Industrial Virtual Pipeline Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430708 | Date : Nov, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Industrial Virtual Pipeline Market Size

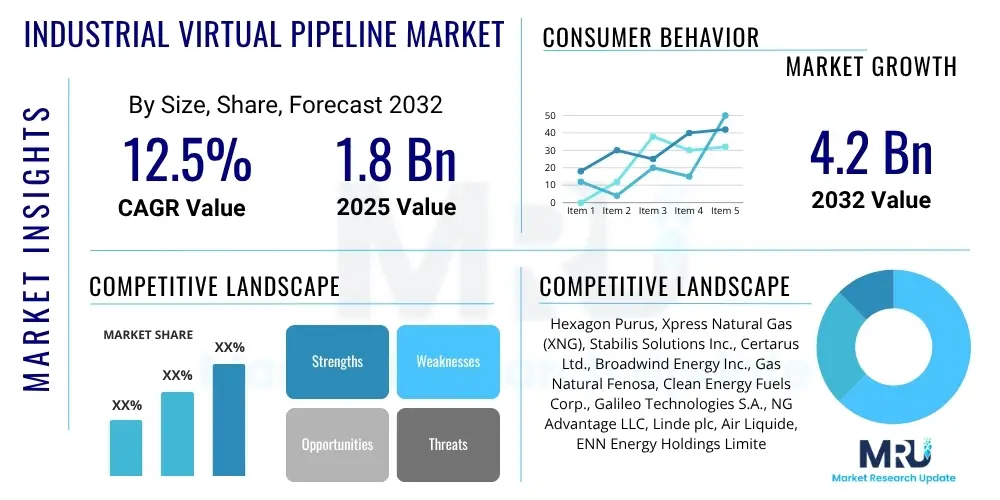

The Industrial Virtual Pipeline Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.5% between 2025 and 2032. The market is estimated at 1.8 Billion USD in 2025 and is projected to reach 4.2 Billion USD by the end of the forecast period in 2032.

Industrial Virtual Pipeline Market introduction

The Industrial Virtual Pipeline (IVP) market encompasses the transportation of natural gas, Liquefied Natural Gas (LNG), Compressed Natural Gas (CNG), and other industrial gases from supply sources to demand centers without the need for traditional, fixed pipelines. This is achieved through the use of specialized mobile transportation methods, primarily high-capacity trailers, trucks, ships, or railcars equipped with advanced containment vessels. These virtual pipelines offer a flexible and cost-effective alternative for delivering energy to remote industrial sites, areas with nascent infrastructure, or regions where constructing conventional pipelines is economically unfeasible or environmentally challenging. The core concept revolves around liquefaction or compression at the source, followed by transport, and then regasification or decompression at the consumption point, making energy access more versatile and responsive to fluctuating demand.

The product description highlights a comprehensive system comprising gas conditioning, compression or liquefaction units, specialized high-pressure storage and transportation modules, and terminal facilities for decompression or regasification. Major applications span across various industries including oil and gas for flare gas recovery, power generation in remote areas, manufacturing facilities requiring a reliable and scalable energy supply, mining operations, and even municipalities seeking cleaner energy solutions. This flexibility allows for the efficient monetization of stranded gas reserves and provides a robust energy bridge in regions lacking conventional pipeline networks, contributing significantly to global energy security and diversification.

The benefits of industrial virtual pipelines are multifaceted, including significant cost savings due to reduced infrastructure development, enhanced operational flexibility allowing rapid deployment and relocation, and environmental advantages through the utilization of cleaner fuels and reduction of gas flaring. Driving factors for market growth include the increasing global demand for energy, the discovery of new gas reserves in remote or unconventional locations, growing environmental regulations pushing for cleaner fuel alternatives, and technological advancements in gas compression, liquefaction, and transportation vessel materials. Furthermore, the rising focus on decentralized power generation and the need to extend gas infrastructure to underserved industrial zones are propelling the adoption of virtual pipeline solutions, positioning them as a critical component of modern energy logistics.

Industrial Virtual Pipeline Market Executive Summary

The Industrial Virtual Pipeline market is experiencing robust expansion, driven by critical business trends such as the escalating global energy demand, particularly from emerging industrial economies, and the increasing emphasis on sustainable and flexible energy supply solutions. Companies are investing heavily in advanced logistics platforms and specialized transportation fleets, integrating real-time monitoring and predictive analytics to enhance operational efficiency and safety. There is a discernible shift towards more modular and scalable virtual pipeline systems that can quickly adapt to changing supply and demand dynamics, reducing capital expenditure and lead times compared to traditional pipeline projects. Furthermore, strategic collaborations between gas producers, logistics providers, and end-users are becoming more prevalent, aiming to create integrated supply chains that optimize delivery routes and ensure reliable energy access.

Regional trends indicate significant growth opportunities in Asia Pacific, propelled by rapid industrialization, urbanization, and a strong push for natural gas as a transitional fuel, especially in countries like India and China where pipeline infrastructure is still developing. North America remains a significant market, characterized by mature oil and gas industries leveraging virtual pipelines for flare gas recovery and supplying remote drilling operations, alongside an increasing interest in transporting renewable gases like biomethane. Europe is focused on diversifying gas supply routes and enhancing energy security, with virtual pipelines playing a supplementary role in importing LNG and distributing it to landlocked industrial centers. Latin America and the Middle East & Africa regions are emerging as high-growth markets, driven by the monetization of stranded gas reserves, new industrial developments, and a need to reduce reliance on more polluting fuels.

Segmentation trends highlight a strong demand for both Compressed Natural Gas (CNG) and Liquefied Natural Gas (LNG) virtual pipeline solutions, with LNG gaining traction for longer distances and larger volumes due to its higher energy density. The application segment sees the oil and gas industry as a dominant end-user, utilizing virtual pipelines for wellhead gas monetization and remote field operations. However, significant growth is projected from the power generation sector, particularly for distributed power plants and off-grid electricity supply, along with robust demand from the manufacturing and mining sectors seeking reliable and cost-effective energy sources. This diversification across applications underscores the versatility and increasing acceptance of virtual pipeline technologies as an essential component of the global energy landscape.

AI Impact Analysis on Industrial Virtual Pipeline Market

User inquiries concerning AI's influence on the Industrial Virtual Pipeline market frequently revolve around its potential to revolutionize logistics, enhance operational safety, and optimize resource allocation. Key themes include predictive maintenance for transport vessels and compression/regasification units, intelligent route planning to minimize transit times and fuel consumption, and real-time demand forecasting for gas supply. Users are keen to understand how AI can mitigate risks associated with gas transportation, improve overall system efficiency, and contribute to more sustainable and cost-effective energy delivery. The overarching expectation is that AI will transform virtual pipelines from reactive systems to highly proactive and adaptive networks, capable of anticipating challenges and optimizing performance autonomously, thereby significantly increasing their competitiveness and reliability in the energy sector.

- AI-driven predictive maintenance for compressors, liquefaction units, and specialized transport vessels, reducing downtime and operational costs.

- Optimized logistics and route planning using machine learning algorithms to account for traffic, weather, road conditions, and demand fluctuations, enhancing delivery efficiency.

- Real-time monitoring and anomaly detection for gas containment and transportation, significantly improving safety protocols and preventing potential incidents.

- Automated demand forecasting and supply chain management, enabling better inventory control and ensuring consistent gas availability for end-users.

- Enhanced energy efficiency through AI control of compression and regasification processes, minimizing energy waste during gas handling.

- Development of autonomous or semi-autonomous virtual pipeline transport systems, leading to reduced labor costs and increased operational consistency.

DRO & Impact Forces Of Industrial Virtual Pipeline Market

The Industrial Virtual Pipeline market is propelled by several significant drivers, including the increasing global energy demand, particularly in regions with limited conventional pipeline infrastructure, and the growing focus on utilizing natural gas as a cleaner alternative to traditional fossil fuels. The flexibility and scalability offered by virtual pipelines make them an attractive solution for monetizing stranded gas assets and delivering energy to remote industrial sites or communities that are not economically viable for fixed pipeline connections. Furthermore, stringent environmental regulations aimed at reducing carbon emissions and mitigating gas flaring provide a strong impetus for adopting virtual pipeline technologies, which facilitate the capture and utilization of associated gas that would otherwise be wasted. The inherent cost-effectiveness in terms of initial capital expenditure and faster deployment compared to constructing physical pipelines also serves as a crucial driver for market expansion.

However, the market faces notable restraints, such as the high initial investment required for specialized transportation equipment, compression/liquefaction terminals, and regasification facilities, which can be a barrier for smaller players or regions with limited access to capital. Regulatory complexities and varying safety standards across different geographies for transporting hazardous materials like natural gas and LNG pose significant challenges for cross-border operations and market harmonization. The inherent safety concerns associated with the transportation of highly flammable gases, coupled with the potential for public opposition to increased heavy vehicle traffic, also act as formidable restraints. Additionally, intense competition from established conventional pipeline networks and alternative energy sources in specific regions can limit the market penetration and growth of virtual pipeline solutions, particularly for high-volume, long-term supply contracts.

Opportunities within the Industrial Virtual Pipeline market are abundant, especially in exploring untapped remote and offshore gas reserves that are currently uneconomical to exploit via traditional methods. The burgeoning demand for hydrogen as a clean energy carrier presents a substantial future growth avenue, as virtual pipelines could be adapted for its transportation, leveraging existing infrastructure and expertise. Continuous advancements in materials science, particularly for high-pressure composite vessels, and the integration of advanced digital technologies like IoT, AI, and telematics are creating more efficient, safer, and cost-effective virtual pipeline solutions. The expansion into new industrial applications, such as distributed power generation, industrial feedstock supply, and the provision of fuel for heavy-duty transportation, further broadens the market's potential, ensuring its long-term viability and growth trajectory. The industry is also poised to capitalize on opportunities in developing countries where rapid industrialization outpaces infrastructure development, creating a strong demand for flexible energy delivery.

Segmentation Analysis

The Industrial Virtual Pipeline market is comprehensively segmented based on various critical attributes, allowing for a detailed understanding of its dynamics and growth trajectories. These segmentations typically include the type of gas transported, the specific application or end-use industry, and the primary mode of transportation employed. This structured approach helps in identifying distinct market niches, understanding the competitive landscape within each segment, and forecasting demand patterns across diverse industrial requirements. By analyzing these segments, stakeholders can better tailor their products and services to meet specific customer needs, optimize their supply chain, and strategize for targeted market expansion, ensuring sustained growth and relevance in a rapidly evolving energy sector.

- By Type

- Compressed Natural Gas (CNG) Virtual Pipeline

- Liquefied Natural Gas (LNG) Virtual Pipeline

- Other Industrial Gases (e.g., Biogas, Hydrogen, Propane, Ethane)

- By Application

- Oil and Gas (Wellhead Gas Monetization, Flare Gas Recovery, Remote Drilling)

- Power Generation (Distributed Power Plants, Off-grid Electricity)

- Industrial Feedstock and Fuel (Manufacturing, Chemical, Metallurgy)

- Mining Operations

- Commercial and Residential (Remote Communities, Heating)

- Transportation Fuel (Heavy-Duty Vehicles, Marine)

- By Mode of Transportation

- Truck-based Virtual Pipeline

- Rail-based Virtual Pipeline

- Ship-based Virtual Pipeline

Value Chain Analysis For Industrial Virtual Pipeline Market

The value chain of the Industrial Virtual Pipeline market begins with the upstream activities primarily centered around gas sourcing and conditioning. This involves the exploration, production, and processing of natural gas, as well as the initial treatment such as dehydration and impurity removal. Following this, the gas undergoes either compression for CNG or liquefaction for LNG, transforming it into a transportable state. This initial phase requires significant investment in gas processing facilities, specialized compression stations, or liquefaction plants, which are crucial for preparing the gas for efficient long-distance movement. Key players in this segment include major oil and gas companies, independent gas producers, and specialized engineering firms that design and build these processing units, ensuring the gas meets quality specifications for downstream applications.

Moving downstream, the value chain encompasses the actual transportation and final delivery to the end-users. This phase involves specialized logistics companies, equipment manufacturers providing high-pressure storage vessels (e.g., cascades for CNG, cryogenic tanks for LNG) and trailers, and advanced telemetry systems for monitoring gas parameters during transit. Upon reaching the destination, the gas undergoes decompression or regasification at the receiving terminal before being injected into the end-user's distribution network or directly consumed. This stage demands sophisticated infrastructure for safe handling and integration with existing industrial or power generation systems. Downstream activities are critical for maintaining the integrity and availability of the gas supply, making reliability and safety paramount.

The distribution channel within the Industrial Virtual Pipeline market can be categorized into direct and indirect methods. Direct distribution typically involves virtual pipeline operators or gas suppliers directly contracting with large industrial end-users or power plants, managing the entire supply chain from source to consumption point. This direct engagement ensures tailored solutions and often long-term supply agreements. Indirect distribution involves third-party logistics providers, specialized freight companies, or regional distributors who facilitate the transportation and delivery on behalf of gas producers or marketers. These intermediaries often possess the expertise in hazardous materials transport and access to specialized fleets, extending the reach of virtual pipeline services to a wider array of customers. Both channels contribute to the market's reach and flexibility, adapting to diverse operational scales and customer requirements.

Industrial Virtual Pipeline Market Potential Customers

Potential customers for the Industrial Virtual Pipeline market primarily encompass a broad spectrum of industries and entities that require a reliable and flexible supply of natural gas or other industrial gases, especially in locations where conventional pipeline infrastructure is either non-existent, insufficient, or economically unfeasible. This includes industrial facilities situated in remote or underserved geographical areas that face challenges in accessing traditional grid-supplied energy. Manufacturing plants, particularly those in energy-intensive sectors such as steel, cement, glass, and chemicals, represent a significant customer base. These facilities often require large, consistent volumes of gas for processes like heating, firing, and as a feedstock, and benefit from the consistent supply and cost predictability offered by virtual pipelines, especially when replacing more expensive or polluting fuels.

Another crucial segment of end-users consists of power generation companies, specifically those operating distributed power plants, off-grid electricity systems, or temporary power solutions for large-scale projects. Virtual pipelines enable these power generators to establish operations in remote regions, providing essential electricity without the substantial upfront investment and long lead times associated with physical pipelines. Furthermore, the oil and gas industry itself is a major consumer, leveraging virtual pipelines for flare gas recovery at remote wellheads, supplying gas to isolated drilling and production sites, and for early production facilities that precede the installation of permanent pipeline infrastructure. This allows for the monetization of associated gas that would otherwise be flared, contributing to both economic and environmental benefits.

Beyond the core industrial and power sectors, potential customers also include mining operations in isolated locations that require significant energy for machinery and processing, municipal authorities seeking to provide cleaner energy to remote communities, and large commercial establishments or resorts that cannot be connected to the gas grid. Emerging applications also include the transportation of natural gas as a fuel for heavy-duty transportation fleets, including trucks, rail, and marine vessels, promoting a cleaner alternative to diesel. The versatility of virtual pipelines in addressing diverse energy needs across various industrial and commercial landscapes underscores their growing importance and the expanding base of potential customers actively seeking these flexible and efficient gas delivery solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | 1.8 Billion USD |

| Market Forecast in 2032 | 4.2 Billion USD |

| Growth Rate | 12.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hexagon Purus, Xpress Natural Gas (XNG), Stabilis Solutions Inc., Certarus Ltd., Broadwind Energy Inc., Gas Natural Fenosa, Clean Energy Fuels Corp., Galileo Technologies S.A., NG Advantage LLC, Linde plc, Air Liquide, ENN Energy Holdings Limited, CP Energy Group, Prometheus Energy Company, Global Gas Solutions, GenNx360 Capital Partners, Titan CNG, Wärtsilä, Cryostar, Flogas. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Virtual Pipeline Market Key Technology Landscape

The Industrial Virtual Pipeline market is underpinned by a dynamic and evolving technology landscape focused on enhancing efficiency, safety, and cost-effectiveness across the entire gas supply chain. Central to this are advanced gas compression and liquefaction technologies, which are crucial for preparing natural gas for transportation. High-efficiency compressors, often incorporating variable speed drives and smart controls, minimize energy consumption during the compression of CNG. For LNG, advanced cryogenic liquefaction plants, including modular and compact designs, are becoming more prevalent, allowing for deployment closer to smaller gas fields and reducing infrastructure footprint. These technologies ensure that gas is processed to its optimal state for transport, maximizing volume within safety limits and minimizing energy loss.

Another critical area of technological innovation lies in the design and materials of high-pressure containment vessels and transportation modules. The adoption of lightweight, high-strength composite materials, such as carbon fiber reinforced polymers, for CNG cascade cylinders significantly reduces the tare weight of trailers, enabling greater payload capacity and improved fuel efficiency during transport. For LNG, advanced cryogenic tank designs, incorporating vacuum insulation and multi-layered materials, minimize boil-off losses during transit, preserving the integrity and quantity of the liquefied gas over long distances. These advancements in material science and engineering are pivotal in improving the safety, durability, and economic viability of virtual pipeline operations, making the mobile transport of large volumes of gas increasingly practical.

Furthermore, the integration of digital technologies, including the Internet of Things (IoT), telematics, and advanced analytics, is transforming the operational aspects of virtual pipelines. IoT sensors embedded in storage vessels and transport units provide real-time data on pressure, temperature, fill levels, and GPS location, allowing for continuous monitoring and proactive incident management. Telematics systems optimize fleet management, enabling dynamic route optimization, predictive maintenance scheduling for vehicles, and efficient dispatching based on demand and traffic conditions. Predictive analytics, often powered by artificial intelligence, processes this vast dataset to forecast demand, identify potential equipment failures, and enhance overall supply chain resilience. These technological innovations collectively contribute to a smarter, safer, and more responsive virtual pipeline ecosystem, significantly impacting operational efficiency and customer satisfaction.

Regional Highlights

- North America: This region is a mature yet expanding market, driven by the abundant shale gas resources and the necessity to monetize associated gas from remote drilling sites. Virtual pipelines are extensively used for flare gas recovery and supplying remote industrial and power generation facilities. The focus is on optimizing logistics and integrating advanced digital solutions to enhance existing infrastructure.

- Europe: Characterized by stringent environmental regulations and a strong emphasis on energy security and diversification of gas supplies, Europe utilizes virtual pipelines primarily for distributing imported LNG to industrial zones not connected by traditional grids and as a backup supply. There is also a growing interest in transporting biomethane and potentially hydrogen in the future.

- Asia Pacific (APAC): APAC represents the fastest-growing market due to rapid industrialization, urbanization, and a significant energy demand-supply gap, particularly in emerging economies like India, China, and Southeast Asian nations. Virtual pipelines are crucial for extending gas access to regions lacking comprehensive pipeline networks and for facilitating the transition to cleaner fuels in manufacturing and power generation.

- Latin America: This region is emerging with significant potential, driven by the development of new oil and gas fields, especially in countries like Argentina and Brazil, and the need to supply gas to isolated industrial and mining operations. Virtual pipelines offer a flexible solution to overcome challenging terrains and limited infrastructure, supporting economic development and energy access.

- Middle East and Africa (MEA): The MEA region is witnessing growth spurred by initiatives to reduce gas flaring, monetize stranded gas assets, and meet the energy demands of expanding industrial sectors. Virtual pipelines provide a viable solution for delivering gas to new industrial projects and remote communities, particularly in countries with vast gas reserves but underdeveloped distribution infrastructure.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Virtual Pipeline Market.- Hexagon Purus

- Xpress Natural Gas (XNG)

- Stabilis Solutions Inc.

- Certarus Ltd.

- Broadwind Energy Inc.

- Gas Natural Fenosa

- Clean Energy Fuels Corp.

- Galileo Technologies S.A.

- NG Advantage LLC

- Linde plc

- Air Liquide

- ENN Energy Holdings Limited

- CP Energy Group

- Prometheus Energy Company

- Global Gas Solutions

- GenNx360 Capital Partners

- Titan CNG

- Wärtsilä

- Cryostar

- Flogas

Frequently Asked Questions

What defines an industrial virtual pipeline?

An industrial virtual pipeline is a flexible gas transportation system that delivers natural gas, LNG, CNG, or other industrial gases from a source to an end-user without a fixed physical pipeline. This is accomplished using specialized mobile transport such as trucks, railcars, or ships equipped with high-capacity containment vessels, offering a versatile and scalable energy solution for remote or underserved locations.

What are the primary benefits of utilizing virtual pipelines?

Virtual pipelines offer numerous benefits, including significant cost savings by avoiding the substantial capital expenditure and lengthy construction times of traditional pipelines. They provide enhanced operational flexibility, allowing for rapid deployment and relocation based on demand. Furthermore, they support environmental objectives by enabling the use of cleaner fuels and the capture of flared gas, reducing emissions and operational footprint.

Which industries are the main adopters of industrial virtual pipelines?

The main industries adopting industrial virtual pipelines include the oil and gas sector for wellhead gas monetization and flare gas recovery, power generation companies for distributed and off-grid electricity supply, and various manufacturing facilities (e.g., chemicals, cement, metallurgy) requiring consistent gas feedstock or fuel. Mining operations in remote areas also heavily rely on virtual pipelines for their energy needs.

What types of gases can be efficiently transported via virtual pipeline systems?

Virtual pipeline systems are primarily designed for the efficient transportation of various industrial gases. The most common include Compressed Natural Gas (CNG) and Liquefied Natural Gas (LNG). Additionally, these systems can be adapted to transport other specialized industrial gases such as biogas, propane, ethane, and with ongoing technological advancements, potentially hydrogen, catering to diverse energy and industrial requirements.

What are the future growth prospects and emerging trends in the industrial virtual pipeline market?

The future of the industrial virtual pipeline market is characterized by strong growth, driven by increasing energy demand in developing regions and the global transition to cleaner fuels. Emerging trends include advanced material science for lighter, safer containment vessels, enhanced integration of AI and IoT for optimized logistics and predictive maintenance, and the potential expansion into hydrogen transportation. These factors will continue to broaden its application scope and enhance its competitiveness.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager