Industrial Wooden Crates Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429968 | Date : Nov, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Industrial Wooden Crates Market Size

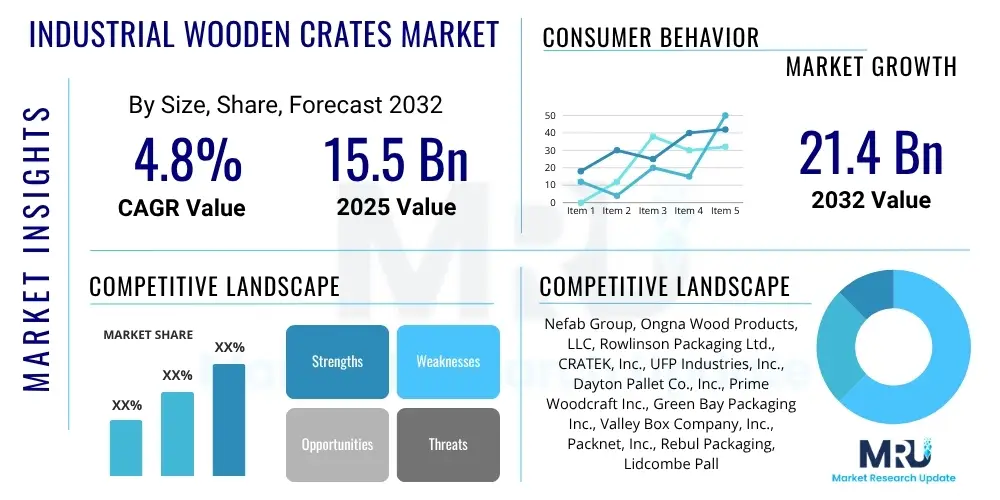

The Industrial Wooden Crates Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2025 and 2032. The market is estimated at USD 15.5 Billion in 2025 and is projected to reach USD 21.4 Billion by the end of the forecast period in 2032.

Industrial Wooden Crates Market introduction

The Industrial Wooden Crates Market encompasses the design, manufacturing, and distribution of robust wooden containers primarily used for packaging, shipping, and storing heavy, fragile, or unusually shaped industrial goods. These crates serve as critical components in the global supply chain, ensuring the safe transit of products across various industries. They are engineered to provide superior protection against physical damage, moisture, and environmental stressors during handling, transportation, and storage, making them indispensable for international trade and domestic logistics.

Industrial wooden crates are custom-built packaging solutions that offer exceptional strength, durability, and versatility. They are constructed from various types of wood, including pine, oak, and plywood, often treated for pest control (ISPM 15 compliance) to facilitate international shipping. Their primary applications span numerous sectors, including heavy machinery, automotive components, aerospace parts, electronics, agricultural produce, and defense equipment. The inherent benefits of wooden crates include their high load-bearing capacity, shock absorption, recyclability, and ability to be custom-fabricated to precise specifications, accommodating items of diverse sizes and weights. These attributes, coupled with their relatively cost-effective nature compared to some alternative materials, underscore their continued relevance in industrial packaging.

Key driving factors propelling the growth of this market include the sustained expansion of global manufacturing industries, the increasing volume of international trade, and the burgeoning demand for specialized and protective packaging solutions. Furthermore, the rising focus on sustainable and recyclable packaging materials positions wooden crates favorably, given wood's renewable nature. The ongoing globalization of supply chains, coupled with the need for secure and reliable transit of high-value industrial assets, continues to fuel demand for custom-engineered wooden crates, supporting market expansion through the forecast period.

Industrial Wooden Crates Market Executive Summary

The Industrial Wooden Crates Market is currently experiencing robust growth, driven by an expanding global manufacturing sector and intensified international trade activities. Business trends highlight a strong emphasis on customization, with manufacturers increasingly investing in advanced design software and automated cutting technologies to produce crates that precisely meet specific industry requirements, from shock absorption for sensitive electronics to heavy-duty support for machinery. The focus is also shifting towards sustainability, with a growing demand for crates made from sustainably sourced and recyclable timber, aligning with corporate environmental responsibilities and consumer preferences.

Regionally, Asia Pacific continues to dominate the market, largely due to its extensive manufacturing base and significant export activities, particularly in countries like China, India, and Southeast Asian nations. North America and Europe represent mature markets, where demand is stable and driven by high-value industrial goods, sophisticated logistics, and stringent quality standards. Emerging economies in Latin America, the Middle East, and Africa are showing promising growth, fueled by infrastructure development, industrialization initiatives, and increased foreign investment, thereby expanding the potential customer base for wooden crates in these regions.

Segmentation trends indicate a strong demand for heavy-duty and custom-sized crates, reflecting the diverse and often specialized nature of industrial goods being transported. The market is also seeing a rise in heat-treated (ISPM 15 compliant) wood solutions, crucial for preventing pest infestations during international shipping. Furthermore, the adoption of collapsible or reusable wooden crates is gaining traction, offering cost efficiencies and environmental benefits. Innovation in wood processing and crate design continues to shape segment dynamics, catering to evolving logistical challenges and industry-specific protective packaging needs.

AI Impact Analysis on Industrial Wooden Crates Market

User inquiries about AI's impact on the Industrial Wooden Crates Market frequently revolve around how artificial intelligence can optimize manufacturing processes, enhance supply chain efficiency, and improve product design. Common questions address the potential for AI-driven demand forecasting, smart inventory management, and automated quality control for wood and crate assembly. Users are keenly interested in how AI can lead to more efficient resource utilization, reduce waste in production, and integrate predictive analytics for maintenance of machinery involved in crate fabrication. There is also significant curiosity about AI's role in creating "smart packaging" solutions, such as intelligent tracking and condition monitoring embedded within or facilitated by the crates themselves, to provide real-time data during transit and storage. Expectations are high that AI will streamline operations, cut costs, and ultimately elevate the overall value proposition of industrial wooden crates within the broader logistics ecosystem.

- AI-powered demand forecasting optimizes wood procurement and production schedules.

- Generative design algorithms assist in creating optimized crate designs for specific products, reducing material usage.

- Automated quality inspection systems improve consistency and detect defects in wood and assembled crates.

- Predictive maintenance for manufacturing equipment reduces downtime and increases operational efficiency.

- AI-driven supply chain optimization enhances logistics, tracking, and delivery efficiency for crates.

- Intelligent inventory management systems reduce storage costs and minimize waste of raw materials.

- Machine learning algorithms can analyze transit data to recommend optimal packaging and route choices.

- Integration with RFID and IoT sensors can enable smart crates for real-time condition monitoring during shipment.

DRO & Impact Forces Of Industrial Wooden Crates Market

The Industrial Wooden Crates Market is significantly influenced by a confluence of drivers, restraints, opportunities, and broader impact forces that shape its growth trajectory. Key drivers include the robust expansion of global manufacturing sectors, particularly in heavy machinery, automotive, and electronics, which necessitate protective packaging for their products. The increasing volume of international trade, coupled with stringent shipping regulations requiring durable and secure packaging, further boosts demand. Additionally, the growing e-commerce sector for B2B industrial components and the rising emphasis on sustainable packaging solutions, given wood's renewable nature, are pivotal in driving market expansion.

However, the market also faces considerable restraints. Volatility in timber prices, influenced by supply chain disruptions, environmental policies, and geopolitical factors, can impact production costs and market stability. Competition from alternative packaging materials like plastic, metal, and corrugated cardboard, which may offer advantages in weight, reusability, or weather resistance for specific applications, poses a challenge. Furthermore, environmental regulations concerning deforestation and sustainable sourcing, while also presenting opportunities, can act as restraints if compliance costs become prohibitive or raw material access is restricted. The lead times required for custom crate orders can also sometimes be a limiting factor for fast-paced logistics operations.

Opportunities for growth lie in the increasing demand for highly customized and specialized crates tailored to unique product specifications, offering enhanced protection and value. The development of 'smart' crates integrated with IoT sensors for tracking and condition monitoring presents a significant avenue for innovation. Expanding into emerging markets with rapidly industrializing economies, alongside the adoption of lightweight and collapsible crate designs for improved logistics efficiency, are also key opportunities. The underlying impact forces include global economic growth, which directly correlates with industrial output and trade, technological advancements in wood processing and automation, and evolving regulatory landscapes related to trade and environmental protection, all of which dynamically influence market dynamics.

Segmentation Analysis

The Industrial Wooden Crates Market is segmented based on various attributes, including the type of crate, the specific wood used, the application industry, the size of the crate, and the end-use industry. This segmentation helps to understand the diverse demands and preferences across different sectors, allowing manufacturers to tailor their products and services effectively. The market encompasses a wide range of products from standard, heavy-duty shipping containers to specialized, custom-designed packaging for highly sensitive or oversized industrial components.

Each segment reflects unique requirements and growth drivers. For instance, heavy-duty crates are predominantly used for shipping large machinery and equipment, where maximum protection and load-bearing capacity are paramount. In contrast, light-duty crates might be suitable for smaller, less fragile industrial parts. The choice of wood type often depends on cost, durability requirements, and regulatory compliance (e.g., ISPM 15 for international shipping). Understanding these intricate segments is crucial for market players to identify niche opportunities, optimize their product portfolios, and develop targeted marketing strategies that resonate with specific customer needs within the industrial packaging landscape.

- By Type

- Heavy Duty Crates

- Medium Duty Crates

- Light Duty Crates

- Collapsible Crates

- Reusable Crates

- By Wood Type

- Pine Wood Crates

- Oak Wood Crates

- Plywood Crates

- Hardwood Crates

- Engineered Wood Crates

- Other Wood Types

- By Application

- Machinery & Equipment Packaging

- Automotive Parts Packaging

- Electronics Components Packaging

- Aerospace & Defense Packaging

- Agricultural Product Packaging

- Medical Equipment Packaging

- Industrial Parts & Components Packaging

- Others

- By Size

- Small Crates

- Medium Crates

- Large Crates

- Custom Sized Crates

- By End-Use Industry

- Manufacturing

- Logistics & Shipping

- Automotive

- Aerospace & Defense

- Electronics

- Agriculture

- Construction

- Energy

- Pharmaceutical & Healthcare

- Others

Value Chain Analysis For Industrial Wooden Crates Market

The value chain for the Industrial Wooden Crates Market begins with the upstream activities involving the sourcing and processing of raw materials. This typically includes sustainable timber harvesting from forests, followed by primary processing at sawmills to convert logs into lumber. Further upstream activities involve kiln drying, grading, and treating the wood to ensure it meets quality standards and regulatory requirements, such as ISPM 15 for international trade. These initial stages are critical as they determine the quality, cost, and availability of the foundational material for crate manufacturing.

Midstream activities primarily focus on the manufacturing process itself. This involves cutting and shaping the lumber into specific components, assembling the crates, and integrating any specialized features such as bracing, skids, or internal dunnage. Manufacturers often leverage computer-aided design (CAD) and computer numerical control (CNC) machinery to achieve precision and efficiency, especially for custom orders. Quality control, finishing, and packaging of the crates for distribution are also integral parts of this stage, ensuring the final product is robust, fit-for-purpose, and ready for shipment.

Downstream analysis encompasses the distribution channels and ultimate end-users. Industrial wooden crates reach their potential customers through various channels, including direct sales from manufacturers to large industrial clients, through distributors and wholesalers specializing in packaging solutions, or via third-party logistics (3PL) providers who integrate packaging services into their broader offerings. The end-users, such as manufacturing firms, automotive companies, and aerospace industries, then utilize these crates for their own product packaging and shipping needs. Both direct sales, offering tailored solutions and stronger client relationships, and indirect channels, providing broader market reach and convenience, play crucial roles in ensuring market penetration and customer accessibility.

Industrial Wooden Crates Market Potential Customers

Potential customers for industrial wooden crates represent a diverse array of industries that require robust and reliable packaging solutions for their products, particularly for shipping heavy, fragile, or high-value goods globally. The primary end-users are manufacturing companies across various sectors, including those producing heavy machinery, industrial equipment, and large components, which rely on crates for secure transit and protection against physical damage and environmental factors during storage and transportation. These manufacturers often have specific requirements for load-bearing capacity, internal dunnage, and overall crate dimensions tailored to their unique product lines.

Another significant customer segment includes logistics and freight forwarding companies. These entities frequently purchase industrial wooden crates to offer comprehensive packaging and shipping services to their clients. They are driven by the need for versatile, durable, and compliant packaging solutions that can withstand the rigors of multi-modal transportation, ensuring the integrity of goods from origin to destination. The automotive industry, including original equipment manufacturers (OEMs) and aftermarket parts suppliers, constitutes a major buyer due to the constant movement of engines, transmissions, and large body parts that require robust and often custom-designed wooden crates for protection.

Furthermore, aerospace and defense contractors regularly utilize industrial wooden crates for transporting sensitive aircraft components, military hardware, and specialized equipment, where precision protection and security are paramount. The electronics industry, for large appliances and industrial-grade electronics, and the agriculture sector, for bulk shipping of certain produce or machinery, also represent substantial customer bases. Construction companies requiring transit for heavy tools or prefabricated building elements, and companies involved in the energy sector for equipment like turbines or solar panels, also contribute significantly to the demand for specialized wooden crating solutions. The diversity of these end-user industries underscores the widespread utility and indispensability of industrial wooden crates in the global economy.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 15.5 Billion |

| Market Forecast in 2032 | USD 21.4 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Nefab Group, Ongna Wood Products, LLC, Rowlinson Packaging Ltd., CRATEK, Inc., UFP Industries, Inc., Dayton Pallet Co., Inc., Prime Woodcraft Inc., Green Bay Packaging Inc., Valley Box Company, Inc., Packnet, Inc., Rebul Packaging, Lidcombe Pallet & Crates, Australian Crates & Boxes, Crate and Pack Solutions, Universal Forest Products, Inc., Conifer Wood Pack Private Limited, Atlas Box & Crating Co. Inc., Timber Creek Pallet & Crate, Inc., Timber Packaging & Pallet Co. Ltd., Fox Blocks |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Wooden Crates Market Key Technology Landscape

The Industrial Wooden Crates Market is increasingly leveraging advanced technologies to enhance efficiency, precision, and sustainability throughout the manufacturing process. Computer-aided design (CAD) software plays a crucial role in creating highly customized crate designs, allowing for precise dimensions, optimal material utilization, and virtual prototyping to ensure structural integrity. This digital approach minimizes material waste and shortens design cycles, addressing the growing demand for bespoke packaging solutions for diverse industrial goods. Furthermore, the integration of automation and robotics in cutting, shaping, and assembly lines is becoming more prevalent, particularly in larger manufacturing facilities, to improve production speed and consistency.

Computer Numerical Control (CNC) machinery is a cornerstone of modern crate manufacturing, enabling highly accurate cutting and drilling of wood components. This technology ensures that each piece fits perfectly, resulting in stronger, more reliable crates and reducing manual errors. Beyond manufacturing, the adoption of tracking technologies like Radio Frequency Identification (RFID) and Global Positioning System (GPS) is transforming supply chain management. These technologies allow for real-time monitoring of crate location and condition during transit, providing valuable data for logistics optimization, security, and ensuring the integrity of high-value cargo. Such advancements are critical for meeting the increasingly complex demands of global trade and logistics.

Moreover, technologies related to wood treatment and quality control are also advancing. Heat treatment facilities, vital for ISPM 15 compliance to prevent pest infestations in international shipments, are becoming more energy-efficient and precise. Non-destructive testing methods, such as moisture detection sensors and advanced visual inspection systems, are used to assess wood quality, identify defects, and ensure durability before assembly. These technological improvements collectively contribute to producing higher-quality, more sustainable, and more functional industrial wooden crates, catering to the evolving needs of various end-user industries and bolstering the market's competitive edge.

Regional Highlights

- North America: This region represents a mature market characterized by advanced manufacturing capabilities and a strong demand for high-quality, specialized packaging solutions, particularly from the automotive, aerospace, and heavy machinery sectors. The focus here is on efficiency, reliability, and increasingly, sustainability.

- Europe: European countries exhibit a robust demand driven by stringent environmental regulations and a focus on sustainable sourcing and recyclable materials. Key industries such as automotive, pharmaceuticals, and industrial machinery contribute significantly, alongside a preference for custom-engineered and compliant packaging for international trade.

- Asia Pacific (APAC): APAC is the largest and fastest-growing market, propelled by its status as a global manufacturing hub and burgeoning export activities. Rapid industrialization in countries like China, India, Japan, and Southeast Asian nations generates immense demand for industrial packaging, with a strong emphasis on cost-effectiveness and volume production.

- Latin America: This region is experiencing steady growth, fueled by developing industrial bases, increasing agricultural exports, and infrastructure projects. Countries such as Brazil and Mexico are emerging as significant contributors to the demand for wooden crates, particularly for agricultural machinery and raw material exports.

- Middle East and Africa (MEA): The MEA region shows promising potential, driven by ongoing infrastructure development, investments in oil & gas, mining, and emerging manufacturing sectors. The need for robust packaging for heavy equipment and machinery used in these industries is a primary growth driver.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Wooden Crates Market.- Nefab Group

- Ongna Wood Products, LLC

- Rowlinson Packaging Ltd.

- CRATEK, Inc.

- UFP Industries, Inc.

- Dayton Pallet Co., Inc.

- Prime Woodcraft Inc.

- Green Bay Packaging Inc.

- Valley Box Company, Inc.

- Packnet, Inc.

- Rebul Packaging

- Lidcombe Pallet & Crates

- Australian Crates & Boxes

- Crate and Pack Solutions

- Universal Forest Products, Inc.

- Conifer Wood Pack Private Limited

- Atlas Box & Crating Co. Inc.

- Timber Creek Pallet & Crate, Inc.

- Timber Packaging & Pallet Co. Ltd.

- Fox Blocks

Frequently Asked Questions

What are industrial wooden crates primarily used for?

Industrial wooden crates are primarily used for the protective packaging, shipping, and storage of heavy, fragile, or unusually shaped industrial goods, ensuring their safe transit across global supply chains.

Why choose wooden crates over other packaging materials?

Wooden crates offer superior strength, high load-bearing capacity, customization flexibility for specific product dimensions, and shock absorption, making them ideal for heavy or valuable industrial items. They are also often a sustainable and recyclable option.

Are industrial wooden crates environmentally friendly?

Yes, when sourced from sustainably managed forests and designed for reusability or recyclability, industrial wooden crates are considered an environmentally friendly packaging solution due to wood being a renewable resource.

How does customization work for industrial wooden crates?

Customization involves designing crates to precise specifications based on the product's size, weight, fragility, and transportation requirements. This often includes specialized bracing, dunnage, and external dimensions, often facilitated by CAD software.

What is ISPM 15 compliance in relation to wooden crates?

ISPM 15 (International Standards for Phytosanitary Measures No. 15) is an international treaty that requires all wood packaging materials used in international trade to be debarked and heat treated or fumigated to prevent the spread of pests and diseases.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager