Liquid-Tight Flexible Non-Metallic Conduit Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428244 | Date : Oct, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Liquid-Tight Flexible Non-Metallic Conduit Market Size

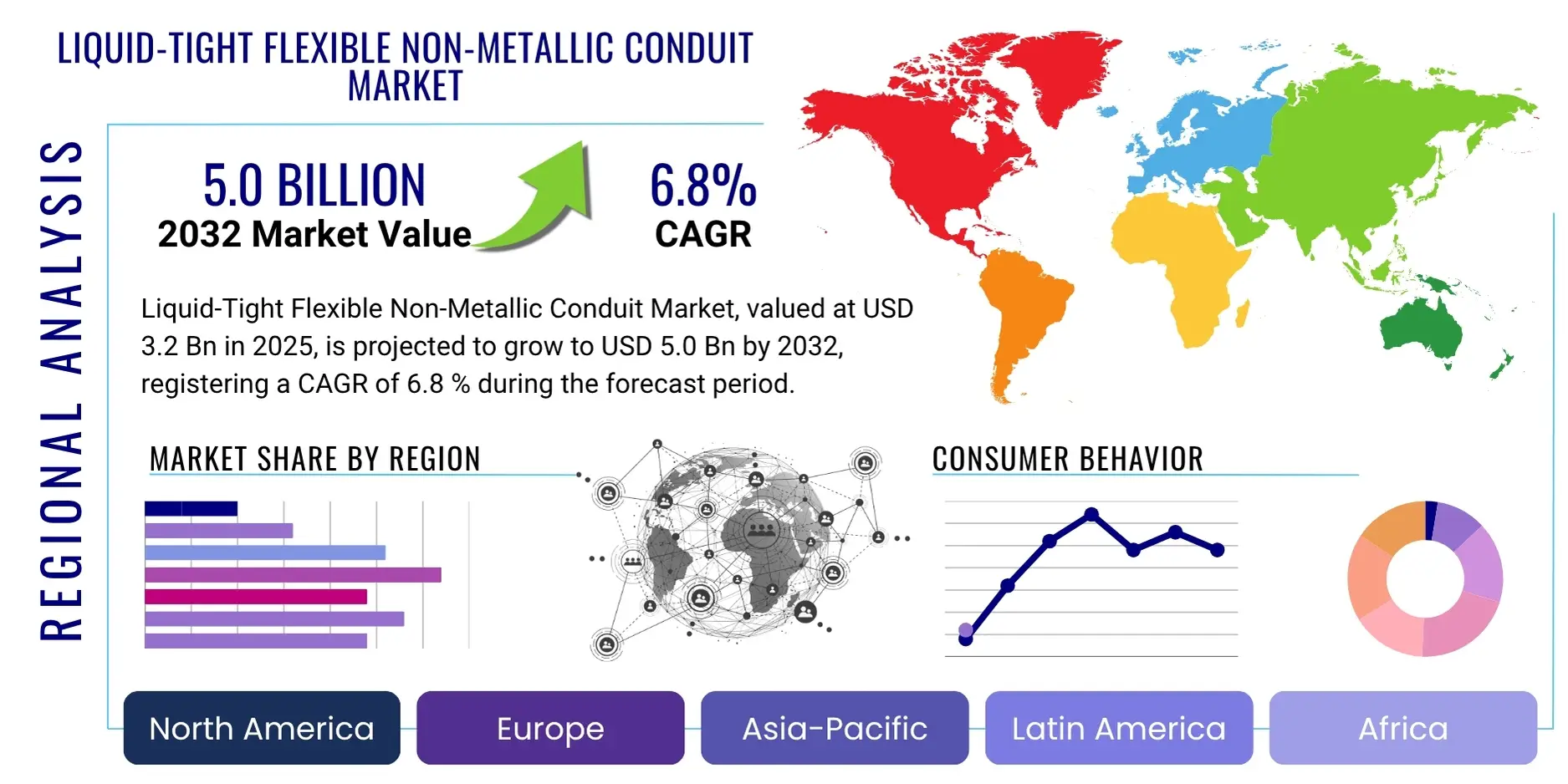

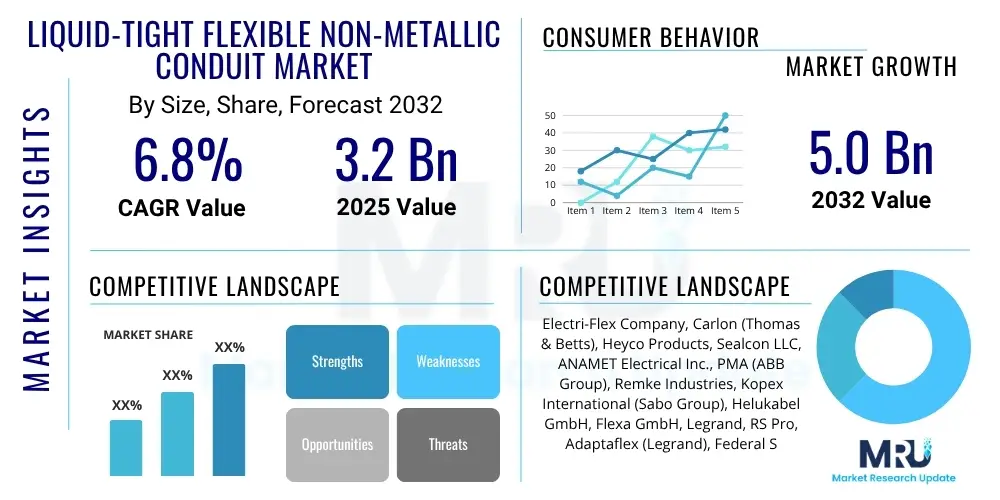

The Liquid-Tight Flexible Non-Metallic Conduit Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 3.2 Billion in 2025 and is projected to reach USD 5.0 Billion by the end of the forecast period in 2032.

Liquid-Tight Flexible Non-Metallic Conduit Market introduction

The Liquid-Tight Flexible Non-Metallic Conduit (LTFNMC) market encompasses a specialized segment within the broader electrical conduit industry, focusing on protective raceways meticulously engineered to shield electrical conductors from the ingress of liquids, oils, greases, and various corrosive chemicals. These conduits are fabricated from robust, non-metallic polymeric materials such as Polyvinyl Chloride (PVC), polypropylene, nylon, and High-Density Polyethylene (HDPE), chosen for their inherent resistance to degradation in challenging environments. The core design principle behind LTFNMC is to offer a sealed, flexible pathway that ensures the integrity and longevity of electrical wiring in conditions where traditional metallic conduits would be susceptible to corrosion, rust, or chemical attack. Their application is critical in maintaining operational safety and preventing costly electrical failures in demanding settings.

Major applications for LTFNMC are remarkably diverse, spanning sectors such as industrial automation, machine tools, HVAC systems, food and beverage processing facilities, marine and shipbuilding, and outdoor electrical installations including renewable energy projects and telecommunication infrastructure. In industrial settings, they protect critical wiring from machine coolants, lubricants, and washdown procedures. For outdoor use, their weather-resistant properties shield cables from rain, snow, and UV radiation, ensuring uninterrupted power supply and signal transmission. The versatility and protective capabilities of LTFNMC make it an indispensable component in modern electrical installations that prioritize reliability and safety under adverse conditions.

The primary benefits of LTFNMC are multifaceted, contributing significantly to its growing market adoption. These conduits are inherently lightweight, which simplifies handling and installation, reducing labor costs and logistical complexities. Their exceptional flexibility allows for easy routing around obstacles and tight bends without requiring specialized tools or fittings, accelerating project completion times. Furthermore, LTFNMC provides superior corrosion resistance, eliminating concerns about rust or galvanic corrosion often associated with metallic alternatives. It also offers excellent electrical insulation, enhancing safety by minimizing the risk of electrical shock. Key driving factors propelling market growth include the escalating global demand for infrastructure development, increasing industrial automation across manufacturing sectors, and the worldwide implementation of more stringent electrical safety regulations. Additionally, the expansion of renewable energy projects and smart city initiatives further fuels the need for resilient and adaptable electrical containment solutions like LTFNMC, which can withstand diverse environmental stressors and contribute to long-term system reliability.

Liquid-Tight Flexible Non-Metallic Conduit Market Executive Summary

The Liquid-Tight Flexible Non-Metallic Conduit (LTFNMC) market is experiencing dynamic growth, propelled by the increasing global emphasis on electrical safety, industrial efficiency, and robust infrastructure. Business trends within the market indicate a significant shift towards product innovation, with manufacturers investing in advanced polymer formulations that offer enhanced performance characteristics, such as improved flame retardancy, superior UV stability, and resistance to an even broader spectrum of chemicals. There is a discernible focus on sustainability, with a rising demand for conduits made from recycled content or bio-based polymers, aligning with global environmental objectives and corporate social responsibility initiatives. Additionally, the integration of smart manufacturing processes and automation in conduit production is optimizing efficiency and reducing costs, contributing to a competitive market landscape and driving forward technological advancements.

Regionally, the Asia Pacific market is demonstrating unparalleled growth, primarily driven by rapid urbanization, massive government investments in infrastructure, and the expansion of manufacturing capabilities, particularly in emerging economies like China, India, and Southeast Asian countries. North America and Europe, while being mature markets, are witnessing steady demand fueled by the modernization of existing electrical grids, replacement of aging infrastructure, and a growing emphasis on industrial automation and renewable energy projects. These regions are characterized by stringent regulatory environments that favor the adoption of high-quality, compliant LTFNMC solutions. Meanwhile, Latin America and the Middle East & Africa are emerging as high-potential markets due to ongoing industrialization, construction booms, and diversified economic strategies necessitating robust electrical infrastructure.

Segment trends within the LTFNMC market highlight distinct growth patterns. The material segment is seeing increased adoption of advanced PVC and nylon formulations that offer enhanced durability and specialized resistance properties for specific applications. In terms of diameter, there is a growing demand for larger conduits in heavy industrial and utility projects, while smaller diameters remain crucial for machine tools and commercial building wiring. Application-wise, industrial machinery and renewable energy sectors are exhibiting strong growth, driven by the need for reliable protection in harsh operating conditions. The end-user segment indicates sustained demand from the construction industry, along with escalating requirements from the manufacturing, oil & gas, and telecommunications sectors, each seeking customized conduit solutions that meet their unique operational and environmental challenges, fostering innovation across the value chain.

AI Impact Analysis on Liquid-Tight Flexible Non-Metallic Conduit Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Liquid-Tight Flexible Non-Metallic Conduit (LTFNMC) market frequently center on how AI can fundamentally transform the manufacturing lifecycle, from optimizing material selection and production processes to enhancing the product's performance and integration within intelligent systems. Queries often include whether AI can facilitate the development of novel, high-performance polymer compounds, reduce waste in extrusion processes, or enable more predictive maintenance schedules for electrical installations utilizing these conduits. Users are keenly interested in the potential for AI to drive cost efficiencies, improve quality control, and contribute to the overall sustainability of conduit production, as well as how AI might enable LTFNMC to play a more integral role in smart building automation and industrial Internet of Things (IIoT) frameworks.

The key themes emerging from this user analysis encompass the strategic application of AI across the LTFNMC value chain. There is significant expectation that AI will streamline complex manufacturing operations through predictive maintenance of machinery, optimization of extrusion parameters, and real-time quality assurance, thereby minimizing defects and maximizing throughput. Furthermore, AI's analytical capabilities are anticipated to revolutionize supply chain management, improving demand forecasting, inventory optimization, and raw material procurement, which is crucial given the volatility of polymer prices. From a product perspective, AI is expected to accelerate material innovation by simulating new compound properties and testing performance under various environmental stressors, leading to the development of next-generation conduits with enhanced thermal stability, chemical resistance, and flexibility.

Beyond manufacturing and supply chain, AI's influence extends to the functional deployment of LTFNMC. In smart buildings and industrial facilities, AI-powered building management systems (BMS) can optimize wiring layouts, predict potential stress points on conduits, and even monitor the environmental conditions within which conduits operate, ensuring proactive maintenance and system longevity. This integration enables a more intelligent and responsive electrical infrastructure. The insights derived from AI can also inform product design, tailoring conduits with specific features for emerging applications such as electric vehicle charging stations or advanced data centers, where specialized protection and routing are paramount. Ultimately, AI is poised to enhance the efficiency, reliability, and innovative capacity of the LTFNMC market, driving both operational excellence and strategic product development to meet future demands.

- AI-driven optimization of manufacturing processes, leading to reduced waste, increased production efficiency, and lower operational costs.

- Predictive analytics for precise demand forecasting, optimized inventory management, and building resilient, responsive supply chains.

- Enhanced material science research and development through AI for synthesizing superior conduit polymer formulations with advanced properties.

- Integration of LTFNMC design data into AI-powered smart building and industrial automation systems for optimized wiring routes and intelligent infrastructure management.

- AI-enabled real-time quality control systems, employing machine vision to ensure product consistency, detect subtle defects, and improve overall reliability.

- Facilitating the development of specialized conduit solutions for emerging AI-driven applications like robotics, autonomous systems, and advanced sensor networks.

- Utilizing AI for predictive maintenance in electrical systems protected by LTFNMC, enhancing system uptime and operational safety.

DRO & Impact Forces Of Liquid-Tight Flexible Non-Metallic Conduit Market

The Liquid-Tight Flexible Non-Metallic Conduit (LTFNMC) market is fundamentally propelled by a confluence of robust drivers. Foremost among these is the accelerating pace of global infrastructure development, encompassing extensive construction of residential, commercial, and industrial facilities, alongside upgrades to public utility networks. This pervasive growth necessitates resilient electrical containment solutions capable of enduring diverse environments. Simultaneously, rapid industrial expansion and increasing automation across manufacturing sectors globally demand protective conduits that can reliably safeguard sensitive wiring from the ingress of oils, coolants, and particulate matter found in machine tool operations and production lines. The lightweight nature, exceptional flexibility, and inherent corrosion resistance of LTFNMC make it an optimal choice for these dynamic and often harsh settings, contributing significantly to its sustained market demand.

Further bolstering market expansion are the increasingly stringent electrical safety regulations and building codes implemented worldwide. These mandates prioritize the protection of electrical systems from environmental hazards and mechanical damage, often specifying the use of liquid-tight and flexible conduits in wet, oily, or corrosive locations to prevent electrical failures and enhance operational safety. The intrinsic insulating properties of non-metallic conduits also contribute to their appeal by reducing the risk of electrical shock. Moreover, the global shift towards renewable energy sources, such as solar and wind power, creates substantial demand for LTFNMC in outdoor installations, where conduits must withstand harsh weather conditions, UV exposure, and wide temperature fluctuations while ensuring the integrity of power transmission lines. This continuous expansion of applications into critical and environmentally challenging areas underpins the market's positive trajectory.

However, the market also contends with specific restraints that can impede its growth. The most significant challenge is the inherent volatility in the prices of raw materials, primarily polymers like PVC, polypropylene, and nylon, which are derivatives of petrochemicals. Fluctuations in crude oil prices directly impact manufacturing costs, potentially leading to price instability for end-products and affecting profit margins for conduit manufacturers. The presence of alternative conduit materials, including various metallic conduits (e.g., rigid metallic conduit, intermediate metallic conduit) and other non-metallic options (e.g., electrical metallic tubing, rigid non-metallic conduit), also presents a competitive restraint. While LTFNMC offers distinct advantages in specific environments, these alternatives may be preferred in less demanding applications or where cost considerations are paramount. Furthermore, economic slowdowns in key industrial or construction sectors, along with disruptions in global supply chains due to geopolitical events or natural disasters, can temporarily dampen market demand and hinder production, creating operational challenges for market players.

Despite these challenges, substantial opportunities exist within the LTFNMC market. The burgeoning investments in smart city initiatives and advanced data center infrastructure present niche but high-value applications requiring specialized, high-performance conduits with features such as enhanced fire resistance and superior electromagnetic interference (EMI) shielding. The ongoing research and development into advanced polymer compounds offer avenues for product innovation, enabling the creation of conduits with improved resistance to extreme temperatures, specific chemicals, and enhanced durability, thereby expanding their applicability. The increasing focus on sustainability and green building practices also creates opportunities for manufacturers to develop and market conduits made from recycled or bio-based materials, aligning with evolving environmental standards and consumer preferences. Furthermore, underserved markets in developing regions, coupled with the modernization of existing industrial plants, represent significant untapped potential for market penetration and expansion.

The market is also shaped by several critical impact forces. Technological advancements are continually influencing product evolution, with ongoing innovations in polymer science leading to the development of lighter, stronger, and more resistant conduit materials. Manufacturing process improvements, such as advanced extrusion techniques, are enhancing production efficiency and product quality. Regulatory changes, including updates to electrical codes (e.g., NFPA 70, IEC standards) or new environmental directives, can significantly alter product specifications and market demand, compelling manufacturers to adapt quickly. Environmental concerns, particularly regarding plastic waste and carbon footprint, are driving the industry towards more sustainable manufacturing practices and the development of eco-friendly conduit solutions. Moreover, geopolitical factors and global trade policies can impact the availability and cost of raw materials, as well as influence market access and competitive dynamics, requiring strategic agility from market participants to navigate a complex global landscape.

Segmentation Analysis

The Liquid-Tight Flexible Non-Metallic Conduit (LTFNMC) market is meticulously segmented to provide a granular understanding of its diverse components, allowing for precise market sizing, trend analysis, and strategic targeting. This detailed segmentation is crucial for identifying distinct customer needs, understanding competitive dynamics within specific niches, and forecasting growth trajectories across different product categories and end-use sectors. By breaking down the market into manageable units based on material type, diameter, application, and end-user industry, stakeholders can gain profound insights into market demand drivers, technological advancements, and regional consumption patterns, facilitating informed business decisions and product development strategies tailored to specific market requirements.

The segmentation by material type is critical as it dictates the conduit's primary performance characteristics, including chemical resistance, temperature rating, flexibility, and cost-effectiveness. PVC conduits are widely utilized for their balance of affordability, good chemical resistance, and ease of processing. Polypropylene and nylon variants offer superior temperature performance, enhanced chemical inertness, and higher mechanical strength, making them suitable for more demanding industrial applications. HDPE conduits are valued for their robustness and environmental resistance, particularly in outdoor and underground installations. Each material possesses unique attributes that cater to specific environmental stressors and operational requirements, with continuous research aiming to blend these properties for multi-functional solutions, thereby expanding their market reach into specialized applications.

Diameter-based segmentation is essential for understanding the capacity and application scope of LTFNMC, ranging from small diameters (e.g., 1/2 inch to 1 inch) used primarily for machine tools, control wiring, and compact electrical enclosures, to medium diameters (e.g., 1.25 inches to 2 inches) prevalent in commercial buildings and light industrial settings, and large diameters (e.g., 2.5 inches and above) critical for heavy industrial power distribution and utility infrastructure. The application segmentation delineates the specific uses of LTFNMC across various industries, highlighting areas of high demand such as industrial machinery for protecting power and control cables, HVAC systems for condensation and moisture resistance, and outdoor lighting or renewable energy installations for weatherproofing. Specialized applications like marine environments, food and beverage processing, and automotive industries further emphasize the need for conduits with tailored properties that meet rigorous industry standards for liquid-tightness and durability.

Finally, the end-user industry segmentation categorizes demand based on the ultimate consumers of LTFNMC, providing insights into sector-specific purchasing behaviors and growth drivers. The construction sector, including residential, commercial, and infrastructure projects, remains a foundational end-user. The manufacturing industry, particularly in automation-heavy segments, drives demand for protective solutions for complex machinery. The oil & gas and chemical processing industries rely on LTFNMC for its corrosion resistance in volatile environments, while transportation (e.g., rail, aerospace) requires robust yet flexible solutions for onboard wiring. Emerging sectors such as data centers, which require specialized conduits for sensitive network cabling and cooling systems, and healthcare facilities, where sterile and reliable electrical systems are paramount, represent significant growth opportunities, underscoring the market's adaptability and expanding utility across a broad spectrum of economic activities.

- By Material

- PVC (Polyvinyl Chloride): Widely used for its balance of cost, chemical resistance, and flexibility.

- Polypropylene (PP): Offers higher temperature resistance and improved chemical inertness.

- Nylon (Polyamide): Known for superior mechanical strength, abrasion resistance, and higher temperature ratings.

- HDPE (High-Density Polyethylene): Excellent for outdoor, underground, and demanding environmental applications due to robustness.

- Other Polymers (e.g., TPE, EVA): Specialized blends offering unique properties like extreme flexibility or specific chemical resistance.

- By Diameter

- 1/2 inch to 1 inch: Commonly used for control wiring, machine tools, and compact enclosures.

- 1.25 inch to 2 inches: Standard for commercial buildings, light industrial applications, and general power circuits.

- 2.5 inches and above: Employed in heavy industrial, utility, and large-scale infrastructure projects for main power feeds.

- By Application

- Industrial Machinery: Protecting power and control cables from coolants, oils, and vibrations.

- HVAC Systems: Shielding wiring from moisture, condensation, and mechanical stress.

- Outdoor Lighting: Ensuring weather-resistant protection for external illumination systems.

- Marine & Shipbuilding: Resisting saltwater corrosion and humid environments.

- Food & Beverage Processing: Meeting stringent hygiene standards and resisting frequent washdowns.

- Utilities (Power & Telecom): Protecting underground and exposed electrical and communication lines.

- Automotive: Used in vehicle manufacturing for wiring harnesses and control systems.

- Renewable Energy (Solar, Wind): Safeguarding wiring in outdoor, weather-exposed installations.

- General Construction: For commercial, residential, and institutional building electrical wiring.

- By End-User Industry

- Manufacturing: Automation lines, robotics, machine tools, process control.

- Construction: Commercial, residential, infrastructure, public works projects.

- Oil & Gas: Refineries, drilling platforms, pipeline control systems in corrosive environments.

- Chemical Processing: Protecting wiring from aggressive chemicals and acids.

- Transportation: Rail, automotive, aerospace applications requiring durable protection.

- Data Centers: Managing and protecting sensitive network and power cabling.

- Agriculture: Irrigation systems, farm machinery, and outdoor electrical installations.

- Healthcare: Hospitals, laboratories, and medical equipment requiring reliable electrical systems.

Value Chain Analysis For Liquid-Tight Flexible Non-Metallic Conduit Market

The value chain for the Liquid-Tight Flexible Non-Metallic Conduit (LTFNMC) market is a complex ecosystem, beginning with the critical upstream segment involving raw material suppliers. These are primarily petrochemical companies and specialized chemical manufacturers responsible for producing the foundational polymeric resins such as PVC, polypropylene, nylon, and HDPE. The quality, purity, and specific chemical formulations of these raw materials directly dictate the performance characteristics of the final conduit product, including its flexibility, temperature resistance, UV stability, and resistance to various chemicals. Strategic partnerships between conduit manufacturers and raw material suppliers are crucial for ensuring a consistent supply of high-grade materials and fostering innovation in polymer science, leading to the development of advanced compounds with superior properties. Price volatility in the petrochemical market significantly impacts this upstream segment and, consequently, the entire value chain.

Moving downstream from raw material procurement, the core of the value chain involves the conduit manufacturing process. This midstream segment is characterized by sophisticated extrusion and molding technologies, where raw polymer pellets are transformed into finished LTFNMC products of various diameters, lengths, and specialized designs. Manufacturers invest heavily in research and development to optimize production efficiencies, enhance product durability, and introduce innovative features such as anti-microbial properties for food processing applications or enhanced flame retardancy for safety-critical environments. Quality control is paramount at this stage, with rigorous testing to ensure adherence to international standards (e.g., UL, CSA, IEC) for liquid-tightness, mechanical strength, and electrical insulation. Automation and lean manufacturing principles are increasingly adopted to reduce production costs, improve consistency, and accelerate time-to-market for new products, thereby enhancing competitive advantage within the market.

The distribution segment, connecting manufacturers to end-users, represents the critical downstream component of the value chain. This involves a multi-tiered network encompassing wholesalers, electrical distributors, direct sales channels to large contractors or original equipment manufacturers (OEMs), and an expanding presence through online retail and e-commerce platforms. Wholesalers and distributors play a vital role in inventory management, logistics, and providing readily available products to a broad customer base, including smaller contractors and maintenance professionals. Direct sales channels are often employed for large-scale industrial projects or specialized applications requiring technical consultation, custom solutions, and direct support from the manufacturer. The proliferation of e-commerce has opened new avenues for market reach, enabling manufacturers to directly access a wider array of customers and offer more niche products. Effective supply chain management, including robust logistics and warehousing, is essential at this stage to ensure timely delivery and customer satisfaction, particularly in fast-paced construction and industrial environments. This intricate network ensures that LTFNMC products efficiently reach diverse end-users across geographical regions and application sectors, maintaining product availability and supporting market growth.

Liquid-Tight Flexible Non-Metallic Conduit Market Potential Customers

The potential customer base for Liquid-Tight Flexible Non-Metallic Conduit (LTFNMC) is expansive and multifaceted, covering virtually any sector where electrical wiring requires protection from environmental contaminants, mechanical stress, or chemical exposure. At its core, the construction industry represents a foundational segment of customers, including general contractors, electrical contractors, and building developers involved in residential, commercial, and large-scale infrastructure projects. These entities utilize LTFNMC for diverse applications such as wiring HVAC systems, outdoor lighting, underground services, and general electrical installations in damp or wet locations, valuing its ease of installation, flexibility, and compliance with building codes that mandate liquid-tight protection for enhanced safety and durability.

Beyond general construction, the industrial sector forms a critically important and high-demand customer segment. This includes manufacturing plants, automotive assembly lines, chemical processing facilities, and oil & gas operations. In these environments, LTFNMC is indispensable for protecting control and power cables connected to machinery, robots, motors, and instrumentation from exposure to coolants, lubricants, corrosive chemicals, and frequent washdowns. Manufacturers in the food and beverage industry are also key customers, as LTFNMC helps meet stringent hygiene standards by providing sealed, easy-to-clean raceways for electrical wiring, preventing contamination and ensuring operational integrity in sensitive processing areas. These industrial applications demand conduits with superior chemical resistance, temperature ratings, and mechanical strength to withstand continuous, rigorous operation.

Furthermore, the utility sector, encompassing power generation, transmission, and distribution, along with telecommunications companies, heavily relies on LTFNMC for protecting critical outdoor and underground cabling infrastructure. Its resistance to weather, UV radiation, and earth acids makes it ideal for solar farms, wind turbine installations, street lighting, and communication network deployment. Emerging sectors also present significant growth opportunities; for instance, the burgeoning electric vehicle (EV) charging infrastructure requires robust, weather-resistant conduits for power delivery. Data centers, with their dense and sensitive network cabling, also increasingly adopt specialized LTFNMC for protection and organization, valuing solutions that offer enhanced fire safety and electromagnetic interference (EMI) shielding. The versatility and protective capabilities of LTFNMC therefore position it as a critical component across a broad spectrum of industries, addressing complex wiring challenges and ensuring electrical system reliability.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 3.2 Billion |

| Market Forecast in 2032 | USD 5.0 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Electri-Flex Company, Carlon (Thomas & Betts), Heyco Products, Sealcon LLC, ANAMET Electrical Inc., PMA (ABB Group), Remke Industries, Kopex International (Sabo Group), Helukabel GmbH, Flexa GmbH, Legrand, RS Pro, Adaptaflex (Legrand), Federal Signal, Interflex, Reiku GmbH, Uniflex, Teaflex S.P.A, Calpipe Industries, Robroy Industries, AFC Cable Systems, Anaconda Sealtite, ABB Installation Products (formerly Thomas & Betts), Hubbell Wiring Device-Kellems, Southwire Company, LLC, Atkore International Group Inc., Allied Tube & Conduit (Atkore), IBOCO Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Liquid-Tight Flexible Non-Metallic Conduit Market Key Technology Landscape

The technological landscape of the Liquid-Tight Flexible Non-Metallic Conduit (LTFNMC) market is continuously evolving, driven by the imperative to enhance product performance, durability, and compliance with increasingly stringent industry standards and environmental regulations. Central to this evolution are advancements in material science, particularly in polymer chemistry. Manufacturers are investing heavily in research and development to formulate new polymer compounds, including specialized PVC, polypropylene, nylon, and HDPE variants. These innovations aim to imbue conduits with superior resistance to extreme temperatures, a wider array of chemicals, enhanced UV stability for outdoor applications, and improved flame retardancy to meet specific fire safety codes. The development of halogen-free flame retardant (HFFR) materials is also gaining traction, driven by environmental concerns and safety requirements in confined spaces, minimizing toxic smoke emissions in case of fire.

Beyond material composition, manufacturing technologies play a pivotal role in shaping the LTFNMC market. Advanced extrusion processes are critical, enabling the precise and efficient production of conduits with consistent wall thickness, smooth interior surfaces for easier wire pulling, and robust exterior protection. Co-extrusion techniques are increasingly utilized to create multi-layered conduits, combining different polymer properties into a single product; for instance, an inner layer optimized for chemical resistance and an outer layer designed for abrasion resistance. Automated production lines, integrated with robotic handling and advanced process control systems, enhance manufacturing consistency, reduce human error, and improve overall production efficiency, contributing to cost competitiveness. Furthermore, the development of sophisticated molding technologies for fittings and connectors ensures a secure, liquid-tight seal that maintains the integrity of the conduit system under various operational stresses, which is paramount for preventing ingress.

Another significant aspect of the key technology landscape involves quality assurance and product integration with modern electrical systems. Non-destructive testing methods, such as ultrasonic inspection and advanced optical scanning, are employed during manufacturing to detect microscopic flaws and ensure compliance with liquid-tightness and mechanical strength specifications. The focus is also on developing conduits that are optimized for integration into intelligent infrastructure, such as smart buildings and industrial Internet of Things (IIoT) environments. This includes conduits designed to protect sensitive fiber optic cables or those engineered to provide superior electromagnetic interference (EMI) shielding for electronic equipment operating in noisy electrical environments. The industry is also exploring sustainable manufacturing technologies, including processes that minimize energy consumption and waste generation, alongside the increasing use of recycled content and bio-based polymers, aligning with global efforts to reduce the environmental footprint of industrial products. These combined technological thrusts are aimed at delivering high-performance, reliable, and future-proof LTFNMC solutions tailored to the complex demands of contemporary electrical installations.

Regional Highlights

- North America: This region represents a mature yet steadily growing market for Liquid-Tight Flexible Non-Metallic Conduit, primarily driven by stringent electrical safety codes, such as those set by the National Electrical Code (NEC) in the United States and CSA standards in Canada. Significant investments in infrastructure modernization, including upgrades to aging electrical grids, public transportation systems, and utility networks, fuel demand. The robust industrial sector, particularly in manufacturing and automotive, continually requires reliable electrical containment for machinery operating in challenging environments. Furthermore, a strong residential and commercial construction pipeline, coupled with a growing emphasis on industrial automation and data center expansion, ensures sustained market relevance and adoption of high-quality LTFNMC solutions compliant with local regulations.

- Europe: The European market for LTFNMC is characterized by high adoption rates, influenced by a strong focus on energy efficiency, sustainable building practices, and comprehensive safety and environmental regulations (e.g., REACH, RoHS, CE marking). Countries such as Germany, the United Kingdom, France, and Italy are at the forefront of industrial automation and renewable energy initiatives, including offshore wind farms and solar installations, which create substantial demand for durable and weather-resistant conduits. The region's commitment to smart building development and the modernization of existing industrial infrastructure further drives the need for advanced polymer-based conduit solutions that offer superior protection, flexibility, and compliance with evolving technical standards, emphasizing innovation in material science and production methods.

- Asia Pacific (APAC): Positioned as the fastest-growing region in the LTFNMC market, APAC's expansion is fundamentally propelled by rapid urbanization, substantial government investments in infrastructure development, and the burgeoning manufacturing capabilities across countries like China, India, Japan, and the ASEAN nations. The region's immense population and economic growth lead to massive residential and commercial construction projects, coupled with a surging demand for industrial and commercial facilities. Increased foreign direct investment, the establishment of new industrial parks, and the expansion of utilities infrastructure are all key drivers. The need for cost-effective yet reliable electrical protection in diverse, often challenging, environmental conditions, from humid coastal areas to rapidly industrializing zones, significantly boosts the adoption of LTFNMC.

- Latin America: This region is experiencing consistent growth in the LTFNMC market, attributed to ongoing industrialization efforts, particularly in Brazil, Mexico, and Argentina, which are seeing increased foreign investment in manufacturing and energy sectors. Modernization of existing infrastructure, coupled with new construction projects in urban and rural areas, creates a steady demand for electrical conduit solutions. The mining, oil & gas, and agricultural sectors also contribute significantly, as they require robust and flexible wiring protection in harsh, often corrosive, environments. Public infrastructure spending and a rising focus on enhancing industrial safety and operational efficiency further stimulate market expansion, with a growing awareness of the benefits of non-metallic flexible conduits over traditional options.

- Middle East and Africa (MEA): The MEA region is demonstrating strong potential for market expansion, driven by ambitious government-led development projects and economic diversification strategies. Significant investments in construction, particularly in the United Arab Emirates and Saudi Arabia with their smart city initiatives (e.g., NEOM), are fueling demand for advanced electrical infrastructure. The region's substantial oil and gas sector requires specialized, corrosion-resistant conduits for both onshore and offshore facilities, while increasing investments in renewable energy projects (solar farms) and tourism infrastructure further propel market growth. The need for reliable and durable electrical protection in harsh desert climates and coastal areas underscores the value proposition of LTFNMC in this rapidly developing region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Liquid-Tight Flexible Non-Metallic Conduit Market.- Electri-Flex Company

- Carlon (Thomas & Betts)

- Heyco Products

- Sealcon LLC

- ANAMET Electrical Inc.

- PMA (ABB Group)

- Remke Industries

- Kopex International (Sabo Group)

- Helukabel GmbH

- Flexa GmbH

- Legrand

- RS Pro

- Adaptaflex (Legrand)

- Federal Signal

- Interflex

- Reiku GmbH

- Uniflex

- Teaflex S.P.A

- Calpipe Industries

- Robroy Industries

- AFC Cable Systems

- Anaconda Sealtite

- ABB Installation Products (formerly Thomas & Betts)

- Hubbell Wiring Device-Kellems

- Southwire Company, LLC

- Atkore International Group Inc.

- Allied Tube & Conduit (Atkore)

- IBOCO Corporation

Frequently Asked Questions

Analyze common user questions about the Liquid-Tight Flexible Non-Metallic Conduit market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of Liquid-Tight Flexible Non-Metallic Conduit compared to other options?

LTFNMC offers a compelling set of benefits including superior protection against moisture, oils, greases, and many chemicals, making it ideal for harsh environments. Its inherent flexibility simplifies routing around obstacles, significantly reducing installation time and labor costs. Being non-metallic, it is lightweight, inherently corrosion-resistant, and provides excellent electrical insulation, enhancing safety by eliminating the need for grounding conductors in many applications. These combined attributes contribute to enhanced durability and reliability of electrical systems, especially in wet or corrosive conditions.

Where is Liquid-Tight Flexible Non-Metallic Conduit commonly applied and what makes it suitable for these uses?

LTFNMC is widely deployed across a diverse range of applications. It is particularly common in industrial machinery, protecting critical power and control cables from coolants, lubricants, and abrasion. In HVAC systems, it shields wiring from condensation and mechanical stress. Outdoor lighting and renewable energy installations (solar, wind) utilize it for its weather-resistant properties against rain, snow, and UV radiation. Its resistance to saltwater corrosion and humidity makes it indispensable in marine and shipbuilding sectors. Furthermore, food and beverage processing plants rely on LTFNMC to meet stringent hygiene standards, with its sealed, smooth surfaces preventing contamination and withstanding frequent washdowns. Its adaptability and robust protection make it suitable for environments where electrical integrity is paramount.

How does Liquid-Tight Flexible Non-Metallic Conduit differ significantly from traditional metallic conduits in terms of performance and installation?

The primary distinction lies in its material composition and resulting properties. Unlike metallic conduits, LTFNMC is entirely non-corrosive, impervious to rust and galvanic corrosion, which is a major advantage in wet, chemical, or outdoor environments. It is considerably lighter, making it easier to transport, handle, and install without heavy machinery. Its flexibility allows for tighter bend radii and simpler routing, reducing the need for numerous fittings and complex bending tools, thereby accelerating installation times. Additionally, LTFNMC provides inherent electrical insulation, often negating the requirement for a separate grounding conductor and enhancing safety by minimizing electrical shock hazards, a key advantage over conductive metallic conduits.

What are the key driving factors propelling the growth of the Liquid-Tight Flexible Non-Metallic Conduit market globally?

Several critical factors are fueling the robust growth of the LTFNMC market. These include extensive global infrastructure development and modernization projects, which necessitate reliable electrical containment. The escalating pace of industrial automation and expansion across various manufacturing sectors, demanding protected wiring for machinery and robotics, is another significant driver. Furthermore, increasingly stringent electrical safety regulations and building codes worldwide mandate the use of durable and liquid-tight conduits in hazardous or damp locations. The intrinsic benefits of LTFNMC, such as its lightweight nature, superior flexibility, and excellent corrosion resistance, further contribute to its widespread adoption across diverse industrial, commercial, and utility applications.

Is Liquid-Tight Flexible Non-Metallic Conduit suitable for use in extreme temperature conditions or specialized environments?

Yes, LTFNMC is engineered for suitability across a broad range of environmental conditions, including moderate to extreme temperatures, depending on the specific polymer material used. For instance, specialized nylon and polypropylene conduits offer higher temperature resistance compared to standard PVC. Manufacturers continuously innovate to develop formulations that withstand specific challenges like high UV exposure, aggressive chemical environments, or enhanced fire safety requirements for confined spaces. When selecting LTFNMC for extreme conditions, it is crucial to consult product specifications and certifications to ensure the chosen conduit's material composition and ratings are appropriate for the intended specialized application and environmental stressors.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager