Level Sensors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429487 | Date : Nov, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Level Sensors Market Size

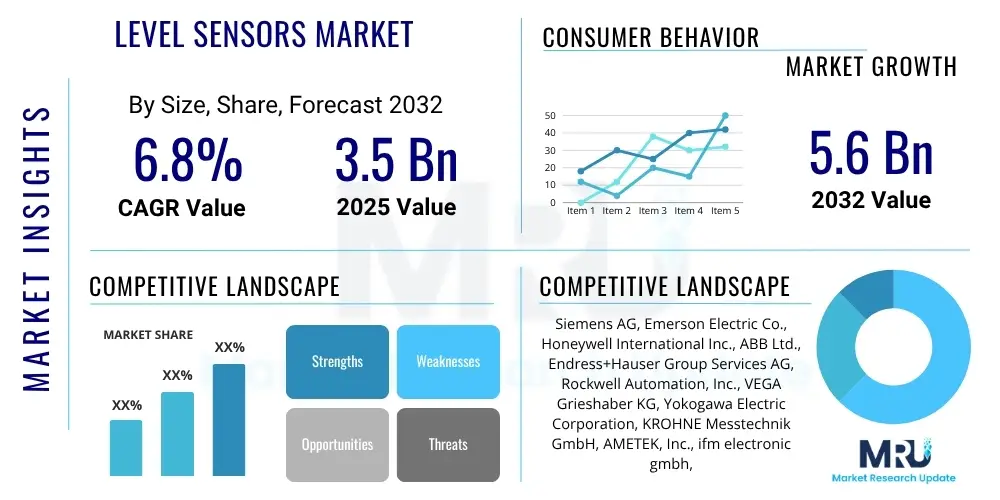

The Level Sensors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 3.5 Billion in 2025 and is projected to reach USD 5.6 Billion by the end of the forecast period in 2032.

Level Sensors Market introduction

Level sensors are critical devices engineered to detect and measure the level of various substances, including liquids, powders, and granular materials, within a container or process. These sensors play an indispensable role across a vast array of industrial and commercial applications, providing real-time data essential for automated process control, efficient inventory management, and robust safety protocols. The fundamental operation involves translating the physical presence or absence of a material at a certain height into an electrical signal, which can then be used for monitoring, alarming, or controlling associated equipment. The market encompasses a diverse portfolio of technologies, such as ultrasonic, radar, capacitive, hydrostatic, and vibratory sensors, each meticulously designed to perform optimally under specific material properties, environmental conditions, and application requirements.

The applications for level sensors are extensive and cross-cutting, deeply embedded in sectors such as industrial automation, where they optimize manufacturing processes; oil and gas, for monitoring storage tanks and pipelines; water and wastewater treatment, to manage reservoir and treatment plant levels; food and beverage, for ingredient and product control; pharmaceuticals, ensuring precise chemical mixing and storage; and various chemical processing industries. The inherent benefits derived from deploying these advanced sensing solutions are profound, including significantly enhanced operational efficiency through automated monitoring, substantial reduction in material waste, improved safety by preventing hazardous overflows or critical dry runs, and optimized utilization of valuable resources. These advantages collectively drive the market's expansion, underscoring the indispensable nature of accurate level measurement.

Driving factors propelling the growth of the Level Sensors Market are multifaceted. A primary catalyst is the accelerating trend towards industrial automation and the widespread adoption of Industry 4.0 paradigms across global manufacturing sectors, necessitating precise and reliable sensing technologies. Furthermore, the increasing demand for remote monitoring and control capabilities, enabled by IoT integration, allows for more efficient and safer management of processes. Stringent regulatory frameworks pertaining to process control, environmental protection, and workplace safety in industries like chemicals and oil and gas also mandate the deployment of sophisticated level sensing solutions, ensuring compliance and mitigating risks. The continuous innovation in sensor technology, leading to more accurate, durable, and cost-effective devices, further fuels market demand by expanding applicability and improving performance.

Level Sensors Market Executive Summary

The global Level Sensors Market is currently experiencing a period of significant expansion, fundamentally influenced by overarching business trends that prioritize digitalization, operational efficiency, and sustainable practices. A key business trend is the increasing integration of smart sensors capable of offering real-time data analytics, predictive maintenance insights, and seamless connectivity within broader Industrial IoT (IIoT) ecosystems. This shift is driving substantial innovation in product development, with manufacturers focusing on developing highly accurate, robust, and intelligent solutions that can adapt to complex industrial environments and provide actionable intelligence. Furthermore, consolidation activities, including mergers and acquisitions, are shaping the competitive landscape, as companies seek to expand their technological portfolios and market reach to meet evolving customer demands for integrated solutions and comprehensive service offerings.

Regional trends reveal a dynamic geographical distribution of market growth and technological adoption. Asia Pacific (APAC) stands out as the most dominant and rapidly expanding market, primarily fueled by extensive industrialization, significant infrastructure development, and burgeoning manufacturing sectors in economies like China, India, and Southeast Asian countries. The region's growth is also propelled by increasing investments in water management and energy projects, alongside a growing focus on environmental compliance. Meanwhile, North America and Europe maintain strong market positions, characterized by high technological penetration, stringent regulatory frameworks that mandate advanced process control, and a strong emphasis on smart factory initiatives. These regions are pioneers in adopting cutting-edge sensor technologies and advanced automation solutions, ensuring continued market maturity and innovation through continuous R&D investment and a focus on high-value applications.

Segmentation trends within the Level Sensors Market indicate clear preferences and growth areas across different product types, technologies, and end-use applications. There is a notable and growing demand for non-contact level sensing technologies, such as radar and ultrasonic, due to their distinct advantages in applications involving corrosive, abrasive, or hygienic materials, where direct physical contact with the media is undesirable. Simultaneously, continuous level measurement solutions are witnessing a steady increase in deployment across a diverse range of industries, driven by the critical need for precise, real-time inventory and process monitoring. The oil and gas, water and wastewater treatment, and chemical sectors remain core consumers, demanding highly reliable and accurate sensors for safety-critical applications, while the food and beverage industry increasingly adopts advanced sensors to meet strict hygiene and quality standards. This granular demand dictates product innovation, market strategy, and specialized solution development across the value chain.

AI Impact Analysis on Level Sensors Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Level Sensors Market frequently center on how AI can fundamentally enhance the accuracy and reliability of sensor readings, and enable more sophisticated functionalities like predictive maintenance and self-calibration. Users are keen to understand the practical implications of integrating AI into existing and new level sensing systems, often raising concerns about the complexity of implementation, the associated initial investment costs, and the cybersecurity risks tied to data transmission and analysis. There is a strong expectation that AI will lead to more autonomous and intelligent level monitoring solutions, capable of adapting to dynamic environmental conditions, providing deeper operational insights, and significantly reducing manual intervention, ultimately contributing to greater efficiency, safety, and cost savings across various industrial applications. The anticipation is for AI to transform raw sensor data into actionable intelligence, moving beyond mere measurement to informed decision-making and proactive system management.

- AI significantly enhances data analytics capabilities, enabling sophisticated predictive maintenance models for level sensors by anticipating failures before they occur and minimizing unscheduled downtime.

- Optimizes sensor performance through adaptive algorithms that learn from historical data and real-time inputs, making automatic adjustments for improved accuracy, stability, and responsiveness to dynamic process conditions.

- Facilitates seamless integration with broader Industrial Internet of Things (IIoT) platforms, enabling comprehensive, centralized process monitoring and control across entire facilities for holistic operational views.

- Empowers intelligent decision-making at the edge, allowing level sensing systems to react autonomously to critical changes, thereby reducing human intervention and minimizing errors in complex operational scenarios.

- Improves diagnostic capabilities by rapidly identifying anomalous sensor readings or patterns indicative of potential malfunctions, streamlining troubleshooting efforts and accelerating resolution times.

- Enables automated calibration and self-correction mechanisms, ensuring the sustained accuracy and reliability of level measurements over extended operational periods without requiring manual intervention.

- Contributes to energy efficiency by optimizing pump and valve operations based on intelligent level predictions, leading to reduced power consumption and lower operational costs in fluid management systems.

- Enhances safety protocols by providing early warnings for potential overflow or dry-run conditions through AI-driven anomaly detection and predictive alerts, safeguarding personnel and assets.

DRO & Impact Forces Of Level Sensors Market

The Level Sensors Market is significantly influenced by a dynamic interplay of drivers, restraints, opportunities, and broader impact forces that shape its growth trajectory and competitive landscape. A primary driver is the accelerating global trend towards industrial automation and the widespread adoption of smart manufacturing principles (Industry 4.0), which inherently demand precise and reliable level measurement for optimizing production processes, managing inventory, and ensuring quality control. Concurrently, the imperative for improved operational safety across hazardous industries such as oil and gas, chemicals, and pharmaceuticals, where accurate level monitoring prevents spills, overflows, and other critical incidents, further propels market expansion. The sustained growth of core process industries, coupled with stringent environmental and safety regulations, underscores the fundamental need for advanced level sensing solutions.

However, the market also faces notable restraints that can impede its growth. The relatively high initial installation costs associated with advanced, high-precision level sensor systems, particularly for radar and ultrasonic technologies, can be a barrier for small and medium-sized enterprises (SMEs) or budget-constrained projects. Furthermore, the inherent technical complexities involved in selecting the appropriate sensor technology for diverse applications, integrating various sensor types into existing control systems, and ensuring proper calibration and maintenance can pose significant challenges for end-users, often requiring specialized expertise. The susceptibility of certain sensor types to harsh environmental conditions, such as extreme temperatures, corrosive media, foam, or turbulence, can also limit their applicability and necessitate specialized, often more expensive, robust solutions, adding to the overall cost and complexity of deployment.

Despite these restraints, substantial opportunities exist for market growth and innovation. The burgeoning adoption of smart sensors with integrated Internet of Things (IoT) connectivity and wireless communication capabilities presents a significant avenue for expansion, enabling remote monitoring, predictive analytics, and seamless data integration into enterprise resource planning (ERP) systems. There is also a continuous opportunity for the development and adoption of advanced non-contact technologies that offer superior performance in challenging applications, alongside advancements in sensor miniaturization and power efficiency for niche markets. Emerging economies undergoing rapid industrialization and infrastructure development, particularly in Asia Pacific and Latin America, represent untapped markets with growing demand for modern level sensing solutions, driven by foreign direct investment and government support for industrial modernization. Furthermore, the increasing focus on sustainability and resource efficiency creates demand for sensors that can optimize material usage, reduce waste, and improve environmental compliance.

The market is also shaped by several overarching impact forces. Technological advancements represent a powerful force, continuously pushing the boundaries of sensor capabilities in terms of accuracy, reliability, durability, and intelligence. Innovations in material science, signal processing, and communication protocols lead to more robust, versatile, and intelligent sensors. Regulatory pressures from governmental bodies and industry standards organizations are another significant force, mandating higher safety and environmental standards, which in turn drives the adoption of more sophisticated and compliant level sensing equipment across various sectors. Lastly, global economic shifts, including industrial output fluctuations, investment trends in key end-use sectors, and supply chain dynamics, inevitably influence the overall demand and pricing structures within the Level Sensors Market, creating both challenges and opportunities for market participants to adapt and innovate in response to changing global conditions.

Segmentation Analysis

The Level Sensors Market is systematically segmented across various critical dimensions, providing a granular and comprehensive view of its intricate structure and underlying dynamics. This segmentation is crucial for understanding specific market niches, identifying dominant technological preferences, and discerning the varied demands stemming from distinct end-use industries. By categorizing the market based on sensor type, underlying technology, measurement methodology, and application sector, stakeholders gain invaluable insights into where growth is most pronounced, which technologies are gaining traction, and how different customer needs are being addressed. This detailed breakdown enables manufacturers to strategically align their product portfolios, investors to pinpoint high-potential segments, and policymakers to understand the technological landscape more effectively, fostering targeted innovation and market development strategies that cater to specific industrial requirements and operational challenges.

- By Type:

- Capacitive Level Sensors

- Ultrasonic Level Sensors

- Radar Level Sensors

- Vibrating Fork Level Sensors

- Conductive Level Sensors

- Hydrostatic Level Sensors

- Magnetic Level Sensors

- Optical Level Sensors

- Laser Level Sensors

- Float Level Sensors

- Differential Pressure Level Sensors

- Thermal Dispersion Level Sensors

- Displacer Level Sensors

- Radiometric Level Sensors

- Others (e.g., Load Cell based, Microwave)

- By Technology:

- Contact Level Sensors (e.g., Capacitive, Conductive, Vibrating Fork, Hydrostatic, Float, Magnetic, Displacer, Differential Pressure, Thermal Dispersion)

- Non-Contact Level Sensors (e.g., Ultrasonic, Radar, Laser, Optical, Radiometric, Microwave)

- By Measurement Type:

- Continuous Level Measurement (provides exact level at all times, e.g., Radar, Ultrasonic, Hydrostatic, Magnetic Float, Capacitive, Differential Pressure, Laser)

- Point Level Measurement (detects level at a specific point, e.g., Vibrating Fork, Conductive, Capacitive, Optical, Float Switches, Thermal Dispersion, Displacer)

- By End-Use Industry:

- Oil and Gas (Upstream, Midstream, Downstream operations for crude oil, refined products, natural gas, LNG storage, wellhead monitoring)

- Water and Wastewater Treatment (Reservoir monitoring, tank levels, treatment processes, pumping stations, irrigation systems, flood control)

- Chemicals (Bulk chemical storage, reaction vessels, blending tanks, hazardous materials, petrochemical production, fertilizer manufacturing)

- Food and Beverage (Ingredient storage, processing tanks, packaging lines, hygienic applications, dairy, brewing, soft drinks, confectionery)

- Pharmaceuticals (Precise dosing, sterile processing, critical inventory management, clean-in-place systems, bioreactors, blood banks)

- Power Generation (Boiler level control, fuel storage, cooling systems in thermal, nuclear, hydro, and renewable energy plants, ash disposal)

- Industrial Automation (General manufacturing processes, machinery integration, fluid management in factories, pulp and paper, textiles)

- Pulp and Paper (Slurry and liquid stock management, chemical recovery, effluent treatment, pulp digestion)

- Mining (Slurry and tailing ponds, ore processing, chemical solutions, froth flotation, material handling)

- Marine and Shipbuilding (Ballast tanks, fuel tanks, cargo levels, wastewater systems on commercial vessels, naval ships, offshore platforms)

- Agriculture (Silo monitoring for grains, irrigation water levels, fertilizer tanks, liquid feed systems, greenhouse climate control)

- HVAC and Refrigeration (Refrigerant levels, condensate control, chilled water loops, cooling towers)

- Building and Construction (Concrete mixing, aggregate storage, water management in construction sites, stormwater retention)

- Others (e.g., Medical Devices, Logistics, Research & Development, Aerospace, Environmental Monitoring)

Value Chain Analysis For Level Sensors Market

The value chain for the Level Sensors Market is a complex and interconnected network of activities, commencing from the foundational raw material procurement and extending all the way to the final consumption by end-users, with each stage contributing incremental value and demanding specialized expertise. The upstream segment of this chain is characterized by the meticulous sourcing of specialized components and raw materials from a global supply network. This includes procuring highly precise transducers for ultrasonic sensors, advanced radar emitters and receivers, high-grade metals and alloys for robust mechanical components, sophisticated microcontrollers and integrated circuits for signal processing, and various electronic components and engineered polymers. The quality, availability, and cost of these foundational elements directly impact the performance, durability, and cost-effectiveness of the final sensor product. Key relationships here are often long-term strategic partnerships between sensor manufacturers and component suppliers, crucial for ensuring consistent supply, technological innovation, and compliance with stringent quality standards.

Moving downstream, the value chain progresses through the intricate stages of manufacturing, assembly, rigorous testing, and calibration of the level sensors, ensuring they meet precise operational specifications and industry standards. This stage involves advanced manufacturing techniques, lean production processes, and stringent quality control protocols to produce reliable and accurate sensing units. Post-manufacturing, the products enter diverse distribution channels designed to reach a global customer base. These channels typically include direct sales forces engaging with large industrial clients or original equipment manufacturers (OEMs) who integrate sensors into their own systems, a comprehensive network of authorized distributors who handle sales to smaller enterprises and offer localized support, and specialized system integrators who incorporate level sensors into broader automation solutions. The efficiency and reach of these distribution networks are paramount for market penetration and customer satisfaction, often supported by extensive logistics and inventory management systems to ensure timely delivery.

The effectiveness of these distribution channels is further enhanced by robust after-sales support, which is a critical component of the value chain. This support encompasses services such as initial installation, expert technical assistance, on-site commissioning, periodic calibration, and comprehensive maintenance programs. For complex industrial applications, direct sales allow for a deeper understanding of customer-specific requirements and facilitate custom solutions, while indirect channels provide wider geographical coverage, local expertise, and often better accessibility for a broader customer base, including crucial maintenance, repair, and overhaul (MRO) operations. The increasing prominence of e-commerce platforms is also creating new direct and indirect avenues for market reach, particularly for standardized or less complex sensor types, streamlining the procurement process for certain customer segments. This complete value chain structure ensures that level sensing solutions are not only effectively developed and delivered but also competently supported throughout their entire operational lifecycle, maximizing their value for diverse industrial applications.

Level Sensors Market Potential Customers

The Level Sensors Market caters to a remarkably broad and diverse spectrum of potential customers, essentially encompassing any industrial or commercial entity that requires precise and reliable measurement of material levels for operational optimization, safety compliance, or inventory management. These end-users are predominantly found in sectors where large volumes of fluids, granular materials, or powders are routinely processed, stored, transported, or utilized as part of their core operations. The criticality of accurate level data spans from preventing costly product waste and ensuring consistent product quality to mitigating hazardous situations like spills or equipment damage from dry runs. Therefore, the demand for level sensing solutions is driven by both economic efficiency and safety imperatives across myriad applications, making the customer base highly varied and expansive, constantly seeking solutions tailored to their specific process challenges.

Key industrial sectors form the bedrock of the customer base. The oil and gas industry represents a significant segment, with extensive needs for monitoring crude oil, refined products, natural gas, and wastewater in exploration, production, refining, and transportation stages, including offshore platforms and onshore facilities. Similarly, the water and wastewater treatment sector heavily relies on level sensors for managing reservoir levels, monitoring tanks in treatment plants, overseeing various pumping stations, and ensuring efficient water distribution to protect public health and the environment. Chemical manufacturing plants are substantial consumers, requiring precise level control for a wide array of often hazardous chemicals in storage tanks, reaction vessels, and blending processes, where accuracy is paramount for safety, product integrity, and regulatory adherence. The food and beverage industry utilizes these sensors for hygienic measurement of ingredients, processing liquids, and finished products, adhering to strict quality, sanitation, and compliance standards.

Beyond these major segments, the pharmaceutical and biotechnology industries are increasingly adopting advanced level sensors for critical applications involving sterile processing, precise dosing of active pharmaceutical ingredients, and managing highly sensitive or valuable substances under strict environmental controls. Power generation facilities, including thermal, nuclear, and hydroelectric plants, employ level sensors for boiler water levels, fuel storage, and cooling system management, where reliability is non-negotiable for safety and continuous operation. Industrial automation encompasses a vast number of general manufacturing and assembly processes where automated fluid and material handling requires consistent level monitoring to maintain production efficiency. Other important customer segments include mining and metallurgy for slurry and chemical processing, pulp and paper mills for stock management, marine and shipbuilding for ballast and fuel tanks, and agriculture for silo and irrigation management. This extensive range of applications underscores the universal utility and widespread demand for reliable level sensing technology, driving continuous innovation to meet evolving customer needs.

- Oil and Gas companies (Upstream, Midstream, Downstream operations, storage terminals, refineries, pipelines, offshore platforms)

- Water and Wastewater Treatment facilities (Municipal waterworks, industrial wastewater plants, desalination plants, irrigation systems, flood control)

- Chemical Manufacturing plants (Petrochemicals, specialty chemicals, basic chemicals, paints and coatings, agricultural chemicals)

- Food and Beverage processing companies (Dairies, breweries, soft drink manufacturers, confectioneries, bakeries, food packaging)

- Pharmaceutical and Biotechnology firms (API manufacturing, drug formulation, vaccine production, R&D labs, sterile processing)

- Power Generation plants (Thermal power, nuclear power, hydroelectric, renewable energy facilities for fuel and fluid management, ash disposal)

- Industrial Automation and Discrete Manufacturing (Automotive, electronics, machinery manufacturing for process control, textiles, general assembly)

- Pulp and Paper mills (Stock preparation, chemical recovery, effluent treatment, pulp digestion, bleaching processes)

- Mining and Metallurgy operations (Ore processing, acid leaching, tailing ponds, mineral separation, material handling, smelting)

- Marine and Shipbuilding industry (Commercial vessels, naval ships for fuel, ballast, and cargo tank monitoring, offshore drilling rigs)

- Agriculture sector (Grain silos, fertilizer tanks, irrigation water levels, liquid feed systems, greenhouse climate control)

- HVAC and Refrigeration industries (Refrigerant level monitoring, condensate management, chilled water loops, cooling towers)

- Building and Construction (Concrete mixing, aggregate storage, water management in construction sites, stormwater retention, civil infrastructure)

- Original Equipment Manufacturers (OEMs) integrating sensors into their machinery (Pumps, compressors, processing equipment, industrial mixers)

- Logistics and Storage companies (Tank farms, bulk material handling facilities, chemical storage depots)

- Environmental Monitoring Agencies (Pollution control, flood warning systems, landfill leachate monitoring)

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 3.5 Billion |

| Market Forecast in 2032 | USD 5.6 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, Emerson Electric Co., Honeywell International Inc., ABB Ltd., Endress+Hauser Group Services AG, Rockwell Automation, Inc., VEGA Grieshaber KG, Yokogawa Electric Corporation, KROHNE Messtechnik GmbH, AMETEK, Inc., ifm electronic gmbh, Pepperl+Fuchs SE, Schneider Electric SE, sick AG, Dwyer Instruments, Inc., Baumer Group, Gems Sensors & Controls, GWR Instruments, Inc., NIVELCO Process Control Co., OMEGA Engineering Inc., TE Connectivity Ltd., General Electric Company, Delta Controls, Fuji Electric Co., Ltd., WIKA Alexander Wiegand SE & Co. KG. |

| Regions Covered | North America (U.S., Canada, Mexico), Europe (Germany, UK, France, Italy, Spain, Rest of Europe), Asia Pacific (China, India, Japan, South Korea, Australia, Southeast Asia, Rest of APAC), Latin America (Brazil, Argentina, Rest of Latin America), Middle East, and Africa (MEA) (GCC Countries, South Africa, Rest of MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Level Sensors Market Key Technology Landscape

The Level Sensors Market is characterized by a rapidly evolving and highly diversified technology landscape, driven by continuous innovation aimed at enhancing accuracy, reliability, versatility, and cost-effectiveness across an expanding range of industrial applications. Among the prominent technologies, ultrasonic sensors stand out for their non-contact measurement capabilities, employing high-frequency sound waves to determine levels, making them ideal for liquids and some solids where physical contact is undesirable due to corrosiveness, viscosity, or hygiene requirements. Radar sensors, operating on electromagnetic waves, offer superior precision, robustness against process variations like temperature, pressure, and vacuum, and are highly effective in challenging environments, including those with foam, vapor, or agitation, making them suitable for critical applications in oil and gas and chemicals. Capacitive sensors detect level changes based on alterations in capacitance, providing versatile point or continuous measurement for a wide array of materials, from conductive to non-conductive, and are often favored for compact installations and viscous media.

Further enriching this landscape are hydrostatic level sensors, which measure the pressure exerted by a liquid column to infer its level, widely used in deep tanks, reservoirs, and open channels due to their simplicity and reliability. Vibrating fork sensors provide robust and reliable point level detection for powders, granules, and liquids, indicating high or low levels by detecting changes in their vibration frequency when immersed in the material. Magnetic level sensors, including magnetic float switches and magnetic level indicators (MLI), offer highly visible, reliable, and continuous measurement, particularly well-suited for high-pressure, high-temperature, and hazardous environments due to their sealed construction. Optical sensors, utilizing light reflection or refraction principles, are increasingly employed for precise liquid level detection, especially in small vessels, clear liquids, and for interface detection in laboratory and pharmaceutical settings. Laser level sensors provide extremely accurate, non-contact measurement for both solids and liquids over long distances, offering narrow beam characteristics that are advantageous for applications with obstructions.

The contemporary technological trajectory for level sensors is also heavily influenced by the integration of advanced digital capabilities. The rise of the Industrial Internet of Things (IIoT) and Industry 4.0 paradigms has led to the development of smart sensors equipped with enhanced processing power, embedded diagnostics, and communication protocols such as WirelessHART, LoRaWAN, and Ethernet/IP. These smart sensors facilitate remote monitoring, enable predictive maintenance through advanced data analytics, and offer seamless integration into distributed control systems (DCS) and supervisory control and data acquisition (SCADA) systems. Moreover, ongoing research and development efforts are focused on miniaturization, reducing power consumption for battery-operated wireless solutions, and developing multi-parameter sensors that can simultaneously measure level alongside temperature, pressure, or density. Innovations in material science are also crucial, leading to the creation of sensors from more durable and corrosion-resistant materials, thereby extending their lifespan and expanding their applicability in increasingly harsh and demanding industrial processes, while contributing to overall operational efficiency and safety through advanced intelligent features and enhanced data accessibility.

Regional Highlights

- North America: This region represents a mature and technologically advanced market for level sensors, characterized by early adoption of sophisticated automation technologies and stringent regulatory frameworks, particularly in the oil and gas, chemical processing, and water and wastewater treatment sectors. The presence of numerous key market players, robust R&D infrastructure, and significant investments in industrial infrastructure modernization further bolster market growth. Emphasis on safety, efficiency, and sustainability drives the demand for high-precision and smart level sensing solutions, with strong uptake in the United States and Canada.

- Europe: Europe is a significant market driven by strong manufacturing bases, particularly in Germany, the UK, and France, along with a proactive approach towards environmental protection and energy efficiency. The region demonstrates high adoption rates of Industry 4.0 initiatives and smart factory concepts, necessitating advanced and integrated level sensing technologies. Stringent EU regulations pertaining to industrial emissions, process safety, and quality control create consistent demand for compliant and reliable sensing solutions across pharmaceuticals, food and beverage, and chemical industries, with a focus on sustainable and efficient operations.

- Asia Pacific (APAC): The Asia Pacific region is unequivocally the fastest-growing market for level sensors globally, propelled by rapid industrialization, extensive urbanization, and substantial infrastructure development across economies such as China, India, Japan, and Southeast Asian nations. Governments and private entities are investing heavily in manufacturing expansion, water management projects, and energy infrastructure, driving robust demand. The increasing focus on process automation, coupled with a growing middle class leading to expanded food and beverage production, further fuels this market's impressive growth trajectory, alongside rising environmental awareness.

- Latin America: This region exhibits steady growth in the Level Sensors Market, primarily attributed to significant investments in its vast oil and gas reserves, particularly in Brazil and Mexico, alongside expanding mining operations and ongoing efforts to upgrade water and wastewater treatment facilities. Economic recovery in several countries and government initiatives aimed at modernizing industrial infrastructure contribute to the rising demand for efficient and reliable level sensing solutions. The industrial automation sector is also slowly but consistently expanding, opening new opportunities for sensor adoption in various manufacturing segments.

- Middle East and Africa (MEA): The MEA market is largely driven by large-scale capital investments in the region's prominent oil and gas exploration, production, and refining sectors, where precise and robust level sensors are indispensable for operational safety and efficiency. Additionally, substantial water infrastructure projects, including desalination plants and water distribution networks, due to water scarcity, significantly contribute to the demand. The need for sensors capable of operating reliably in harsh environmental conditions (high temperatures, sand, corrosive media) is a defining characteristic of this market, alongside growing investments in power generation and petrochemicals.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Level Sensors Market, recognizing their critical role in driving innovation, shaping competitive dynamics, and meeting diverse industry demands. These companies are at the forefront of technological advancement, offering a wide array of level sensing solutions that cater to various applications and process requirements globally. Their strategic initiatives, including extensive research and development, geographical expansion, and strategic partnerships, contribute significantly to the evolution and growth of the market by enhancing product portfolios and improving market reach.- Siemens AG

- Emerson Electric Co.

- Honeywell International Inc.

- ABB Ltd.

- Endress+Hauser Group Services AG

- Rockwell Automation, Inc.

- VEGA Grieshaber KG

- Yokogawa Electric Corporation

- KROHNE Messtechnik GmbH

- AMETEK, Inc.

- ifm electronic gmbh

- Pepperl+Fuchs SE

- Schneider Electric SE

- sick AG

- Dwyer Instruments, Inc.

- Baumer Group

- Gems Sensors & Controls

- GWR Instruments, Inc.

- NIVELCO Process Control Co.

- OMEGA Engineering Inc.

- TE Connectivity Ltd.

- General Electric Company

- Delta Controls

- Fuji Electric Co., Ltd.

- WIKA Alexander Wiegand SE & Co. KG

- BinMaster

- Mobrey (part of Emerson)

- Flowline Inc.

- Badger Meter, Inc.

- Hycontrol Ltd.

Frequently Asked Questions

Common user questions about the Level Sensors market are typically focused on practical aspects of implementation, selection criteria, technological comparisons, and the benefits of modern advancements. Users frequently inquire about the optimal sensor type for specific applications, how to ensure measurement accuracy and long-term reliability in challenging environments, and the implications of integrating level sensors with broader industrial control systems and IoT platforms. These questions reflect a consistent need for clear, actionable insights to navigate the complexities of deploying and optimizing level sensing solutions across various industrial contexts, highlighting concerns around cost-effectiveness, maintenance, and future-proofing investments to achieve optimal operational efficiency and safety.

What are the primary types of level sensors available and their typical applications?

The primary types of level sensors include ultrasonic, radar, capacitive, hydrostatic, vibratory fork, magnetic, optical, and laser sensors, among others. Ultrasonic and radar sensors are non-contact and ideal for liquids and solids in challenging environments, such as chemicals, oil and gas, and food and beverage processing, where physical contact is undesirable. Capacitive sensors are versatile for both conductive and non-conductive materials, often used for point or continuous measurement. Hydrostatic sensors measure liquid levels based on pressure, commonly in tanks and reservoirs. Vibratory forks are robust point level switches for powders and granules. Magnetic sensors offer reliable continuous measurement in harsh conditions, while optical and laser sensors provide precise detection, especially for clear liquids or specific distances, and in laboratory settings.

How does a continuous level sensor differ from a point level sensor, and when is each preferred?

A continuous level sensor provides real-time, ongoing measurement of the exact level of a substance within a vessel or tank, offering precise data for advanced process control, inventory management, and trend analysis. Examples include radar, ultrasonic, hydrostatic, and magnetic float sensors, which are preferred when accurate, dynamic level information is crucial. Conversely, a point level sensor only indicates whether the substance has reached or passed a specific predetermined high or low threshold, triggering an alarm or initiating a process (e.g., stopping a pump). Point sensors, such as vibratory forks, conductive probes, or float switches, are typically chosen for simple overflow prevention, dry-run protection, or basic ON/OFF control applications where discrete level indication is sufficient.

Which key factors should be critically considered when selecting a level sensor for a specific industrial application?

Selecting the appropriate level sensor requires careful consideration of several critical factors to ensure optimal performance and reliability. These include the physical and chemical properties of the material being measured (e.g., liquid, solid, corrosive, viscous, abrasive, dielectric constant, temperature, pressure, density, foam, vapor), the geometry and size of the tank or vessel, the required accuracy, repeatability, and response time of the measurement, the presence of environmental interferences (e.g., dust, turbulence, agitation), available budget, and the desired output signal or integration capabilities (e.g., analog, digital, wireless, Modbus, Ethernet). Additionally, safety certifications (e.g., ATEX, IECEx for hazardous areas) and ease of installation, calibration, and long-term maintenance are crucial considerations for operational efficiency and compliance.

Can modern level sensors be seamlessly integrated with Industrial IoT (IIoT) and Industry 4.0 systems, and what are the benefits?

Yes, modern level sensors are increasingly designed for seamless and robust integration with Industrial IoT (IIoT) and Industry 4.0 ecosystems. They often feature embedded intelligence, advanced processing capabilities, and support various digital and wireless communication protocols (e.g., WirelessHART, LoRaWAN, OPC UA, Modbus TCP/IP, Profinet), enabling real-time data transmission to cloud platforms, edge devices, or SCADA/DCS systems. The benefits of such integration are substantial: enabling remote monitoring and control from any location, facilitating predictive maintenance through advanced data analytics and machine learning algorithms, optimizing process efficiency by providing actionable insights, improving operational safety through proactive alerts, and significantly reducing manual inspections and associated operational costs, ultimately leading to enhanced productivity and agility in industrial operations.

What are the primary advantages of utilizing non-contact level sensing technologies over contact-based methods?

Non-contact level sensing technologies, such as ultrasonic, radar, and laser sensors, offer several distinct advantages over traditional contact-based methods. Foremost among these is the elimination of direct physical contact with the process media, which significantly reduces the risk of sensor corrosion, abrasion, build-up, or contamination, thereby extending sensor lifespan and minimizing maintenance requirements. This characteristic makes them exceptionally suitable for highly corrosive, viscous, abrasive, or hygienic applications (e.g., food and beverage, pharmaceuticals) where process integrity is paramount. Additionally, non-contact sensors often provide more reliable measurements in applications with high temperatures, pressures, or turbulent conditions, and are generally easier to install and maintain without interrupting the process, leading to enhanced operational uptime, reduced downtime costs, and improved overall safety by isolating the sensor from hazardous materials.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Hydrostatic Liquid Level Sensors Market Statistics 2025 Analysis By Application (Water Management, Industrial, Household), By Type (Ultrasonic Liquid Level Sensor, Pressure Liquid Level Sensor, Radar Liquid Level Sensor, Capacitance Liquid Level Sensor, Other), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Optical Liquid Level Sensors Market Statistics 2025 Analysis By Application (Chemical & Petrochemical, Food and Beverage Systems, Pharmaceutical Systems, Automotive & Transportation), By Type (Digital Optical Liquid Level Sensors, Analog Optical Liquid Level Sensors), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Float Level Sensors Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Magnetic Float Level Sensors, Mechanical Float Level Sensors, Others), By Application (Petroleum Industry, Chemical Industry, Food Industry, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager