IoT in Manufacturing Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428103 | Date : Oct, 2025 | Pages : 257 | Region : Global | Publisher : MRU

IoT in Manufacturing Market Size

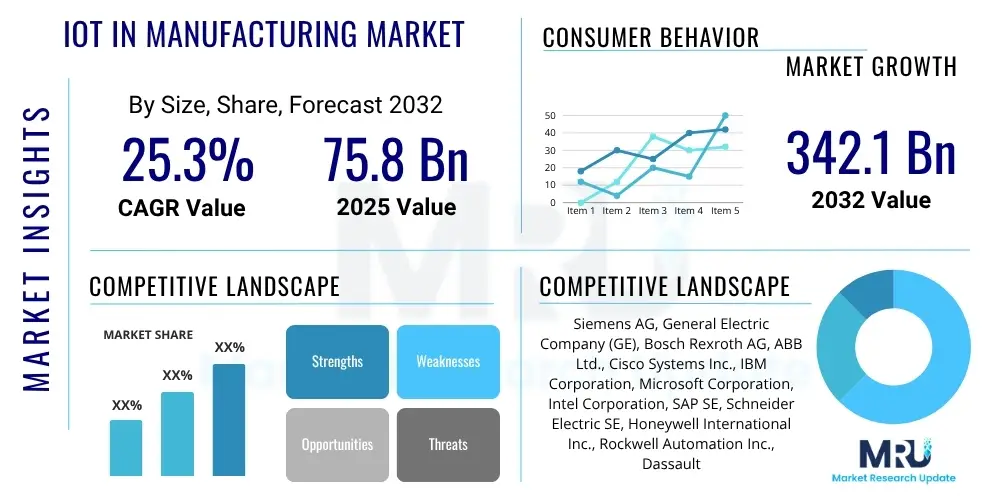

The IoT in Manufacturing Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 25.3% between 2025 and 2032. The market is estimated at USD 75.8 Billion in 2025 and is projected to reach USD 342.1 Billion by the end of the forecast period in 2032.

IoT in Manufacturing Market introduction

The Internet of Things (IoT) in Manufacturing market represents a transformative paradigm shift, integrating physical devices, sensors, software, and other technologies to connect and exchange data over the internet, particularly within industrial settings. This integration allows for real-time monitoring, data collection, and control of manufacturing processes, leading to enhanced operational efficiency, reduced downtime, and improved product quality. The core product offering revolves around smart sensors, RFID tags, connectivity solutions (5G, Wi-Fi), analytics platforms, and cloud services specifically tailored for industrial applications, facilitating predictive maintenance, asset tracking, and remote operational management.

Major applications of IoT in manufacturing span across various domains, including asset performance management, supply chain optimization, quality control, energy management, and worker safety. For instance, in asset performance, IoT sensors monitor machinery health, predicting failures before they occur and minimizing costly interruptions. In supply chain management, real-time tracking of materials and finished goods ensures transparency and efficiency. The benefits are multifold: increased productivity, cost reduction through optimized resource utilization, enhanced decision-making capabilities, and the creation of new business models centered on data-driven insights and services. These advantages are increasingly compelling manufacturers to adopt IoT solutions to stay competitive in a rapidly evolving global landscape.

Driving factors propelling the growth of this market include the escalating demand for automation and digital transformation in industries, the increasing adoption of cloud computing and big data analytics, and the growing focus on improving operational efficiency and reducing manufacturing costs. Furthermore, favorable government initiatives promoting Industry 4.0 and smart manufacturing across developed and developing economies are providing significant impetus. The continuous advancements in sensor technologies, network connectivity, and artificial intelligence are also lowering implementation barriers and expanding the scope of IoT applications, making these solutions more accessible and impactful for a wider range of manufacturers.

IoT in Manufacturing Market Executive Summary

The IoT in Manufacturing market is undergoing robust expansion, driven by widespread digital transformation initiatives and the imperative for operational excellence. Business trends indicate a significant shift towards data-driven decision-making, with enterprises investing heavily in IoT platforms that offer comprehensive analytics and predictive capabilities. There is a notable increase in the adoption of subscription-based IoT solutions and platform-as-a-service (PaaS) models, reflecting a desire for scalability, flexibility, and reduced upfront investment. Strategic partnerships between technology providers and industrial players are becoming more common, fostering innovation and facilitating integrated solution deployment. Furthermore, the market is seeing a convergence of IT and OT (Operational Technology), enabling seamless data flow and holistic control across manufacturing operations, which is critical for achieving true smart factory capabilities.

Regional trends highlight North America and Europe as early adopters and leading markets, fueled by mature industrial infrastructures, high technological readiness, and significant R&D investments in advanced manufacturing. Asia Pacific, particularly countries like China, India, Japan, and South Korea, is emerging as a high-growth region, driven by rapid industrialization, large manufacturing bases, and supportive government policies for smart manufacturing initiatives. Latin America, the Middle East, and Africa are also showing promising growth, albeit from a smaller base, as industrial sectors in these regions increasingly recognize the competitive advantages offered by IoT technologies. The demand for localized solutions tailored to specific regional industrial needs and regulatory environments is a key driver across all geographies, influencing market entry strategies for technology vendors.

Segmentation trends reveal a strong performance across various components, applications, and industries. The hardware segment, including sensors and devices, continues to be foundational, but the software and services segments are experiencing accelerated growth due to the increasing complexity of data management and the need for specialized integration and analytical support. In terms of applications, asset performance management, predictive maintenance, and supply chain management remain paramount, with quality control and energy management also gaining significant traction. Vertical-wise, the automotive, electronics, heavy machinery, and aerospace and defense sectors are leading in IoT adoption, demonstrating the technology's versatile applicability across diverse manufacturing environments. This diversified growth across segments underscores the broad applicability and value proposition of IoT in addressing multifaceted manufacturing challenges.

AI Impact Analysis on IoT in Manufacturing Market

User inquiries about AI's impact on the IoT in Manufacturing market frequently revolve around its potential to enhance data analysis, enable predictive capabilities, and drive automation, while also expressing concerns regarding data security, implementation complexity, and job displacement. Users are keen to understand how AI can transform raw IoT data into actionable insights, facilitating proactive decision-making for maintenance, quality control, and operational optimization. Expectations are high for AI to move beyond descriptive analytics to prescriptive actions, providing real-time recommendations and autonomous control within smart factory environments. There is also significant interest in AI's role in improving human-machine collaboration and creating more adaptive and intelligent manufacturing systems.

- AI significantly enhances predictive maintenance by analyzing IoT sensor data to forecast equipment failures, minimizing downtime and maintenance costs.

- Optimized production processes are achieved through AI algorithms that learn from real-time operational data, identifying inefficiencies and suggesting adjustments for improved output and quality.

- AI-powered quality control systems use machine vision and analytics to detect defects with higher accuracy and speed than human inspection, reducing waste and ensuring product consistency.

- Supply chain visibility and efficiency are boosted as AI processes IoT data from logistics, enabling better demand forecasting, inventory management, and route optimization.

- Enhanced worker safety is facilitated by AI analyzing data from wearables and environmental sensors, predicting potential hazards and alerting personnel to mitigate risks.

- The development of autonomous robots and cobots is accelerated by AI, allowing them to perform complex tasks, collaborate with humans, and adapt to changing manufacturing demands.

- AI contributes to energy efficiency by analyzing IoT data from machinery and utility meters, identifying patterns of consumption, and optimizing energy usage across facilities.

DRO & Impact Forces Of IoT in Manufacturing Market

The IoT in Manufacturing market is significantly shaped by a dynamic interplay of Drivers, Restraints, and Opportunities, all contributing to its overall Impact Forces. A primary driver is the accelerating imperative for digital transformation across industrial sectors, pushing manufacturers to adopt smart technologies to remain competitive and efficient. The escalating demand for operational efficiency, cost reduction, and improved productivity serves as a powerful catalyst, compelling businesses to leverage IoT for real-time monitoring, predictive analytics, and process optimization. Furthermore, the increasing availability of affordable and robust IoT sensors, advanced connectivity options like 5G, and sophisticated data analytics platforms are lowering adoption barriers and expanding the scope of viable applications. Government initiatives globally promoting Industry 4.0 and smart factory concepts also provide crucial policy support and funding, further accelerating market growth and technological integration.

Despite the strong growth trajectory, several restraints impede the market's full potential. High initial investment costs for implementing comprehensive IoT solutions, including hardware, software, and integration services, can be a significant barrier for small and medium-sized enterprises (SMEs). Concerns regarding data security, privacy, and the potential for cyber-attacks on connected industrial systems are paramount, necessitating robust security protocols and compliance measures. The complexity of integrating diverse legacy systems with new IoT infrastructure often presents technical challenges, requiring specialized expertise and significant customization. A shortage of skilled personnel proficient in IoT deployment, data science, and operational technology further complicates implementation and maintenance, highlighting the need for workforce reskilling and development programs.

Opportunities within the IoT in Manufacturing market are abundant and diverse. The proliferation of edge computing capabilities promises to enhance real-time processing and reduce latency, unlocking new applications in critical and time-sensitive manufacturing environments. The emergence of Artificial Intelligence (AI) and Machine Learning (ML) integration with IoT data offers immense potential for advanced analytics, predictive insights, and autonomous decision-making, moving beyond simple monitoring to truly intelligent operations. The growing focus on sustainability and energy efficiency presents an opportunity for IoT solutions to monitor and optimize energy consumption, waste reduction, and carbon footprint. Moreover, the development of specialized vertical solutions tailored to specific industry needs, such as automotive, aerospace, or pharmaceuticals, allows for deeper market penetration and higher value creation, opening new avenues for product differentiation and competitive advantage.

Segmentation Analysis

The IoT in Manufacturing market is segmented comprehensively across various dimensions, including components, applications, industries, and connectivity technologies, to provide a granular understanding of its diverse landscape. This detailed segmentation helps in identifying key growth areas, understanding specific market dynamics, and tailoring solutions to meet the distinct needs of different stakeholders within the manufacturing ecosystem. Each segment plays a crucial role in the overall market structure, contributing to the development and deployment of integrated IoT solutions that enhance operational efficiency and drive innovation across industrial processes.

- Component:

- Hardware (Sensors, RFID, Connectivity Devices, Processors, Memory)

- Software (Data Management, Analytics, Security, Application Management, Cloud Platforms)

- Services (Consulting, Integration, Managed Services, Support & Maintenance)

- Application:

- Asset Performance Management (APM)

- Predictive Maintenance

- Process and Operations Optimization

- Real-time Workforce Tracking and Safety

- Quality Control and Compliance

- Supply Chain Management and Logistics

- Energy Management

- Inventory Management

- Industry Vertical:

- Automotive

- Aerospace & Defense

- Electronics & Semiconductor

- Heavy Machinery

- Pharmaceuticals & Chemicals

- Food & Beverages

- Metals & Mining

- Textile

- Oil & Gas

- Others (e.g., Paper & Pulp, Packaging)

- Connectivity Technology:

- Wired (Ethernet, Fieldbus)

- Wireless (Wi-Fi, Bluetooth, Zigbee, LoRaWAN, Cellular (4G/5G), Satellite)

- Deployment Type:

- On-Premise

- Cloud-Based

- Hybrid

Value Chain Analysis For IoT in Manufacturing Market

The value chain for the IoT in Manufacturing market is intricate, encompassing various stages from device manufacturing to end-user application and service delivery. It begins with upstream analysis, which involves the foundational layers of technology development and component manufacturing. This includes companies specializing in producing sensors, microcontrollers, gateways, and communication modules that form the backbone of any IoT deployment. Semiconductor manufacturers, hardware component providers, and firms involved in basic research and development of connectivity standards (e.g., 5G, LoRaWAN) are critical upstream players. Their innovations in miniaturization, power efficiency, and processing capabilities directly influence the performance and cost-effectiveness of subsequent IoT solutions, setting the stage for industrial adoption.

Moving further along the value chain, the midstream involves solution integrators, platform providers, and software developers. These entities take the raw hardware components and build complete IoT systems, including data acquisition platforms, cloud infrastructure, analytics engines, and application interfaces. This stage is crucial for translating hardware capabilities into actionable insights and operational improvements for manufacturers. It involves substantial engineering effort in system design, cybersecurity implementation, and the development of industry-specific applications. The integration layer, where various devices and software components are brought together to function as a cohesive system, is particularly complex and often requires specialized expertise to ensure interoperability and seamless data flow across the manufacturing floor and beyond.

The downstream analysis focuses on the distribution channels and the ultimate end-users. Distribution channels can be direct, where major IoT solution providers engage directly with large manufacturing enterprises, offering tailored deployments and ongoing support. Indirect channels involve a network of value-added resellers (VARs), system integrators, and channel partners who help distribute and implement IoT solutions to a broader range of industrial clients, including SMEs. These partners often provide localized support, customization, and integration services, playing a vital role in market penetration. The end-users, primarily manufacturing companies across various sectors like automotive, electronics, and heavy machinery, are the ultimate beneficiaries, leveraging these IoT solutions to enhance productivity, optimize processes, and gain competitive advantages. The feedback loop from end-users to solution providers is essential for continuous improvement and innovation within the value chain.

IoT in Manufacturing Market Potential Customers

The potential customers for IoT in Manufacturing solutions span a broad spectrum of industrial enterprises, fundamentally comprising end-users or buyers seeking to enhance their operational efficiency, reduce costs, improve product quality, and drive digital transformation. These customers primarily consist of companies operating in discrete manufacturing, such as automotive, aerospace and defense, electronics, and heavy machinery, where real-time monitoring of assembly lines, asset tracking, and predictive maintenance are critical. The need to optimize production schedules, manage complex supply chains, and ensure worker safety makes IoT an indispensable tool for these sectors, driving their investments in smart factory technologies to maintain competitiveness and meet stringent industry standards.

Process manufacturing industries also represent a significant segment of potential customers, including sectors like pharmaceuticals, chemicals, food and beverages, oil and gas, and metals and mining. In these environments, IoT solutions are crucial for monitoring continuous processes, managing critical infrastructure, ensuring regulatory compliance, and optimizing resource consumption. For instance, in pharmaceuticals, IoT can track environmental conditions during drug manufacturing to ensure purity and quality, while in oil and gas, it enables remote monitoring of pipelines and equipment to prevent costly downtime and ensure safety. The ability to collect and analyze vast amounts of operational data from various stages of production allows these industries to achieve greater control, reduce waste, and improve overall yield.

Beyond traditional manufacturing giants, small and medium-sized enterprises (SMEs) are emerging as increasingly viable potential customers, driven by the availability of more scalable and affordable IoT solutions, often delivered as a service. While SMEs might have different budgetary constraints and technical capabilities compared to larger corporations, their strong imperative to improve efficiency and compete effectively motivates them to adopt targeted IoT applications. Furthermore, utility companies and infrastructure operators, though not strictly manufacturing, often leverage similar IoT technologies for asset management, grid optimization, and predictive maintenance of their industrial equipment and networks, blurring the lines and expanding the potential customer base for core IoT components and services tailored to industrial applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 75.8 Billion |

| Market Forecast in 2032 | USD 342.1 Billion |

| Growth Rate | 25.3% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, General Electric Company (GE), Bosch Rexroth AG, ABB Ltd., Cisco Systems Inc., IBM Corporation, Microsoft Corporation, Intel Corporation, SAP SE, Schneider Electric SE, Honeywell International Inc., Rockwell Automation Inc., Dassault Systèmes SE, PTC Inc., Huawei Technologies Co. Ltd., Advantech Co. Ltd., KUKA AG, Beckhoff Automation GmbH & Co. KG, Dell Technologies Inc., Oracle Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

IoT in Manufacturing Market Key Technology Landscape

The IoT in Manufacturing market is underpinned by a robust and evolving technological landscape, essential for enabling smart factory capabilities and operational excellence. At the core are advanced sensing technologies, including industrial sensors for temperature, pressure, vibration, acoustics, and vision systems (cameras), which collect granular data from machinery, processes, and environments. These sensors are increasingly miniaturized, more robust, and capable of operating in harsh industrial conditions, providing the foundational data streams required for real-time monitoring and analytics. Furthermore, RFID tags and barcodes play a crucial role in asset tracking, inventory management, and supply chain visibility, providing unique identifiers for materials and products throughout the manufacturing lifecycle.

Connectivity technologies form the nervous system of IoT deployments, enabling seamless data transfer across the manufacturing floor and to cloud platforms. Key among these are wireless technologies such as industrial Wi-Fi, Bluetooth Low Energy (BLE), Zigbee, and LoRaWAN for short-range and low-power applications. For broader coverage and mission-critical communications, cellular technologies like 4G LTE and particularly 5G are becoming increasingly vital due to their high bandwidth, low latency, and ability to support a massive number of connected devices, crucial for real-time control and large-scale deployments. Wired technologies like Ethernet and Fieldbus protocols also continue to play a role for stable, high-speed connections in specific industrial contexts, ensuring reliable data backbone infrastructure for critical operations.

Beyond data collection and transmission, the technology landscape includes sophisticated data processing and analytics platforms. Edge computing is gaining prominence, allowing data to be processed closer to its source on the factory floor, reducing latency, conserving bandwidth, and enhancing real-time decision-making for critical applications like robotic control and defect detection. Cloud platforms provide scalable storage and computational resources for big data analytics, machine learning, and artificial intelligence, transforming raw IoT data into actionable insights for predictive maintenance, process optimization, and demand forecasting. Additionally, cybersecurity solutions, blockchain for supply chain transparency, and digital twin technology for virtual modeling and simulation are emerging as crucial components, further solidifying the technological foundation of the evolving IoT in Manufacturing ecosystem.

Regional Highlights

- North America: A leading market characterized by high technology adoption rates, significant investments in R&D, and the presence of numerous key IoT solution providers. The region benefits from a mature industrial base and a strong emphasis on smart factory initiatives and automation across automotive, aerospace, and electronics sectors.

- Europe: Driven by robust government initiatives like Industry 4.0 in Germany and similar programs across the EU, Europe showcases strong growth, particularly in advanced manufacturing, machinery, and automotive industries. High regulatory standards often drive the adoption of IoT for efficiency and compliance.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, large manufacturing hubs (e.g., China, India, Japan, South Korea), and increasing government support for smart manufacturing. The region is a key consumer and producer of IoT hardware and is quickly scaling up software and service capabilities.

- Latin America: An emerging market with growing awareness and adoption of IoT in manufacturing, particularly in countries like Brazil and Mexico. The focus is on leveraging IoT to improve operational efficiency, supply chain management, and reduce costs in sectors such as automotive, mining, and food & beverage.

- Middle East and Africa (MEA): Demonstrating nascent but significant growth, especially in the Gulf Cooperation Council (GCC) countries, driven by diversification efforts away from oil and gas, and investments in smart city and industrial infrastructure projects. IoT adoption is focused on optimizing resource-intensive industries and developing new manufacturing capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the IoT in Manufacturing Market.- Siemens AG

- General Electric Company (GE)

- Bosch Rexroth AG

- ABB Ltd.

- Cisco Systems Inc.

- IBM Corporation

- Microsoft Corporation

- Intel Corporation

- SAP SE

- Schneider Electric SE

- Honeywell International Inc.

- Rockwell Automation Inc.

- Dassault Systèmes SE

- PTC Inc.

- Huawei Technologies Co. Ltd.

- Advantech Co. Ltd.

- KUKA AG

- Beckhoff Automation GmbH & Co. KG

- Dell Technologies Inc.

- Oracle Corporation

Frequently Asked Questions

What is IoT in Manufacturing?

IoT in Manufacturing refers to the integration of internet-connected sensors, devices, software, and platforms within industrial operations to collect, analyze, and exchange data in real-time. This enables automation, remote monitoring, predictive maintenance, and optimized production processes, ultimately leading to enhanced efficiency and decision-making in smart factories.

What are the primary benefits of implementing IoT in manufacturing?

The primary benefits include significant improvements in operational efficiency, reduced downtime through predictive maintenance, enhanced product quality control, optimized supply chain management, lower operational costs, and greater data-driven insights for strategic decision-making. It also fosters innovation and enables new service-based business models.

What are the key challenges associated with IoT adoption in manufacturing?

Key challenges involve high initial investment costs for hardware and software, cybersecurity risks and data privacy concerns, the complexity of integrating new IoT systems with legacy infrastructure, and a shortage of skilled personnel proficient in IoT deployment and data analytics. Scalability and interoperability issues can also arise.

How does AI impact IoT in Manufacturing?

AI significantly enhances IoT in manufacturing by providing advanced analytical capabilities to process vast amounts of sensor data. This enables more accurate predictive maintenance, real-time quality control, autonomous robotic operations, optimized energy management, and deeper insights for continuous process improvement and adaptive decision-making.

Which industries are leading in the adoption of IoT in Manufacturing?

Industries leading in IoT adoption include automotive, aerospace and defense, electronics and semiconductors, heavy machinery, and pharmaceuticals. These sectors heavily rely on precision, efficiency, and complex supply chain management, making IoT solutions critical for maintaining their competitive edge and operational excellence.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager