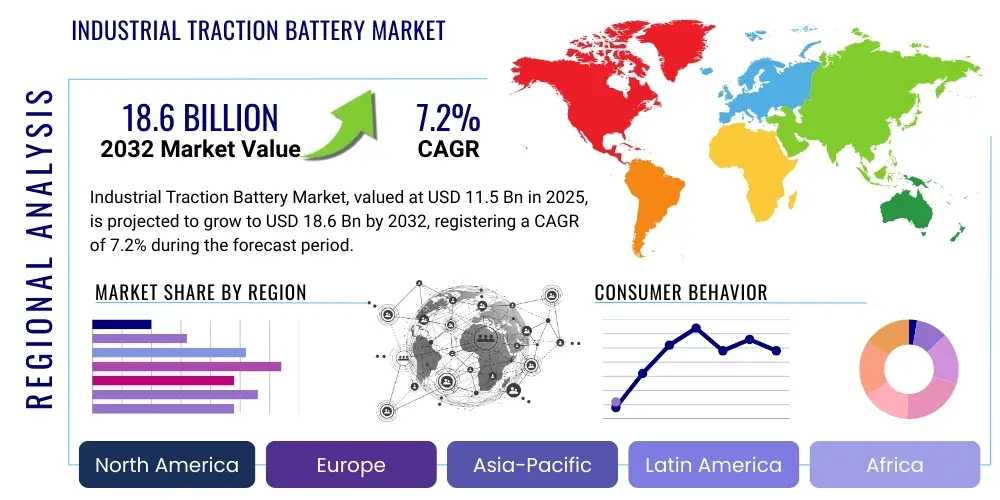

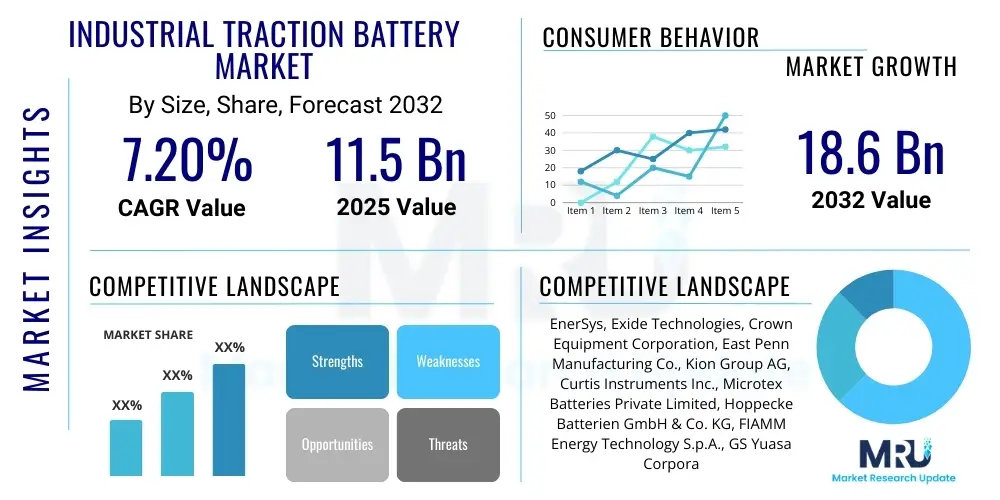

Industrial Traction Battery Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427545 | Date : Oct, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Industrial Traction Battery Market Size

The Industrial Traction Battery Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2025 and 2032. The market is estimated at USD 11.5 billion in 2025 and is projected to reach USD 18.6 billion by the end of the forecast period in 2032. This trajectory reflects increasing global demand for efficient, sustainable power solutions in industrial applications, driven by battery technology advancements, expanding automation, and stringent environmental regulations across various sectors. The market expansion underscores the critical role these batteries play in modern industrial ecosystems, facilitating a broader shift towards electrification in material handling, mining, and other heavy-duty operations.

Industrial Traction Battery Market introduction

Industrial traction batteries are critical components in modern industrial operations, serving as foundational power sources for a wide array of electric and hybrid industrial vehicles. Engineered to deliver consistent, high-current power over extended durations, they differ significantly from conventional automotive batteries designed for short, high-power bursts. Their robust design withstands deep discharge cycles and demanding environments, making them indispensable for equipment like electric forklifts, automated guided vehicles (AGVs), mining locomotives, airport ground support machinery, and specific railway applications. These batteries ensure sustained operational uptime and enhance efficiency and productivity in rigorous industrial settings, forming the backbone of electrified logistics and material handling systems globally.

The market encompasses a sophisticated array of battery chemistries, primarily advanced lead-acid technologies, cutting-edge lithium-ion formulations, and niche nickel-cadmium solutions. Each chemistry offers unique advantages balanced across performance metrics such as energy density, cycle life, charging velocity, and cost-effectiveness. Lithium-ion batteries are increasingly favored for superior energy density and faster charging, offering extended operational periods and reduced charging intervals, thereby optimizing workflow in demanding 24/7 environments. Enhanced lead-acid batteries, conversely, remain reliable and more economical for a significant market segment, particularly where initial investment is a primary consideration. Continuous evolution of these technologies addresses diverse and evolving industrial application requirements, fostering adaptability and innovation.

The markets expansion is fundamentally propelled by potent macroeconomic and technological driving factors. Paramount is the exponential growth of global e-commerce, necessitating sophisticated warehousing and logistics operations reliant on electric material handling equipment. Concurrently, increased automation in manufacturing, driven by widespread AGV and robotic system adoption, amplifies demand for high-performance, dependable battery solutions. Furthermore, increasingly stringent global environmental regulations, coupled with corporate emphasis on sustainability, accelerate the transition from fossil fuel-powered vehicles to cleaner electric alternatives. These cumulative forces, alongside advancements in battery performance, intelligent energy management systems, and robust charging infrastructure, collectively underpin the markets strong growth trajectory, facilitating reliable, environmentally sound, and economically viable power solutions.

Industrial Traction Battery Market Executive Summary

The Industrial Traction Battery Market is experiencing dynamic shifts, characterized by extensive electrification, pervasive automation, and unwavering commitment to sustainable industrial practices. A global imperative to mitigate carbon emissions accelerates the transition from fossil fuel-powered equipment to advanced electric counterparts, driving escalating demand for high-performance traction batteries. Manufacturers are increasingly channeling efforts towards sophisticated lithium-ion battery solutions, lauded for superior energy density, significantly longer cycle life, and substantially faster charging capabilities. Despite this, conventional lead-acid batteries maintain a formidable market presence, particularly within cost-sensitive applications where reliability and lower upfront investment remain compelling.

Regional trends position Asia-Pacific as the preeminent market, fueled by rapid industrialization, burgeoning manufacturing sectors, and unprecedented growth of e-commerce, with China and India as pivotal engines. North America and Europe also demonstrate considerable expansion, underpinned by stringent environmental regulations, swift technological adoption, and substantial investments in advanced logistics and warehousing automation. These regions favor smart, connected battery solutions integrated into complex operational environments. Emerging economies across Latin America and Africa, while nascent, show promising growth trajectories as industrial infrastructures mature and modern material handling solutions gain wider acceptance, indicative of future market potential.

Segment-wise, the market observes a pronounced and accelerating preference for advanced lithium-ion battery technologies across diverse industrial applications. This trend reflects continuous breakthroughs and the gradual decline in production costs, making lithium-ion solutions more economically viable. The material handling segment (forklifts, AGVs) remains the largest application area, driven by the exponential surge in automated logistics operations. Furthermore, growing industry trends include innovative "battery-as-a-service" models and widespread integration of highly intelligent battery management systems (BMS). These advancements enhance operational efficiency and reliability while extending battery asset lifespan across all industrial applications, delivering greater value to end-users.

AI Impact Analysis on Industrial Traction Battery Market

Artificial intelligence is poised to profoundly influence the industrial traction battery market, revolutionizing design, manufacturing, utilization, and maintenance. User inquiries frequently explore AIs benefits in extending battery life, reducing downtime, and enhancing energy management in industrial settings. Concerns often center on integration challenges with existing infrastructure, data security, and demonstrating a clear return on investment from AI-powered solutions. Expectations are high for AI to deliver smarter, adaptive charging algorithms, real-time battery health monitoring, and precise predictive maintenance forecasting. The pervasive theme is leveraging advanced data intelligence to maximize utility, safety, and longevity of industrial power assets, achieving more reliable, cost-effective, and sustainable operations.

- AI-driven optimization of charging and discharging cycles dynamically adapts to operational demands, reducing degradation and extending lifespan.

- Predictive analytics, powered by AI, identifies early signs of potential failures, enabling proactive maintenance and minimizing unplanned downtime.

- Real-time data monitoring and AI-powered analysis of historical energy consumption improve operational efficiency across industrial fleets.

- AI integration into manufacturing enhances precision, consistency, and quality control, leading to higher performance and faster production.

- Advanced Battery Management Systems (BMS) integrate AI for superior diagnostics, active cell balancing, and intelligent performance optimization, ensuring peak safety.

- Autonomous Guided Vehicles (AGVs) leverage AI for intelligent power management, optimizing battery usage based on real-time task allocation and route planning.

- Supply chain for critical raw materials benefits from AI-driven demand forecasting, optimized logistics, and risk management, enhancing resilience.

- AI facilitates smart grid integration, allowing industrial batteries to participate in demand response programs, optimizing energy costs and supporting grid stability.

- AI-enabled robotic systems enhance safety during battery handling, installation, and maintenance, reducing human exposure and improving operational safety.

DRO & Impact Forces Of Industrial Traction Battery Market

The Industrial Traction Battery Market experiences robust acceleration driven by an array of compelling forces. Paramount is the escalating global imperative towards comprehensive electrification across all industrial sectors, reinforced by stringent environmental regulations and corporate commitment to sustainability. This pivot from fossil fuels directly fuels demand for sophisticated, high-performance traction batteries. Concurrently, the unprecedented expansion of global e-commerce necessitates highly efficient warehousing and supply chain operations, increasingly reliant on electric material handling equipment, consequently boosting battery market growth. Furthermore, relentless automation within manufacturing and logistics environments, exemplified by the proliferation of Automated Guided Vehicles (AGVs) and autonomous forklifts, generates insatiable demand for reliable, high-density, and long-lasting power solutions. These symbiotic trends underscore a powerful market impetus towards cleaner, more efficient, and technologically advanced industrial power sources.

Despite significant drivers, the market faces formidable restraints. A primary impediment is the comparatively high initial capital expenditure for advanced battery chemistries like lithium-ion, a substantial barrier for smaller enterprises. Development and deployment of adequate, high-speed charging infrastructure, crucial for large fleets, present significant logistical and financial challenges. Moreover, volatility in critical raw material prices (lithium, cobalt, nickel, lead) introduces uncertainty into manufacturing costs and product pricing. Addressing complex thermal management and mitigating safety concerns for high-energy density batteries necessitates continuous innovation and adherence to rigorous standards, posing ongoing hurdles for sustained market penetration.

Amidst these challenges, the Industrial Traction Battery Market is replete with substantial opportunities. Emerging economies, undergoing rapid industrialization and infrastructure development, represent fertile ground for new market penetration and expansion of electrified material handling and logistics. Significant investment in R&D for next-generation battery technologies (solid-state, improved lead-acid) promises revolutionary improvements in performance, safety, and cost-effectiveness. The burgeoning focus on circular economy principles generates opportunities in battery recycling and repurposing, addressing sustainability and resource scarcity while fostering novel business models. Evolution of smart charging solutions and seamless grid integration further optimize energy management, enhancing operational efficiency and making industrial traction batteries an increasingly attractive asset for a broader spectrum of end-users.

Segmentation Analysis

A granular segmentation analysis of the Industrial Traction Battery Market is paramount for dissecting its complexities and gaining a nuanced understanding of its components. This breakdown offers invaluable insights into specific product types, varying capacity ranges, diverse application scenarios, and distinct end-use industries, enabling stakeholders to identify precise growth vectors, navigate competitive landscapes, and pinpoint unmet market demands. Such an analytical approach is indispensable for discerning shifts in technological preferences, tracking adoption rates, and comprehending unique regional demand dynamics that influence market behavior. By meticulously examining these discrete segments, businesses can accurately assess the current market equilibrium and formulate robust, data-driven strategies for future product development, market entry, and sustainable growth, ensuring alignment with evolving industry needs and maximizing strategic efficacy in a competitive environment.

- By Type: Delineates the market based on chemical composition and design, impacting performance characteristics and application suitability.

- Lead-Acid Batteries: Comprising traditional Flooded, Sealed Lead-Acid (SLA), and Gel batteries, known for cost-effectiveness and proven reliability.

- Lithium-Ion Batteries: Including Lithium Iron Phosphate (LFP) for safety and long cycle life, Nickel Manganese Cobalt (NMC) for higher energy density, and Lithium Titanate Oxide (LTO) for ultra-fast charging.

- Nickel-Cadmium Batteries: Valued for robust performance in extreme temperatures and high discharge rates, though less common due to environmental concerns.

- Others: Encompassing emerging technologies such as Sodium-Ion, Zinc-Air, and Fuel Cell Hybrids, representing future growth potential.

- By Capacity: Categorization based on energy storage capability, directly influencing operational duration and power output.

- Low Capacity (up to 200 Ah): Typically used in smaller, lighter-duty material handling equipment and compact AGVs for shorter shifts.

- Medium Capacity (201-500 Ah): Common in standard electric forklifts, medium-sized AGVs, and general industrial vehicles requiring moderate endurance.

- High Capacity (above 500 Ah): Employed in heavy-duty forklifts, large AGVs, mining locomotives, and airport ground support equipment demanding extensive operational time and high power.

- By Application: Analyzes demand based on specific industrial equipment or vehicle type where traction batteries are deployed, reflecting diverse power requirements.

- Forklifts: Including counterbalance, reach, pallet trucks, and order pickers, forming the largest segment due to widespread use in logistics and warehousing.

- Automated Guided Vehicles (AGVs): Covering tow tractors, unit load carriers, and pallet trucks, crucial for automated internal logistics and manufacturing.

- Mining Equipment: Such as electric mining locomotives, load-haul-dump (LHD) machines, and utility vehicles operating in challenging environments.

- Airport Ground Support Equipment (GSE): Encompassing electric baggage tractors, cargo loaders, aircraft pushback tugs, and passenger stairs for efficient airport operations.

- Railway Applications: Utilized in shunting locomotives, maintenance-of-way vehicles, and certain commuter trains for efficiency and environmental benefits.

- Other Industrial Vehicles: Including floor cleaning machines, industrial sweepers, aerial work platforms, and specialized port equipment.

- By End-Use Industry: Classification based on sectors that procure and utilize industrial traction batteries, revealing industry-driven demands and growth patterns.

- Logistics and Material Handling: Dominant sector driven by e-commerce growth, warehousing, and supply chain automation.

- Manufacturing: Includes automotive, food and beverage, electronics, and general manufacturing plants utilizing electric vehicles for internal transport.

- Mining: Characterized by demand for robust, high-power batteries for underground and surface mining equipment, prioritizing safety and durability.

- Construction: For electric excavators, loaders, and other heavy equipment, supporting sustainable construction practices.

- Pharmaceutical and Chemical: Requires specialized, often sealed, batteries for cleanroom operations and hazardous environments.

- Aerospace and Defense: For ground support equipment and specialized electric vehicles within secure facilities.

- Others: Encompassing agriculture, marine, and public utility sectors.

Industrial Traction Battery Market Value Chain Analysis

The intricate value chain of the Industrial Traction Battery Market begins with crucial upstream activities: meticulous sourcing, extraction, and initial processing of essential raw materials like lithium, cobalt, nickel, manganese, and lead, plus specialized chemicals for battery cell fabrication. This segment also includes component suppliers for electrodes, separators, electrolytes, and robust battery casings. In an era defined by environmental stewardship and supply chain resilience, achieving optimal efficiency and sustainability in raw material processing is critical, given scrutiny over ethical sourcing and resource scarcity. Establishing robust, transparent relationships with reliable raw material providers is paramount for stable production, competitive pricing, and mitigating potential supply chain disruptions in this initial phase.

Midstream activities form the core manufacturing segment, involving sophisticated production of individual battery cells, their assembly into modules, and final integration into complete, functional battery packs. This stage demands precision engineering, stringent quality control, and seamless integration of advanced Battery Management Systems (BMS) to optimize performance, enhance safety, and prolong battery life. Original Equipment Manufacturers (OEMs) often integrate these battery packs directly into their industrial vehicles, while specialized manufacturers produce traction battery systems for diverse industrial applications. Extensive R&D focuses on continuously improving energy density, extending cycle life, accelerating charging speeds, and enhancing cost-effectiveness of the final product.

The downstream segment encompasses distribution, sales, and comprehensive after-sales services, vital for market penetration and sustained customer satisfaction. Products reach end-users through combined direct sales (manufacturers supplying large industrial customers or OEMs) and indirect channels (extensive networks of distributors, dealers, and service providers). Crucially, exemplary after-sales support—including maintenance, repairs, and increasingly, advanced battery recycling and repurposing services—constitutes an indispensable part of the value chain. This not only ensures high customer satisfaction and retention but also promotes a circular economy. The efficiency and responsiveness of these distribution and service networks are fundamental determinants of market success and enduring customer loyalty.

Industrial Traction Battery Market Potential Customers

The primary potential customers for industrial traction batteries are diverse enterprises profoundly dependent on efficient material handling equipment and electric industrial vehicles. This includes leading logistics and warehousing behemoths, e-commerce giants, and third-party logistics (3PL) providers, managing vast fleets of electric forklifts, automated pallet trucks, and sophisticated Automated Guided Vehicles (AGVs) essential for seamless goods movement. These customers demand extremely robust, durable, and long-lasting battery solutions to minimize operational downtime, significantly reduce costs, and effectively meet rigorous operational schedules in their distribution centers and storage facilities. Paramount considerations for these buyers include total cost of ownership, uncompromised reliability, and rapid-charging capabilities indispensable for 24/7 continuous operations.

Another significant market segment comprises a wide array of manufacturing plants across diverse industries, including automotive, food and beverage, pharmaceuticals, and heavy machinery production. These facilities extensively utilize electric vehicles for critical internal transport, assembly line operations, and efficient material movement, often requiring specialized batteries tailored to unique operational environments like cold storage or hazardous areas. Large-scale mining operations and extensive construction sites also represent crucial customer bases, particularly for electric locomotives and heavy-duty electric vehicles. In these demanding, often remote locations, powerful, durable, and intrinsically safe traction batteries are absolutely essential for sustained performance, prioritizing unparalleled safety, extended endurance, and robust reliability.

Furthermore, major international airports and extensive railway operators constitute an increasingly vital customer group, driven by both operational efficiency and environmental mandates. Airports globally deploy industrial traction batteries within their comprehensive suite of ground support equipment (GSE), including electric baggage tractors, cargo loaders, and aircraft pushback tugs, ensuring seamless, quiet, and environmentally friendly operations. Railway companies, particularly for shunting locomotives, maintenance-of-way vehicles, and certain electric commuter trains, heavily rely on these batteries for their demonstrated efficiency, unwavering reliability, and superior performance. The overarching need for all these potential customers is a profoundly dependable, high-performance power source that steadfastly supports sustainability goals, substantially enhances operational efficiency, rigorously ensures safety, and delivers measurable economic benefits across their specialized industrial applications.

Industrial Traction Battery Market Key Technology Landscape

The technological landscape within the Industrial Traction Battery Market is undergoing rapid innovation, driven by collective industry objectives to enhance performance, optimize energy efficiency, and ingrain deeper sustainability. At the forefront are advancements in dominant battery chemistries. While advanced lead-acid technologies evolve with improved designs for extended cycle life and faster recharging, the paradigm shifts towards sophisticated lithium-ion solutions. Lithium-ion variants, notably LFP for safety and longevity, and NMC for higher energy density, lead this charge. These are preferred for superior energy density, faster charging times, and significantly extended cycle life. The core focus is to augment power output while concurrently reducing the physical footprint and weight of battery packs, increasing payload capacity and improving vehicle maneuverability and efficiency.

Beyond core chemistry, profound technological strides are being made in Battery Management Systems (BMS). Modern BMS integrate advanced algorithms for real-time, granular monitoring of critical battery parameters (health, temperature, voltage, current). This comprehensive oversight is crucial for optimal performance, preventing detrimental conditions like overcharging or deep discharge, and significantly enhancing operational safety by mitigating thermal runaway risks. These intelligent systems increasingly incorporate predictive analytics, leveraging AI and machine learning to forecast maintenance needs, identify impending issues, and dynamically optimize charging strategies. This extends battery lifespan and drastically minimizes unscheduled downtime. Concurrently, fast-charging technologies are pivotal, with innovations in charger design and infrastructure reducing charging windows to minutes or hours, supporting continuous 24/7 operations and maximizing fleet utilization.

Looking ahead, several emerging technologies are poised to reshape the market. Solid-state batteries, though in advanced R&D for industrial applications, promise even higher energy densities, intrinsically greater safety, and ultra-fast charging. Furthermore, pervasive integration of cloud connectivity and IoT capabilities enables unprecedented remote monitoring, comprehensive data collection, and sophisticated analytics. This wealth of data provides operators with invaluable, actionable insights into fleet performance and energy consumption, facilitating proactive management. Parallel developments in advanced battery recycling processes and innovative second-life applications are gaining traction. These initiatives reflect broader industry commitment to circular economy principles and sustainable resource management, creating new value streams and mitigating environmental impact, shaping the market towards a more efficient, safer, and ecologically responsible paradigm.

Regional Highlights

- Asia-Pacific: Dominant market, propelled by rapid industrialization, a colossal manufacturing base, and burgeoning e-commerce sectors, particularly in China, India, and Japan. Characterized by high adoption of electric material handling equipment and substantial investments in modern industrial infrastructure, leading to continuous, high-volume demand for advanced battery solutions.

- North America: Robust market growth driven by strong commitment to advanced automation, increasingly stringent environmental regulations, and significant investments in sophisticated warehousing and logistics networks. The United States and Canada lead in early adoption of high-performance lithium-ion technologies and integration of smart Battery Management Systems (BMS), prioritizing efficiency and sustainability.

- Europe: Characterized by a pronounced focus on sustainability, highly advanced manufacturing, and strong regulatory frameworks supporting electric vehicle adoption in industrial settings. Germany, France, and the United Kingdom lead in R&D and implementation of efficient, environmentally conscious battery solutions tailored for advanced material handling and specialized industrial applications, aligning with the EUs green agenda.

- Latin America: Emerging market with increasing industrialization and modernization of logistics infrastructure. Growth is significantly driven by the expansion of mining operations (e.g., Chile, Brazil) and a growing manufacturing sector, leading to rising demand for durable, efficient, and robust traction batteries capable of withstanding diverse operational conditions and contributing to economic development.

- Middle East and Africa: Nascent yet promising growth trajectory, specifically propelled by substantial investments in critical infrastructure development, establishment of strategic logistics hubs, and expansion of mining sectors. The market emphasizes securing cost-effective, highly robust battery solutions tailored for diverse challenging operational requirements, with increasing awareness of environmental benefits and operational efficiencies offered by electric industrial vehicles.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Traction Battery Market.- EnerSys

- Exide Technologies

- Crown Equipment Corporation

- East Penn Manufacturing Co.

- Kion Group AG

- Curtis Instruments Inc.

- Microtex Batteries Private Limited

- Hoppecke Batterien GmbH & Co. KG

- FIAMM Energy Technology S.p.A.

- GS Yuasa Corporation

- C&D Technologies, Inc.

- Shandong Sacred Sun Power Sources Co., Ltd.

- Guangdong Aokly Power Co., Ltd.

- BYD Company Ltd.

- CATL (Contemporary Amperex Technology Co. Limited)

- LG Energy Solution

- Samsung SDI Co., Ltd.

- Northvolt AB

- ACCUMALUX S.A.

- ATIB Elettronica S.p.A.

- Delta-Q Technologies Corp.

- IBG-Goerz GmbH

Frequently Asked Questions

What are industrial traction batteries and their primary function?

Industrial traction batteries are specialized, deep-cycle rechargeable power sources engineered to provide sustained, high-capacity electrical energy for motive power in electric industrial vehicles and material handling equipment. Their primary function is to enable prolonged operational periods for machinery such as electric forklifts, automated guided vehicles (AGVs), mining locomotives, and airport ground support equipment, ensuring consistent performance in demanding industrial applications through repeated charge-discharge cycles.

What are the predominant types of industrial traction batteries available in the market?

The market is primarily dominated by two key types: lead-acid batteries and lithium-ion batteries. Lead-acid variants include flooded, sealed lead-acid (SLA), and gel batteries, favored for cost-effectiveness and proven reliability. Lithium-ion batteries, notably Lithium Iron Phosphate (LFP) and Nickel Manganese Cobalt (NMC) chemistries, are increasingly preferred for their superior energy density, faster charging capabilities, and significantly extended cycle life. Nickel-cadmium batteries are also utilized in niche applications for robust performance in extreme conditions.

What factors are driving the growth of the Industrial Traction Battery Market?

The markets expansion is fundamentally propelled by several critical factors: the global imperative towards industrial electrification to reduce carbon emissions, the exponential growth of e-commerce necessitating efficient warehousing and logistics, the increasing adoption of automation technologies like AGVs in manufacturing, and the implementation of stringent environmental regulations that favor cleaner industrial operations. Furthermore, continuous technological advancements in battery performance, energy management systems, and charging infrastructure significantly contribute to this robust growth trajectory.

What are the significant challenges confronting the Industrial Traction Battery Market?

Key challenges for the market include the relatively high initial capital expenditure associated with advanced battery technologies, particularly lithium-ion, which can be a barrier for some enterprises. Other major hurdles encompass the necessity for substantial investment in comprehensive charging infrastructure, the inherent volatility and supply chain risks related to critical raw material prices, and the ongoing technical complexities of ensuring optimal safety and efficient thermal management for high-energy density battery systems. Additionally, effective battery recycling and disposal remain persistent environmental and logistical concerns.

How is Artificial Intelligence (AI) influencing the industrial traction battery sector?

Artificial Intelligence profoundly influences the industrial traction battery market by enabling sophisticated optimizations across multiple facets. AI-driven algorithms enhance battery charging and discharge cycles to prolong lifespan and improve efficiency. Predictive maintenance, facilitated by AI, anticipates potential battery failures, minimizing downtime. Furthermore, AI is integrated into smart Battery Management Systems (BMS) for real-time diagnostics and performance optimization, playing a crucial role in improving overall energy management, fleet operations, and manufacturing processes for superior battery quality and resilience in industrial environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager