Industrial Ozone Generator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427561 | Date : Oct, 2025 | Pages : 239 | Region : Global | Publisher : MRU

Industrial Ozone Generator Market Size

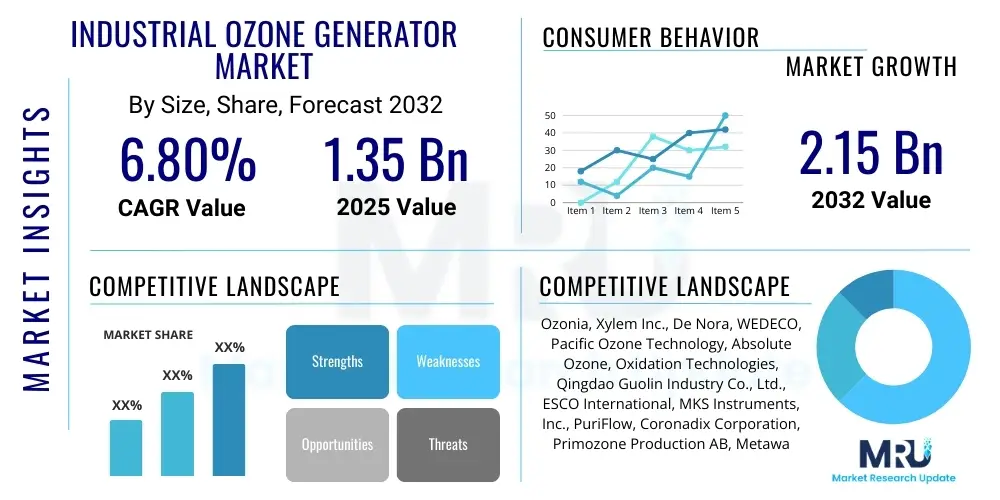

The Industrial Ozone Generator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 1.35 Billion in 2025 and is projected to reach USD 2.15 Billion by the end of the forecast period in 2032.

Industrial Ozone Generator Market introduction

The Industrial Ozone Generator Market is a critical segment within environmental technology, driven by the escalating global demand for effective and sustainable solutions in water treatment, air purification, and industrial sanitation. Industrial ozone generators are sophisticated devices designed to produce ozone gas (O3) from an oxygen source, which then serves as a powerful oxidizing agent and disinfectant across a diverse range of applications. This technology offers a compelling alternative to traditional chemical treatments, providing superior disinfection capabilities without the generation of harmful byproducts, thereby enhancing environmental compliance and operational safety.

The primary function of these generators is to harness ozones strong oxidizing potential to neutralize pollutants, eliminate microorganisms, and remove odors, colors, and unwanted chemicals from various industrial streams. Key applications span municipal and industrial wastewater treatment, where ozone effectively removes complex organic compounds, pharmaceuticals, and micropollutants; air purification systems for odor control and volatile organic compound (VOC) destruction; and sanitation processes in the food and beverage, pharmaceutical, and aquaculture industries, ensuring high standards of hygiene and product safety. The robust nature of ozone as a disinfectant, coupled with its ability to decompose back into oxygen, makes it an environmentally friendly choice for critical industrial processes.

The benefits of adopting industrial ozone generators are multifaceted, including enhanced disinfection efficacy, reduced chemical consumption, lower operational costs in some applications, and improved environmental footprints. These advantages are increasingly recognized by industries striving for sustainability and regulatory adherence. The markets expansion is significantly propelled by several driving factors, such as the implementation of more stringent environmental regulations globally, increasing public and industrial awareness regarding water and air quality, and the continuous industrialization efforts in developing economies, all of which necessitate advanced treatment solutions. Furthermore, advancements in ozone generation technology, particularly in energy efficiency and system integration, are broadening the applicability and appeal of these generators across various sectors.

Industrial Ozone Generator Market Executive Summary

The Industrial Ozone Generator Market is experiencing robust growth, primarily fueled by a confluence of evolving business trends, distinct regional dynamics, and significant advancements across various application segments. Business trends indicate a strong emphasis on technological innovation, with manufacturers focusing on developing more energy-efficient and compact ozone generation systems. There is a discernible shift towards integrated solutions that incorporate smart controls and automation, allowing for real-time monitoring and optimization of ozone treatment processes. Furthermore, companies are investing in research and development to enhance the purity and concentration of ozone output while minimizing operational footprint and maintenance requirements, catering to the increasingly sophisticated demands of industrial end-users seeking higher performance and lower total cost of ownership.

Regional trends reveal a diverse landscape of market expansion and adoption. Asia-Pacific stands out as the leading region, driven by rapid industrialization, burgeoning populations, and the subsequent increase in demand for both potable water treatment and industrial wastewater management. Governments in countries like China and India are enacting more rigorous environmental protection laws, thereby accelerating the adoption of ozone technology. North America and Europe, characterized by mature industrial infrastructures and stringent environmental regulations, maintain a steady growth trajectory, with a strong emphasis on advanced oxidation processes, water recycling, and air quality control. These regions also exhibit a higher propensity for adopting innovative, high-capacity, and technologically advanced ozone systems, often integrated into larger, complex treatment facilities. Emerging markets in Latin America, the Middle East, and Africa are also showing promising growth, albeit from a smaller base, spurred by infrastructure development and increasing environmental consciousness.

Segment trends highlight the critical role of water treatment as the dominant application area, encompassing municipal drinking water, industrial wastewater, and process water purification. Within this segment, the demand for ozone generators is driven by the need to combat persistent organic pollutants, micro-contaminants, and disinfection byproducts. The air treatment segment is also expanding rapidly, particularly for odor control in municipal solid waste facilities, industrial exhaust gas treatment, and indoor air quality management in commercial and healthcare settings. Beyond these traditional applications, there is an increasing penetration of ozone technology in niche sectors such as food and beverage sanitation, aquaculture for pathogen control, medical sterilization, and advanced oxidation processes in the pulp and paper industry. These segments are witnessing growth due to the rising imperative for chemical-free disinfection, enhanced food safety standards, and the adoption of more sustainable industrial practices, further diversifying the markets revenue streams and application portfolio.

AI Impact Analysis on Industrial Ozone Generator Market

Common user questions regarding the impact of Artificial Intelligence on the Industrial Ozone Generator Market frequently revolve around how AI can enhance efficiency, optimize operational parameters, and contribute to predictive maintenance strategies. Users are keenly interested in understanding if AI can lead to more precise control over ozone dosage, thereby reducing energy consumption and chemical usage, and if it can improve the overall reliability and lifespan of ozone generation systems. There is also significant curiosity about AIs potential to interpret complex operational data, identify anomalies, and provide actionable insights for proactive decision-making, ultimately aiming for more autonomous and intelligent ozone treatment processes. The overarching theme is the expectation that AI integration will translate into smarter, more cost-effective, and environmentally sustainable industrial ozone applications.

- Enhanced Process Control: AI algorithms can analyze real-time data from water quality sensors, flow rates, and ozone output to dynamically adjust generator parameters, ensuring optimal ozone dosage for varying contaminant loads and achieving precise treatment targets while minimizing waste.

- Predictive Maintenance: Machine learning models can monitor equipment performance, vibrations, temperatures, and electrical signals to predict potential component failures, enabling proactive maintenance scheduling, reducing downtime, and extending the operational life of industrial ozone generators.

- Optimized Energy Consumption: AI can learn from historical operational patterns and external factors (e.g., energy prices, demand fluctuations) to optimize the energy input required for ozone production, significantly reducing operational costs and improving the environmental footprint of treatment facilities.

- Improved Fault Detection and Diagnostics: By continuously analyzing vast datasets, AI systems can quickly identify subtle anomalies that may indicate impending malfunctions or inefficiencies, providing early warnings and precise diagnostic information to operators, thus preventing major system failures.

- Data-Driven Insights and Reporting: AI tools can aggregate and interpret complex operational data, generating comprehensive reports on performance, efficiency, and compliance. This provides operators and management with actionable insights for continuous improvement, regulatory reporting, and strategic planning.

DRO & Impact Forces Of Industrial Ozone Generator Market

The Industrial Ozone Generator Market is profoundly influenced by a complex interplay of Drivers, Restraints, and Opportunities, collectively forming the impact forces that shape its growth trajectory. Key drivers include the ever-tightening global environmental regulations, which mandate higher standards for wastewater discharge and air emissions, compelling industries to adopt advanced treatment technologies like ozone. Growing industrialization across emerging economies further exacerbates water stress and pollution, creating an urgent demand for efficient water and air purification solutions. Additionally, increasing public awareness about the health impacts of water and air pollutants, coupled with the rising demand for chemical-free disinfection processes in sectors such as food & beverage and pharmaceuticals, significantly propels market expansion, as ozone offers a powerful and environmentally benign alternative to traditional chemical agents.

Despite these robust drivers, the market faces several notable restraints. The initial capital expenditure required for installing industrial ozone generation systems can be substantial, especially for large-scale applications, which can deter smaller enterprises or projects with limited budgets. Furthermore, ozone generation is an energy-intensive process, and concerns regarding operational electricity consumption remain a restraint, particularly in regions with high energy costs. The technical complexity involved in designing, installing, and maintaining sophisticated ozone systems also presents a barrier, necessitating specialized expertise and skilled labor. Moreover, ozone itself is a powerful oxidant and a respiratory irritant, requiring stringent safety protocols and careful management to prevent occupational exposure, which adds to the operational challenges and regulatory compliance burdens for end-users.

Nevertheless, the market is brimming with promising opportunities that could mitigate these restraints and unlock new avenues for growth. Technological advancements in ozone generation, such as the development of more energy-efficient corona discharge cells, compact designs, and advanced control systems, are progressively addressing the cost and energy consumption concerns. The expanding application landscape, particularly in emerging fields like aquaculture for water quality management, medical device sterilization, and the treatment of complex industrial effluents, offers significant market diversification. Furthermore, the increasing global emphasis on water recycling and reuse, driven by growing water scarcity, positions ozone technology as a crucial enabler for achieving circular economy principles. Investment in research and development aimed at improving system integration with existing infrastructure and developing modular, scalable solutions will further enhance market penetration and foster widespread adoption across diverse industrial sectors, leveraging the inherent sustainability advantages of ozone treatment.

Segmentation Analysis

The Industrial Ozone Generator Market is comprehensively segmented across various dimensions, providing a granular view of its structure, dynamics, and growth potential. This segmentation allows for a detailed analysis of market behavior, identifying specific drivers, restraints, and opportunities within each category. The primary segmentation criteria typically include technology type, application area, capacity of the generator, and the specific end-use industry. Each segment exhibits unique characteristics influenced by technological innovation, regulatory mandates, and the specific requirements of industrial processes, leading to varied adoption rates and market concentrations globally. Understanding these segments is crucial for stakeholders to tailor strategies, optimize product development, and target specific market niches effectively.

- By Technology:

- Corona Discharge (Dielectric Barrier Discharge - DBD): The most prevalent and efficient technology for industrial-scale ozone production, offering high ozone concentrations suitable for demanding applications like water and wastewater treatment.

- Ultraviolet (UV) Ozone Generation: Less efficient for high concentrations but suitable for smaller-scale applications or specific air treatment needs, often integrated into commercial and residential purification systems.

- Electrolytic Ozone Generation: Produces high-purity ozone directly from water, eliminating the need for an external oxygen source, ideal for niche applications requiring ultrapure ozone in pharmaceutical and laboratory settings.

- By Application:

- Water Treatment: Encompasses municipal drinking water, industrial wastewater, process water, and cooling tower water treatment for disinfection, oxidation, and micropollutant removal.

- Air Treatment: Includes industrial odor control, VOC destruction, exhaust gas purification, and indoor air quality management in commercial and public spaces.

- Pulp & Paper Bleaching: Used as an environmentally friendly alternative to chlorine-based bleaching agents, reducing environmental impact and improving pulp quality.

- Food & Beverage: Applied for surface disinfection, water sanitization, and food preservation to enhance safety and extend shelf life.

- Medical & Pharmaceutical: Utilized for sterilization of equipment, water purification for drug manufacturing, and laboratory sanitation, requiring high-purity ozone.

- Aquaculture: Employed for water disinfection, pathogen control, and organic matter removal in fish farms, improving fish health and yield.

- Other Applications: Includes laundry sanitation, agricultural applications, chemical synthesis, and soil remediation.

- By Capacity:

- Small Capacity Generators: Typically for commercial, laboratory, or small-scale industrial use, producing ozone in grams per hour (g/hr).

- Medium Capacity Generators: Suited for medium-sized industrial processes and municipal applications, producing ozone in kilograms per hour (kg/hr).

- Large Capacity Generators: Designed for extensive industrial facilities and large municipal water treatment plants, producing ozone in hundreds of kilograms per hour (kg/hr) or more.

- By End-Use Industry:

- Municipal: Water and wastewater treatment plants for public consumption and discharge.

- Industrial: Manufacturing, chemical, pharmaceutical, mining, textile, and food & beverage industries.

- Commercial: Hotels, hospitals, shopping malls, and other public facilities for air and water purification.

- Residential: Niche market for household air and water purification systems.

Industrial Ozone Generator Market Value Chain Analysis

The value chain for the Industrial Ozone Generator Market is a sophisticated network encompassing raw material suppliers, component manufacturers, ozone generator manufacturers, distributors, system integrators, and diverse end-users. This chain begins with the sourcing of essential raw materials, primarily high-purity oxygen or air, and critical components such as power supplies, dielectric materials, high-voltage transformers, and control systems. Upstream activities involve specialized suppliers providing these precise materials and components, which are crucial for the efficient and reliable operation of ozone generators. The quality and availability of these inputs directly impact the performance and cost-effectiveness of the final product, necessitating strong relationships between generator manufacturers and their component suppliers to ensure supply chain resilience and quality control. Innovation in material science and power electronics at this stage can significantly enhance the efficiency and longevity of ozone generation systems, driving down overall production costs and improving product competitiveness.

Midstream in the value chain, ozone generator manufacturers assemble and integrate these components into complete systems, incorporating advanced engineering for optimal ozone production, efficiency, and safety. This stage involves significant research and development efforts to improve generator designs, enhance energy efficiency, and integrate smart control features. Downstream activities focus on delivering the manufactured ozone generators to a broad spectrum of end-users. This involves a crucial phase of installation, commissioning, and ongoing maintenance services, which are often provided by the manufacturers themselves or through their authorized service partners. Post-sales support, including spare parts supply, troubleshooting, and system upgrades, is vital for ensuring the continuous and effective operation of these industrial systems, thus building long-term customer relationships and supporting the product lifecycle.

Distribution channels for industrial ozone generators are typically a mix of direct and indirect approaches. For large-scale industrial projects and major municipal contracts, direct sales by the manufacturer or through specialized project engineering firms are common, allowing for customized solutions and direct technical support. Indirect channels, such as independent distributors, regional resellers, and system integrators, play a vital role in reaching smaller industrial clients, commercial end-users, and specific geographical markets. These partners often provide localized sales, installation, and maintenance services, extending the manufacturers reach and expertise. The choice of distribution channel often depends on the scale of the project, geographical location, and the level of technical support required by the end-user, with a growing trend towards integrated solutions where manufacturers collaborate closely with engineering procurement and construction (EPC) companies to deliver complete water or air treatment plants.

Industrial Ozone Generator Market Potential Customers

The Industrial Ozone Generator Market targets a broad and diverse range of potential customers across various sectors, all united by a critical need for advanced oxidation, disinfection, and purification solutions for water, air, or surfaces. These end-users are typically organizations that require high levels of environmental compliance, process efficiency, and public health protection. The primary buyers are often large-scale industrial facilities, municipal entities, and commercial enterprises that confront significant challenges related to pollution control, resource scarcity, and stringent regulatory frameworks. Their purchasing decisions are driven by factors such as the efficacy of treatment, operational costs, environmental impact, and adherence to evolving health and safety standards, making ozone generators an increasingly attractive investment for sustainable operations.

Key segments of potential customers include municipal water and wastewater treatment plants, which utilize ozone for primary disinfection, taste and odor control, removal of emerging contaminants, and advanced oxidation processes for water reuse. Industrial end-users form a substantial customer base, spanning sectors such as food and beverage processing, where ozone ensures sanitation and extends product shelf life; pharmaceutical manufacturing, requiring ultrapure water and sterile environments; pulp and paper mills, adopting ozone for environmentally friendly bleaching; and chemical industries, employing ozone for oxidation of complex organic compounds and effluent treatment. These industrial customers often seek customized, high-capacity ozone systems integrated into their existing production lines to meet specific operational and regulatory demands, emphasizing reliability and cost-effectiveness in their procurement strategies.

Beyond these major industrial and municipal applications, there is a growing customer base in specialized commercial and agricultural sectors. This includes aquaculture farms, which employ ozone for water quality management, disease prevention, and enhanced aquatic health; medical facilities and laboratories, where ozone ensures sterilization and cleanroom environments; and agricultural businesses, exploring ozone for post-harvest treatment and irrigation water disinfection. Commercial establishments like hotels and resorts also represent potential customers for air purification and water treatment for recreational facilities. The increasing demand for sustainable practices, coupled with a push for reduced chemical usage across all sectors, continues to expand the potential customer landscape for industrial ozone generator manufacturers, highlighting the versatility and broad applicability of this advanced technology.

Industrial Ozone Generator Market Key Technology Landscape

The Industrial Ozone Generator Market is characterized by a dynamic technology landscape, primarily dominated by a few core methods of ozone production, each with distinct advantages and application niches. The overarching trend is towards developing more energy-efficient, compact, and highly controllable systems, reflecting the industrial demand for lower operational costs, reduced footprint, and precise dosing capabilities. Manufacturers are continuously innovating to improve the lifespan of critical components, enhance system reliability, and integrate smart functionalities that allow for remote monitoring and automated adjustments. This technological evolution is crucial for expanding the applicability of ozone beyond traditional uses and addressing more complex environmental and industrial challenges, solidifying ozones position as a leading advanced oxidation technology.

The most prevalent technology in industrial ozone generation is the Corona Discharge (CD) method, also known as Dielectric Barrier Discharge (DBD). This process involves passing oxygen or air through a high-voltage electrical discharge across a dielectric barrier, causing oxygen molecules (O2) to dissociate and then recombine to form ozone (O3). CD generators are highly efficient for producing large quantities of ozone at high concentrations, making them ideal for municipal water treatment, industrial wastewater applications, and pulp bleaching. Recent advancements in CD technology focus on optimizing dielectric materials, improving power supply efficiency through solid-state electronics, and enhancing cooling systems to manage heat, which is a byproduct of ozone generation. These innovations aim to reduce energy consumption per unit of ozone produced and increase the overall stability and reliability of the generators under demanding industrial conditions.

While Corona Discharge remains dominant, other technologies like Ultraviolet (UV) Ozone Generation and Electrolytic Ozone Generation also play significant roles in specific market segments. UV generators produce ozone by exposing oxygen to short-wavelength ultraviolet light, which causes O2 molecules to split and recombine into O3. Although less efficient for high ozone concentrations, UV systems are simpler, compact, and suitable for smaller-scale applications such as odor control or commercial water purification. Electrolytic ozone generators produce ozone directly from water, often requiring no external oxygen feed, yielding high-purity ozone. This method is particularly valued in niche applications such as pharmaceutical manufacturing, medical device sterilization, and laboratories, where the absence of nitrogen byproducts and precise control over ozone production are critical. The ongoing development of advanced control systems, including PLC-based controls and IoT integration, across all these technologies further enhances operational flexibility, safety, and performance, allowing for real-time process optimization and predictive maintenance strategies.

Regional Highlights

- North America: Characterized by stringent environmental regulations, particularly regarding drinking water quality and industrial wastewater discharge. The region demonstrates a high adoption rate of industrial ozone generators, driven by an emphasis on water reuse, advanced oxidation processes for emerging contaminants, and air quality control. Mature infrastructure and significant investments in municipal and industrial upgrades further bolster market growth.

- Europe: A key market leader, with strong regulatory frameworks like the Water Framework Directive driving demand for advanced water and wastewater treatment solutions. Europe also benefits from a robust innovation ecosystem, leading to the development and adoption of energy-efficient and highly automated ozone generation systems. Emphasis on sustainability and circular economy principles fuels continued market expansion.

- Asia-Pacific: Projected to be the fastest-growing region, propelled by rapid industrialization, urbanization, and escalating environmental pollution challenges. Countries like China, India, and Southeast Asian nations are investing heavily in new infrastructure for water and wastewater treatment, as well as industrial air purification, creating immense opportunities for ozone generator manufacturers. Government initiatives to curb pollution significantly contribute to market expansion.

- South America: An emerging market with growing awareness of water scarcity and pollution. The region is witnessing increased investments in mining, agriculture, and municipal infrastructure, driving demand for cost-effective and efficient water treatment solutions. While currently smaller, the market is expected to grow steadily as environmental regulations become more enforced and industrial capacity expands.

- Middle East & Africa: Driven by acute water scarcity issues, particularly in the Middle East, leading to significant investments in desalination plants and water reuse technologies, where ozone plays a crucial role. African nations are also seeing increased adoption as industrial development progresses and public health concerns related to water quality become more prominent, though market penetration is still in its early stages.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Ozone Generator Market.- Ozonia (Suez)

- Xylem Inc.

- De Nora

- WEDECO (Xylem brand)

- Pacific Ozone Technology

- Absolute Ozone

- Oxidation Technologies

- Qingdao Guolin Industry Co., Ltd.

- ESCO International

- MKS Instruments, Inc.

- PuriFlow

- Coronadix Corporation

- Primozone Production AB

- Metawater Co., Ltd.

- Ozonetech AB

Frequently Asked Questions

What are the primary applications of industrial ozone generators?

Industrial ozone generators are primarily used for water and wastewater treatment, air purification, food and beverage sanitation, pulp and paper bleaching, and medical sterilization due to ozones powerful oxidizing and disinfecting properties.

How do industrial ozone generators work?

These generators typically produce ozone (O3) by passing oxygen or air through a high-voltage electrical discharge (corona discharge) or exposing it to ultraviolet (UV) light, causing oxygen molecules to split and then recombine into ozone.

What are the key environmental benefits of using ozone in industrial processes?

Ozone serves as a potent oxidizer and disinfectant that effectively breaks down pollutants and eliminates microorganisms without generating harmful chemical byproducts, reducing the reliance on traditional chemicals and improving overall environmental water and air quality.

What factors are driving the growth of the industrial ozone generator market?

Market growth is significantly driven by increasingly stringent environmental regulations, global water scarcity issues, rapid industrialization, and a growing demand for sustainable, chemical-free treatment solutions across various industries.

How is Artificial Intelligence expected to impact the industrial ozone generator market?

AI is anticipated to revolutionize industrial ozone generation by enabling enhanced process optimization, predictive maintenance capabilities, improved energy efficiency, and real-time control with data analytics, leading to more intelligent and cost-effective operations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager