Instrumentation Cable Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428536 | Date : Oct, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Instrumentation Cable Market Size

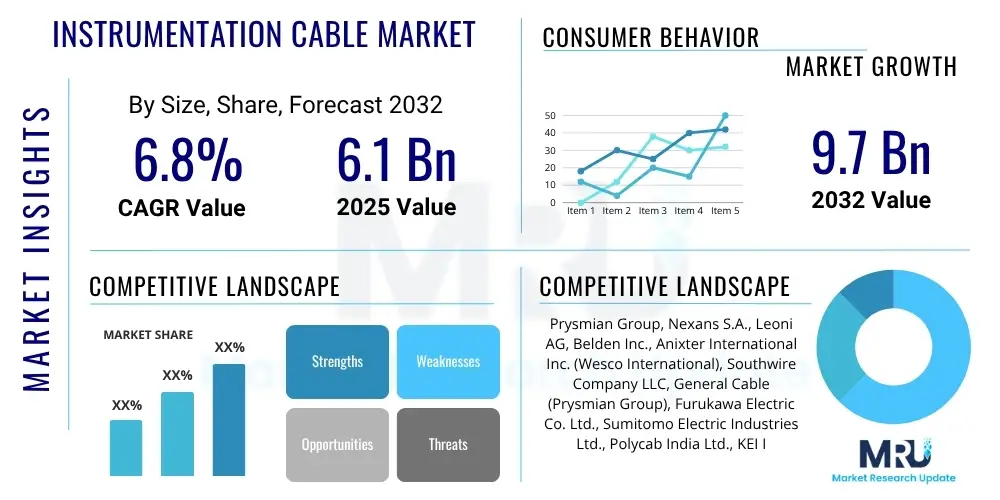

The Instrumentation Cable Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 6.1 Billion in 2025 and is projected to reach USD 9.7 Billion by the end of the forecast period in 2032.

Instrumentation Cable Market introduction

Instrumentation cables are a specialized category of electrical cables primarily designed for transmitting low-level signals from field instrumentation and sensors to control systems, ensuring reliable and accurate data transfer in complex industrial environments. These cables are crucial for the proper functioning of control systems, process automation, and data acquisition in various sectors. Their design often incorporates features such as shielding, armoring, and specific insulation materials to protect against electromagnetic interference (EMI), mechanical damage, and harsh environmental conditions, maintaining signal integrity over long distances and in electrically noisy settings.

The product description of instrumentation cables emphasizes their capability to handle low-voltage, low-current signals with minimal loss or distortion, making them indispensable for precision applications. They are engineered to provide high insulation resistance, low capacitance, and exceptional noise rejection, which are critical for accurate measurement and control. Different types exist, including multicore, multipair, and individual pair shielded cables, tailored to specific application requirements concerning signal type, noise immunity, and environmental resilience. Materials like copper for conductors, and PVC, XLPE, or FEP for insulation and jacketing, are commonly used, each offering distinct advantages in terms of temperature rating, chemical resistance, and flexibility.

Major applications for instrumentation cables span across a multitude of industries, including oil and gas, chemical and petrochemical, power generation, manufacturing, metals and mining, and pharmaceuticals, among others. In these sectors, they are vital for connecting process control instruments, thermocouples, pressure transmitters, flow meters, and various sensors to programmable logic controllers (PLCs), distributed control systems (DCS), and supervisory control and data acquisition (SCADA) systems. The benefits derived from their use include enhanced operational efficiency, improved safety through precise monitoring, reduced downtime due to reliable data transmission, and compliance with stringent industry standards. The driving factors for this market are closely tied to global industrialization, the escalating demand for automation, significant investments in infrastructure development, and the increasing adoption of Industry 4.0 paradigms across diverse economies.

Instrumentation Cable Market Executive Summary

The Instrumentation Cable Market is experiencing robust growth, primarily propelled by the accelerating pace of industrial automation, digitalization initiatives, and substantial investments in critical infrastructure globally. Business trends indicate a rising emphasis on advanced cable solutions that offer superior electromagnetic interference protection, enhanced fire resistance, and improved durability to meet the demands of sophisticated industrial processes and smart factory deployments. Manufacturers are increasingly focusing on developing specialized cables with features like low smoke zero halogen (LSZH) properties for safety-critical environments and armored constructions for mechanical protection in harsh conditions. The market is also witnessing a shift towards customized cable solutions that cater to specific project requirements, offering greater flexibility and optimized performance for diverse industrial applications.

Regional trends highlight the Asia Pacific (APAC) region as a dominant and rapidly expanding market, driven by rapid industrialization, burgeoning manufacturing sectors, significant infrastructure projects, and increasing foreign direct investments in countries like China, India, and Southeast Asian nations. North America and Europe continue to represent mature markets with stable demand, primarily fueled by modernization of existing industrial facilities, stringent regulatory frameworks promoting safety and efficiency, and sustained investments in renewable energy and smart grid initiatives. Latin America and the Middle East and Africa (MEA) regions are also showing considerable potential, supported by investments in oil and gas exploration, new energy projects, and growing industrial bases, albeit with varying paces of adoption and infrastructure development.

Segment trends within the instrumentation cable market reveal that shielded and armored cables are witnessing heightened demand due to their superior performance in noise-prone and mechanically challenging environments. The oil and gas, chemical and petrochemical, and power generation sectors remain the primary consumers, accounting for a significant share of the market, driven by continuous expansion and maintenance activities in these industries. There is a growing trend towards the adoption of hybrid cables that combine power, control, and data transmission capabilities, simplifying installation and reducing overall system complexity. Furthermore, the increasing integration of IoT and AI in industrial settings is creating a demand for instrumentation cables capable of higher data transfer rates and enhanced reliability, pushing innovation in cable design and material science. This comprehensive market overview underscores a dynamic landscape characterized by technological advancements, evolving industrial needs, and strategic regional growth.

AI Impact Analysis on Instrumentation Cable Market

The advent of artificial intelligence (AI) is profoundly influencing the instrumentation cable market by driving demand for more sophisticated, reliable, and data-efficient cabling solutions. Common user questions revolve around how AI and Industry 4.0 integration will affect the types and specifications of cables required, whether traditional instrumentation cables are adequate for AI-driven systems, and what innovations are emerging to support smart manufacturing environments. Users are also concerned about the capacity of existing infrastructure to handle the massive data flows generated by AI-powered sensors and devices, and the implications for future cable investments. This analysis summarizes that AI's pervasive integration in industrial processes necessitates instrumentation cables capable of robust, high-integrity data transmission, enhanced noise immunity, and potential for predictive maintenance capabilities, transforming design and application expectations.

AI-driven industrial systems, characterized by vast networks of intelligent sensors and actuators, generate an unprecedented volume of data that requires rapid and accurate transmission to central processing units and cloud platforms. This intensifies the need for instrumentation cables with superior electromagnetic compatibility (EMC) and signal-to-noise ratio, ensuring that critical data is not compromised by interference. The demand for advanced shielding and insulation materials, coupled with precise manufacturing techniques, is rising to meet these stringent performance requirements. Furthermore, AI's role in predictive maintenance within industrial facilities also extends to the cabling infrastructure itself, prompting interest in smart cables that can monitor their own condition and transmit diagnostic data, thus enabling proactive replacement and minimizing operational disruptions.

The long-term impact of AI on the instrumentation cable market is expected to foster innovation in material science and cable design, pushing towards lighter, more flexible, and environmentally sustainable solutions without compromising performance. As factories become smarter and more autonomous, the reliance on perfectly functioning data communication pathways will only increase, making instrumentation cables a critical, albeit often overlooked, component of the AI ecosystem. This integration also encourages the development of standardized protocols and interfaces for industrial data transmission, potentially influencing cable specifications globally. The industry will likely see a continued evolution towards higher performance, greater reliability, and intelligence embedded within the cabling infrastructure to fully leverage the benefits of AI and Industry 4.0.

- Increased demand for high-performance, shielded instrumentation cables due to AI-driven data intensity.

- Requirement for enhanced electromagnetic compatibility (EMC) to prevent AI system interference.

- Development of "smart cables" with integrated sensors for condition monitoring and predictive maintenance, leveraging AI analytics.

- Shift towards more robust and reliable cables to ensure uninterrupted data flow for AI-powered industrial automation.

- Innovation in cable materials and design to support higher data rates and reduced latency for real-time AI applications.

DRO & Impact Forces Of Instrumentation Cable Market

The Instrumentation Cable Market is significantly shaped by a confluence of drivers, restraints, and opportunities, underpinned by various impactful forces. Among the primary drivers, the global surge in industrial automation and the widespread adoption of Industry 4.0 technologies stand out. Industries across sectors are investing heavily in automated processes, smart factories, and IoT-enabled systems, all of which require reliable and high-integrity data transmission, directly fueling the demand for specialized instrumentation cables. Concurrently, substantial investments in critical infrastructure development, particularly in emerging economies, including power generation, oil and gas, manufacturing, and transportation, are creating a robust demand for robust and dependable cabling solutions. Stringent regulatory frameworks and safety standards in hazardous environments also necessitate the use of high-quality, often fire-retardant and armored, instrumentation cables, further driving market growth by ensuring compliance and operational safety.

However, the market also faces notable restraints. The volatility in raw material prices, particularly for copper, PVC, and various polymers, poses a significant challenge, directly impacting manufacturing costs and, consequently, the final product pricing. This price instability can lead to unpredictable market dynamics and profitability pressures for manufacturers. Furthermore, the intense competition within the market, characterized by numerous global and regional players, often leads to price wars and reduced profit margins, especially for standardized cable products. Additionally, the increasing complexity of industrial systems and the need for highly specialized cable solutions can present challenges related to standardization and technical expertise, hindering broader adoption in some niche applications where custom solutions are required at a higher cost.

Despite these challenges, substantial opportunities exist for market expansion and innovation. The growing trend of smart factories and the integration of the Industrial Internet of Things (IIoT) present immense opportunities for advanced instrumentation cables capable of handling vast amounts of data and supporting complex network architectures. The renewable energy sector, including solar and wind power installations, is another lucrative avenue, as these projects require specialized cables for monitoring and control systems. Developing economies, with their rapid industrialization and urbanization, offer significant untapped market potential, as they embark on large-scale infrastructure and industrial expansion projects. Moreover, continuous technological advancements in cable design, materials, and manufacturing processes, aimed at enhancing performance, durability, and environmental compliance, will unlock new applications and market segments, driven by a constant push for greater efficiency and reliability in industrial operations.

- Drivers:

- Growing industrial automation and adoption of Industry 4.0 across sectors.

- Significant global investments in infrastructure development and modernization.

- Increasing demand for reliable and accurate data transmission in industrial processes.

- Stringent safety regulations and industrial standards requiring high-performance cables.

- Expansion of oil and gas, chemical, power generation, and manufacturing industries.

- Restraints:

- Volatility in raw material prices (copper, plastics) impacting production costs.

- Intense competition from local and international manufacturers leading to price pressures.

- Challenges related to standardization for highly specialized cable applications.

- Economic slowdowns or geopolitical instabilities affecting industrial investments.

- Long product lifecycle reducing replacement demand in some mature markets.

- Opportunity:

- Emergence of smart factories and the Industrial Internet of Things (IIoT).

- Growing renewable energy sector requiring specialized monitoring and control cables.

- Expansion into developing economies with rapid industrialization and infrastructure projects.

- Development of hybrid cables combining power, control, and data functionalities.

- Technological advancements in fire-retardant and low smoke zero halogen (LSZH) materials.

- Impact Forces:

- Technological advancements: Innovations in cable materials, design, and manufacturing processes.

- Regulatory landscape: Evolution of safety standards, environmental regulations, and industry certifications.

- Economic growth: Global and regional economic conditions influencing industrial investments.

- Competition: Market structure, competitive strategies, and new market entrants.

- Supply Chain Dynamics: Raw material availability, logistics, and supplier relationships.

Segmentation Analysis

The Instrumentation Cable Market is extensively segmented to reflect the diverse applications and technical requirements across various industrial landscapes. This segmentation allows for a comprehensive understanding of market dynamics, identifying key growth areas and niche opportunities based on specific product characteristics, industry end-users, and functional needs. Analyzing these segments provides strategic insights into consumer preferences, technological trends, and regional demand patterns, enabling market players to tailor their product offerings and investment strategies effectively. The market is typically categorized by factors such as cable type, application, end-use industry, material composition, and voltage rating, each playing a crucial role in determining the overall market landscape.

- By Type:

- Shielded Cables: Designed with metallic shielding (foil, braid, or both) to protect signals from electromagnetic interference (EMI) and radio frequency interference (RFI), crucial for sensitive data transmission.

- Unshielded Cables: Lacking metallic shielding, suitable for environments with minimal electromagnetic noise or for less critical applications where cost is a primary concern.

- Armored Cables: Feature a protective layer, typically steel wire armor (SWA) or steel tape armor (STA), providing mechanical protection against crushing or impact in harsh industrial settings.

- Fire-Resistant Cables: Engineered to maintain circuit integrity during fire conditions, essential for safety and emergency systems.

- Low Smoke Zero Halogen (LSZH) Cables: Produce minimal smoke and no toxic halogens when exposed to fire, ideal for enclosed spaces with high human occupancy.

- By Application:

- Oil and Gas: Used in offshore platforms, refineries, and petrochemical plants for process control and monitoring.

- Chemical and Petrochemical: Critical for transmitting signals in chemical processing units, often requiring chemical-resistant sheathing.

- Power Generation: Employed in conventional and renewable power plants for control circuits, instrumentation, and plant monitoring.

- Manufacturing: Essential for automated assembly lines, robotics, and quality control systems in various manufacturing industries.

- Metals and Mining: Utilized in harsh environments for sensor connections and control systems in mining operations and metal processing.

- Pharmaceuticals: Required for precise temperature and pressure monitoring in drug manufacturing, often with strict hygiene standards.

- Water and Wastewater Treatment: For monitoring and controlling pumps, valves, and purification processes.

- Food and Beverage: Used in process control, requiring hygiene-compliant and sometimes wash-down resistant cables.

- Cement and Construction: For monitoring heavy machinery and automated processes.

- Pulp and Paper: For process control and machinery monitoring in paper mills.

- Rail and Transportation: For signaling, control, and communication systems.

- Building Automation: For HVAC, lighting control, and security systems in commercial buildings.

- By End-Use Industry:

- Process Industries: Encompasses sectors like oil and gas, chemical, power, and food processing, characterized by continuous production flows.

- Discrete Industries: Includes manufacturing, automotive, aerospace, and electronics, involving the assembly of individual components.

- By Material:

- Copper Conductors: Predominantly used due to high electrical conductivity and ductility.

- Aluminum Conductors: Used in some applications for lighter weight and cost-effectiveness, especially for larger cross-sections.

- Insulation Materials: PVC, XLPE, PE, FEP, PTFE, Rubber, Silicon.

- Sheathing Materials: PVC, LSZH, PE, PUR.

- By Voltage Rating:

- Low Voltage (up to 1 kV): Most common for instrumentation, signal, and control applications.

- Medium Voltage (1 kV to 35 kV): Less common for pure instrumentation but may be part of integrated solutions.

Value Chain Analysis For Instrumentation Cable Market

The value chain for the instrumentation cable market encompasses a series of interconnected stages, beginning from raw material sourcing and extending to the final delivery and installation at the end-user site. This intricate network involves various stakeholders, each adding value at different points, influencing the overall cost, quality, and availability of the final product. Understanding this value chain is critical for market participants to identify areas for cost optimization, enhance operational efficiencies, and ensure a competitive edge. The process typically starts with the extraction and processing of fundamental materials and culminates in the functional integration of cables within complex industrial systems.

The upstream analysis of the value chain primarily involves the procurement and processing of key raw materials. This includes copper for conductors, derived from mining and refining operations, and various polymers such as Polyvinyl Chloride (PVC), Cross-linked Polyethylene (XLPE), Polyethylene (PE), Fluorinated Ethylene Propylene (FEP), and Thermoplastic Elastomers (TPE) for insulation and jacketing. Steel wire or tape is sourced for armoring applications, and other specialty chemicals are procured for fire retardants, UV stabilizers, and other additives. Suppliers of these raw materials play a crucial role in determining the quality, consistency, and cost-effectiveness of the inputs, thereby directly impacting the manufacturing process of instrumentation cables. Relationships with reliable and cost-effective raw material suppliers are paramount for maintaining competitive pricing and production schedules.

Downstream analysis focuses on the distribution, sales, and end-use of instrumentation cables. Manufactured cables move through various distribution channels, including direct sales from manufacturers to large industrial clients, original equipment manufacturers (OEMs), and engineering, procurement, and construction (EPC) contractors. Indirect channels involve a network of wholesalers, distributors, and authorized dealers who cater to smaller projects, maintenance, repair, and operations (MRO) demand, and provide local availability. The selection of distribution channels often depends on the project size, geographical reach, and the level of technical support required. Ultimately, the cables are installed by system integrators, electrical contractors, or in-house engineering teams within diverse end-user industries such as oil and gas, power generation, manufacturing, and pharmaceuticals, where they perform their critical function of reliable signal transmission. Post-sales services, technical support, and product lifecycle management also form an integral part of the downstream value proposition.

Instrumentation Cable Market Potential Customers

The potential customers for instrumentation cables are predominantly enterprises and organizations operating within highly industrialized and process-driven sectors where accurate and reliable data transmission is critical for operational efficiency, safety, and compliance. These end-users are characterized by their reliance on complex control systems, extensive networks of sensors, and the need for robust infrastructure capable of withstanding harsh industrial environments. Their purchasing decisions are heavily influenced by factors such as cable performance, adherence to specific industry standards, environmental resistance, and the total cost of ownership, including installation and maintenance. The continued global emphasis on automation and digitalization further expands this customer base across both mature and emerging markets.

Major segments of end-users include the oil and gas industry, which uses instrumentation cables extensively in exploration, production, refining, and distribution processes to monitor pressure, temperature, and flow rates in hazardous locations. Similarly, the chemical and petrochemical sectors rely on these cables for process control in manufacturing various chemicals, often requiring specific chemical and corrosion-resistant properties. Power generation plants, both conventional and renewable, represent another significant customer base, utilizing instrumentation cables for monitoring and controlling turbines, generators, and distribution networks. Manufacturers across automotive, metals and mining, food and beverage, and pharmaceutical industries are also key buyers, integrating these cables into their automated production lines, robotics, and quality control systems to ensure precise operations and product integrity.

Beyond traditional industrial sectors, emerging applications and evolving infrastructure projects are broadening the customer base. These include water and wastewater treatment facilities, which require instrumentation cables for controlling pumps and purification processes, and the growing smart cities initiatives, where they are integral to intelligent building management systems, traffic control, and public safety infrastructure. Engineering, Procurement, and Construction (EPC) contractors also form a crucial customer segment, as they procure these cables for large-scale industrial projects on behalf of various clients. System integrators, who design and implement automation solutions, are also significant buyers, often specifying particular cable types to meet specific project demands and performance criteria. Ultimately, any industry prioritizing precision control, data integrity, and operational safety will be a potential customer for instrumentation cables.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 6.1 Billion |

| Market Forecast in 2032 | USD 9.7 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Prysmian Group, Nexans S.A., Leoni AG, Belden Inc., Anixter International Inc. (Wesco International), Southwire Company LLC, General Cable (Prysmian Group), Furukawa Electric Co. Ltd., Sumitomo Electric Industries Ltd., Polycab India Ltd., KEI Industries Ltd., RPG Cables (KEC International Ltd.), Havells India Ltd., Finolex Cables Ltd., LS Cable & System Ltd., NKT A/S, Elsewedy Electric, Top Cable S.A., Eland Cables, Allied Wire & Cable. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Instrumentation Cable Market Key Technology Landscape

The instrumentation cable market is continuously evolving, driven by advancements in materials science, manufacturing processes, and the increasing demand for enhanced performance in complex industrial environments. A key technological focus is on improving signal integrity and noise immunity, which are paramount for accurate data transmission in the presence of electromagnetic interference. This involves the development of superior shielding techniques, such as multi-layered foil and braid combinations, along with advanced twisting patterns for conductor pairs to minimize crosstalk and external noise pick-up. Innovations in insulation materials are also critical, with higher-performance polymers offering improved dielectric strength, temperature resistance, and chemical compatibility, ensuring stable electrical properties over the cable's lifespan. These technological improvements are essential to meet the precise demands of modern industrial control systems and increasingly sensitive instrumentation.

Another significant area of technological advancement lies in the development of robust and resilient cable constructions designed to withstand harsh operating conditions. This includes the widespread adoption of armoring solutions, such as steel wire armor (SWA) or steel tape armor (STA), to provide mechanical protection against physical damage in outdoor, direct burial, or highly abrasive industrial settings. Furthermore, there is a strong emphasis on fire safety, leading to the proliferation of Low Smoke Zero Halogen (LSZH) and fire-resistant (FR) compounds for cable jacketing and insulation. LSZH cables significantly reduce the emission of toxic fumes and corrosive gases in case of fire, making them indispensable for enclosed spaces and public areas, while FR cables maintain circuit integrity during a fire, crucial for emergency systems. These developments reflect a concerted effort to enhance both operational reliability and personnel safety across diverse industrial applications.

The future technology landscape for instrumentation cables is poised for further innovation, driven by the integration of Industry 4.0, the Industrial Internet of Things (IIoT), and artificial intelligence (AI). This includes the potential for "smart cables" that incorporate embedded sensors for self-monitoring, capable of reporting on their own con

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager