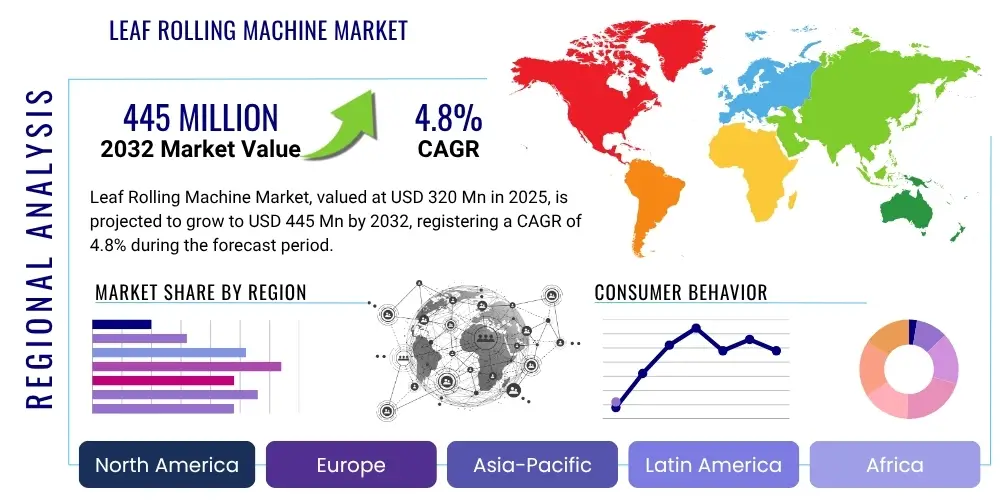

Leaf Rolling Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430051 | Date : Nov, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Leaf Rolling Machine Market Size

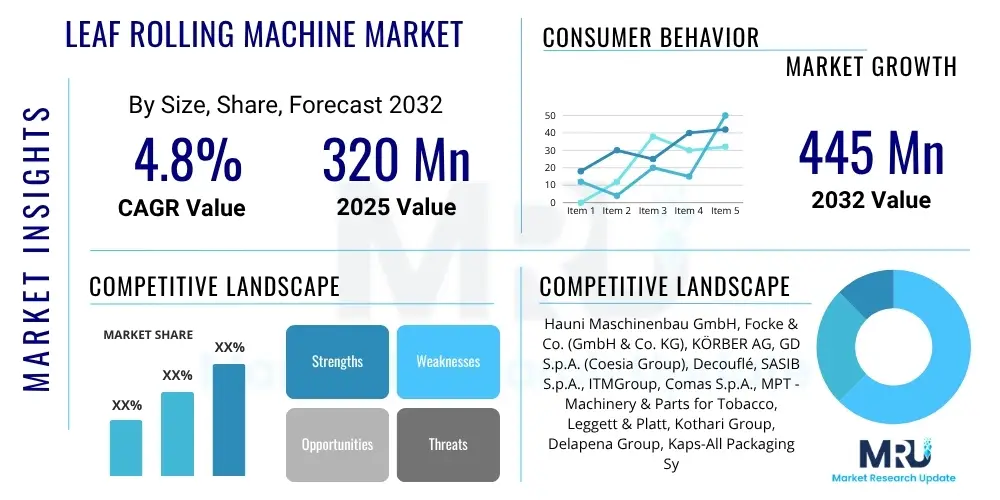

The Leaf Rolling Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2025 and 2032. The market is estimated at $320 Million in 2025 and is projected to reach $445 Million by the end of the forecast period in 2032.

Leaf Rolling Machine Market introduction

The Leaf Rolling Machine Market encompasses a specialized segment within industrial machinery, dedicated to the automated or semi-automated processing of various leaf materials into consumer-ready or intermediate products. These machines are engineered for precision and efficiency, primarily used in the tobacco, cannabis, and herbal industries to create consistently rolled items. The core function involves feeding processed leaf material into a mechanism that uniformly shapes and often encases it within a wrapper, such as paper or another leaf, ensuring product integrity and aesthetic appeal. This market is crucial for manufacturers seeking to optimize production lines, reduce manual labor, and maintain stringent quality control standards across diverse product offerings.

Product descriptions within this market range from compact, table-top semi-automatic units suitable for small-to-medium scale operations to large, fully integrated automatic lines capable of high-volume output for major industrial players. Major applications extend beyond traditional tobacco cigarettes and cigars to include cannabis pre-rolls, herbal blunts, and even certain food processing tasks requiring precise leaf encapsulation. The primary benefits derived from these machines include enhanced production speed, improved product uniformity, significant reduction in labor costs, and a heightened level of quality assurance. Key driving factors propelling market growth include the escalating global demand for convenience-oriented rolled products, increasing regulatory clarity in emerging industries like cannabis, and a continuous industry-wide push towards automation to achieve operational efficiencies and cost savings in manufacturing processes.

Leaf Rolling Machine Market Executive Summary

The Leaf Rolling Machine Market is poised for steady expansion, driven by robust business trends emphasizing automation, precision, and efficiency in production. Businesses are increasingly investing in advanced leaf rolling solutions to meet escalating consumer demand for consistent, high-quality rolled products across the tobacco, cannabis, and herbal sectors. The adoption of smart manufacturing principles and the integration of IoT for real-time monitoring and predictive maintenance are becoming paramount, streamlining operations and reducing downtime. Furthermore, a discernible trend towards modular and customizable machine designs reflects manufacturers' needs for adaptable solutions that can cater to varying product specifications and production scales, ensuring market responsiveness and product diversification capabilities.

Regional trends indicate significant dynamism, with Asia Pacific emerging as a dominant manufacturing hub and a rapidly growing consumer market for rolled products, fueled by population growth and evolving consumption patterns. North America exhibits strong growth, particularly propelled by the expanding legalization and commercialization of cannabis, which has created a burgeoning demand for specialized pre-roll and cigarillo production machinery. Europe, characterized by established tobacco markets and a growing herbal product industry, demonstrates steady adoption of advanced rolling technologies focused on efficiency and compliance with strict quality standards. These regional variations highlight diverse market drivers and investment priorities.

Segmentation trends reveal a clear shift towards automatic leaf rolling machines, which offer superior throughput, consistency, and reduced operational costs compared to their manual and semi-automatic counterparts, especially in large-scale industrial settings. However, semi-automatic machines maintain relevance for niche markets, artisan producers, or facilities with lower volume requirements. Beyond operational type, the market is seeing increased diversification in end-use applications, with significant growth in the cannabis and herbal sectors complementing the traditional tobacco industry. This diversification is fostering innovation in machine design to accommodate a wider variety of leaf consistencies and product formats, underpinning the market's resilient growth trajectory.

AI Impact Analysis on Leaf Rolling Machine Market

User inquiries about AI's impact on the Leaf Rolling Machine Market frequently revolve around how artificial intelligence can enhance operational efficiency, improve product quality, and contribute to cost savings. Users are keen to understand the practical applications of AI in areas such as predictive maintenance, intelligent quality control, and optimized material handling. There is a strong expectation that AI integration will lead to more autonomous machines, reduced human intervention, and the ability to process complex data for real-time decision-making, ultimately improving overall production line performance. Concerns often include the initial investment costs, the complexity of integrating AI into existing infrastructure, and the need for skilled labor to manage advanced AI-driven systems, highlighting a balance between innovation and practical implementation challenges.

- Enhanced predictive maintenance: AI algorithms analyze machine performance data to forecast potential failures, minimizing downtime.

- Superior quality control: Computer vision systems powered by AI identify defects in rolled products with greater accuracy and speed than human inspection.

- Optimized material usage: AI-driven systems can precisely measure and distribute leaf material, reducing waste and ensuring consistent product density.

- Increased automation and autonomy: AI enables machines to adapt to variations in raw material and environmental conditions, performing adjustments autonomously.

- Improved production efficiency: Machine learning models optimize production parameters, leading to higher throughput and reduced energy consumption.

- Data-driven decision making: AI provides actionable insights from production data, allowing manufacturers to refine processes and improve product development.

- Personalized product configurations: AI can assist in rapid prototyping and customization of rolling parameters for diverse product specifications.

DRO & Impact Forces Of Leaf Rolling Machine Market

The Leaf Rolling Machine Market is significantly shaped by a dynamic interplay of drivers, restraints, opportunities, and impact forces that collectively dictate its growth trajectory and evolutionary path. Key drivers include the ever-increasing global demand for consistently manufactured rolled products across the tobacco, cannabis, and herbal industries. The imperative for manufacturers to achieve higher production efficiency, reduce escalating labor costs, and maintain uncompromising product quality and consistency further propels the adoption of advanced leaf rolling machinery. Technological advancements, particularly in automation, precision engineering, and sensor integration, also serve as powerful accelerators, enabling the development of more sophisticated and versatile machines capable of handling diverse materials and complex rolling specifications.

However, the market faces notable restraints that can impede its growth. The substantial initial capital investment required for high-end automatic leaf rolling machines can be a barrier for smaller manufacturers or those in developing economies. Maintenance costs, specialized spare parts, and the need for skilled technicians to operate and service these complex machines also add to the operational expenditure. Furthermore, stringent regulatory environments, especially concerning the processing of tobacco and cannabis products, can impose compliance hurdles and restrict market entry or expansion in certain regions. The relatively niche nature of some applications compared to broader industrial machinery markets can also limit overall market size and investment.

Despite these challenges, significant opportunities abound for the Leaf Rolling Machine Market. Emerging markets, particularly in Asia Pacific and Latin America, present untapped potential due to growing industrialization and increasing consumer bases for rolled products. Diversification into new material processing, such as specialty teas or pharmaceutical applications requiring precise leaf encapsulation, offers avenues for market expansion. The integration of cutting-edge technologies like the Internet of Things (IoT) and Artificial Intelligence (AI) for enhanced monitoring, predictive maintenance, and optimized performance presents lucrative innovation opportunities. Additionally, developing custom solutions tailored to specific client needs or product innovations can provide competitive advantages. These impact forces, ranging from technological innovation and evolving regulatory landscapes to shifting consumer preferences and raw material availability, constantly reshape the competitive dynamics and strategic imperatives within the market, demanding agility and foresight from market participants.

Segmentation Analysis

The Leaf Rolling Machine Market is systematically segmented to provide a granular understanding of its diverse components and underlying dynamics. This segmentation facilitates a comprehensive analysis of market performance across different operational methodologies, end-use industry applications, production capacities, and the specific materials being processed. By categorizing the market in this manner, stakeholders can identify key growth areas, understand competitive landscapes within specific niches, and tailor strategies to address the unique needs and demands of distinct market segments. This approach allows for a more precise evaluation of market size, growth rates, and future potential, guiding investment decisions and product development efforts across the industry.

- By Operation Type:

- Manual

- Semi-Automatic

- Automatic

- By End-Use Industry:

- Tobacco

- Cannabis

- Herbal/Pharmaceutical

- Food & Beverage

- By Capacity:

- Small Scale

- Medium Scale

- Large Scale

- By Material Processed:

- Tobacco Leaf

- Cannabis Flower/Leaf

- Herbal Blends

- Paper

Value Chain Analysis For Leaf Rolling Machine Market

The value chain for the Leaf Rolling Machine Market begins with a comprehensive upstream analysis, focusing on the sourcing and supply of critical raw materials and components essential for machine manufacturing. This involves key suppliers of high-grade metals such as stainless steel and aluminum, crucial for structural integrity and hygiene, as well as specialized electronic components including PLCs, sensors, and motors that enable automation and precision control. Additionally, manufacturers rely on suppliers for pneumatic and hydraulic systems, precision-machined parts, and durable seals and bearings. The quality and reliability of these upstream inputs directly impact the performance, longevity, and overall cost-effectiveness of the final leaf rolling machines, underscoring the importance of robust supplier relationships and supply chain management to mitigate risks and ensure consistent production.

Moving downstream, the value chain encompasses the distribution channels and the ultimate end-users of the leaf rolling machines. After manufacturing, machines are transported to customers through a combination of direct sales and indirect channels. Direct sales typically involve large-scale manufacturers purchasing directly from the machine producer, often with custom specifications and dedicated support services. This approach fosters strong client relationships and allows for tailored solutions. Indirect channels involve a network of wholesalers, distributors, and agents who facilitate market access, particularly for smaller enterprises or in regions where a direct presence is less feasible for the manufacturer. These intermediaries play a crucial role in providing local sales, technical support, and after-sales service, expanding the market reach of the original equipment manufacturers (OEMs).

The distribution channels, whether direct or indirect, are critical for market penetration and customer satisfaction. Direct distribution ensures greater control over sales, service, and brand representation, allowing for more personalized engagement with major clients. Indirect distribution, leveraging the established networks and logistical capabilities of partners, allows manufacturers to efficiently reach a broader customer base, including small to medium-sized businesses and various niche markets. The choice of channel often depends on the target customer, regional market characteristics, and the manufacturer's strategic objectives. Both models require effective coordination and communication to ensure machines are delivered efficiently, installed correctly, and supported adequately throughout their operational lifespan, thereby maximizing customer value and strengthening market presence.

Leaf Rolling Machine Market Potential Customers

The primary potential customers and end-users of leaf rolling machines span a diverse range of industries, all seeking efficient and consistent methods for processing leafy materials into finished or semi-finished products. The tobacco industry represents a foundational customer base, encompassing large-scale cigarette and cigar manufacturers who rely on high-capacity automatic machines for mass production, as well as smaller artisan cigar makers requiring more specialized or semi-automatic equipment. These manufacturers prioritize precision, speed, and the ability to handle various tobacco leaf types and wrapper materials to maintain product consistency and meet stringent quality standards. The enduring demand for traditional tobacco products ensures a continuous need for advanced rolling machinery tailored to their specific production environments.

Beyond traditional tobacco, the rapidly expanding cannabis industry has emerged as a significant growth driver for the leaf rolling machine market. Producers of cannabis pre-rolls, blunts, and infused cigars are increasingly investing in automated solutions to scale their operations, ensure consistent dosing, and comply with evolving regulatory requirements regarding product integrity and labeling. This sector often demands machines capable of handling the unique characteristics of cannabis flower and trim, requiring specialized grinding, dosing, and rolling mechanisms. Similarly, the herbal and pharmaceutical industries constitute another vital segment, utilizing these machines for encapsulating medicinal herbs, producing herbal blends, or creating various botanical preparations in a standardized, controlled manner, where accuracy and purity are paramount. These applications often involve processing delicate or high-value plant materials, necessitating gentle yet efficient rolling techniques.

Furthermore, specialty food processors and even individual consumers represent potential, albeit smaller, segments of this market. In the food industry, leaf rolling machines can be adapted for applications such as creating certain types of filled pastries or confectionery items that involve wrapping ingredients in edible sheets. For individual consumers, particularly those interested in DIY tobacco or herbal product creation, smaller, more accessible manual or semi-automatic machines cater to personal use, emphasizing ease of operation and affordability. The versatility of leaf rolling technology, therefore, allows manufacturers to target a broad spectrum of end-users, each with distinct requirements for capacity, precision, and material handling, reflecting the dynamic adaptability of this market to various industrial and personal needs.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $320 Million |

| Market Forecast in 2032 | $445 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hauni Maschinenbau GmbH, Focke & Co. (GmbH & Co. KG), KÖRBER AG, GD S.p.A. (Coesia Group), Decouflé, SASIB S.p.A., ITMGroup, Comas S.p.A., MPT - Machinery & Parts for Tobacco, Leggett & Platt, Kothari Group, Delapena Group, Kaps-All Packaging Systems, S.M.P. S.r.l., Shenyang Tobacco Machinery Co., Ltd., Kunming Hengsheng Machinery Co., Ltd., Nantong Nanguang Tobacco Machinery Co., Ltd., Beijing Kangda Tobacco Machine Co., Ltd., China Tobacco Machinery Co., Ltd. (CTMC), Hebei Shengfang Tobacco Machinery Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Leaf Rolling Machine Market Key Technology Landscape

The Leaf Rolling Machine Market is continually evolving, driven by significant advancements in its underlying technology landscape, which primarily focuses on enhancing efficiency, precision, and versatility. Automation remains at the forefront, with Programmable Logic Controllers (PLCs) and sophisticated robotic systems increasingly integrated to manage complex rolling processes, material handling, and quality inspection with minimal human intervention. These systems allow for faster production cycles, greater consistency in product output, and reduced operational errors. Precision engineering is critical, ensuring that components are manufactured to extremely tight tolerances, which directly translates into the consistent rolling of delicate leaf materials and accurate product dimensions, vital for market acceptance and regulatory compliance across various industries.

The integration of sensor technology is another pivotal aspect, allowing machines to monitor various parameters in real-time, such as leaf moisture content, material density, and wrapper tension. These sensors feed data back to the control systems, enabling dynamic adjustments to the rolling process, thereby optimizing performance and preventing defects. Furthermore, the advent of the Internet of Things (IoT) has begun to transform the market by enabling interconnected machines that can communicate with each other and with central monitoring systems. This connectivity facilitates remote diagnostics, predictive maintenance, and overall production line optimization, reducing downtime and extending machine lifespan. Human Machine Interface (HMI) systems have also become more intuitive, with touch screens and user-friendly software providing operators with comprehensive control and data visualization, simplifying complex operations and training requirements.

Looking ahead, the application of Artificial Intelligence (AI) and Machine Learning (ML) is poised to further revolutionize the leaf rolling machine market. AI algorithms are being developed for advanced quality control, where computer vision systems can identify subtle imperfections in rolled products that would be imperceptible to the human eye, ensuring only flawless products reach the market. Predictive maintenance, powered by ML models analyzing operational data, can anticipate equipment failures before they occur, scheduling maintenance proactively and dramatically reducing unexpected shutdowns. Moreover, modular machine designs are gaining traction, allowing manufacturers to easily reconfigure or upgrade machines to adapt to new product formats or materials without requiring a complete overhaul. Energy efficiency features are also becoming standard, with optimized motor controls and power management systems contributing to lower operational costs and a reduced environmental footprint, aligning with global sustainability initiatives and providing a significant competitive edge.

Regional Highlights

- North America: This region is a significant market, primarily driven by the expanding legalization and commercialization of cannabis across various states and Canada. The demand for automated pre-roll and blunt machines is robust, with manufacturers focusing on high-speed, high-precision equipment to meet stringent quality and safety standards. Innovation in machine design to accommodate diverse cannabis strains and product formats is also a key characteristic here.

- Europe: Characterized by established tobacco markets and a growing interest in herbal products, Europe demonstrates stable demand for leaf rolling machines. Strict regulatory frameworks for tobacco and emerging regulations for herbal products necessitate sophisticated machinery capable of precise control and consistency. Germany, Italy, and the UK are key markets, with an emphasis on advanced automation and energy efficiency.

- Asia Pacific (APAC): This region is projected to be the fastest-growing market, propelled by large manufacturing bases, increasing disposable incomes, and the widespread consumption of tobacco and traditional herbal products. Countries like China, India, and Indonesia are witnessing significant investment in both domestic production and export-oriented manufacturing facilities. The focus here is on cost-effective, high-volume production solutions.

- Latin America: The market in Latin America is witnessing growth driven by both traditional tobacco consumption and the nascent but expanding cannabis industry in countries like Uruguay and certain parts of Mexico. Manufacturers are seeking efficient and reliable machines to support local production and cater to evolving consumer preferences for rolled products.

- Middle East and Africa (MEA): This region presents emerging opportunities, particularly in traditional tobacco markets and for local herbal product manufacturing. Investment in modernized production facilities is gradually increasing, leading to a rising demand for semi-automatic and automatic leaf rolling machines to improve production capabilities and product quality.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Leaf Rolling Machine Market.- Hauni Maschinenbau GmbH

- Focke & Co. (GmbH & Co. KG)

- KÖRBER AG

- GD S.p.A. (Coesia Group)

- Decouflé

- SASIB S.p.A.

- ITMGroup (Industrial Tobacco Machines)

- Comas S.p.A.

- MPT - Machinery & Parts for Tobacco

- Leggett & Platt

- Kothari Group

- Delapena Group

- Kaps-All Packaging Systems

- S.M.P. S.r.l.

- Shenyang Tobacco Machinery Co., Ltd.

- Kunming Hengsheng Machinery Co., Ltd.

- Nantong Nanguang Tobacco Machinery Co., Ltd.

- Beijing Kangda Tobacco Machine Co., Ltd.

- China Tobacco Machinery Co., Ltd. (CTMC)

- Hebei Shengfang Tobacco Machinery Co., Ltd.

Frequently Asked Questions

What is a leaf rolling machine used for?

Leaf rolling machines are primarily used to efficiently process and shape various leaf materials, such as tobacco, cannabis, and herbs, into consistently rolled products like cigarettes, cigars, pre-rolls, or herbal sticks, ensuring uniformity and quality in mass production.

What are the main types of leaf rolling machines available?

The main types include manual, semi-automatic, and automatic leaf rolling machines. Manual machines require significant human intervention, semi-automatic automate parts of the process, while automatic machines offer high-speed, fully automated production with minimal human oversight.

How does automation impact the leaf rolling machine market?

Automation significantly boosts production efficiency, enhances product consistency, reduces labor costs, and improves overall quality control. It also enables integration with advanced technologies like AI and IoT for predictive maintenance and optimized operations, driving market growth.

Which regions are showing the most growth in the leaf rolling machine market?

The Asia Pacific region is anticipated to show the most significant growth due to large manufacturing bases and increasing consumption. North America also exhibits strong growth, largely driven by the expanding cannabis industry and its demand for specialized rolling equipment.

What are the key technological advancements in leaf rolling machines?

Key advancements include enhanced automation with PLCs and robotics, integrated sensor technology for real-time monitoring, IoT connectivity for remote diagnostics, AI for quality control and predictive maintenance, and modular designs for greater adaptability and energy efficiency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager