Liquid and Paste Filling Machines Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427801 | Date : Oct, 2025 | Pages : 239 | Region : Global | Publisher : MRU

Liquid and Paste Filling Machines Market Size

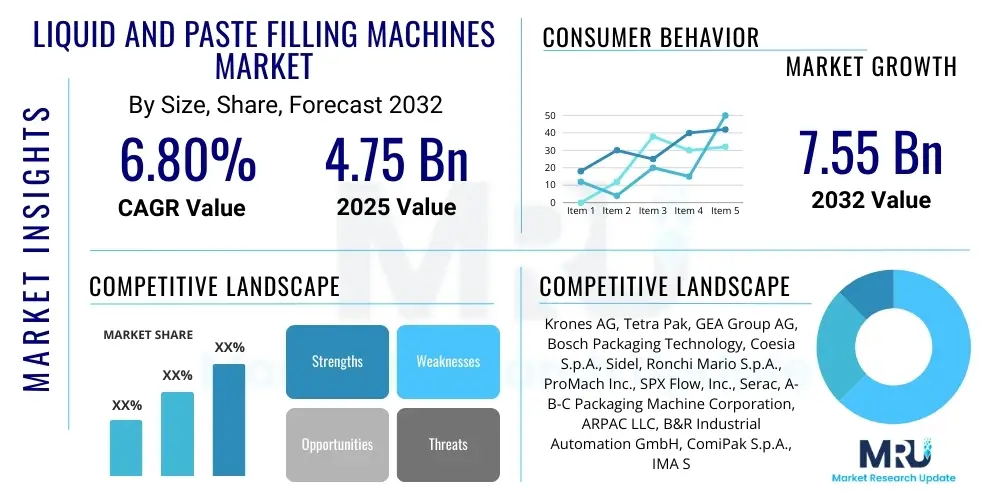

The Liquid and Paste Filling Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 4.75 billion in 2025 and is projected to reach USD 7.55 billion by the end of the forecast period in 2032.

Liquid and Paste Filling Machines Market introduction

The Liquid and Paste Filling Machines Market encompasses a diverse range of automated and semi-automated equipment designed for precise and efficient dispensing of viscous and non-viscous products into various containers. These machines are crucial in numerous industries for ensuring product integrity, consistent fill levels, and high production throughput. They handle a wide spectrum of materials, from thin liquids like water, juices, and pharmaceuticals to thick pastes such as creams, sauces, and chemical compounds, accommodating different container types including bottles, jars, tubes, pouches, and cans.

The primary benefit of these machines lies in their ability to significantly enhance operational efficiency, reduce labor costs, and minimize product waste, while simultaneously improving packaging quality and consumer safety. The demand for these advanced filling solutions is predominantly driven by the expanding global packaged goods industry, stringent regulatory requirements for hygiene and accuracy, and the continuous push towards automation in manufacturing processes. Key applications span across food and beverage, pharmaceuticals, cosmetics, chemicals, and automotive sectors, where precise filling is not only a matter of efficiency but also crucial for product efficacy and compliance.

Innovations in sensor technology, control systems, and material handling further bolster their adoption, offering manufacturers greater flexibility, faster changeovers, and enhanced diagnostic capabilities. The markets growth trajectory is strongly linked to consumer demand for convenience foods, personal care products, and over-the-counter medications, all of which require sophisticated filling technologies to meet market demands and maintain competitive edge.

Liquid and Paste Filling Machines Market Executive Summary

The Liquid and Paste Filling Machines Market is experiencing robust growth, primarily fueled by the accelerating demand for packaged goods across diverse end-use industries and the continuous drive for automation to optimize production efficiencies and adhere to strict quality standards. Business trends indicate a strong inclination towards fully automated systems that integrate advanced robotics and intelligent controls, offering manufacturers greater precision, reduced operational costs, and higher throughput. Companies are increasingly investing in flexible machinery capable of handling multiple product types and container sizes, addressing the dynamic nature of consumer preferences and the proliferation of product variations. This shift is also influenced by the need for rapid product launches and shorter production cycles, necessitating adaptable and scalable filling solutions.

Regionally, Asia Pacific stands out as the fastest-growing market, propelled by rapid industrialization, increasing disposable incomes, and the burgeoning food and beverage and pharmaceutical sectors in countries like China, India, and Southeast Asian nations. North America and Europe maintain significant market shares, driven by technological advancements, high regulatory standards, and a mature manufacturing infrastructure, focusing on advanced features like IoT integration and predictive maintenance. Emerging markets in Latin America and the Middle East & Africa are also showing promising growth, as local manufacturers seek to upgrade their production capabilities to meet growing domestic and export demands, adopting more sophisticated and efficient filling technologies.

Segmentation trends highlight the dominance of automatic filling machines due to their high capacity and minimal human intervention, particularly in large-scale production environments. Volumetric and piston fillers are gaining traction for their precision with a wide range of viscosities, while aseptic filling machines are critical for pharmaceutical and dairy applications, ensuring product sterility. The food and beverage industry remains the largest end-use segment, with significant growth also observed in pharmaceuticals and cosmetics, where product integrity and precise dosing are paramount. The market is also witnessing a rise in demand for sustainable packaging solutions, influencing the design and material handling capabilities of modern filling machines.

AI Impact Analysis on Liquid and Paste Filling Machines Market

User inquiries regarding AIs impact on the Liquid and Paste Filling Machines Market frequently revolve around how artificial intelligence can enhance operational efficiency, precision, and predictive maintenance, alongside concerns about implementation costs and job displacement. Common questions address the potential for AI to optimize fill accuracy, minimize downtime through intelligent diagnostics, and streamline complex changeover processes. Users are keenly interested in understanding how AI can contribute to real-time quality control, detect anomalies, and adapt machine parameters autonomously for various product viscosities and container types. The overarching themes include the desire for smarter, more autonomous filling lines that can self-optimize and provide deeper insights into production data, ultimately leading to significant improvements in yield, consistency, and overall equipment effectiveness.

- AI-driven predictive maintenance extends machine lifespan by analyzing sensor data to forecast potential failures, reducing unscheduled downtime and maintenance costs.

- Enhanced fill accuracy and consistency through real-time adjustment of filling parameters based on AI analysis of product characteristics and environmental factors.

- Automated quality control and defect detection systems utilize computer vision and machine learning to identify irregularities in filling, sealing, and packaging with superior precision.

- Optimized production scheduling and resource allocation by leveraging AI algorithms to analyze demand forecasts, raw material availability, and machine performance data.

- Faster and more efficient product changeovers and recipe management, as AI systems learn and automate the necessary adjustments for different product types and container formats.

- Improved energy efficiency through AI-powered optimization of machine operations, minimizing power consumption during idle times or low-demand periods.

- Enhanced operator safety and training through AI-powered virtual simulations and augmented reality overlays for complex machine operations and troubleshooting.

DRO & Impact Forces Of Liquid and Paste Filling Machines Market

The Liquid and Paste Filling Machines Market is profoundly shaped by a confluence of drivers, restraints, and opportunities, alongside significant impact forces. Key drivers include the ever-growing demand for packaged goods fueled by urbanization, rising disposable incomes, and changing consumer lifestyles across developing economies. The stringent regulatory environment, particularly in pharmaceutical and food and beverage sectors, mandates high levels of hygiene, accuracy, and compliance, thereby driving the adoption of advanced, automated filling solutions. Furthermore, the persistent need for operational efficiency, cost reduction, and waste minimization in manufacturing processes propels industries to invest in sophisticated filling machinery that offers higher throughput and precision.

However, the market also faces notable restraints. The high initial capital investment required for advanced, fully automated filling machines can be a significant barrier for small and medium-sized enterprises (SMEs), particularly those in emerging markets with limited access to financing. Technical complexities associated with integrating these machines into existing production lines, the need for specialized training for operation and maintenance, and the ongoing challenge of customizing solutions for a vast array of product viscosities and container types can also impede market growth. Furthermore, maintenance costs and the availability of skilled labor to manage these intricate systems pose additional challenges for widespread adoption.

Opportunities for growth are abundant, particularly in the expansion into emerging markets, where industrialization and consumer demand for packaged products are rapidly escalating. The rising adoption of sustainable and eco-friendly packaging materials presents new avenues for innovation in filling machine design, requiring adaptability to novel container types and materials. The ongoing trend towards smart factories and Industry 4.0 also opens doors for integrating advanced technologies like IoT, AI, and robotics into filling lines, enhancing connectivity, data analysis, and predictive capabilities. Impact forces such as technological advancements, shifting consumer preferences towards convenience and customization, and evolving global trade policies significantly influence market dynamics, pushing manufacturers to innovate constantly and adapt to new production paradigms.

Segmentation Analysis

The Liquid and Paste Filling Machines Market is comprehensively segmented to provide a detailed understanding of its diverse components and growth dynamics. These segmentations categorize the market based on key attributes such as machine type, product type, end-use industry, and capacity, allowing for granular analysis of market trends, consumer preferences, and technological advancements across various applications. This detailed breakdown aids stakeholders in identifying high-growth areas, understanding competitive landscapes, and tailoring strategies to specific market niches. Each segment plays a crucial role in shaping the overall market trajectory, reflecting varying demands for automation, precision, and speed across different industrial requirements.

- By Machine Type:

- Automatic Filling Machines

- Semi-Automatic Filling Machines

- Manual Filling Machines

- By Product Type:

- Liquid Filling Machines (e.g., water, beverages, oils, chemicals)

- Paste Filling Machines (e.g., creams, sauces, gels, ointments)

- Powder Filling Machines (though less relevant to this specific report, often part of broader filling machine portfolios)

- Viscous Liquid Filling Machines

- By End-Use Industry:

- Food and Beverage Industry

- Pharmaceutical Industry

- Cosmetics and Personal Care Industry

- Chemical Industry

- Others (e.g., Automotive, Paints & Coatings)

- By Technology/Filling Principle:

- Volumetric Filling Machines (e.g., Piston Fillers, Time-Pressure Fillers)

- Gravity Filling Machines

- Pressure Filling Machines

- Vacuum Filling Machines

- Net Weight Filling Machines

- Aseptic Filling Machines

- By Capacity:

- Low Capacity

- Medium Capacity

- High Capacity

Liquid and Paste Filling Machines Market Value Chain Analysis

The value chain for the Liquid and Paste Filling Machines Market is a complex ecosystem involving several stages, beginning with upstream raw material and component suppliers, extending through manufacturing and assembly, and culminating in downstream distribution and end-user deployment. Upstream activities involve the procurement of specialized materials such as high-grade stainless steel for sanitary applications, precision electronic components for control systems, sensors, robotics, and other mechanical parts from various suppliers. These components are critical for ensuring the durability, accuracy, and operational efficiency of the filling machines, necessitating strong relationships with reliable and quality-focused vendors who can meet stringent industry standards.

Further along the chain, manufacturers integrate these components into complete filling machine systems, involving design, engineering, software development, assembly, and rigorous testing phases. This stage requires significant investment in research and development to incorporate new technologies like advanced automation, IoT capabilities, and AI-driven features. Once manufactured, these machines move through distribution channels, which can be direct or indirect. Direct channels involve manufacturers selling directly to large industrial clients, often accompanied by comprehensive installation, training, and after-sales support services. This approach allows for closer client relationships and tailored solutions, particularly for complex and custom systems.

Indirect distribution channels involve a network of independent distributors, agents, and system integrators who market and sell the filling machines to a broader customer base, including small and medium-sized enterprises. These partners often provide localized support and can bundle filling machines with other packaging line equipment. The downstream segment of the value chain focuses on the end-users—manufacturers in industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals—who purchase, install, and operate these machines in their production lines. After-sales support, including maintenance, spare parts supply, and upgrades, constitutes a critical part of the value chain, ensuring long-term operational efficiency and customer satisfaction.

Liquid and Paste Filling Machines Market Potential Customers

The Liquid and Paste Filling Machines Market serves a broad and diverse range of potential customers, primarily encompassing manufacturing and production facilities across various industries that require efficient and precise dispensing of their products. The primary end-users are those involved in the packaging of consumer goods, industrial chemicals, and healthcare products, where consistency, hygiene, and speed are paramount. These customers range from multinational corporations with large-scale, highly automated production lines to smaller, specialized businesses that require flexible and adaptable filling solutions for niche products. The demand is intrinsically linked to the consumption patterns of packaged products globally, making virtually any industry that fills liquids or pastes a potential client.

Specifically, the food and beverage industry represents a significant customer base, including dairies, beverage manufacturers, confectionery companies, sauce and condiment producers, and snack food processors. These entities require machines capable of handling a wide array of products, from thin juices and milk to viscous yogurts, ketchups, and jams, into diverse packaging formats like bottles, pouches, and cartons. The pharmaceutical and biotechnology sectors are also critical customers, demanding highly accurate, sterile, and compliant filling solutions for injectable drugs, oral suspensions, creams, and ointments, where product integrity and precise dosage are non-negotiable and governed by stringent regulatory standards like FDA and EMEA.

Furthermore, the cosmetics and personal care industry forms another substantial segment of potential customers, requiring machines for filling lotions, shampoos, perfumes, and makeup into aesthetically pleasing containers. Chemical and industrial manufacturers, including those producing paints, lubricants, adhesives, and detergents, also represent a significant demand source for robust filling machines capable of handling hazardous or corrosive substances safely and efficiently. The continuous expansion of these industries, coupled with the global push for automation and improved product quality, ensures a sustained and growing pool of potential customers for liquid and paste filling machine manufacturers.

Liquid and Paste Filling Machines Market Key Technology Landscape

The technological landscape of the Liquid and Paste Filling Machines Market is characterized by continuous innovation aimed at enhancing precision, speed, flexibility, and connectivity in packaging operations. Modern filling machines increasingly integrate advanced automation and control systems, moving beyond basic mechanical operations to sophisticated electronically controlled processes. Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) are standard, offering intuitive control, recipe management, and real-time monitoring of filling parameters. This allows for quick changeovers between different products and container sizes, significantly boosting operational efficiency and reducing downtime, which is crucial in high-volume production environments.

The incorporation of advanced sensor technologies, such as ultrasonic, laser, and vision sensors, plays a pivotal role in ensuring highly accurate fill levels and detecting potential defects in containers or products. These sensors enable real-time feedback loops, allowing machines to make instantaneous adjustments for optimal performance and minimal waste. Robotics and collaborative robots (cobots) are also becoming more prevalent, especially for tasks requiring high precision, repetitive motion, or handling delicate products, thus improving safety, accuracy, and overall throughput. Furthermore, the advent of hygienic and aseptic filling technologies, utilizing advanced sterilization methods like steam, hydrogen peroxide, or UV light, is critical for industries such as pharmaceuticals and dairy, where product sterility is paramount and regulatory compliance is stringent.

The most transformative advancements are rooted in Industry 4.0 principles, including the Internet of Things (IoT) and Artificial Intelligence (AI). IoT integration enables machines to connect, collect, and exchange data seamlessly across the production line, providing valuable insights into performance, energy consumption, and maintenance needs. AI and machine learning algorithms are then utilized to analyze this data, facilitating predictive maintenance, optimizing filling parameters for various viscosities, and enhancing quality control through anomaly detection. These smart technologies are driving the evolution towards fully autonomous filling lines, capable of self-optimization, remote diagnostics, and intelligent decision-making, offering manufacturers unprecedented levels of efficiency, reliability, and cost savings in their packaging operations.

Regional Highlights

- North America: This region holds a significant market share, driven by a well-established industrial infrastructure, high adoption rates of automation, and stringent regulatory standards in the food, pharmaceutical, and personal care industries. The presence of major key players and a strong focus on advanced technologies like IoT and AI further propels market growth, with a constant demand for high-capacity and flexible filling solutions.

- Europe: Europe is another dominant region, characterized by advanced manufacturing capabilities, a strong emphasis on sustainability, and robust regulatory frameworks, particularly in Germany, Italy, and France. The region is a hub for innovation in packaging machinery, with a high demand for aseptic filling, precision engineering, and energy-efficient solutions to meet evolving consumer and environmental standards.

- Asia Pacific: This region is projected to be the fastest-growing market, primarily due to rapid industrialization, increasing disposable incomes, and the booming food and beverage, pharmaceutical, and cosmetics industries in countries such as China, India, and Japan. The expansion of manufacturing bases and the rising adoption of automated packaging solutions to cater to large consumer bases are key growth drivers.

- Latin America: The market in Latin America is witnessing steady growth, fueled by economic development, increasing foreign investments in manufacturing, and rising consumer demand for packaged goods. Countries like Brazil and Mexico are leading the adoption of modern filling machines to enhance production efficiency and meet local and international market standards.

- Middle East & Africa (MEA): The MEA region is experiencing emerging growth, driven by diversification efforts away from oil economies, investments in food processing, pharmaceuticals, and infrastructure development. The increasing need for sophisticated packaging solutions to improve local production capabilities and reduce reliance on imports is fostering market expansion in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Liquid and Paste Filling Machines Market.- Krones AG

- Tetra Pak (Tetra Laval Group)

- GEA Group AG

- Bosch Packaging Technology (Syntegon Technology GmbH)

- Coesia S.p.A.

- Sidel (Tetra Laval Group)

- Ronchi Mario S.p.A.

- ProMach Inc.

- SPX Flow, Inc.

- Serac

- A-B-C Packaging Machine Corporation

- ARPAC LLC

- B&R Industrial Automation GmbH

- ComiPak S.p.A.

- IMA S.p.A.

- Mg2 s.r.l.

- Accutek Packaging Equipment Companies, Inc.

- O.M.A.R. S.r.l.

- Shibuya Corporation

- Universal Filling Machine Company

Frequently Asked Questions

What is the projected growth rate for the Liquid and Paste Filling Machines Market?

The Liquid and Paste Filling Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032, reaching an estimated USD 7.55 billion by 2032 from USD 4.75 billion in 2025.

How is AI transforming the Liquid and Paste Filling Machines Market?

AI is transforming the market by enabling predictive maintenance, enhancing fill accuracy through real-time adjustments, improving quality control with automated defect detection, optimizing production scheduling, and streamlining changeovers, leading to more autonomous and efficient filling lines.

Which industries are the primary end-users of liquid and paste filling machines?

The primary end-users are the food and beverage, pharmaceutical, cosmetics and personal care, and chemical industries, all of which require precise and efficient packaging of their liquid and paste products to meet high quality and regulatory standards.

What are the main types of liquid and paste filling machines available?

The main types include automatic, semi-automatic, and manual machines, categorized by their level of automation. They also vary by filling principle, such as volumetric, gravity, pressure, vacuum, and aseptic filling technologies, each suited for different product viscosities and applications.

What are the key drivers for the growth of this market?

Key drivers include the increasing global demand for packaged goods, stringent regulatory requirements for product safety and quality, the continuous push for automation to improve operational efficiency and reduce labor costs, and technological advancements enhancing machine precision and flexibility.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager