Industrial Safety Footwear Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429142 | Date : Oct, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Industrial Safety Footwear Market Size

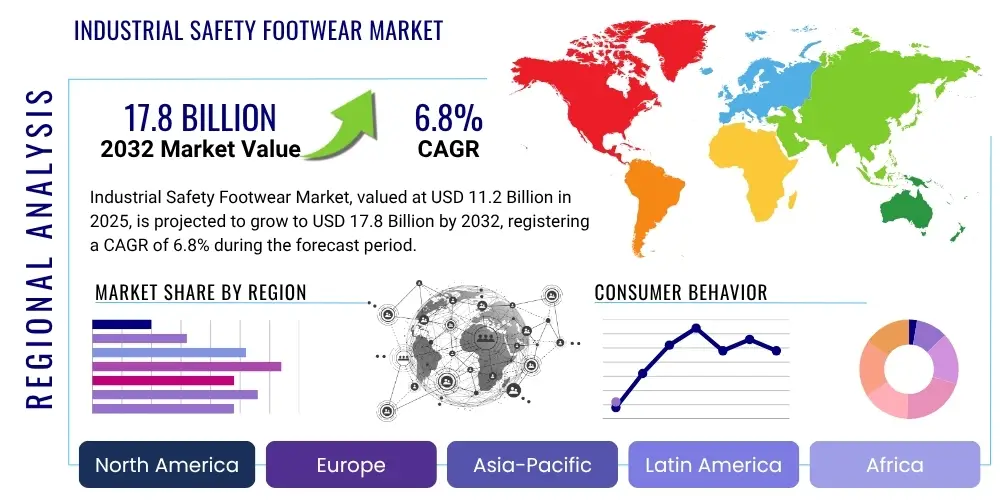

The Industrial Safety Footwear Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 11.2 Billion in 2025 and is projected to reach USD 17.8 Billion by the end of the forecast period in 2032.

Industrial Safety Footwear Market introduction

The Industrial Safety Footwear Market encompasses a diverse range of specialized footwear designed to protect workers from various workplace hazards. This critical equipment is mandated across numerous industries to ensure compliance with occupational safety and health regulations, mitigating risks associated with falling objects, sharp perforations, electrical shocks, slippery surfaces, and extreme temperatures. The market is driven by an increasing global emphasis on worker safety and the implementation of stringent regulatory frameworks.

Products within this market include safety boots, shoes, and trainers, each engineered with specific protective features such as steel or composite toe caps, puncture-resistant midsoles, slip-resistant outsoles, and electrical hazard protection. Major applications span construction, manufacturing, oil and gas, mining, logistics, and chemical industries, where physical hazards are prevalent. The primary benefits derived from these products are enhanced worker safety, reduced workplace injuries, and compliance with industry standards, which collectively contribute to operational efficiency and lower liabilities for employers.

Key driving factors for market expansion include the rapid industrialization in emerging economies, increasing awareness among employers and employees regarding occupational safety, and the continuous evolution of safety standards. Furthermore, technological advancements leading to more comfortable, lighter, and durable safety footwear solutions are bolstering market growth, as manufacturers innovate to meet the diverse and evolving needs of industrial workers.

Industrial Safety Footwear Market Executive Summary

The Industrial Safety Footwear Market is experiencing robust growth, primarily propelled by global regulatory mandates and a heightened focus on occupational safety. Business trends indicate a strong shift towards advanced material science, integrating lightweight composites and ergonomic designs to enhance wearer comfort without compromising protection. There is also a growing demand for specialized footwear tailored to specific industrial hazards, coupled with an increasing emphasis on sustainable manufacturing practices and recycled materials in production processes. The market is witnessing consolidation among larger players and innovation from specialized firms.

Regionally, Asia Pacific continues to emerge as a dominant force due to its burgeoning manufacturing and construction sectors, coupled with increasing adoption of international safety standards. North America and Europe, while mature markets, are characterized by stringent safety regulations and a high demand for premium, technologically advanced safety footwear. Latin America and the Middle East and Africa regions are showing promising growth, driven by infrastructure development projects and expansion in their respective oil and gas and mining industries. These regions represent significant opportunities for market penetration and expansion.

Segmentation trends reveal that safety boots remain a prominent category due to their comprehensive protection, while safety shoes are gaining traction for their versatility and comfort. The manufacturing and construction end-use industries consistently account for the largest market shares, though logistics and transportation are also rapidly expanding segments. Demand for footwear offering multiple protection types, such as impact and puncture resistance combined with slip and electrical hazard protection, is on the rise, reflecting the complex risk profiles of modern industrial environments.

AI Impact Analysis on Industrial Safety Footwear Market

User inquiries regarding AI's influence on the Industrial Safety Footwear Market frequently revolve around how artificial intelligence can enhance worker safety, improve footwear design, and optimize manufacturing processes. Common questions explore the practical applications of AI in predictive maintenance for footwear, integrating smart features, and streamlining supply chains. Users are keen to understand the tangible benefits for both industrial workers in terms of enhanced protection and comfort, and for manufacturers in terms of efficiency, cost reduction, and product innovation. There is also a notable interest in the challenges associated with implementing AI technologies in a traditionally conservative industry, including data privacy, cost of integration, and ensuring user acceptance.

The key themes emerging from these discussions include the potential for AI to move beyond passive protection towards proactive hazard mitigation. Users envision smart footwear that can monitor environmental conditions, track worker movements, and detect potential risks in real time, alerting both the wearer and supervisors. Expectations are high for AI to personalize footwear design based on individual biomechanics and specific job requirements, leading to superior ergonomic fit and reduced musculoskeletal strain. Concerns also touch upon the scalability of such technologies and the necessary digital infrastructure for their effective deployment across diverse industrial settings.

Furthermore, the discussion highlights a desire for AI-driven insights to inform material selection and product development, enabling manufacturers to create more durable, resilient, and environmentally sustainable footwear. Users anticipate that AI analytics could identify common wear patterns, predict equipment failure, and suggest preventative measures, thereby extending the lifespan of safety footwear and reducing waste. The overall sentiment indicates a strong belief in AI's transformative potential to revolutionize the industrial safety footwear industry, making it more responsive, intelligent, and worker-centric.

- AI-powered predictive maintenance for footwear lifespan and replacement scheduling.

- Integration of smart sensors for real-time monitoring of environmental hazards and worker biometrics.

- AI-driven ergonomic design and customization for enhanced comfort and fit.

- Optimization of supply chain and inventory management using AI analytics.

- Quality control and defect detection during manufacturing processes through AI vision systems.

- Personalized safety recommendations based on AI analysis of worker activity and risk exposure.

DRO & Impact Forces Of Industrial Safety Footwear Market

The Industrial Safety Footwear Market is significantly influenced by a confluence of driving factors, restrictive elements, and emergent opportunities, all shaped by various impact forces. Drivers primarily include the escalating global awareness of occupational safety, leading to increasingly stringent safety regulations and standards imposed by governmental and international bodies. Rapid industrialization, particularly in developing economies, fuels demand as new manufacturing units, construction sites, and infrastructure projects require comprehensive worker protection. Continuous innovation in materials and manufacturing techniques also drives market growth, offering more comfortable, durable, and protective footwear solutions that encourage adoption.

Conversely, the market faces several restraints. The high initial cost of premium safety footwear, especially those incorporating advanced features or smart technologies, can deter adoption in price-sensitive markets or by smaller enterprises with limited budgets. A lack of awareness or enforcement of safety regulations in certain regions, particularly informal sectors, poses a significant impediment. Moreover, the prevalence of counterfeit products, which fail to meet safety standards, undermines legitimate market growth and poses serious risks to workers. The challenge of balancing enhanced protection with wearer comfort and aesthetic appeal also represents a continuous design hurdle for manufacturers.

Opportunities for market expansion are abundant, particularly in the development of smart safety footwear equipped with IoT sensors for real-time monitoring of worker health, environmental conditions, and potential hazards. The growing trend towards sustainable manufacturing, utilizing recycled and eco-friendly materials, presents a niche for differentiation and attracts environmentally conscious consumers. Customization and personalized fit solutions, leveraging technologies like 3D scanning and printing, can cater to individual worker needs, improving comfort and compliance. Emerging markets offer untapped potential for growth as their industrial sectors mature and safety standards improve, creating new demand frontiers for advanced safety footwear products.

Segmentation Analysis

The Industrial Safety Footwear Market is meticulously segmented across various dimensions to provide a comprehensive understanding of its structure and dynamics. These segmentations allow for detailed analysis of market trends, consumer preferences, and competitive landscapes, enabling stakeholders to identify key growth areas and tailor strategies effectively. The market can be broadly categorized by product type, the materials used in construction, specific application or end-use industry, the type of protection offered, and the distribution channels through which these products reach consumers.

- By Product Type

- Safety Boots

- Safety Shoes

- Safety Trainers/Athletic Footwear

- Others (e.g., Clogs, Waders)

- By Material

- Leather

- Rubber

- Polyurethane (PU)

- Polyvinyl Chloride (PVC)

- Synthetic (e.g., Microfiber, Nylon)

- Others (e.g., Composite, Gore-Tex)

- By Application/End-use Industry

- Manufacturing

- Construction

- Oil and Gas

- Mining

- Chemicals

- Logistics and Transportation

- Food and Beverage

- Healthcare

- Utilities

- Others

- By Protection Type

- Impact Protection (Toe Protection)

- Compression Protection

- Puncture Protection (Midsole)

- Electrical Hazard Protection (EH Rated)

- Slip Resistance

- Chemical Resistance

- Heat Resistance

- Water Resistance

- Anti-Static

- Metatarsal Protection

- By Distribution Channel

- Offline Retail (Specialty Stores, Department Stores, Supermarkets, Hypermarkets)

- Online Retail (E-commerce Websites, Company-owned Portals)

- Wholesalers and Distributors

- Direct Sales (Business-to-Business)

Value Chain Analysis For Industrial Safety Footwear Market

The value chain for the Industrial Safety Footwear Market commences with a robust upstream segment focused on raw material procurement and component manufacturing. This stage involves suppliers of various critical materials such as industrial leather, synthetic fabrics like nylon and microfiber, advanced composites for toe caps (e.g., carbon fiber, fiberglass), steel for toe caps and midsoles, rubber for outsoles, and specialized materials for insulation, waterproofing membranes, and comfort linings. Manufacturers often maintain long-term relationships with these suppliers to ensure consistent quality and availability, which are paramount for meeting safety standards. Research and development activities also play a crucial role upstream, focusing on material innovation to enhance protection, durability, and comfort.

The manufacturing stage involves the design, assembly, and quality control of the footwear. This process includes intricate steps such as pattern cutting, stitching, sole attachment, and the integration of protective components. Manufacturers must adhere to stringent international and national safety standards (e.g., ASTM, EN ISO) and often employ advanced manufacturing technologies to ensure precision and consistency. Downstream activities involve the distribution and sales of finished products. This includes packaging, warehousing, and logistical operations to transport the footwear efficiently to various markets globally, often necessitating a well-organized supply chain network.

Distribution channels for industrial safety footwear are diverse, encompassing both direct and indirect sales models. Direct sales typically involve business-to-business (B2B) transactions where manufacturers supply directly to large industrial enterprises, government agencies, or institutional buyers. Indirect channels leverage a network of wholesalers, specialized safety equipment distributors, and retail outlets, including brick-and-mortar stores and a rapidly expanding online retail presence. The rise of e-commerce platforms has provided manufacturers with new avenues to reach a wider customer base, including individual contractors and smaller businesses, while also facilitating international sales. The effectiveness of these channels is crucial for market penetration and customer accessibility.

Industrial Safety Footwear Market Potential Customers

The primary potential customers and end-users of industrial safety footwear are workers operating in hazardous environments across a multitude of industries where foot protection is essential. This broad demographic includes individuals whose daily tasks expose them to risks such as falling objects, sharp materials, chemical splashes, electrical hazards, extreme temperatures, and slippery surfaces. The demand originates from a fundamental need to comply with occupational safety regulations and to safeguard employee well-being, thereby reducing workplace accidents and associated costs for businesses.

Key end-use sectors driving demand include the construction industry, where workers are exposed to heavy machinery, falling debris, and uneven terrain; manufacturing and fabrication, involving interaction with moving parts, hot materials, and sharp tools; and the oil and gas sector, which presents risks from heavy equipment, slippery surfaces, and potential chemical exposure. Mining operations, logistics and transportation, and chemical processing plants also represent significant segments of potential customers, all requiring specialized footwear tailored to their specific risk profiles.

Beyond traditional industrial settings, the market extends to utilities, agriculture, waste management, and even certain segments of the food and beverage industry where hygiene and slip resistance are paramount. Employers across these sectors are the direct buyers, responsible for equipping their workforce with appropriate personal protective equipment (PPE). Increasingly, individual contractors and self-employed professionals also constitute a growing customer base, purchasing safety footwear to protect themselves and comply with project-specific safety requirements. The continuous evolution of these industries and their associated regulatory landscapes ensures a sustained and expanding customer base for industrial safety footwear.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 11.2 Billion |

| Market Forecast in 2032 | USD 17.8 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Honeywell International Inc., 3M Company, Wolverine Worldwide Inc., VF Corporation (Timberland PRO, Dickies), Bata Industrials, ROCK FALL (UK) Ltd., JALAS (Ejendals AB), Safety Jogger (Cortina Group), Uvex Safety Group, KEEN Utility, Red Wing Shoe Company, Dr Martens (Airwair International Ltd.), Dunlop Protective Footwear, HAIX Group, COFRA S.r.l., MSA Safety Inc., Sioen Industries NV, Gaston Mille SAS, Heckel Securite, Atlas Schuhfabrik GmbH & Co KG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Safety Footwear Market Key Technology Landscape

The Industrial Safety Footwear Market is increasingly characterized by advancements in material science and innovative manufacturing processes aimed at enhancing worker protection, comfort, and footwear durability. A key technological trend involves the integration of advanced composite materials such as carbon fiber and fiberglass for toe caps and midsoles, offering comparable or superior protection to traditional steel while significantly reducing weight. This reduction in weight directly contributes to improved wearer comfort and reduced fatigue, which are critical factors in industries requiring long hours on foot. Nanotechnology is also being explored to develop new coatings and treatments that provide enhanced water repellency, chemical resistance, and anti-microbial properties, ensuring a safer and more hygienic environment for the wearer.

Another significant area of technological evolution is in smart footwear, where Internet of Things (IoT) sensors are embedded to provide real-time data and actionable insights. These sensors can monitor various parameters, including environmental conditions (temperature, humidity), worker biometrics (heart rate, step count, fatigue levels), and detect potential hazards such as slips, trips, or falls. Data collected can be transmitted to a central system or mobile application, enabling proactive safety interventions, predictive maintenance for footwear replacement, and personalized safety coaching. The integration of such smart features transforms safety footwear from a passive protective device into an active safety monitoring tool, enhancing overall occupational safety.

Furthermore, advancements in manufacturing technologies like 3D printing and sophisticated CAD CAM software are enabling greater customization and ergonomic design. 3D printing allows for the rapid prototyping of unique sole geometries and personalized inserts, catering to individual foot anatomies and specific occupational requirements, thereby maximizing comfort and reducing the risk of musculoskeletal injuries. Advanced sole technologies, including multi-density polyurethane injections and specialized rubber compounds, are being developed to offer superior slip resistance, shock absorption, and energy return. These innovations collectively push the boundaries of traditional safety footwear, making it more functional, comfortable, and intelligent for the modern industrial workforce.

Regional Highlights

- North America: Characterized by stringent occupational safety regulations, high awareness, and significant adoption of premium and technologically advanced safety footwear. The US and Canada are key markets due to mature industrial sectors.

- Europe: Driven by strict EU directives for worker safety and a strong emphasis on quality, comfort, and sustainable manufacturing practices. Germany, the UK, and France are leading contributors with innovation in ergonomic designs.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, burgeoning manufacturing and construction sectors, and increasing enforcement of safety standards, particularly in China, India, and Southeast Asian countries.

- Latin America: Showing steady growth due to investments in infrastructure development, mining, and oil and gas sectors, leading to increased demand for safety footwear in countries like Brazil and Mexico.

- Middle East and Africa (MEA): Growth is primarily attributed to large-scale infrastructure projects, expansion in the oil and gas industry, and increasing awareness of worker safety in countries such as Saudi Arabia, UAE, and South Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Safety Footwear Market.- Honeywell International Inc.

- 3M Company

- Wolverine Worldwide Inc.

- VF Corporation (Timberland PRO, Dickies)

- Bata Industrials

- ROCK FALL (UK) Ltd.

- JALAS (Ejendals AB)

- Safety Jogger (Cortina Group)

- Uvex Safety Group

- KEEN Utility

- Red Wing Shoe Company

- Dr Martens (Airwair International Ltd.)

- Dunlop Protective Footwear

- HAIX Group

- COFRA S.r.l.

- MSA Safety Inc.

- Sioen Industries NV

- Gaston Mille SAS

- Heckel Securite

- Atlas Schuhfabrik GmbH & Co KG

Frequently Asked Questions

What is the projected growth rate for the Industrial Safety Footwear Market?

The Industrial Safety Footwear Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032, reaching an estimated USD 17.8 Billion by 2032.

Which factors are driving the demand for industrial safety footwear?

Key drivers include stringent occupational safety regulations, increasing awareness of worker safety, rapid industrialization in emerging economies, and continuous technological advancements in footwear design and materials.

What types of protection do industrial safety footwear typically offer?

Industrial safety footwear offers various types of protection, including impact (toe cap), compression, puncture resistance, electrical hazard protection, slip resistance, chemical resistance, heat resistance, and anti-static properties.

How is AI impacting the Industrial Safety Footwear Market?

AI is impacting the market through predictive maintenance for footwear lifespan, real-time monitoring of hazards via smart sensors, AI-driven ergonomic design for customization, and optimization of supply chain logistics.

Which region holds the largest market share for industrial safety footwear?

The Asia Pacific region is anticipated to hold the largest market share and exhibit the fastest growth, driven by extensive industrialization and increasing adoption of safety standards in countries like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager