Inspection Machines Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427563 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Inspection Machines Market Size

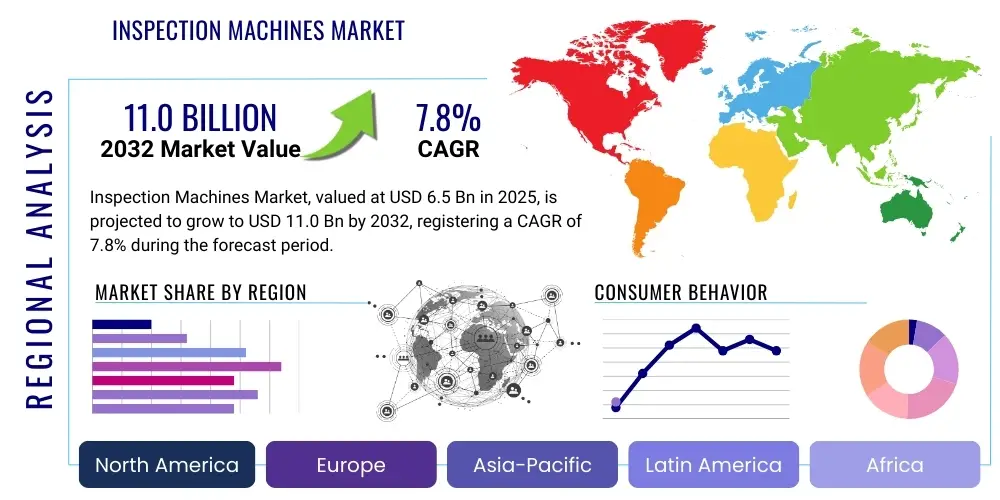

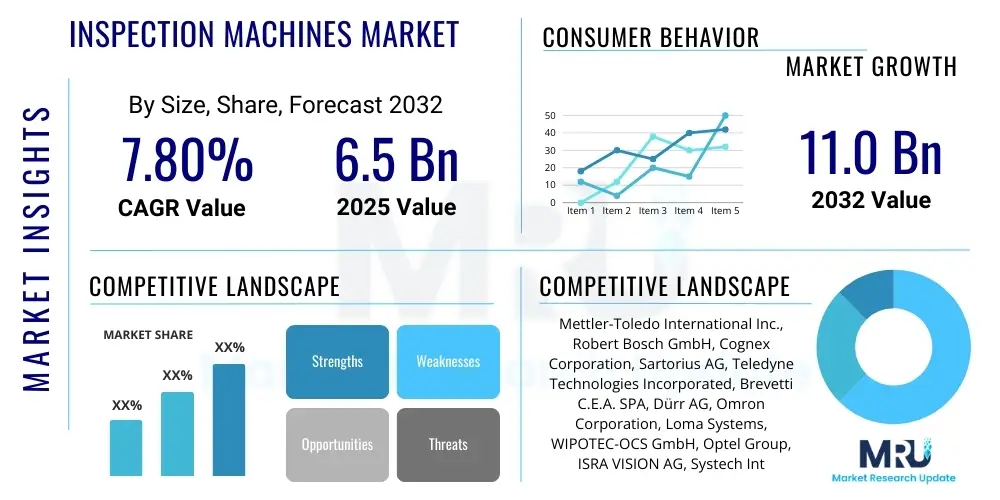

The Inspection Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at USD 6.5 Billion in 2025 and is projected to reach USD 11.0 Billion by the end of the forecast period in 2032.

Inspection Machines Market introduction

Inspection machines represent a critical technological cornerstone in modern industrial quality assurance, designed to meticulously examine products for defects, contaminants, or deviations from specified standards. These sophisticated systems utilize a variety of advanced technologies, including machine vision, X-ray, metal detection, and checkweighing, to ensure product integrity, safety, and compliance with stringent regulatory requirements. The primary function of these machines is to enhance production line efficiency by minimizing manual inspection errors, accelerating detection processes, and maintaining consistent quality across large volumes of manufactured goods. They are indispensable for industries where product reliability and consumer safety are paramount, offering unparalleled precision and speed in detecting even minute imperfections.

Major applications of inspection machines span across a multitude of sectors, significantly impacting quality control in pharmaceuticals, food and beverage processing, automotive manufacturing, electronics assembly, and medical device production. In the pharmaceutical sector, they are crucial for detecting foreign particles in injectables, ensuring proper tablet coating, and verifying packaging integrity. For food and beverage industries, these machines protect against physical contaminants, check fill levels, and confirm label accuracy, safeguarding public health. The automotive and electronics industries leverage inspection machines to verify component dimensions, solder joint quality, and assembly correctness, which is vital for product performance and longevity. The benefits derived from deploying these advanced systems are extensive, including reduced product recalls, enhanced brand reputation, increased operational throughput, and significant cost savings associated with waste reduction and optimized resource utilization.

The market for inspection machines is driven by several compelling factors. Foremost among these are the increasingly stringent regulatory landscapes, particularly from bodies like the FDA and EMEA, which mandate rigorous quality control standards across various manufacturing sectors. The escalating demand for high-quality, defect-free products from discerning consumers further propels market expansion. Furthermore, the global shift towards greater automation in manufacturing processes, fueled by Industry 4.0 initiatives and the need to mitigate rising labor costs, is a significant catalyst. The continuous advancements in sensing technologies, artificial intelligence, and data analytics also contribute to the development of more capable and efficient inspection solutions, thereby expanding their applicability and market penetration.

Inspection Machines Market Executive Summary

The Inspection Machines Market is currently experiencing robust growth, primarily driven by an increasing emphasis on product quality, safety, and regulatory compliance across global manufacturing sectors. Key business trends include a notable shift towards integrated and fully automated inspection solutions that can seamlessly interface with existing production lines, thereby enhancing overall operational efficiency and reducing human intervention. The competitive landscape is characterized by continuous innovation, with leading manufacturers investing heavily in research and development to introduce advanced capabilities such as predictive maintenance, enhanced data analytics, and user-friendly interfaces. Strategic partnerships and mergers and acquisitions are also prevalent, as companies seek to consolidate market share, expand technological portfolios, and gain access to new geographical markets. The demand for customized solutions tailored to specific product types and industry needs is also a significant trend, driving manufacturers to offer more flexible and modular system designs.

From a regional perspective, North America and Europe continue to hold substantial market shares, primarily due to the presence of well-established pharmaceutical, medical device, and food processing industries, coupled with stringent regulatory frameworks that necessitate advanced inspection technologies. These regions are characterized by early adoption of new technologies and high investment in automation and quality control. However, the Asia-Pacific region is poised for the fastest growth, propelled by rapid industrialization, expanding manufacturing bases in countries like China and India, and increasing foreign direct investment in manufacturing sectors. The rising awareness regarding product quality and safety among consumers in developing economies, along with a growing middle class, is further accelerating the adoption of inspection machines in this region. Latin America, the Middle East, and Africa also present emerging opportunities, as these regions witness infrastructure development and industrial expansion.

Market segmentation trends highlight the dominance of vision-based inspection systems, which are widely adopted due to their versatility and high precision in detecting visual defects, label errors, and ensuring correct product assembly. The pharmaceutical and biotechnology sectors remain the largest end-user segments, driven by strict regulatory mandates for drug safety and efficacy, leading to a high demand for inspection machines for vials, ampoules, syringes, and tablets. The food and beverage industry also represents a significant and rapidly expanding segment, with a growing need for machines capable of detecting foreign objects, verifying packaging integrity, and checking fill levels to meet food safety standards. Furthermore, there is a clear trend towards fully automatic inspection machines over semi-automatic or manual systems, reflecting the industrys drive for higher throughput, reduced labor costs, and superior accuracy.

AI Impact Analysis on Inspection Machines Market

Common user questions regarding AIs impact on inspection machines frequently revolve around how artificial intelligence can overcome traditional limitations, enhance the accuracy and speed of defect detection, and provide more intelligent, predictive insights. Users are keen to understand how AI-powered systems can minimize false positives, reduce the need for constant calibration, and adapt to new product variations or subtle defect types without extensive reprogramming. There is significant interest in AIs role in enabling autonomous decision-making processes, integrating seamlessly with Industry 4.0 ecosystems, and offering more robust data analytics for continuous process improvement. Users also question the learning capabilities of AI in differentiating critical defects from cosmetic imperfections, thereby optimizing rejection rates and contributing to more sustainable manufacturing practices. The core expectation is that AI will transform inspection machines from mere defect detectors into intelligent, adaptive, and proactive quality control hubs.

- AI significantly enhances defect detection capabilities by employing deep learning algorithms to identify subtle, complex, or previously unseen defects that might be missed by traditional rule-based systems or human operators, leading to superior accuracy and consistency.

- Predictive analytics powered by AI allows inspection machines to forecast potential equipment failures or quality issues by analyzing historical data, enabling proactive maintenance and preventing costly production downtimes.

- AI-driven image processing and pattern recognition drastically reduce false positive rates, ensuring that only actual defects trigger rejections, thereby minimizing waste and improving overall manufacturing efficiency and yield.

- Adaptive learning algorithms enable inspection machines to continuously improve their performance over time, adjusting to variations in product characteristics, environmental conditions, or new types of defects without extensive manual recalibration.

- Integration of AI facilitates autonomous decision-making in real-time, allowing machines to optimize inspection parameters, sort products, and even adjust upstream production processes to correct deviations, moving towards self-optimizing manufacturing lines.

- AI-powered systems provide advanced data analysis and reporting, transforming raw inspection data into actionable insights for quality control managers, enabling informed decisions for process optimization and regulatory compliance.

- Enhanced object recognition and classification through AI allows for more precise categorization of defects, providing detailed information that can be used for root cause analysis and targeted corrective actions in the production process.

DRO & Impact Forces Of Inspection Machines Market

The Inspection Machines Market is propelled by a confluence of powerful drivers, tempered by specific restraints, and presenting significant opportunities that shape its growth trajectory. Key drivers include the ever-increasing stringency of global regulatory standards across industries such as pharmaceuticals, food and beverage, and medical devices, which mandate meticulous quality control and validation. The imperative to ensure product safety and integrity, particularly in consumer-facing sectors, further fuels demand for reliable inspection systems. Furthermore, the global trend towards automation and digitization in manufacturing, spearheaded by Industry 4.0 initiatives, encourages the adoption of sophisticated inspection technologies to enhance production efficiency, reduce labor costs, and minimize human error. The rising costs associated with product recalls and brand reputation damage also compel manufacturers to invest in advanced inspection solutions that can preemptively identify and eliminate defects, ensuring compliance and consumer trust.

Despite the strong growth drivers, the Inspection Machines Market faces several notable restraints. The high initial capital investment required for purchasing and implementing advanced inspection systems can be a significant barrier, particularly for small and medium-sized enterprises (SMEs) with limited budgets. The technical complexity associated with integrating these sophisticated machines into existing production lines, along with the need for specialized technical expertise for operation and maintenance, also poses challenges. Furthermore, the rapid pace of technological evolution means that systems can quickly become obsolete, requiring continuous upgrades and retraining, which adds to the operational burden. Another restraint is the potential for false positives or negatives in certain highly complex inspection scenarios, which can lead to unnecessary product rejection or, more critically, the release of defective products, underscoring the continuous need for system refinement and calibration.

Opportunities within the Inspection Machines Market are abundant and diverse, pointing towards sustained future growth. Emerging markets, especially in Asia-Pacific and Latin America, present vast untapped potential as industrialization accelerates and regulatory standards evolve, creating new demand for quality control solutions. The continuous integration of cutting-edge technologies like artificial intelligence, machine learning, and advanced robotics is opening doors for more intelligent, adaptive, and autonomous inspection systems capable of handling a wider range of inspection tasks with unprecedented accuracy and speed. Furthermore, the expansion of inspection applications into new industries, such as e-commerce logistics for package integrity verification, or specialized manufacturing for additive manufacturing quality control, offers new avenues for market penetration. The increasing focus on sustainable manufacturing practices also provides an opportunity for inspection machines to contribute by reducing waste from defective products and optimizing resource utilization through precise quality control.

Segmentation Analysis

The Inspection Machines Market is extensively segmented to reflect the diverse applications and technological solutions available, allowing for a granular understanding of market dynamics and targeted strategic development. These segmentations typically categorize the market based on the type of product being inspected, the technology employed for inspection, the level of automation involved in the operation, and the end-user industry requiring these solutions. This detailed breakdown facilitates analysis of specific growth drivers and challenges within each sub-segment, offering clarity on market penetration and future opportunities. The diverse nature of manufacturing processes and product characteristics across industries necessitates a wide array of inspection machine types, each optimized for specific quality control parameters, from detecting microscopic particles to verifying structural integrity.

- By Product Type: This segment includes a range of inspection technologies such as vision inspection systems (cameras, sensors, software), X-ray inspection systems (for internal defects, contaminants), metal detection systems (ferrous, non-ferrous, stainless steel detection), checkweighers (for weight accuracy and completeness), and other specialized systems like leak detection and infrared.

- By Type of Packaging: This category differentiates machines based on the packaging format they are designed to inspect, including vials, ampoules, syringes, blisters, bottles, cartridges, and other custom packaging solutions specific to various industries.

- By End-User Industry: Major end-user sectors encompass the pharmaceutical and biotechnology industries (for drug safety and efficacy), food and beverage (for food safety and packaging integrity), automotive (for component quality and assembly), electronics (for PCB and component inspection), medical devices (for precision and sterility), and other industrial manufacturing sectors.

- By Operation: This segmentation classifies inspection machines based on their level of automation: fully automatic inspection machines (requiring minimal human intervention), semi-automatic inspection machines (combining machine and human inspection), and manual inspection machines (primarily human-driven with aid of basic tools).

Inspection Machines Market Value Chain Analysis

The value chain for the Inspection Machines Market encompasses a comprehensive network of activities, starting from the procurement of raw materials and specialized components, extending through the manufacturing and assembly processes, and culminating in the distribution, installation, and post-sales support for end-users. Upstream activities involve a diverse set of suppliers providing critical components such as high-resolution cameras, advanced sensors, specialized lighting systems, robotics, sophisticated software algorithms, and processing units. These component manufacturers often represent highly specialized technology firms that contribute significantly to the overall performance and capabilities of the final inspection machinery. The quality and innovation of these upstream components directly influence the precision, speed, and reliability of the inspection systems, making supplier relationships a crucial aspect of the value chain.

Midstream in the value chain, inspection machine manufacturers undertake the research and development, design, assembly, and rigorous testing of the final products. This stage involves significant engineering expertise to integrate various components, develop proprietary software, and ensure the machines meet stringent industry standards and performance specifications. Manufacturers focus on creating robust, efficient, and customizable solutions that cater to the unique needs of diverse industries. This includes developing machines with capabilities such as machine vision for visual defect detection, X-ray for internal anomaly identification, and precise weight measurement. The competitive advantage at this stage often lies in technological innovation, product reliability, and the ability to offer tailored solutions that address specific client challenges.

Downstream activities involve the distribution channel, which can be direct or indirect. Direct sales involve manufacturers selling directly to end-users, often facilitated by a dedicated sales force and technical support teams, particularly for large-scale or highly customized projects. Indirect channels include a network of distributors, value-added resellers (VARs), and system integrators who provide regional coverage, localized support, and integration services for clients. These partners play a vital role in market penetration, especially in diverse geographical areas, by offering local expertise and support. Post-sales services, including installation, calibration, maintenance contracts, software updates, and training, form an integral part of the value chain, ensuring the long-term operational efficiency and customer satisfaction of the inspection machines deployed in various manufacturing facilities.

Inspection Machines Market Potential Customers

The potential customers for inspection machines are diverse and primarily comprise organizations operating in regulated and high-precision manufacturing environments where product quality, safety, and compliance are non-negotiable. At the forefront are pharmaceutical companies and biotechnology firms, which require inspection machines to ensure the sterility of injectables, integrity of tablets, and accurate labeling of all drug products, adhering to strict regulatory guidelines such as those from the FDA and European Medicines Agency. These customers invest heavily in automated inspection to minimize the risk of product recalls, maintain patient safety, and uphold their brand reputation, often integrating these machines directly into critical production lines to continuously monitor quality.

Another significant segment of potential customers includes food processing units and beverage manufacturers. These industries face immense pressure to prevent contamination, ensure packaging integrity, and accurately measure fill levels to comply with food safety regulations and protect consumer health. Inspection machines capable of detecting foreign objects like metal, glass, or plastic, alongside systems that verify correct product weight and packaging seal, are indispensable for these manufacturers. The increasing consumer demand for safe and high-quality food products, coupled with the potential for massive financial and reputational damage from recalls, drives substantial investment in advanced inspection technology within this sector.

Beyond pharmaceuticals and food and beverage, the automotive, electronics, and medical device manufacturing industries also represent substantial customer bases. Automotive component suppliers utilize inspection machines to verify the dimensional accuracy, material integrity, and assembly quality of critical parts, impacting vehicle safety and performance. Electronics manufacturers rely on these machines for inspecting printed circuit boards (PCBs), solder joints, and micro-components to ensure the functionality and reliability of electronic devices. Medical device manufacturers, operating under similarly stringent regulatory oversight as pharmaceuticals, use inspection machines to verify the precision, sterility, and defect-free nature of implants, surgical instruments, and diagnostic equipment, where any imperfection could have severe consequences for patient care. Additionally, contract manufacturing organizations (CMOs) and packaging companies serving these sectors also represent key potential customers, as they must meet the quality standards of their clients.

Inspection Machines Market Key Technology Landscape

The key technology landscape of the Inspection Machines Market is characterized by continuous innovation and the integration of multiple advanced engineering disciplines, all aimed at enhancing detection capabilities, speed, and reliability. Machine vision technology forms the bedrock of many modern inspection systems, utilizing high-resolution cameras, sophisticated illumination techniques, and powerful image processing software to capture and analyze visual data. This allows for the detection of surface defects, dimensional inaccuracies, label verification, and assembly errors with exceptional precision. The evolution of industrial cameras, including 2D, 3D, and multi-spectral imaging, coupled with faster processors and advanced algorithms, continues to push the boundaries of what is visually detectable, making machine vision indispensable across numerous industries.

Beyond optical inspection, technologies such as X-ray inspection and metal detection are crucial for identifying hidden contaminants or structural flaws within products and packaging. X-ray systems are highly effective for detecting foreign objects made of glass, bone, metal, or dense plastics inside sealed products, as well as verifying product completeness and fill levels. Metal detectors, on the other hand, are specifically designed to identify metallic contaminants, which is vital for food safety and the protection of production machinery. Checkweighing systems, another fundamental technology, employ highly accurate load cells to verify the weight of individual products or packages, ensuring compliance with specified tolerances and preventing under-filling or over-filling, thereby reducing waste and ensuring regulatory adherence.

The most transformative advancements in the technology landscape are driven by the integration of Artificial Intelligence (AI) and Machine Learning (ML). These capabilities enable inspection machines to learn from vast datasets, recognize complex patterns, differentiate critical defects from minor cosmetic flaws, and adapt to new product variations with minimal human intervention. Deep learning algorithms are particularly effective in challenging inspection tasks, offering enhanced accuracy and reduced false positives. Furthermore, the incorporation of robotics allows for precise product handling and automated rejection, while the Industrial Internet of Things (IIoT) facilitates connectivity, real-time data exchange, and remote monitoring of inspection processes. Cloud computing supports the storage and analysis of large volumes of inspection data, enabling predictive maintenance and continuous process optimization, thereby revolutionizing the intelligence and autonomy of inspection systems.

Regional Highlights

- North America: This region holds a significant share of the inspection machines market, driven by stringent regulatory frameworks in pharmaceutical and medical device industries, high adoption rates of advanced automation technologies, and a strong presence of key market players and R&D facilities.

- Europe: Europe is a mature market characterized by robust manufacturing sectors, particularly in Germany, France, and the UK, with a strong emphasis on quality control and adherence to high safety standards, especially within the food and beverage and automotive industries.

- Asia-Pacific: Poised for the fastest growth, this region is experiencing rapid industrialization, expansion of manufacturing hubs in China and India, increasing investments in automation, and a growing awareness of product quality and safety standards, particularly in the pharmaceutical and electronics sectors.

- Latin America: This emerging market is witnessing increasing adoption of inspection machines due to growing foreign investments in manufacturing, expanding consumer markets, and evolving regulatory landscapes, leading to a rising demand for quality assurance solutions.

- Middle East & Africa: Characterized by nascent but growing industrial sectors, this region shows potential for market expansion, driven by government initiatives to diversify economies, increasing investments in manufacturing infrastructure, and a rising focus on meeting international quality standards.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Inspection Machines Market.- Mettler-Toledo International Inc.

- Robert Bosch GmbH

- Cognex Corporation

- Sartorius AG

- Teledyne Technologies Incorporated

- Brevetti C.E.A. SPA

- Dürr AG

- Omron Corporation

- Loma Systems

- WIPOTEC-OCS GmbH

- Optel Group

- ISRA VISION AG

- Systech International

- ACG Inspection

Frequently Asked Questions

What is an inspection machine and why is it important in manufacturing?

An inspection machine is an automated system designed to examine products for defects, contaminants, or deviations from quality standards using technologies like machine vision, X-ray, or metal detection. It is crucial in manufacturing because it ensures product quality, safety, and compliance with stringent regulations, significantly reducing errors, recalls, and operational costs while enhancing brand reputation.

What industries primarily benefit from the use of inspection machines?

Inspection machines are indispensable across numerous sectors, with significant benefits observed in the pharmaceutical and biotechnology industries for drug safety, food and beverage for contaminant detection and packaging integrity, automotive for component quality, electronics for assembly verification, and medical devices for precision and sterility assurance.

How is Artificial Intelligence (AI) transforming the capabilities of inspection machines?

AI is revolutionizing inspection machines by enabling enhanced defect detection through deep learning, reducing false positives, and facilitating predictive maintenance. AI-powered systems can adapt to new defect types, make autonomous decisions, and provide sophisticated data analytics, transforming machines into more intelligent and proactive quality control tools for superior accuracy and efficiency.

What are the key drivers propelling the growth of the Inspection Machines Market?

The markets growth is primarily driven by increasingly stringent global regulatory standards across manufacturing sectors, compelling demand for high product quality and safety, and the accelerating global trend towards industrial automation and Industry 4.0 initiatives. Furthermore, the rising cost of product recalls and the imperative to protect brand reputation significantly contribute to market expansion.

What challenges does the Inspection Machines Market face, and how are they being addressed?

The market faces challenges such as high initial capital investment, the technical complexity of integration, and the need for specialized operational expertise. These are being addressed through modular system designs, enhanced user interfaces, comprehensive training programs, and the development of more cost-effective solutions for SMEs, alongside continuous technological advancements that simplify operation and maintenance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Semiconductor Inspection Machines Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Gear Inspection Machines Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Fabric Inspection Machines Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Fabric Inspection Machines Market Statistics 2025 Analysis By Application (Apparel, Home Textiles, Medical & Nonwoven, Others), By Type (Semi-Automatic Machine, Automatic Machine), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Fabric Inspection Machines Market Statistics 2025 Analysis By Application (Apparel, Home Textiles, Medical & Nonwoven), By Type (Semi-Automatic Machine, Automatic Machine), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager