Artificial Intelligence (AI) are foundational, enabling the creation of precise virtual replicas and intelligent automation. Extended Reality (XR) technologies like AR and VR are critical for immersive interaction, while 5G and IoT provide the necessary connectivity and data streams. Application-wise, manufacturing, logistics, and energy & utilities are projected to be the largest segments, as these industries stand to gain the most from operational efficiencies and enhanced decision-making capabilities offered by the Industrial Metaverse. The market is also seeing increasing adoption in training, design, and remote assistance, reflecting its versatility.

AI Impact Analysis on Industrial Metaverse Market

User inquiries about the impact of Artificial Intelligence on the Industrial Metaverse consistently revolve around its potential to unlock unprecedented levels of automation, intelligence, and predictive capabilities within industrial operations. Common questions frequently explore how AI will enhance the realism and functionality of digital twins, facilitate more intuitive human-machine interaction in virtual environments, and drive efficiencies in complex simulations. Users are keen to understand AI's role in data processing from myriad IoT devices, enabling real-time insights, predictive maintenance, and autonomous decision-making. There is a strong interest in AI's capacity to personalize and adapt virtual training modules, optimize supply chains within metaverse frameworks, and ensure the security and integrity of these intricate digital ecosystems. Furthermore, concerns are often raised regarding the ethical implications, data privacy challenges, and the need for robust AI governance as these technologies become more deeply embedded in critical industrial infrastructure.

The synergy between AI and the Industrial Metaverse is profound, with AI acting as the intelligence layer that powers and optimizes the virtual industrial worlds. AI algorithms process vast amounts of data streamed from physical assets, allowing digital twins to reflect real-world conditions with unparalleled accuracy and respond dynamically to changes. This intelligent data interpretation is crucial for predictive analytics, enabling companies to foresee equipment failures, optimize energy consumption, and identify bottlenecks in production lines before they occur. Beyond data analysis, AI also plays a pivotal role in creating more sophisticated and adaptive virtual experiences, from generating realistic simulations for design and testing to powering intelligent agents that assist human operators within the metaverse. This integration transforms the Industrial Metaverse from a mere visualization tool into a proactive, intelligent operational platform.

The continuous development of AI, particularly in areas like reinforcement learning and computer vision, promises to further elevate the capabilities of the Industrial Metaverse. AI-driven simulation engines can explore a multitude of scenarios at speeds impossible for human teams, allowing for rapid iteration in product design, process optimization, and disaster preparedness. AI also underpins the development of intelligent interfaces, making interaction with complex metaverse environments more natural and accessible, potentially through natural language processing or advanced gesture recognition. As industries strive for greater autonomy and efficiency, the role of AI will only intensify, transforming the Industrial Metaverse into a self-optimizing, highly responsive system capable of adapting to dynamic market conditions and operational challenges. Addressing user questions about ethical AI and data security will be crucial for widespread adoption and trust in these advanced systems.

- Enhanced Digital Twin Realism and Predictive Maintenance: AI processes real-time IoT data to accurately mirror physical assets, predict failures, and optimize operational performance.

- Intelligent Automation and Simulation: AI algorithms drive autonomous processes, optimize manufacturing flows, and power complex simulations for design and testing.

- Human-Machine Interaction and Training: AI improves natural language processing and computer vision for intuitive interaction within virtual environments, personalizing immersive training experiences.

- Data Optimization and Insights: AI efficiently analyzes massive datasets from industrial assets, extracting actionable insights for decision-making and resource allocation.

- Cybersecurity and Threat Detection: AI monitors and secures the complex digital infrastructure of the Industrial Metaverse, identifying and mitigating cyber threats.

- Adaptive Supply Chain Management: AI optimizes logistics and supply chain processes within the metaverse, improving efficiency and resilience.

DRO & Impact Forces Of Industrial Metaverse Market

The Industrial Metaverse market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, collectively shaping its growth trajectory and adoption patterns. A primary driver is the accelerating integration of digital twin technology across industries, which forms the foundational layer for creating precise virtual replicas of physical assets and processes. This is coupled with the broader movement towards Industry 4.0, emphasizing automation, data exchange, and smart manufacturing, for which the Industrial Metaverse serves as a critical enabling platform. The post-pandemic era has also amplified the demand for advanced remote collaboration tools and virtual training solutions, compelling businesses to invest in immersive environments that can bridge geographical distances and ensure operational continuity. Furthermore, technological advancements in Extended Reality (XR) hardware, 5G connectivity, and cloud/edge computing are making the Industrial Metaverse more accessible, powerful, and scalable, fostering innovation and broadening its application across diverse industrial sectors.

Despite these robust drivers, several significant restraints challenge the market's full potential. The high initial investment costs associated with developing and deploying Industrial Metaverse solutions, including specialized hardware, complex software platforms, and the necessary infrastructure upgrades, can be prohibitive for many small and medium-sized enterprises (SMEs). Data security and privacy concerns represent another critical barrier, as industrial operations involve sensitive intellectual property and operational data that, if compromised, could lead to severe consequences. The lack of standardized interoperability protocols among different metaverse platforms and technologies hinders seamless integration and data exchange, creating fragmented ecosystems. Additionally, the need for specialized skills and a skilled workforce to manage and operate these advanced systems poses a talent gap, requiring significant investment in training and education programs to realize the full benefits of the Industrial Metaverse.

However, the market is rich with opportunities that promise to propel its future growth. The development of new business models, such as "Metaverse as a Service" (MaaS) and subscription-based access to industrial virtual environments, can lower adoption barriers and expand market reach. The Industrial Metaverse offers immense potential for skill development and workforce training, allowing for realistic simulations of complex machinery and hazardous scenarios in a safe, cost-effective manner. Its capacity to enable global connectivity and collaboration fosters innovation by bringing together geographically dispersed teams for design, problem-solving, and operational oversight. Moreover, the increasing focus on sustainability and efficiency presents an opportunity, as virtual environments can be used to optimize resource consumption, reduce waste, and monitor environmental impacts. The continuous evolution of underlying technologies, especially in AI and haptic feedback, will unlock new functionalities and use cases, ensuring a sustained pipeline of innovation for the Industrial Metaverse.

Segmentation Analysis

The Industrial Metaverse market is segmented across various dimensions, providing a granular view of its structure and growth drivers. These segments include components, technology, application, and end-user industry, each playing a crucial role in defining market dynamics and investment areas. Understanding these segments is vital for stakeholders to identify specific market niches, tailor product offerings, and devise effective market entry strategies. The interplay between advanced hardware, sophisticated software platforms, and comprehensive services forms the backbone of the market, while the integration of diverse technologies like AI and XR enables a wide array of applications across industrial verticals. This multi-faceted segmentation highlights the market's complexity and its immense potential for specialized solutions targeting distinct industrial needs.

By component, the market is broadly divided into hardware, software, and services. Hardware includes AR/VR headsets, haptic devices, and powerful computing infrastructure. Software encompasses platforms for digital twin creation, simulation, content generation, and collaboration tools. Services involve consultation, integration, maintenance, and custom solution development. Technology segmentation delves into the specific innovations powering the Industrial Metaverse, such as Artificial Intelligence (AI) and Machine Learning (ML) for data analysis and automation, Extended Reality (XR) for immersive experiences, Digital Twin technology for virtual replicas, 5G/6G for high-speed connectivity, the Internet of Things (IoT) for data collection, and Cloud Computing/Edge Computing for scalable processing and storage. Blockchain technology is also gaining traction for secure data management and asset ownership in virtual environments.

Application-wise, the market sees significant deployment in areas like manufacturing operations, logistics & supply chain management, energy & utilities, healthcare, retail & e-commerce, and education & training. Each application leverages the Industrial Metaverse to address specific operational challenges, from optimizing production lines in manufacturing to enhancing surgical training in healthcare. Finally, end-user industry segmentation categorizes adoption based on the primary sector, including automotive, aerospace & defense, pharmaceuticals & biotechnology, consumer goods, and heavy industry. This comprehensive segmentation allows for a detailed analysis of market opportunities, competitive landscapes, and the varying requirements across different industrial ecosystems, paving the way for targeted innovation and market development efforts. The diversity in applications and end-user industries underscores the widespread utility and transformative potential of the Industrial Metaverse.

- By Component:

- Hardware (AR/VR Devices, Haptic Devices, Sensors, Robotics)

- Software (Platform & Tools, Digital Twin Software, Simulation & Modeling Software, Content Creation Tools, Collaboration Platforms)

- Services (Consulting, Integration, Maintenance & Support, Managed Services)

- By Technology:

- Artificial Intelligence (AI) & Machine Learning (ML)

- Extended Reality (XR) (Augmented Reality (AR), Virtual Reality (VR), Mixed Reality (MR))

- Digital Twin

- Internet of Things (IoT)

- 5G/6G Connectivity

- Cloud Computing & Edge Computing

- Blockchain

- By Application:

- Manufacturing Operations & Design

- Logistics & Supply Chain Management

- Energy & Utilities Management

- Healthcare & Medical Training

- Retail & E-commerce

- Education & Training

- Remote Collaboration & Assistance

- Field Service & Maintenance

- By End-User Industry:

- Automotive

- Aerospace & Defense

- Pharmaceuticals & Biotechnology

- Consumer Goods

- Heavy Industry (Mining, Construction)

- Electronics & Telecommunications

- Oil & Gas

Value Chain Analysis For Industrial Metaverse Market

The value chain for the Industrial Metaverse market is multifaceted, beginning with upstream activities focused on foundational technology development and content creation. This involves research and development by semiconductor manufacturers creating powerful GPUs and specialized processors, as well as the fabrication of advanced sensors, haptic feedback devices, and high-resolution display components essential for immersive experiences. Software developers in this upstream segment are crucial, focusing on creating robust digital twin platforms, 3D modeling tools, AI/ML algorithms, and networking protocols that form the technological bedrock of any industrial metaverse solution. Companies specializing in industrial design and content creation also fall here, developing the complex virtual environments, asset models, and simulation scenarios that populate these digital worlds. These upstream players provide the essential building blocks without which the Industrial Metaverse cannot exist, emphasizing innovation in hardware capabilities and software intelligence.

Moving downstream, the value chain encompasses system integrators, platform providers, and application developers who consolidate these foundational technologies into comprehensive solutions tailored for specific industrial needs. System integrators play a critical role in customizing and deploying Industrial Metaverse platforms within client infrastructure, ensuring seamless integration with existing operational technology (OT) and information technology (IT) systems. Platform providers offer scalable, cloud-based or on-premise metaverse environments, often with SDKs and APIs for further customization. Application developers then build industry-specific use cases, such as virtual factory simulations for manufacturing, digital twins for predictive maintenance in energy, or immersive training modules for aerospace. This segment is characterized by specialized expertise in various industrial domains, transforming generic technological capabilities into tangible business value for end-users. Their role is to translate complex technical features into practical, problem-solving applications, making the Industrial Metaverse accessible and beneficial.

Distribution channels for Industrial Metaverse solutions are evolving, incorporating both direct and indirect models. Direct sales channels involve technology vendors and solution providers engaging directly with large enterprise clients, often through dedicated sales teams, proofs of concept, and tailored implementation agreements for complex, high-value projects. This approach allows for deep customization and direct client relationship management. Indirect channels, on the other hand, leverage a network of channel partners, value-added resellers (VARs), and strategic alliances with consulting firms or industrial automation specialists. These partners often possess regional market knowledge and established client relationships, extending the reach of Industrial Metaverse solutions to a broader customer base, including small and medium-sized enterprises. The choice of distribution channel often depends on the complexity of the solution, the target market segment, and the required level of post-sales support, with a growing trend towards hybrid models that combine the strengths of both direct engagement and partner ecosystems to maximize market penetration and service delivery.

Industrial Metaverse Market Potential Customers

The Industrial Metaverse market targets a diverse range of potential customers, primarily end-users and buyers who seek to leverage advanced digital technologies for operational transformation, efficiency gains, and competitive advantage. These customers span across multiple heavy industries and specialized sectors, united by the common goal of optimizing their physical processes through digital immersion. Large multinational corporations, particularly those in manufacturing, automotive, aerospace, and energy, represent a significant segment of potential buyers due to their complex operational needs, substantial R&D budgets, and existing infrastructure that can integrate these sophisticated solutions. These enterprises are driven by the imperative to reduce downtime, accelerate product development cycles, and enhance global collaboration, making the Industrial Metaverse an ideal solution for their strategic objectives. They are typically early adopters, willing to invest in cutting-edge technologies that promise substantial returns on investment.

Beyond the industrial giants, small and medium-sized enterprises (SMEs) are emerging as increasingly viable potential customers, especially as the cost of entry for some Industrial Metaverse solutions begins to decrease and as "Metaverse as a Service" (MaaS) models gain traction. While SMEs may not have the same scale of operations or budget as larger corporations, they are equally motivated by the desire to enhance productivity, improve training, and stay competitive. Industries such as specialized manufacturing, local logistics providers, and vocational training centers are examples of SMEs that can significantly benefit from tailored Industrial Metaverse applications. The key for engaging this segment lies in providing scalable, accessible, and cost-effective solutions that can demonstrate clear and immediate value, addressing their specific pain points without requiring overwhelming capital expenditure or extensive in-house technical expertise. Focused solutions that target specific functions like predictive maintenance for a single production line or immersive safety training modules are particularly attractive.

Moreover, government agencies and public sector organizations are increasingly recognized as potential customers, especially in areas related to infrastructure management, smart city development, and defense. These entities can utilize the Industrial Metaverse for planning urban development, simulating disaster response scenarios, managing large-scale public utilities, and training personnel in complex operational environments. Educational and research institutions also represent a valuable customer base, leveraging the Industrial Metaverse for advanced engineering education, scientific visualization, and collaborative research initiatives that push the boundaries of industrial innovation. The demand from these varied customer groups underscores the wide applicability and transformative potential of the Industrial Metaverse, indicating a robust and expanding market for providers who can develop adaptable and value-driven solutions across different scales and industries. Engaging with these diverse segments requires a deep understanding of their unique challenges and a clear articulation of how the Industrial Metaverse can provide tangible, measurable benefits.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 135.8 Billion |

| Market Forecast in 2032 | USD 812.5 Billion |

| Growth Rate | 28.7% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, NVIDIA Corporation, Microsoft Corporation, Meta Platforms Inc., Dassault Systèmes, PTC Inc., Unity Technologies, Epic Games, Rockwell Automation, Schneider Electric, General Electric, Amazon Web Services, IBM, Accenture, Capgemini, SAP SE, Altair Engineering, Ericsson, Huawei, Vodafone |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Metaverse Market Key Technology Landscape

The Industrial Metaverse is fundamentally powered by a convergence of cutting-edge technologies, each playing a critical role in building, sustaining, and enhancing its immersive and functional capabilities. At its core, Extended Reality (XR) technologies, encompassing Augmented Reality (AR), Virtual Reality (VR), and Mixed Reality (MR), provide the immersive interfaces that allow users to interact with digital content in either real-world overlays or fully virtual environments. These technologies are crucial for visualization, remote assistance, and interactive training. Complementing XR is the foundational concept of Digital Twin technology, which creates a precise virtual replica of physical assets, processes, or even entire factories. This digital twin is continuously updated with real-time data from the physical world via IoT sensors, enabling accurate simulations, predictive analytics, and proactive problem-solving. The fidelity and responsiveness of these digital twins are paramount for the Industrial Metaverse's utility in real-world industrial applications.

Artificial Intelligence (AI) and Machine Learning (ML) serve as the intelligence layer, processing the vast amounts of data generated by IoT devices and digital twins to extract actionable insights. AI algorithms enable predictive maintenance by identifying patterns indicating potential equipment failure, optimize complex manufacturing processes, and facilitate autonomous operations within the metaverse. Furthermore, AI enhances user interaction through natural language processing and advanced computer vision, making the Industrial Metaverse more intuitive and efficient. The Internet of Things (IoT) is the backbone for data collection, providing the sensory input from physical machinery, sensors, and environmental monitors that feeds into the digital twin models and AI algorithms. Reliable and high-speed connectivity, particularly 5G and the emerging 6G, is essential for transmitting this massive volume of data in real-time with low latency, enabling seamless and synchronized interaction between the physical and digital industrial worlds.

Cloud Computing and Edge Computing infrastructures provide the necessary processing power and scalable storage for the Industrial Metaverse. Cloud computing offers the flexibility and computational resources to host complex simulations, store vast datasets, and support collaborative platforms, while edge computing processes data closer to the source, reducing latency and enabling real-time decision-making in critical industrial environments. This hybrid approach ensures both scalability and responsiveness. Blockchain technology is also gaining prominence for its potential to secure data integrity, manage digital asset ownership, and facilitate transparent transactions within decentralized industrial metaverse environments. These combined technologies create a robust and dynamic ecosystem, continuously evolving to deliver increasingly sophisticated and impactful solutions for industrial transformation. The continuous advancement in these technical domains is a primary driver for the expansion and maturation of the Industrial Metaverse market, promising even more innovative applications in the future.

Regional Highlights

- North America: A global leader in Industrial Metaverse adoption, driven by early technology integration, significant R&D investments, and a robust ecosystem of tech giants and startups. Countries like the United States and Canada exhibit high adoption rates in aerospace, automotive, and advanced manufacturing sectors, benefiting from strong venture capital funding and a culture of innovation. The region leads in developing core technologies such as AI, XR hardware, and cloud infrastructure, fostering a competitive market landscape.

- Europe: Characterized by strong governmental support for Industry 4.0 initiatives and a focus on advanced manufacturing, particularly in Germany (with its Industrie 4.0 program), the UK, and France. European industries are leveraging the Industrial Metaverse for digital twin applications, smart factories, and remote operational oversight. The region emphasizes data privacy and security, influencing the development of robust and compliant metaverse solutions for critical infrastructure and sensitive industrial data.

- Asia Pacific (APAC): The fastest-growing region, propelled by rapid industrialization, large manufacturing bases, and increasing digital transformation efforts in countries like China, Japan, South Korea, and India. Governments are actively promoting the adoption of advanced technologies, and a burgeoning tech-savvy workforce is driving innovation. Significant investments in 5G infrastructure and a vast consumer market for AR/VR devices further accelerate the integration of the Industrial Metaverse in sectors ranging from automotive to logistics.

- Latin America: An emerging market for the Industrial Metaverse, with increasing interest in sectors such as mining, oil & gas, and manufacturing in countries like Brazil and Mexico. While adoption is still in its nascent stages, growing investments in digital infrastructure and the need for operational efficiency are driving initial explorations and pilot projects. The region presents significant opportunities for scalable and cost-effective solutions tailored to local industrial needs and resource-intensive economies.

- Middle East & Africa (MEA): Demonstrating growing potential, particularly in the Middle East with initiatives focused on economic diversification, smart city development, and large-scale industrial projects in countries like UAE and Saudi Arabia. Investments in new technologies are aimed at creating future-proof economies. Africa shows nascent adoption, primarily in resource management and basic manufacturing, with opportunities tied to improving digital infrastructure and fostering technological skill development to unlock the region's vast industrial potential.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Metaverse Market.- Siemens AG

- NVIDIA Corporation

- Microsoft Corporation

- Meta Platforms Inc.

- Dassault Systèmes

- PTC Inc.

- Unity Technologies

- Epic Games

- Rockwell Automation

- Schneider Electric

- General Electric

- Amazon Web Services (AWS)

- IBM

- Accenture

- Capgemini

- SAP SE

- Altair Engineering

- Ericsson

- Huawei

- Vodafone

Frequently Asked Questions

Analyze common user questions about the Industrial Metaverse market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the Industrial Metaverse?

The Industrial Metaverse is a persistent, interconnected virtual environment mirroring real-world industrial operations using digital twin technology, AI, and XR. It enables real-time monitoring, simulation, remote collaboration, and immersive training, transforming how industries design, operate, and maintain systems.

How does the Industrial Metaverse benefit businesses?

Businesses benefit through enhanced operational efficiency, reduced costs via predictive maintenance and remote operations, accelerated product development, improved safety with virtual training, and better decision-making from AI-driven insights and real-time data analysis.

What key technologies power the Industrial Metaverse?

Key technologies include Extended Reality (AR/VR/MR) for immersion, Digital Twin for virtual replicas, Artificial Intelligence and Machine Learning for intelligence and analytics, IoT for data collection, and 5G/6G, Cloud, and Edge Computing for connectivity and processing power.

What are the main challenges for Industrial Metaverse adoption?

Major challenges include high initial investment costs, concerns over data security and privacy, lack of standardized interoperability between different platforms, and a significant shortage of skilled professionals required to implement and manage these complex systems.

Which industries are adopting the Industrial Metaverse most rapidly?

Manufacturing, automotive, aerospace & defense, energy & utilities, and logistics & supply chain management are among the most rapid adopters, leveraging the Industrial Metaverse for factory optimization, predictive maintenance, training, and remote operational control.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager