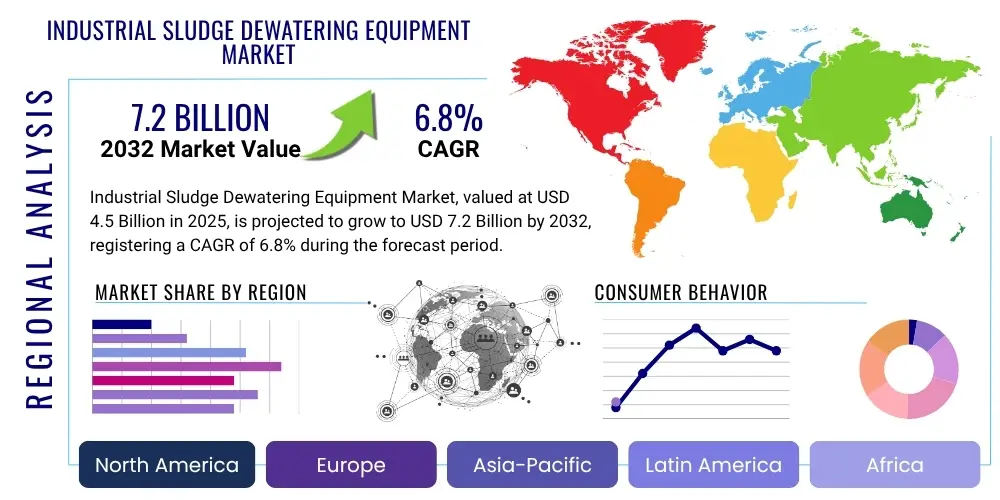

Industrial Sludge Dewatering Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428487 | Date : Oct, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Industrial Sludge Dewatering Equipment Market Size

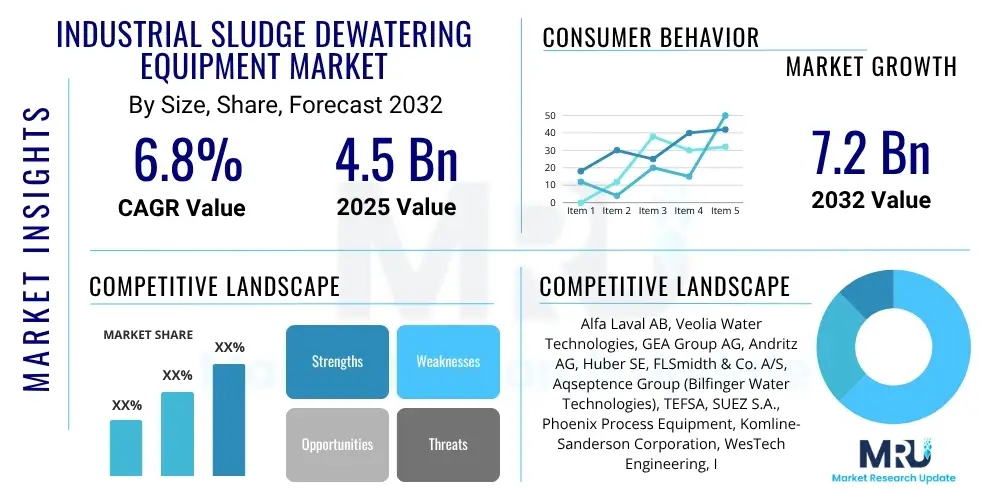

The Industrial Sludge Dewatering Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at $4.5 Billion in 2025 and is projected to reach $7.2 Billion by the end of the forecast period in 2032.

Industrial Sludge Dewatering Equipment Market introduction

The Industrial Sludge Dewatering Equipment Market encompasses a range of specialized machinery and systems designed to reduce the water content in sludge, a byproduct generated across various industrial and municipal processes. These sophisticated solutions separate solids from liquids, transforming voluminous, semi-liquid waste into a more manageable, drier solid cake and cleaner effluent. The primary objective is to minimize sludge volume, thereby significantly lowering transportation and disposal costs, enhancing the efficiency of downstream waste treatment, and ensuring compliance with increasingly stringent environmental regulations regarding industrial discharge and waste management. Major applications span critical sectors such as municipal wastewater treatment, chemical manufacturing, oil and gas, food and beverage processing, mining operations, pharmaceuticals, and pulp and paper industries, where efficient sludge management is paramount for operational sustainability and ecological responsibility. The benefits derived from implementing effective dewatering equipment include substantial cost savings on landfilling and transport, improved process control, potential for resource recovery from dewatered sludge, and a reduced environmental footprint through cleaner water discharge. Key driving factors propelling market growth include the escalating volume of industrial wastewater generated globally due to rapid industrialization, stringent environmental protection policies mandating proper sludge disposal, growing awareness about resource efficiency and sustainability, and the continuous need for cost optimization in waste management processes across diverse industries.

Industrial Sludge Dewatering Equipment Market Executive Summary

The Industrial Sludge Dewatering Equipment Market is currently experiencing robust growth driven by a confluence of evolving business trends, significant regional developments, and dynamic segment-specific shifts. Business trends indicate a strong move towards automation, the integration of smart technologies like IoT for remote monitoring and predictive maintenance, and the development of modular, compact dewatering systems that offer flexibility and reduce installation footprints, catering to industries seeking operational efficiency and reduced labor costs. Furthermore, there is an increasing emphasis on energy-efficient designs and systems capable of handling diverse sludge characteristics, signaling a market demand for customized and technologically advanced solutions. Regional trends show Asia Pacific as the fastest-growing market, propelled by rapid industrialization, urbanization, and the establishment of new wastewater treatment infrastructure, alongside increasingly stringent environmental enforcement in countries like China and India. North America and Europe continue to be significant markets, characterized by mature regulatory frameworks, a strong focus on sustainability, and high adoption rates of advanced dewatering technologies to meet strict discharge limits and promote circular economy initiatives. Segment trends highlight the continued dominance of mechanical dewatering technologies, particularly centrifuges and belt filter presses, due to their efficiency and versatility, while newer innovations in thermal drying and specialized filtration are gaining traction for specific high-value or high-volume applications where stringent dryness requirements or resource recovery are critical. The market also observes an increasing demand for comprehensive solutions that include sludge conditioning, chemical dosing, and integrated control systems, reflecting a holistic approach to sludge management beyond mere dewatering.

AI Impact Analysis on Industrial Sludge Dewatering Equipment Market

User inquiries regarding Artificial Intelligence (AI) in the industrial sludge dewatering equipment market frequently revolve around its potential to revolutionize operational efficiency, reduce costs, and enhance environmental compliance. Common themes include how AI can optimize dewatering processes, predict equipment failures, automate complex operations, and provide data-driven insights for better sludge management strategies. Stakeholders are keen to understand if AI can significantly lower energy consumption, improve solid separation efficiency, and enable more precise chemical dosing, thereby making the entire dewatering process more sustainable and economical. There is also considerable interest in AI's role in addressing labor shortages through increased automation and its ability to adapt to varying sludge compositions, which historically has been a challenge for traditional systems. The overall expectation is that AI will transform industrial sludge dewatering from a reactive process into a proactive, intelligent, and highly optimized operation.

- AI-driven Predictive Maintenance: AI algorithms analyze operational data from sensors to predict equipment failures, enabling proactive maintenance and reducing downtime.

- Process Optimization and Control: AI systems can continuously monitor incoming sludge characteristics and equipment performance, adjusting operating parameters (e.g., speed, feed rate, chemical dosage) in real-time to maximize dewatering efficiency and minimize energy consumption.

- Enhanced Data Analytics: AI platforms provide advanced insights into sludge composition, treatment performance, and operational costs, facilitating informed decision-making and continuous improvement.

- Automated Operations: AI enables greater automation of dewatering equipment, reducing reliance on manual intervention and enhancing safety, particularly for routine tasks and parameter adjustments.

- Resource Recovery Optimization: AI can identify optimal conditions for nutrient or valuable material recovery from dewatered sludge, supporting circular economy initiatives.

- Fault Detection and Diagnostics: AI quickly identifies anomalies and potential issues within the dewatering system, providing rapid diagnostics to prevent minor problems from escalating.

- Energy Efficiency Management: AI optimizes power consumption across dewatering units by learning operational patterns and load requirements, leading to significant energy savings.

DRO & Impact Forces Of Industrial Sludge Dewatering Equipment Market

The Industrial Sludge Dewatering Equipment Market is significantly influenced by a complex interplay of drivers, restraints, opportunities, and various impact forces that collectively shape its trajectory and competitive landscape. Key drivers propelling market expansion include increasingly stringent global environmental regulations mandating effective wastewater treatment and safe sludge disposal, particularly in industrialized and rapidly urbanizing regions, compelling industries to invest in advanced dewatering solutions to comply with discharge and landfilling standards. The continuous growth in industrial activities across diverse sectors such as chemical, food and beverage, and mining contributes to a burgeoning volume of industrial wastewater and sludge generation, creating a persistent demand for efficient dewatering equipment. Furthermore, escalating operational costs associated with traditional sludge disposal methods, such as transportation and landfilling, are driving industries to adopt dewatering technologies that significantly reduce sludge volume, thereby offering substantial cost savings. Lastly, the growing global concern over water scarcity and the increasing focus on water reuse and resource recovery from sludge present a strong impetus for investing in dewatering equipment that facilitates these sustainable practices. However, the market faces considerable restraints, including the high initial capital investment required for purchasing and installing sophisticated dewatering systems, which can be a barrier for small and medium-sized enterprises (SMEs) or those with limited budgets. The technical complexity involved in operating and maintaining advanced dewatering equipment, often requiring specialized expertise and regular servicing, also presents a challenge. Additionally, the energy-intensive nature of some dewatering processes and the fluctuating costs of raw materials used in equipment manufacturing can impact profitability and adoption rates. Despite these challenges, significant opportunities abound within the market, particularly through the development and adoption of advanced dewatering technologies that incorporate smart features like IoT connectivity and AI for predictive maintenance and process optimization, offering enhanced efficiency and lower lifecycle costs. The immense untapped potential in emerging economies, driven by rapid industrialization and growing environmental awareness, presents lucrative avenues for market players. Moreover, the increasing focus on the circular economy and resource recovery from sludge, such as biogas production or fertilizer applications, creates new demands for dewatering solutions optimized for these recovery processes. The market is also impacted by several external forces: the bargaining power of buyers is moderate to high, as a diverse range of equipment options and suppliers allows customers to negotiate favorable terms, while the bargaining power of suppliers of specialized components remains moderate. The threat of substitutes for core dewatering functionality is relatively low, as physical and chemical separation methods are foundational, though alternative sludge disposal methods (e.g., incineration, composting) can influence demand. The threat of new entrants is moderate, as high capital intensity, technical expertise requirements, and established brand loyalty create barriers to entry. Finally, the intensity of rivalry is high, characterized by the presence of numerous established global players and regional specialists competing on technology, price, and service offerings, driving continuous innovation and competitive pricing strategies.

Segmentation Analysis

The Industrial Sludge Dewatering Equipment Market is comprehensively segmented to provide a detailed understanding of its diverse components and dynamics. This segmentation facilitates targeted market analysis, allowing stakeholders to identify niche opportunities, understand competitive landscapes, and formulate strategic business decisions. The market is primarily broken down by Product Type, Technology, Application, End-use Industry, and geographical Region, each revealing specific demand patterns and growth drivers. These categories reflect the varied operational requirements and technological preferences across different industrial and municipal settings, ranging from conventional mechanical methods to more advanced thermal processes and their utilization in a myriad of sectors from chemical processing to mining. Each segment offers unique characteristics in terms of market size, growth potential, and the presence of specialized players, underscoring the complexity and richness of this essential environmental technology market.

- By Product Type:

- Belt Filter Press: Utilizes a series of belts to continuously dewater sludge, commonly used for municipal and industrial wastewater.

- Centrifuge: Employs centrifugal force to separate solids from liquids, known for its high capacity and efficiency across various sludge types.

- Screw Press: Uses a rotating screw to compress sludge against a screen, often favored for its low energy consumption and continuous operation.

- Filter Press: Operates batch-wise, pressing sludge between filter plates to achieve a very dry cake, suitable for specific industrial applications requiring minimal moisture.

- Rotary Press: Combines filtration and compression in a compact unit, offering effective dewatering for challenging sludges.

- Drying Beds: Simple, low-cost method utilizing natural evaporation and percolation, typically used for smaller-scale or less critical applications.

- Others: Includes bag filters, vacuum filters, and other specialized dewatering solutions.

- By Technology:

- Mechanical Dewatering: Encompasses methods that use mechanical force (e.g., compression, centrifugal force, filtration) to remove water, representing the majority of the market.

- Thermal Dewatering: Involves heating sludge to evaporate water, resulting in higher dryness levels but typically with higher energy consumption (e.g., rotary dryers, fluid bed dryers).

- By Application:

- Industrial Wastewater Treatment: Addressing sludge generated from manufacturing, processing, and various industrial operations.

- Municipal Sludge Treatment: Managing sludge from urban wastewater treatment plants.

- By End-use Industry:

- Chemical: Sludge from chemical manufacturing processes.

- Oil & Gas: Sludge from drilling, refining, and petrochemical operations.

- Food & Beverage: Waste from food processing, breweries, and dairies.

- Mining: Tailings and sludge from mineral extraction and processing.

- Pulp & Paper: Sludge from paper production and recycling.

- Pharmaceutical: Waste from drug manufacturing.

- Power Generation: Sludge from cooling towers and flue gas desulfurization.

- Textile: Wastewater and sludge from dyeing and finishing processes.

- Metal Processing: Sludge from electroplating, pickling, and metal finishing.

- Others: Includes agriculture, construction, and other sectors.

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Industrial Sludge Dewatering Equipment Market

A comprehensive value chain analysis for the Industrial Sludge Dewatering Equipment Market reveals a sequential flow of activities from raw material sourcing to end-user application and after-sales support, illustrating how value is added at each stage. The upstream analysis begins with the critical suppliers of raw materials and components, including specialized metals (stainless steel, carbon steel), polymers and rubber for belts and seals, filtration media (filter cloths, membranes), electrical components (motors, sensors, control systems), and various chemicals for sludge conditioning (flocculants, coagulants). These suppliers play a vital role in ensuring the quality, durability, and performance of the dewatering equipment, and their bargaining power can impact manufacturing costs and product innovation. The manufacturing phase involves designing, engineering, fabricating, and assembling complex dewatering units such as centrifuges, belt presses, and filter presses, requiring significant R&D investment and skilled labor. Downstream activities are crucial for market penetration and customer satisfaction, encompassing the distribution, installation, commissioning, operation, and maintenance of the equipment, as well as the ultimate disposal or reuse of the dewatered sludge. The distribution channel is multifaceted, featuring both direct sales channels where manufacturers engage directly with large industrial clients and municipal entities, offering customized solutions and comprehensive service packages, and indirect channels involving a network of distributors, agents, and original equipment manufacturers (OEMs) who integrate dewatering units into broader wastewater treatment systems. Indirect channels are particularly important for reaching diverse smaller and medium-sized industries across various geographical locations, providing localized sales and support. Both direct and indirect channels are critical for market reach, with direct sales often preferred for high-value, complex projects requiring extensive technical consultation, while indirect channels provide broader market coverage and quicker deployment, balancing the need for specialized expertise with accessibility to a wider customer base.

Industrial Sludge Dewatering Equipment Market Potential Customers

The potential customers for Industrial Sludge Dewatering Equipment are incredibly diverse, spanning a wide array of sectors that generate significant volumes of liquid or semi-solid waste requiring efficient water removal. These end-users and buyers are primarily industries and public utilities grappling with strict environmental regulations, high disposal costs, and a growing emphasis on resource recovery and sustainable waste management practices. Key buyers include municipal wastewater treatment plants, which continuously process urban sewage and require robust dewatering solutions to manage large volumes of biological sludge. Within the industrial landscape, the chemical manufacturing sector represents a significant customer base, handling various chemical slurries and byproducts that necessitate precise dewatering for safe disposal or further processing. The oil and gas industry, including upstream exploration and production, midstream transportation, and downstream refining, generates considerable volumes of oily sludge and drilling muds, making them vital consumers of specialized dewatering equipment. Food and beverage processing plants, encompassing dairies, breweries, meat processing facilities, and fruit and vegetable processing, produce organic sludge rich in solids, demanding hygienic and efficient dewatering solutions. Furthermore, mining operations generate tailings and mineral slurries, pulp and paper mills produce fiber-rich sludge, and pharmaceutical companies deal with diverse process wastes, all requiring tailored dewatering technologies. Power generation facilities, particularly those with flue gas desulfurization systems, also represent a critical customer segment due to the large quantities of gypsum-based sludge generated. Essentially, any industrial or municipal entity that generates liquid waste with suspended solids, for which volume reduction, compliance, and cost efficiency are priorities, constitutes a potential customer for industrial sludge dewatering equipment, driving demand across a broad spectrum of economic activities.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $4.5 Billion |

| Market Forecast in 2032 | $7.2 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Alfa Laval AB, Veolia Water Technologies, GEA Group AG, Andritz AG, Huber SE, FLSmidth & Co. A/S, Aqseptence Group (Bilfinger Water Technologies), TEFSA, SUEZ S.A., Phoenix Process Equipment, Komline-Sanderson Corporation, WesTech Engineering, Inc., Pure Water Inc., Evoqua Water Technologies LLC, Xylem Inc., Metso Outotec Corporation, SPX Flow, Inc., Bosch Rexroth AG, Mitsubishi Kakoki Kaisha, Ltd., Fujian Longking Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Sludge Dewatering Equipment Market Key Technology Landscape

The industrial sludge dewatering equipment market is characterized by a dynamic technological landscape that continuously evolves to meet the demands for higher efficiency, lower operating costs, and enhanced environmental performance. Established technologies form the backbone of the market, including mechanical dewatering methods such as centrifugation, which utilizes high-speed rotation to separate solids from liquids, offering continuous operation and significant volume reduction for a wide range of sludge types. Filtration-based systems, including belt filter presses, which continuously squeeze sludge between two permeable belts, and plate and frame filter presses, which operate in batches to produce a very dry cake, are also widely employed for their effectiveness in achieving high solids content. Screw presses are gaining traction due to their low energy consumption and ability to handle oily or sticky sludges. Beyond these, thermal drying technologies, while more energy-intensive, are used when extremely high dryness levels are required for disposal or further processing into beneficial products. The market is also witnessing a surge in innovative and emerging technologies aimed at enhancing the intelligence, automation, and sustainability of dewatering processes. This includes the integration of Internet of Things (IoT) sensors for real-time monitoring of critical parameters like sludge flow, consistency, and equipment performance, enabling predictive maintenance and optimized operational adjustments. Artificial intelligence (AI) and machine learning algorithms are being increasingly deployed to analyze complex data patterns, predict optimal chemical dosing for flocculation, and fine-tune equipment settings to maximize dewatering efficiency and minimize chemical and energy consumption. Furthermore, there is a growing trend towards modular and compact dewatering solutions that offer easier installation, scalability, and adaptability to limited space availability, particularly appealing to industries with diverse processing needs. Developments in membrane technology and electro-dewatering are also on the horizon, promising even higher dewatering efficiencies and cleaner effluent quality for specialized applications. These technological advancements collectively aim to reduce the overall environmental footprint of industrial processes by making sludge management more effective, economical, and environmentally sound.

Regional Highlights

- North America: This region is characterized by stringent environmental regulations and a mature industrial base. High adoption rates of advanced dewatering technologies, driven by a focus on sustainable water management and reducing landfill volumes, are prominent. The United States and Canada lead in innovation and investment in modern wastewater treatment infrastructure.

- Europe: Driven by strong regulatory frameworks such as the EU Water Framework Directive and a robust emphasis on circular economy principles, Europe represents a significant market. Countries like Germany, the UK, and France are key players, focusing on energy-efficient solutions and resource recovery from sludge.

- Asia Pacific (APAC): The fastest-growing market globally, fueled by rapid industrialization, urbanization, and increasing investment in wastewater treatment infrastructure, particularly in China, India, and Southeast Asian countries. Growing environmental awareness and the adoption of Western technologies contribute to market expansion.

- Latin America: This region shows increasing potential due to growing industrialization and urbanization, leading to greater wastewater generation. Investments in environmental protection and infrastructure development, especially in Brazil and Mexico, are creating new opportunities for dewatering equipment suppliers.

- Middle East and Africa (MEA): Characterized by severe water scarcity and ongoing industrial development, particularly in the oil and gas, and mining sectors. There is a rising need for efficient water management and sludge treatment solutions, although adoption rates can be slower due to economic and political factors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Sludge Dewatering Equipment Market.- Alfa Laval AB

- Veolia Water Technologies

- GEA Group AG

- Andritz AG

- Huber SE

- FLSmidth & Co. A/S

- Aqseptence Group (Bilfinger Water Technologies)

- TEFSA

- SUEZ S.A.

- Phoenix Process Equipment

- Komline-Sanderson Corporation

- WesTech Engineering, Inc.

- Pure Water Inc.

- Evoqua Water Technologies LLC

- Xylem Inc.

- Metso Outotec Corporation

- SPX Flow, Inc.

- Bosch Rexroth AG

- Mitsubishi Kakoki Kaisha, Ltd.

- Fujian Longking Co., Ltd.

Frequently Asked Questions

What is industrial sludge dewatering equipment and why is it important?

Industrial sludge dewatering equipment encompasses specialized machinery designed to extract water from industrial or municipal sludge, transforming it into a drier, more manageable solid cake and cleaner effluent. This process is crucial because it significantly reduces the volume of sludge, leading to substantial cost savings in transportation and disposal, enhances environmental compliance by meeting strict discharge regulations, and can facilitate resource recovery from the dewatered solids, making it a critical component of sustainable waste management and industrial operations worldwide.

How do environmental regulations influence the industrial sludge dewatering equipment market?

Environmental regulations are a primary driver for the industrial sludge dewatering equipment market. Stricter global and regional mandates regarding wastewater discharge quality, limits on landfilling volumes, and requirements for safe sludge disposal compel industries to invest in advanced dewatering solutions. Compliance with these regulations necessitates efficient sludge volume reduction and improved solid-liquid separation, directly boosting the demand for high-performance dewatering technologies to avoid hefty fines and uphold corporate social responsibility.

What are the primary types of industrial sludge dewatering technologies available?

The primary types of industrial sludge dewatering technologies include mechanical methods like belt filter presses, centrifuges, screw presses, and filter presses, each suited for different sludge characteristics and desired dryness levels. Belt filter presses use continuous filtration and compression, centrifuges employ centrifugal force for high-capacity separation, screw presses offer continuous, low-energy dewatering, and filter presses achieve very dry cakes in batch operations. Thermal dewatering methods, such as drying beds or thermal dryers, are also utilized when extremely low moisture content is required.

How does AI or automation impact the efficiency and cost-effectiveness of sludge dewatering?

AI and automation significantly enhance the efficiency and cost-effectiveness of sludge dewatering by enabling real-time process optimization, predictive maintenance

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager