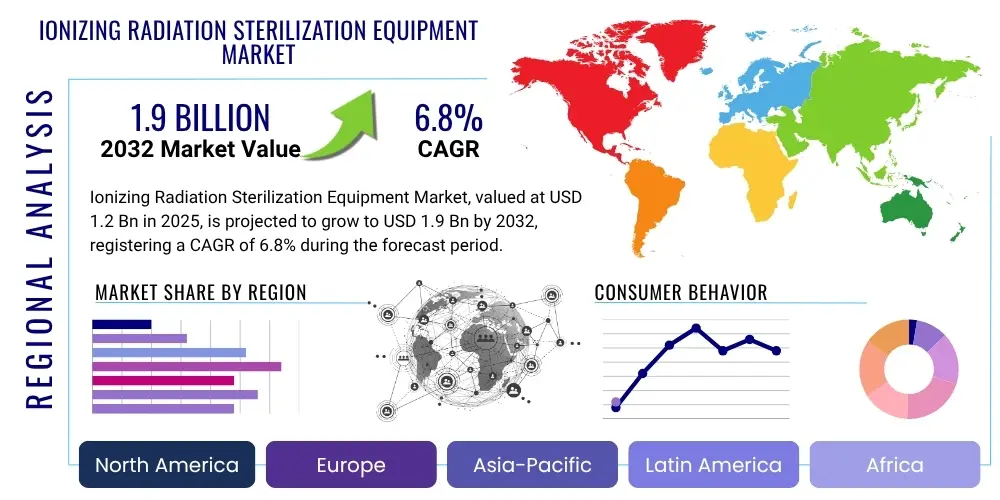

Ionizing Radiation Sterilization Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430524 | Date : Nov, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Ionizing Radiation Sterilization Equipment Market Size

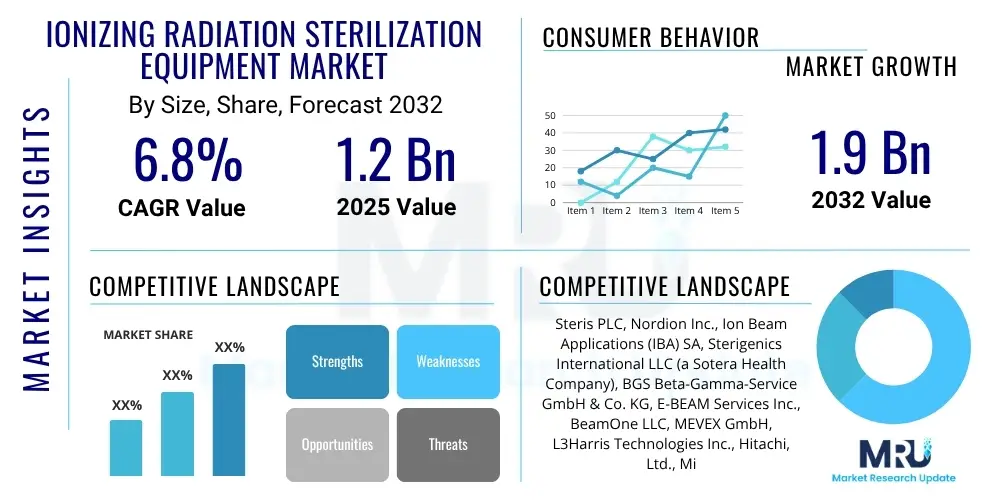

The Ionizing Radiation Sterilization Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at $1.2 Billion in 2025 and is projected to reach $1.9 Billion by the end of the forecast period in 2032.

Ionizing Radiation Sterilization Equipment Market introduction

The Ionizing Radiation Sterilization Equipment Market encompasses advanced technologies and systems utilized for sterilizing a wide array of products through exposure to controlled levels of ionizing radiation, primarily gamma rays, electron beams (e-beams), and X-rays. This method is highly effective for eliminating microorganisms, including bacteria, viruses, fungi, and spores, without raising the product's temperature, thus making it ideal for heat-sensitive materials. The equipment involved ranges from large-scale industrial irradiators for contract sterilization services to more compact systems for specific manufacturing environments, each designed to deliver precise radiation doses for optimal sterilization efficacy and product integrity.

Major applications for ionizing radiation sterilization equipment span critical sectors such as medical device manufacturing, pharmaceuticals, biotechnology, food and beverage processing, cosmetics, and advanced materials. In the medical field, it is indispensable for sterilizing single-use devices, implants, surgical instruments, and personal protective equipment, ensuring patient safety and regulatory compliance. Pharmaceutical applications include the sterilization of active pharmaceutical ingredients, drug-device combination products, and packaging materials. Beyond healthcare, it is increasingly employed for pathogen reduction in food products, extending shelf life and enhancing safety, as well as for sterilizing consumer products like cosmetics to prevent microbial contamination.

The primary benefits of utilizing ionizing radiation sterilization include its superior penetration capabilities, which allow for the sterilization of products within their final packaging, maintaining sterility until use. It is a "cold sterilization" method, avoiding the thermal degradation often associated with heat-based techniques, making it suitable for a broad spectrum of materials. Furthermore, it leaves no toxic residues, unlike chemical sterilization methods, and offers high throughput and process reliability. Driving factors for market expansion include the escalating global demand for sterile medical products due to an aging population and increasing chronic diseases, the stringent regulatory landscape mandating sterilization for health-critical items, and the continuous advancements in radiation technology improving efficiency and safety profiles. The rising adoption of single-use medical devices and the growth of emerging economies further fuel market growth by necessitating robust and scalable sterilization solutions.

Ionizing Radiation Sterilization Equipment Market Executive Summary

The Ionizing Radiation Sterilization Equipment Market is currently experiencing robust growth, driven by an confluence of factors including escalating demand for sterile medical devices and pharmaceutical products, increasingly stringent global health regulations, and technological advancements enhancing the efficiency and safety of irradiation processes. Business trends indicate a significant shift towards greater automation and integration of sophisticated control systems within sterilization facilities, aiming to optimize cycle times, reduce human error, and ensure consistent dosimetry. The contract sterilization services segment is witnessing substantial expansion, as manufacturers increasingly outsource their sterilization needs to specialized providers who can offer high-volume capabilities and expertise, thereby reducing capital expenditure for individual companies. Furthermore, there is a growing emphasis on sustainability, prompting research into more energy-efficient equipment and methods for managing radiation sources. This market dynamism reflects a continuous innovation cycle focused on improving sterilization efficacy while addressing environmental and operational challenges.

Regionally, North America and Europe continue to dominate the market, largely due to established healthcare infrastructure, high healthcare spending, and strict regulatory frameworks that necessitate advanced sterilization techniques. However, the Asia Pacific region is poised for the fastest growth, propelled by rapidly expanding healthcare sectors, increasing medical device manufacturing, and rising disposable incomes leading to greater demand for quality healthcare services and sterile products. Countries like China, India, and Japan are becoming significant hubs for manufacturing and consumption, attracting substantial investments in sterilization capabilities. Latin America, the Middle East, and Africa also present emerging opportunities, albeit with slower growth rates, as healthcare infrastructure develops and awareness of infection control measures increases. These regions are gradually adopting modern sterilization practices, driven by global health initiatives and foreign investments, indicating a progressive but nascent market development.

From a segmentation perspective, the market is primarily categorized by type (gamma, e-beam, X-ray), application (medical devices, pharmaceuticals, food and beverages, cosmetics), and end-user (hospitals, pharmaceutical companies, medical device manufacturers, contract sterilization services). While gamma sterilization equipment historically holds the largest market share due to its established efficacy and cost-effectiveness for bulk processing, the e-beam and X-ray segments are projected to exhibit higher growth rates. This acceleration is attributed to their advantages such as on-demand operation, reduced environmental impact (no radioactive isotopes), faster processing times, and suitability for a broader range of materials. The medical devices application segment remains the largest end-use category, fueled by the growing complexity and volume of disposable medical products. Meanwhile, the pharmaceutical sector and contract sterilization services are also showing significant upward trends, reflecting the increasing outsourcing model and the global pharmaceutical industry's expansion. Overall, the market is characterized by a strategic balance between proven traditional methods and innovative, rapidly evolving technologies.

AI Impact Analysis on Ionizing Radiation Sterilization Equipment Market

User inquiries regarding the integration of Artificial Intelligence (AI) into the Ionizing Radiation Sterilization Equipment Market primarily revolve around optimizing operational efficiency, enhancing product quality and safety, and predicting maintenance needs to minimize downtime. Common questions address how AI can streamline sterilization cycle parameters, improve dose uniformity, and automate quality control processes through advanced data analysis. Stakeholders express keen interest in AI's potential to reduce operational costs by optimizing energy consumption and material handling, as well as its ability to integrate seamlessly with existing infrastructure. Concerns often touch upon the initial investment costs, the complexity of AI implementation in highly regulated environments, data security, and the necessity for skilled personnel to manage these advanced systems. Overall, there is a clear expectation that AI will drive a paradigm shift towards more intelligent, precise, and autonomous sterilization processes, ultimately reinforcing sterility assurance and operational resilience within the industry.

- AI driven optimization of sterilization parameters for enhanced dose uniformity and reduced cycle times.

- Predictive maintenance algorithms for equipment, minimizing unexpected downtime and extending asset lifespan.

- Automated quality control and dosimetry verification through real-time data analysis, reducing manual inspection errors.

- Enhanced supply chain management for radiation sources and sterilized products, improving traceability and efficiency.

- Development of intelligent control systems for remote operation and monitoring of sterilization facilities.

- Improved data analytics for regulatory compliance and audit trails, facilitating easier reporting and validation.

- Simulation and modeling of radiation effects on materials, leading to better process design and material compatibility.

- Reduction in operational costs through optimized energy consumption and resource allocation.

- Integration with robotic systems for automated loading, unloading, and handling of products within irradiators.

- Personalized sterilization protocols based on product characteristics and microbial load predictions.

DRO & Impact Forces Of Ionizing Radiation Sterilization Equipment Market

The Ionizing Radiation Sterilization Equipment Market is profoundly shaped by a dynamic interplay of drivers, restraints, opportunities, and external impact forces. A primary driver is the accelerating demand for sterile medical devices and pharmaceutical products, fueled by an aging global population, the rising prevalence of chronic diseases, and an increasing number of surgical procedures. Stringent global regulatory frameworks, such as those imposed by the FDA and EU MDR, mandate highly effective and validated sterilization methods, inherently favoring ionizing radiation due to its proven efficacy and ability to sterilize products in their final packaging. Furthermore, the expansion of healthcare infrastructure in emerging economies and the growing adoption of single-use medical products significantly contribute to this demand, necessitating robust and scalable sterilization solutions across the globe. These factors collectively push for continuous investment and innovation in the field.

Conversely, several restraints impede the market's growth trajectory. The most significant is the substantial initial capital investment required for establishing or upgrading ionizing radiation sterilization facilities, particularly for gamma irradiators that utilize expensive Cobalt-60 sources. The complex and lengthy regulatory approval processes for constructing new facilities, coupled with strict licensing and safety protocols for handling radioactive materials, also present formidable barriers to entry and expansion. Public perception regarding radiation, often fueled by misconceptions, can lead to concerns about product safety and environmental impact, despite extensive scientific validation of the safety of irradiated products. Additionally, the need for specialized technical expertise for equipment operation, maintenance, and dosimetry validation adds to operational costs and limits widespread adoption, particularly in regions with developing technical infrastructure.

Despite these challenges, the market is replete with significant opportunities. Technological advancements in electron beam (e-beam) and X-ray sterilization systems offer alternatives to gamma irradiation, promising reduced capital costs, faster processing times, and the elimination of radioactive waste management concerns, thereby attracting new investments. The burgeoning contract sterilization services market represents a substantial opportunity, allowing medical device and pharmaceutical manufacturers to outsource sterilization without incurring high upfront capital expenditures, thereby broadening market access for smaller players. Furthermore, the expansion of ionizing radiation sterilization into novel applications, such as the pathogen reduction in cannabis, cosmetics, and agricultural products, and even for aerospace components, presents new revenue streams. These emerging sectors, combined with the increasing demand from established industries for highly reliable and efficient sterilization, create a fertile ground for market innovation and growth.

Impact forces acting on the market include global health crises, such as pandemics, which drastically escalate the demand for sterile medical supplies and personal protective equipment, driving rapid increases in sterilization capacity. Geopolitical tensions and trade policies can disrupt the supply chain for critical components, including Cobalt-60 isotopes, influencing the cost and availability of gamma sterilization. Economic downturns may dampen capital investment in new facilities, potentially slowing market expansion, while conversely, robust economic growth can accelerate infrastructure development. Environmental regulations and the public's growing emphasis on sustainability also impact the market, pushing for the development of more environmentally friendly sterilization methods, such as e-beam and X-ray, that do not rely on radioactive isotopes. Technological obsolescence and the emergence of competing sterilization technologies also represent ongoing impact forces that necessitate continuous innovation and adaptation within the ionizing radiation sterilization equipment market.

Segmentation Analysis

The Ionizing Radiation Sterilization Equipment Market is comprehensively segmented to provide a detailed understanding of its diverse components and growth dynamics across various dimensions. This segmentation allows for precise market analysis, enabling stakeholders to identify key trends, opportunities, and challenges within specific product categories, applications, and end-user groups. Understanding these distinct segments is crucial for strategic planning, product development, and targeted marketing efforts, as each segment often presents unique regulatory requirements, technological preferences, and customer needs. The market's segmentation reflects the broad utility and specialized nature of ionizing radiation sterilization across a multitude of industries requiring high levels of sterility assurance.

- By Type:

- Gamma Sterilization Equipment: Utilizes Cobalt-60 or Cesium-137 isotopes. Dominant for high-density, high-volume products.

- E-beam Sterilization Equipment: Employs electron accelerators. Offers high dose rates and on-demand operation, suitable for lower density products.

- X-ray Sterilization Equipment: Generated by electron accelerators, converting electron energy into X-rays. Provides deep penetration similar to gamma, without radioactive isotopes.

- By Application:

- Medical Devices: Sterilization of single-use devices, implants, surgical kits, and diagnostic tools.

- Pharmaceuticals: Sterilization of active pharmaceutical ingredients, medical packaging, and drug-device combination products.

- Food and Beverages: Pathogen reduction, extending shelf life for spices, fruits, vegetables, and meat products.

- Cosmetics: Microbial decontamination of raw materials and finished cosmetic products to ensure consumer safety.

- Others: Sterilization of agricultural products, industrial products, historical artifacts, and laboratory consumables.

- By End User:

- Hospitals and Clinics: Primarily for in-house sterilization of reusable instruments, though less common for ionizing radiation.

- Pharmaceutical Companies: For sterilizing raw materials, intermediates, and final products in their manufacturing processes.

- Medical Device Manufacturers: A major end-user, ensuring sterility of diverse medical equipment before distribution.

- Contract Sterilization Service Providers: Independent facilities offering sterilization services to various industries, representing a significant market share.

- Academic and Research Institutions: For sterilizing laboratory equipment, research samples, and materials in controlled environments.

Value Chain Analysis For Ionizing Radiation Sterilization Equipment Market

The value chain for the Ionizing Radiation Sterilization Equipment Market is a complex ecosystem, beginning with the upstream supply of specialized components and raw materials, progressing through equipment manufacturing, and extending to downstream distribution and diverse end-user applications. The upstream segment primarily involves suppliers of high-purity metals for accelerator components, specialized electronics for control systems, and critical isotopes like Cobalt-60 for gamma irradiators. These suppliers often operate in highly regulated environments, ensuring the quality and safety of materials that are fundamental to the performance and longevity of sterilization equipment. Research and development activities also play a crucial upstream role, constantly innovating designs, improving efficiency, and enhancing safety features, which directly impacts the capabilities and competitiveness of the final sterilization solutions.

Midstream activities are dominated by the manufacturing and assembly of the sterilization equipment itself, which includes complex electron accelerators, X-ray converters, and robust gamma irradiators. This phase requires highly specialized engineering expertise, precision manufacturing, and rigorous quality control to ensure that the equipment meets stringent performance standards and regulatory requirements. Manufacturers also invest heavily in designing user-friendly interfaces, integrating advanced safety mechanisms, and developing comprehensive software for dosimetry, process control, and data logging. These companies are responsible for the entire equipment lifecycle, from initial design and production to installation, commissioning, and ongoing technical support, ensuring operational integrity and compliance for the end-users. The integration of advanced diagnostics and remote monitoring capabilities is also a growing trend in this manufacturing phase.

The downstream segment of the value chain focuses on the distribution, sales, and post-sales support of the equipment to various end-users. Distribution channels are typically a mix of direct sales, where manufacturers engage directly with large institutional buyers and contract sterilization facilities, and indirect channels, which involve a network of specialized distributors and agents. These indirect partners often provide localized sales, technical support, and maintenance services, particularly in regions where manufacturers do not have a direct presence. Post-sales services, including routine maintenance, calibration, repairs, and upgrades, are critical for ensuring the continuous and reliable operation of the equipment, which is paramount in regulated industries like healthcare and pharmaceuticals. Additionally, training programs for operators and technicians are integral to ensuring the safe and effective utilization of these advanced sterilization systems, thereby completing the cycle of value delivery to the end-users.

Ionizing Radiation Sterilization Equipment Market Potential Customers

The potential customers for Ionizing Radiation Sterilization Equipment are diverse and span across various industries where sterility assurance is paramount for product quality, safety, and regulatory compliance. The largest segment of end-users comprises medical device manufacturers, who rely heavily on these technologies to sterilize a wide array of products, including surgical instruments, implants, catheters, syringes, and diagnostic kits, ensuring they are safe for patient use. The increasing complexity and volume of single-use medical devices further drive demand from this sector, as ionizing radiation offers an efficient and effective method for sterilizing heat-sensitive and pre-packaged items. These manufacturers prioritize solutions that offer high throughput, consistent dose delivery, and robust validation capabilities to meet global healthcare standards and reduce the risk of healthcare-associated infections.

Another significant customer base includes pharmaceutical companies and biotechnology firms. These entities utilize ionizing radiation sterilization for processing active pharmaceutical ingredients, excipients, drug-device combination products, and packaging materials. The method is particularly valuable for sterilizing heat-labile pharmaceuticals and for ensuring the microbial purity of raw materials that are incorporated into sterile drug products. Contract sterilization service providers represent a rapidly expanding customer segment. These specialized facilities offer sterilization services to a multitude of clients, ranging from small and medium-sized enterprises (SMEs) to large corporations, who may lack the capital or expertise to establish their own in-house sterilization capabilities. These providers act as crucial intermediaries, allowing manufacturers across various sectors to outsource their sterilization needs efficiently and cost-effectively, while maintaining strict adherence to regulatory standards.

Beyond the medical and pharmaceutical domains, the food and beverage industry constitutes a growing segment of potential customers. Here, ionizing radiation equipment is employed for pathogen reduction in spices, dried vegetables, fruits, and meat products, significantly extending shelf life and enhancing food safety by eliminating harmful bacteria, viruses, and parasites. Cosmetics manufacturers also represent a notable customer group, utilizing these systems to sterilize raw materials and finished cosmetic products, thereby preventing microbial contamination and ensuring consumer safety. Academic and research institutions further contribute to the customer base, employing ionizing radiation for sterilizing laboratory equipment, culture media, animal feed, and research samples in controlled experimental settings. The increasing regulatory emphasis on product safety and the continuous need for advanced sterilization methods across these diverse industries underscore the broad and expanding customer landscape for ionizing radiation sterilization equipment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $1.2 Billion |

| Market Forecast in 2032 | $1.9 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Steris PLC, Nordion Inc., Ion Beam Applications (IBA) SA, Sterigenics International LLC (a Sotera Health Company), BGS Beta-Gamma-Service GmbH & Co. KG, E-BEAM Services Inc., BeamOne LLC, MEVEX GmbH, L3Harris Technologies Inc., Hitachi, Ltd., Mitsubishi Heavy Industries, Ltd., Varian Medical Systems (part of Siemens Healthineers), GE Healthcare, RadiaBeam, Inc., SCK CEN, Isotron (a STERIS company), TÜV SÜD, Iotron Industries, China Isotope & Radiation Corporation (CIRC), PTB (Physikalisch-Technische Bundesanstalt) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ionizing Radiation Sterilization Equipment Market Key Technology Landscape

The key technology landscape of the Ionizing Radiation Sterilization Equipment Market is characterized by continuous innovation aimed at enhancing efficiency, safety, and versatility across its primary modalities: gamma, electron beam (e-beam), and X-ray sterilization. Gamma sterilization predominantly relies on Cobalt-60 isotopes, which emit high-energy photons capable of deep penetration, allowing for the sterilization of large volumes of products within their final packaging. Technological advancements in this area focus on optimizing irradiator designs, improving source utilization efficiency, and developing advanced shielding and safety systems to comply with stringent regulatory requirements for handling radioactive materials. These innovations also include sophisticated conveyor systems and automated product handling solutions to maximize throughput and minimize human intervention, ensuring both operational safety and process reliability in large-scale facilities.

Electron beam (e-beam) technology utilizes high-energy electron accelerators to generate a beam of electrons that penetrate materials. The technological advancements in e-beam systems are centered around developing more powerful, compact, and energy-efficient accelerators, such as linear accelerators (LINACs) and Dynamitrons, which can deliver higher dose rates and offer greater control over the sterilization process. Innovations also include improved beam scanning systems for enhanced dose uniformity, advanced real-time dosimetry for precise process control, and sophisticated software for automation and data management. These developments enable e-beam systems to offer on-demand sterilization, faster processing times, and significantly reduce the need for radioactive isotopes, making them increasingly attractive for applications requiring high speed and environmental consciousness. The flexibility of e-beam systems also allows for integration into existing production lines, enhancing operational agility.

X-ray sterilization, a more recent but rapidly growing technology, is based on converting electron beam energy into X-rays using a metallic target. This method combines the deep penetration capabilities of gamma radiation with the on-demand and non-radioactive benefits of e-beam technology. The technological landscape for X-ray sterilization equipment is focused on developing more efficient electron-to-X-ray conversion targets, enhancing accelerator designs to produce higher energy X-rays, and integrating advanced cooling systems to manage the heat generated during X-ray production. Software for precise dose mapping, predictive modeling, and real-time monitoring is also crucial for optimizing X-ray sterilization cycles and ensuring product safety. These advancements aim to position X-ray systems as a versatile solution for products that require deep penetration but prefer an isotope-free process, offering a compelling alternative to traditional gamma methods. The ongoing convergence of these technologies, coupled with integrated automation and data analytics, is shaping a future where sterilization processes are more intelligent, adaptable, and robust.

Regional Highlights

- North America: This region holds a dominant share in the Ionizing Radiation Sterilization Equipment Market, driven by a highly developed healthcare infrastructure, substantial R&D investments in medical technology, and stringent regulatory frameworks from bodies like the FDA. The presence of numerous key market players, coupled with high healthcare expenditure and a strong demand for sterile medical devices and pharmaceuticals, propels market growth. The region also benefits from a mature contract sterilization industry, which supports a wide range of manufacturers.

- Europe: Europe represents another significant market for ionizing radiation sterilization equipment, characterized by a strong focus on innovation, advanced medical research, and strict adherence to quality and safety standards, particularly under the EU Medical Device Regulation (MDR). Countries such as Germany, the UK, and France are leading contributors, boasting advanced manufacturing capabilities and a high adoption rate of advanced sterilization technologies. The region is also home to several prominent sterilization service providers and equipment manufacturers, contributing to a robust market.

- Asia Pacific (APAC): The Asia Pacific region is projected to exhibit the highest growth rate in the market, primarily due to the rapid expansion of its healthcare sector, increasing investments in medical device and pharmaceutical manufacturing, and rising awareness about infection control. Emerging economies like China and India are experiencing significant growth in their healthcare spending and medical tourism, leading to greater demand for sterile products. The region's large population base and increasing disposable incomes further fuel the adoption of advanced sterilization technologies.

- Latin America: This region is an emerging market for ionizing radiation sterilization equipment, characterized by developing healthcare infrastructure and increasing access to modern medical treatments. Growth is driven by rising healthcare investments, improving economic conditions, and the expansion of local medical device and pharmaceutical production capabilities. Brazil and Mexico are key markets within this region, showing progressive adoption of advanced sterilization techniques, though challenges related to regulatory harmonization and capital investment persist.

- Middle East and Africa (MEA): The MEA region is at an nascent stage of market development, with growth primarily influenced by government initiatives to enhance healthcare services, increasing foreign direct investment in healthcare infrastructure, and a growing emphasis on public health and safety. While the market here is smaller compared to other regions, there is a gradual adoption of modern sterilization practices, particularly in Gulf Cooperation Council (GCC) countries, driven by the need to meet international healthcare standards and combat infectious diseases.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ionizing Radiation Sterilization Equipment Market.- Steris PLC

- Nordion Inc.

- Ion Beam Applications (IBA) SA

- Sterigenics International LLC (a Sotera Health Company)

- BGS Beta-Gamma-Service GmbH & Co. KG

- E-BEAM Services Inc.

- BeamOne LLC

- MEVEX GmbH

- L3Harris Technologies Inc.

- Hitachi, Ltd.

- Mitsubishi Heavy Industries, Ltd.

- Varian Medical Systems (part of Siemens Healthineers)

- GE Healthcare

- RadiaBeam, Inc.

- SCK CEN

- Isotron (a STERIS company)

- TÜV SÜD

- Iotron Industries

- China Isotope & Radiation Corporation (CIRC)

- PTB (Physikalisch-Technische Bundesanstalt)

Frequently Asked Questions

What are the main types of ionizing radiation sterilization equipment?

The primary types of ionizing radiation sterilization equipment include Gamma Sterilization Equipment, which uses Cobalt-60 isotopes; Electron Beam (E-beam) Sterilization Equipment, which employs electron accelerators; and X-ray Sterilization Equipment, which converts electron beams into X-rays for deeper penetration.

What are the primary applications of ionizing radiation sterilization equipment?

Ionizing radiation sterilization equipment is widely used for sterilizing medical devices, pharmaceuticals, food and beverages, cosmetics, and various industrial products. Its versatility makes it suitable for heat-sensitive items and products sterilized within their final packaging.

What are the key advantages of ionizing radiation sterilization over other methods?

Key advantages include superior penetration capabilities, enabling sterilization of products in their final packaging; it is a "cold sterilization" process, ideal for heat-sensitive materials; it leaves no toxic residues; and it offers high throughput and process reliability. This method ensures product integrity and safety without compromising material properties.

What challenges does the Ionizing Radiation Sterilization Equipment Market face?

The market faces challenges such as high initial capital investment for facility setup, complex and stringent regulatory approval processes, public perception concerns regarding radiation, and the need for highly specialized technical expertise for operation and maintenance. These factors can limit market entry and expansion for some stakeholders.

How is Artificial Intelligence (AI) impacting the Ionizing Radiation Sterilization Equipment Market?

AI is impacting the market by enabling optimization of sterilization parameters, predictive maintenance for equipment, automated quality control and dosimetry, and enhanced supply chain management. This leads to increased efficiency, reduced operational costs, improved safety, and more precise control over sterilization processes, driving a shift towards intelligent and autonomous operations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager