Large Bore Vacuum Insulated Pipe Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429694 | Date : Nov, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Large Bore Vacuum Insulated Pipe Market Size

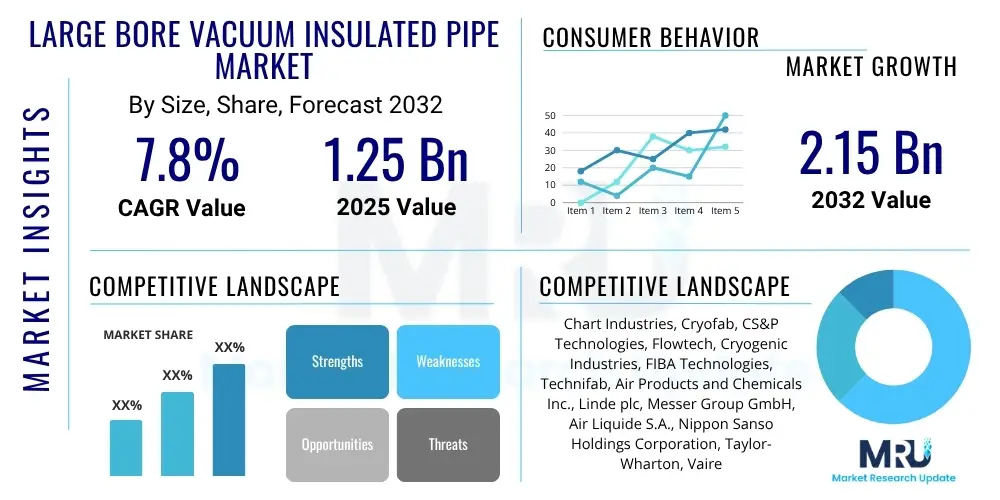

The Large Bore Vacuum Insulated Pipe Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at $1.25 billion in 2025 and is projected to reach $2.15 billion by the end of the forecast period in 2032.

Large Bore Vacuum Insulated Pipe Market introduction

The Large Bore Vacuum Insulated Pipe (LBVIP) market encompasses specialized piping systems designed to minimize heat transfer, primarily for the efficient and safe transport of cryogenic liquids and gases such as Liquid Natural Gas (LNG), liquid oxygen, nitrogen, argon, and increasingly, liquid hydrogen. These sophisticated pipes feature an inner and outer pipe separated by a vacuum annulus, often complemented by multi-layer insulation (MLI), to create a highly effective thermal barrier. This design ensures minimal boil-off and energy loss, critical for maintaining the integrity and economic viability of cryogenic operations.

Major applications for LBVIPs span a wide array of high-tech and industrial sectors, including the burgeoning LNG value chain from liquefaction terminals to regasification plants, industrial gas production and distribution, aerospace for rocket propellants, healthcare for medical gas storage, and advanced research facilities. The inherent benefits of these pipes, such as superior thermal efficiency, enhanced safety due to reduced frost and condensation, and operational cost savings through minimized product loss, make them indispensable for any application requiring precise temperature control of ultra-cold fluids. The market's growth is predominantly driven by increasing global demand for energy, the expansion of industrial gas infrastructure, the accelerating shift towards hydrogen as a clean energy carrier, and stringent environmental and safety regulations promoting more efficient and secure cryogenic transport solutions.

Large Bore Vacuum Insulated Pipe Market Executive Summary

The Large Bore Vacuum Insulated Pipe market is currently experiencing robust growth, propelled by significant business trends including the global energy transition, the expansion of industrial gas production facilities, and substantial investments in cryogenic infrastructure. Businesses are increasingly prioritizing operational efficiency, energy conservation, and safety in the handling of ultra-cold substances, positioning LBVIPs as a crucial component in modern industrial processes. The market sees a heightened focus on modular designs, pre-fabricated solutions, and advanced material science to improve performance and reduce installation times, responding to the demand for more agile and cost-effective project deployments. Regulatory mandates for emissions reduction and enhanced safety also compel industries to adopt superior insulation technologies like LBVIPs.

Regionally, the Asia Pacific continues to dominate the market, driven by rapid industrialization, extensive LNG import and export activities, and the growing adoption of hydrogen energy initiatives in countries like China, Japan, and South Korea. North America and Europe also present strong growth trajectories, fueled by investments in renewable energy infrastructure, space exploration programs, and an expanding industrial gas sector. Emerging markets in Latin America and the Middle East and Africa are witnessing gradual uptake, particularly in oil and gas and industrial manufacturing, as they enhance their cryogenic capabilities. Across segments, the LNG and industrial gas applications remain primary revenue generators, while the hydrogen segment is poised for exponential growth, reflecting a broader shift towards sustainable energy solutions.

Segment-wise, the market demonstrates a clear preference for rigid LBVIPs in fixed installations requiring long-term stability, while flexible variants gain traction in applications demanding adaptability and easier installation. Stainless steel continues to be the predominant material due to its durability and cryogenic performance, though advancements in aluminum and other composites are opening new avenues. The increasing complexity of cryogenic processes necessitates tailored solutions, leading to a surge in demand for customized pipe designs and integrated vacuum insulation systems. This diversified demand across various applications underscores the versatility and critical importance of LBVIP technology in the global industrial landscape.

AI Impact Analysis on Large Bore Vacuum Insulated Pipe Market

The integration of Artificial Intelligence (AI) in the Large Bore Vacuum Insulated Pipe (LBVIP) market is anticipated to revolutionize various stages of the product lifecycle, from design and manufacturing to operational maintenance and supply chain management. Users are particularly interested in how AI can optimize the complex engineering and fabrication processes of LBVIPs, enhance the precision of vacuum insulation, and enable more predictive and proactive maintenance strategies to extend asset life and minimize downtime. There is a strong expectation that AI will contribute significantly to cost reduction through intelligent material selection, waste minimization, and streamlined production workflows. Furthermore, stakeholders anticipate AI's role in improving the overall safety and reliability of cryogenic transport by detecting potential anomalies before they escalate, providing real-time performance analytics, and facilitating rapid diagnostic capabilities.

- AI-driven design optimization for enhanced thermal performance and material efficiency.

- Predictive maintenance analytics to forecast potential failures and schedule proactive interventions.

- Automated quality control systems for welding, vacuum integrity, and insulation layer application.

- Supply chain optimization, including demand forecasting and logistics for specialized components.

- Real-time monitoring and anomaly detection for operational safety and efficiency.

- AI-assisted simulation for new material development and application testing.

- Robotics and automation integration in manufacturing for increased precision and speed.

- Data analytics to identify energy consumption patterns and recommend efficiency improvements.

DRO & Impact Forces Of Large Bore Vacuum Insulated Pipe Market

The Large Bore Vacuum Insulated Pipe market is profoundly influenced by a complex interplay of drivers, restraints, opportunities, and external impact forces. A primary driver is the escalating global demand for cleaner energy sources, particularly the widespread adoption of LNG and the rapid development of the hydrogen economy, both of which necessitate efficient cryogenic storage and transfer solutions. The continuous expansion of industrial gas production and distribution networks worldwide, catering to diverse sectors from manufacturing to healthcare, further fuels the market. Stricter environmental regulations aimed at reducing energy waste and minimizing emissions, alongside heightened safety standards for handling volatile cryogenic substances, also compel industries to invest in high-performance LBVIP systems. These factors collectively underscore the critical role of advanced insulation technology in modern industrial infrastructure.

However, the market faces notable restraints, including the significant upfront capital investment required for LBVIP systems, which can be a barrier for smaller projects or regions with limited infrastructure budgets. The intricate manufacturing processes and the need for specialized installation expertise add to the overall cost and complexity. Furthermore, LBVIPs are susceptible to external damage if not properly protected, and maintaining the vacuum integrity over extended periods demands rigorous quality control and periodic monitoring, posing operational challenges. The highly technical nature of the product and the limited pool of specialized suppliers can also lead to longer lead times and higher procurement costs.

Despite these challenges, substantial opportunities exist, driven by the global push towards decarbonization and the emergence of new applications. The burgeoning green hydrogen sector, encompassing production, storage, and long-distance transport, presents an immense growth avenue for LBVIPs. Advancements in space exploration and satellite technologies requiring cryogenic propellants, coupled with expanding applications in advanced manufacturing and medical diagnostics, open new market segments. Technological innovations in insulation materials, vacuum retention, and smart monitoring systems are expected to enhance product performance and reduce costs, making LBVIPs more accessible and competitive. The confluence of these drivers, restraints, and opportunities creates a dynamic market landscape, shaped by overarching impact forces such as evolving energy policies, technological breakthroughs in cryogenics, and fluctuating commodity prices.

Segmentation Analysis

The Large Bore Vacuum Insulated Pipe market is comprehensively segmented to address the diverse requirements of its extensive application landscape, providing granular insights into varying product types, materials, end-use industries, and geographic demands. This segmentation allows for a detailed understanding of market dynamics, identifying specific growth pockets and evolving customer preferences across different operational scales and technical specifications. The market's structure reflects the specialized nature of cryogenic applications, where precise engineering and material selection are paramount for performance and safety.

- By Application

- LNG (Liquefied Natural Gas) Transport & Storage

- Industrial Gases (Oxygen, Nitrogen, Argon, Helium)

- Hydrogen (Liquid Hydrogen & Gaseous Hydrogen Infrastructure)

- Aerospace & Defense (Rocket Propellants, Test Facilities)

- Medical & Healthcare (MRI Cooling, Biomedical Storage)

- Food & Beverage (Cryogenic Freezing)

- Research & Development

- Others

- By End-Use Industry

- Energy & Power (Oil & Gas, Renewables)

- Chemical & Petrochemical

- Manufacturing

- Healthcare & Pharmaceuticals

- Electronics

- Metallurgy

- Aerospace

- Food & Beverage

- Research Institutions

- By Pipe Type

- Rigid Vacuum Insulated Pipe

- Flexible Vacuum Insulated Pipe

- By Material

- Stainless Steel (304, 316L, 316)

- Aluminum

- Copper Alloys

- Others (e.g., specialized composites)

- By Operating Pressure

- High Pressure

- Medium Pressure

- Low Pressure

- By Diameter

- 100mm – 300mm

- 301mm – 600mm

- Above 600mm

Value Chain Analysis For Large Bore Vacuum Insulated Pipe Market

The value chain for the Large Bore Vacuum Insulated Pipe market is characterized by a series of specialized stages, beginning with the sourcing of high-grade raw materials. Upstream analysis involves suppliers of critical metals such as stainless steel (304, 316L), aluminum, and copper alloys, which form the primary structural components of the inner and outer pipes. Additionally, suppliers of specialized insulation materials, including multi-layer insulation (MLI), perlite, and vacuum pump components, play a vital role. Quality control and material certifications at this stage are paramount to ensure the integrity and performance of the final product under extreme cryogenic conditions. Specialized component manufacturers contribute vacuum seals, bellows, expansion joints, and cryogenic valves, all engineered for ultra-low temperature resistance and high vacuum compatibility.

The core of the value chain resides in the manufacturing and assembly of the LBVIPs, where expert fabrication techniques, precision welding, and advanced vacuum processing are employed. This stage often involves highly automated processes for pipe forming, orbital welding, and the evacuation of the annulus to create the vacuum insulation. Downstream analysis focuses on the distribution, installation, and post-sales support activities. Distribution channels typically involve a mix of direct sales by manufacturers to large-scale industrial projects and indirect sales through specialized distributors, engineering, procurement, and construction (EPC) contractors, or system integrators who incorporate LBVIPs into broader cryogenic systems. These channels are crucial for reaching diverse end-users across various geographies.

Installation services are highly specialized, often requiring expert teams proficient in cryogenic system assembly, leak detection, and vacuum commissioning. Post-sales services include maintenance, repair, and potential upgrades, ensuring the long-term operational efficiency and safety of the installed systems. The strong emphasis on direct engagement with end-users for complex projects, alongside strategic partnerships with EPC firms, highlights the critical role of expertise and trusted relationships within this niche market. Indirect channels also provide broader market access and localized support, particularly for standard products or smaller installations, allowing manufacturers to leverage existing networks for wider reach.

Large Bore Vacuum Insulated Pipe Market Potential Customers

The potential customer base for Large Bore Vacuum Insulated Pipes is diverse and spans a wide array of high-tech and heavy industries, all requiring precise and efficient handling of cryogenic fluids. Primary end-users include operators of large-scale Liquefied Natural Gas (LNG) terminals, both for import and export, where LBVIPs are essential for transferring LNG from storage tanks to tankers or regasification units with minimal boil-off. Industrial gas producers and distributors represent another significant customer segment, utilizing these pipes for the transport of liquid oxygen, nitrogen, argon, and helium across their production facilities and to bulk storage depots. The increasing global demand for these gases in manufacturing, healthcare, and electronics drives consistent demand for LBVIPs.

Furthermore, the rapidly expanding hydrogen economy is a burgeoning segment for LBVIPs, with facilities engaged in the production, liquefaction, storage, and distribution of liquid hydrogen (LH2) as key potential customers. Aerospace and defense organizations also heavily rely on LBVIPs for the transfer of cryogenic rocket propellants, such as liquid oxygen and liquid hydrogen, in launch facilities and test stands. Research and development institutions, particularly those involved in high-energy physics, superconducting technologies, and extreme low-temperature experiments, frequently require customized LBVIP solutions. Healthcare facilities, especially those with large MRI systems or biobanks requiring cryogenic storage, also form a critical, albeit smaller, customer group. These varied applications underscore the indispensable nature of LBVIP technology for any entity involved in large-scale, high-efficiency cryogenic operations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $1.25 billion |

| Market Forecast in 2032 | $2.15 billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Chart Industries, Cryofab, CS&P Technologies, Flowtech, Cryogenic Industries, FIBA Technologies, Technifab, Air Products and Chemicals Inc., Linde plc, Messer Group GmbH, Air Liquide S.A., Nippon Sanso Holdings Corporation, Taylor-Wharton, Vairex GmbH, Cryogenic Service and Supply Inc., Thermal Pipe Systems Inc., CRIO Inc., Sumitomo Precision Products Co. Ltd., Atlas Copco AB, Parker Hannifin Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Large Bore Vacuum Insulated Pipe Market Key Technology Landscape

The Large Bore Vacuum Insulated Pipe market is underpinned by a sophisticated array of technologies continuously evolving to enhance thermal performance, durability, and cost-effectiveness. Central to LBVIPs is advanced vacuum technology, which involves achieving and maintaining ultra-high vacuum levels in the annular space between the inner and outer pipes. This requires specialized vacuum pumps, high-integrity seals, and stringent leak detection methods to prevent thermal bridging and ensure long-term vacuum retention. Complementary to vacuum technology is the use of multi-layer insulation (MLI) systems, which consist of multiple reflective radiation shields separated by vacuum, effectively minimizing radiant heat transfer. Continuous innovation in MLI materials and manufacturing techniques aims to improve insulation effectiveness and reduce overall pipe diameter and weight.

Precision welding techniques are paramount in LBVIP manufacturing, ensuring robust structural integrity and leak-proof connections, especially for the inner pipe handling cryogenic fluids. Orbital welding, for instance, offers high consistency and quality, critical for preventing microscopic leaks that could compromise vacuum performance. Material science plays a crucial role, with ongoing research into new alloys and composite materials that exhibit superior cryogenic properties, such as enhanced ductility at ultra-low temperatures, improved strength-to-weight ratios, and better resistance to thermal cycling. Modular design and pre-fabrication techniques are also gaining prominence, allowing for faster on-site installation, reduced labor costs, and improved quality control, particularly for extensive pipeline networks.

Furthermore, the integration of smart technologies, including sensors for real-time temperature, pressure, and vacuum monitoring, is transforming the operational landscape of LBVIPs. These smart systems enable predictive maintenance, early detection of anomalies, and optimized system performance through data analytics. Innovations in non-invasive inspection technologies, such as infrared thermography and acoustic emission testing, further contribute to ensuring the long-term reliability and safety of these critical cryogenic infrastructures. The combination of these advanced technologies ensures that LBVIPs remain at the forefront of efficient and safe cryogenic fluid transfer solutions.

Regional Highlights

- North America: Characterized by significant investments in LNG export terminals, a robust industrial gas sector, and a thriving aerospace industry including commercial space launch programs. The region benefits from strong governmental support for infrastructure development and technological advancements.

- Europe: Driven by ambitious green hydrogen initiatives, extensive industrial gas production, and strong emphasis on energy efficiency and decarbonization targets. Countries like Germany, France, and the UK are leading in R&D and implementation of cryogenic technologies for sustainable energy.

- Asia Pacific (APAC): The largest and fastest-growing market, propelled by rapid industrialization, burgeoning demand for LNG in economies like China, India, Japan, and South Korea, and increasing investments in hydrogen infrastructure. Regional governments are heavily supporting domestic cryogenic capabilities.

- Latin America: Exhibits growth potential from expanding oil and gas projects, nascent industrial gas industries, and increasing exploration for natural resources. Brazil and Argentina are key countries with developing cryogenic infrastructure.

- Middle East and Africa (MEA): Driven by large-scale oil and gas operations, particularly LNG production and export, and a growing interest in hydrogen production projects as part of economic diversification strategies. Countries like Qatar and Saudi Arabia are significant players in this domain.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Large Bore Vacuum Insulated Pipe Market.- Chart Industries

- Cryofab

- CS&P Technologies

- Flowtech

- Cryogenic Industries

- FIBA Technologies

- Technifab

- Air Products and Chemicals Inc.

- Linde plc

- Messer Group GmbH

- Air Liquide S.A.

- Nippon Sanso Holdings Corporation

- Taylor-Wharton

- Vairex GmbH

- Cryogenic Service and Supply Inc.

- Thermal Pipe Systems Inc.

- CRIO Inc.

- Sumitomo Precision Products Co. Ltd.

- Atlas Copco AB

- Parker Hannifin Corporation

Frequently Asked Questions

What are the primary applications of Large Bore Vacuum Insulated Pipes?

Large Bore Vacuum Insulated Pipes are primarily used for the efficient and safe transfer of cryogenic fluids such as Liquid Natural Gas (LNG), liquid oxygen, nitrogen, argon, and liquid hydrogen. Their main applications are found in LNG terminals, industrial gas production and distribution, aerospace for rocket propellants, and in the emerging hydrogen energy infrastructure, ensuring minimal heat ingress and product loss.

How does VIP technology enhance efficiency in cryogenic transfers?

Vacuum Insulated Pipe (VIP) technology enhances efficiency by creating a highly effective thermal barrier. The vacuum in the annulus between the inner and outer pipes, often augmented by multi-layer insulation (MLI), minimizes all three forms of heat transfer: conduction, convection, and radiation. This significantly reduces boil-off and energy loss, maintaining the desired ultra-low temperature of the transferred cryogenic fluid and thereby lowering operational costs.

What are the key advantages of using LBVIPs over traditional insulated piping?

Key advantages of Large Bore Vacuum Insulated Pipes (LBVIPs) include superior thermal insulation performance, which leads to significantly reduced product loss and lower energy consumption. They also enhance safety by preventing external condensation and ice formation, reducing corrosion, and offering greater resistance to external damage compared to conventionally insulated pipes. LBVIPs provide a cleaner, more reliable, and longer-lasting solution for cryogenic applications.

Which industries primarily benefit from Large Bore VIP systems?

Industries that primarily benefit from Large Bore VIP systems include the energy sector (especially LNG and hydrogen production/transport), industrial gas manufacturing and distribution, aerospace and defense, and specialized segments within healthcare (e.g., MRI cooling) and advanced research. Any industry requiring the high-volume, low-loss transfer of cryogenic liquids finds significant value in LBVIP technology.

What are the main challenges in the Large Bore Vacuum Insulated Pipe market?

The main challenges in the Large Bore Vacuum Insulated Pipe market include the high upfront capital expenditure required for specialized materials and complex manufacturing, the need for expert installation and maintenance, and the susceptibility to damage affecting vacuum integrity. Maintaining long-term vacuum performance and managing the specialized supply chain also pose significant hurdles for market players.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager