Litho Laminated Packaging Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429546 | Date : Nov, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Litho Laminated Packaging Market Size

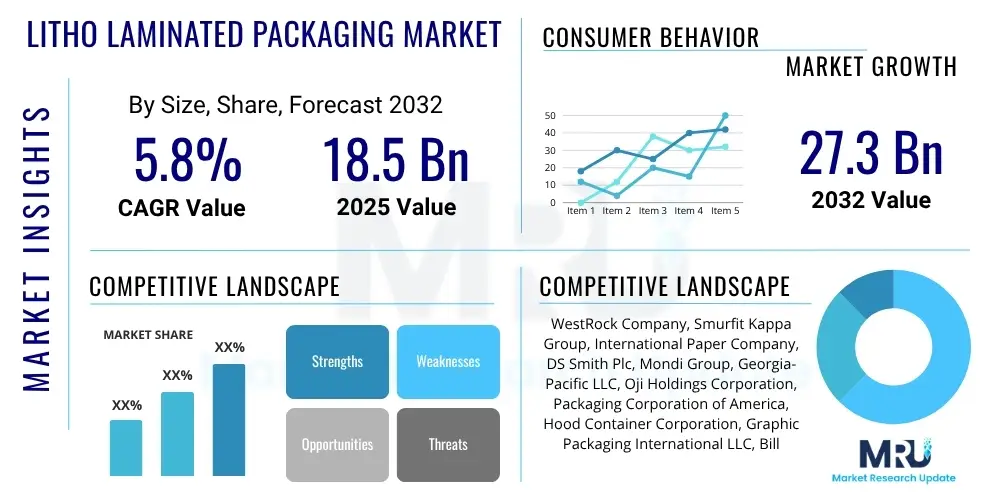

The Litho Laminated Packaging Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 18.5 Billion in 2025 and is projected to reach USD 27.3 Billion by the end of the forecast period in 2032.

Litho Laminated Packaging Market introduction

Litho laminated packaging represents a sophisticated and highly effective packaging solution, combining the inherent strength and structural integrity of corrugated cardboard with the superior visual appeal of high-quality lithographic printing. This specialized manufacturing process involves printing a detailed graphic image onto a thin sheet of paper, typically a coated paperboard, which is then meticulously laminated onto a thicker, more robust corrugated board substrate. The outcome is a premium packaging product that not only offers exceptional protection for enclosed goods during handling and transit but also provides a vibrant, high-definition canvas for intricate branding, marketing messages, and product differentiation on retail shelves. Its ability to marry durability with aesthetic excellence makes it a preferred choice across numerous industries for products demanding both robust containment and strong brand presentation.

The major applications for litho laminated packaging span an extensive range of sectors, including the bustling food and beverage industry, where it is used for items such as confectionery, baked goods, frozen foods, and premium beverage multipacks, requiring both visual appeal and product safety. Furthermore, the electronics industry heavily utilizes this packaging for consumer electronics, home appliances, and sensitive IT peripherals, benefiting from its cushioning properties and sleek presentation. Other significant applications are found in personal care and cosmetics, automotive parts, pharmaceuticals, and various consumer durables. Its inherent versatility allows for bespoke designs, encompassing intricate die-cuts, specialized coatings, and various structural configurations, all tailored to meet specific product requirements and enhance both functionality and overall aesthetic impact, thereby enriching the consumer experience.

The primary benefits fueling the market's continuous expansion include unparalleled enhanced brand visibility, crucial product differentiation in highly competitive markets, and superior physical protection against impact and compression. Brands increasingly leverage this packaging type to effectively communicate premium quality, sustainability messages, and unique selling propositions, thereby building stronger connections with consumers. Key driving factors propelling the Litho Laminated Packaging Market forward include the relentless growth of the global e-commerce sector, which necessitates packaging solutions that are durable enough to withstand complex logistics yet attractive for an enhanced unboxing experience. Additionally, there is a rising consumer demand for visually engaging and increasingly sustainable packaging solutions, coupled with the ongoing advancements in printing and lamination technologies that enable greater design flexibility, faster production cycles, and improved cost-effectiveness for manufacturers.

Litho Laminated Packaging Market Executive Summary

The Litho Laminated Packaging Market is currently undergoing significant transformation, driven by a convergence of evolving consumer preferences, rapid technological advancements, and a heightened global focus on sustainability. Business trends within this sector are heavily characterized by a strong emphasis on customization and personalization, as brands seek unique packaging to stand out. Manufacturers are increasingly investing in sophisticated automated lamination processes and advanced digital printing technologies to efficiently meet diverse design specifications and reduce lead times. This strategic shift towards tailored solutions, coupled with an increasing demand for packaging that balances aesthetic appeal with environmental responsibility, is shaping the competitive landscape and driving innovation across the value chain.

Regional trends indicate a robust growth trajectory, particularly within the Asia Pacific (APAC) region, where burgeoning economies, rapid urbanization, and expanding middle-class populations are fueling a substantial increase in demand for packaged goods. This, in turn, is boosting the adoption of litho laminated solutions across various end-use industries in countries like China, India, and Southeast Asian nations. In contrast, North America and Europe, while representing more mature markets, continue to demonstrate consistent growth, albeit with a stronger focus on premiumization, sustainable packaging innovations, and the integration of smart packaging features. These regions are responding to stringent environmental regulations and high consumer expectations for eco-friendly and sophisticated packaging formats, necessitating continuous investment in research and development.

An analysis of segmentation trends reveals the enduring dominance of the food and beverage industry as a primary application segment for litho laminated packaging. Its capabilities in providing both effective product protection and exceptional shelf appeal make it ideal for a wide array of products, from frozen foods to gourmet snacks. Concurrently, the electronics sector is emerging as a significant growth driver, utilizing these solutions for consumer gadgets and intricate components that require robust, yet aesthetically pleasing, packaging for safe transit and retail presentation. Furthermore, the market is observing accelerated demand for specialized and high-quality packaging in the personal care, pharmaceutical, and automotive industries, underscoring the broad versatility and expanding applicability of litho laminated materials in meeting the distinct requirements and marketing objectives of a diverse range of global markets.

AI Impact Analysis on Litho Laminated Packaging Market

Users frequently pose questions regarding the transformative potential of artificial intelligence (AI) on the Litho Laminated Packaging Market, with common inquiries centering on how AI can enhance efficiency, precision, and sustainability throughout the packaging lifecycle. The key themes that emerge from these questions include AI's capacity to revolutionize design and prototyping, optimize manufacturing processes, streamline supply chain management, and improve quality control. There is a clear expectation that AI will facilitate greater personalization of packaging, enable predictive maintenance for machinery, and significantly contribute to waste reduction efforts. Users are keenly interested in practical implementations that translate into tangible benefits, such as reduced operational costs, faster market entry for new products, and the ability to proactively respond to dynamic consumer demands and environmental mandates, thereby securing a competitive edge in the evolving packaging landscape.

- AI-powered design platforms can rapidly generate complex structural and graphic designs, significantly reducing development cycles and prototyping costs.

- Predictive analytics driven by AI optimizes material procurement and inventory management by accurately forecasting demand and minimizing raw material waste.

- Real-time quality control systems utilizing computer vision and machine learning identify printing defects, lamination inconsistencies, and structural flaws with high accuracy.

- AI algorithms enhance operational efficiency through optimized production scheduling, predictive maintenance for machinery, and intelligent resource allocation on the factory floor.

- Mass customization and personalization of packaging are enabled by AI's ability to analyze consumer data and generate tailored designs and messaging at scale.

- Supply chain optimization benefits from AI-driven route planning, inventory tracking, and risk assessment, ensuring timely delivery and reducing logistical costs.

- AI contributes to sustainability by identifying opportunities for material reduction, optimizing energy consumption in manufacturing, and promoting circular design principles.

DRO & Impact Forces Of Litho Laminated Packaging Market

The Litho Laminated Packaging Market is profoundly influenced by a complex interplay of driving forces, inherent restraints, and compelling opportunities that shape its growth trajectory and competitive dynamics. Among the foremost drivers is the exponential expansion of the global e-commerce sector, which inherently demands robust, protective, and aesthetically appealing packaging solutions to ensure products arrive intact and deliver an engaging unboxing experience. Furthermore, the increasing global emphasis on strong brand differentiation and enhanced consumer engagement at the point of sale critically fuels the demand for premium, high-quality printed packaging. The rising disposable incomes in developing economies, coupled with evolving consumer lifestyles characterized by a preference for convenience and aesthetically pleasing packaged goods, also significantly contribute to the market's sustained growth as consumers increasingly value both the utility and presentation of products.

Despite these powerful drivers, the market faces several notable restraints that impede its growth potential. One significant challenge is the inherent volatility in the prices of key raw materials, including various grades of paperboard, specialized printing inks, and adhesives, which directly impacts manufacturing costs and profit margins across the industry. Stringent and ever-evolving environmental regulations globally, particularly concerning plastic waste and overall packaging sustainability, present considerable hurdles. These regulations compel manufacturers to invest heavily in more eco-friendly and recyclable materials and processes, which often entail higher initial costs or necessitate significant technological advancements, potentially slowing market expansion for conventional solutions. Additionally, intense competition from alternative packaging materials and solutions, alongside the substantial initial capital investment required for specialized lamination and high-speed printing machinery, acts as a significant barrier for new market entrants and smaller enterprises seeking to scale their operations.

Conversely, the Litho Laminated Packaging Market is ripe with substantial opportunities that promise future growth and innovation. The escalating global demand for sustainable, recyclable, and environmentally responsible packaging materials presents a robust avenue for research, development, and market expansion for eco-conscious manufacturers. Significant technological advancements in digital printing, advanced automation, and smart manufacturing processes are enabling greater design flexibility, facilitating shorter production runs, and allowing for cost-effective customization. This caters specifically to niche markets and personalized product offerings, expanding the market's addressable client base. Furthermore, the increasing exploration and integration of smart packaging solutions, such as embedded QR codes, Near Field Communication (NFC) tags, or sophisticated sensors, offers lucrative growth prospects by enhancing consumer interaction, providing product traceability, and delivering valuable data analytics. The growing demand from the pharmaceutical and personal care industries for hygienic, tamper-evident, and aesthetically superior packaging further broadens the market's application scope and revenue streams.

Segmentation Analysis

The Litho Laminated Packaging Market undergoes a comprehensive segmentation based on several critical parameters, offering a granular perspective into its intricate dynamics and facilitating targeted strategic planning for industry stakeholders. This structured analysis enables a deep understanding of prevailing demand patterns, helps in identifying high-growth segments, and supports the formulation of tailored market entry or expansion strategies. The segmentation primarily differentiates market offerings based on the foundational material types used, which encompass various flute profiles of the corrugated board, and the characteristics of the paper employed for the litho printing. Additionally, the market is analyzed by its diverse applications across various product categories and by the specific end-use industries that constitute its primary customer base, each contributing uniquely to the overall market landscape.

- By Material Type: This segment distinguishes packaging solutions based on the structural characteristics of the corrugated board and the type of paper used for lamination, each offering distinct properties in terms of strength, printability, and cost-effectiveness.

- E-Flute Corrugated Board: Known for its fine flute structure, offering excellent printability, smooth surface, and good cushioning, ideal for smaller consumer goods, retail-ready packaging, and POP displays.

- B-Flute Corrugated Board: Provides a balance of cushioning, stacking strength, and crush resistance, making it suitable for a wide range of medium-sized products requiring moderate protection.

- C-Flute Corrugated Board: A versatile and widely used option that balances strength and printability, offering good general-purpose protection for diverse applications, including shipping boxes and display packaging.

- Other Flute Types: Includes A-flute (high cushioning), F-flute (ultra-thin, for compact packaging), and specialized double or triple-wall combinations designed for exceptionally high strength or unique structural requirements.

- Paperboard for Lamination: Encompasses various types such as Coated White Lined Chipboard (CWLC), Solid Bleached Sulfate (SBS), Kraft paper, and specialty papers (e.g., metallic, textured) chosen for their print surface quality, brightness, and sustainability profiles.

- By Application: This segmentation highlights the diverse product categories and contexts where litho laminated packaging is extensively utilized, showcasing its broad applicability.

- Food & Beverage: Covers packaging for confectionery, snacks, frozen foods, baked goods, dairy products, alcoholic and non-alcoholic beverages, and convenience meal kits where visual appeal and protective attributes are crucial.

- Electronics: Includes packaging for consumer electronics (smartphones, tablets), home appliances (small kitchen appliances), IT peripherals, and automotive electronics, requiring both protection and premium branding.

- Personal Care & Cosmetics: Encompasses packaging for skincare products, haircare, makeup, fragrances, and personal hygiene items, emphasizing aesthetic quality and brand prestige.

- Healthcare & Pharmaceuticals: Used for over-the-counter (OTC) medications, medical devices, diagnostic kits, and health supplements, demanding high-quality printing for instructions and branding, alongside protective integrity.

- Automotive: Primarily for packaging automotive spare parts, accessories, and components, where durability and clear branding are essential for logistics and retail.

- Consumer Durables: Includes packaging for small household appliances, tools, toys, and other non-electronic consumer goods that benefit from robust protection and attractive presentation.

- Other Applications: Broadly covers sectors like textiles, agriculture (e.g., fruit and vegetable trays), industrial components, and promotional kits, demonstrating the wide scope of its utility.

- By End-Use Industry: This category segments the market based on the primary industrial sectors that are the ultimate consumers of litho laminated packaging solutions.

- Food Processing Industry: Packaging for processed foods, convenience meals, and bulk food items supplied to retail and foodservice.

- Beverage Industry: Custom packaging for soft drinks, juices, spirits, and craft beers, focusing on multi-packs and promotional cartons.

- Electronics Manufacturing Industry: For the secure and branded packaging of finished electronic products and their components during manufacturing and distribution.

- Retail & E-commerce Sector: Packaging solutions designed for direct-to-consumer shipping, in-store displays, and enhancing the unboxing experience for online purchases across various product categories.

- Logistics & Transportation Industry: Packaging used by third-party logistics providers and shipping companies to ensure product safety and integrity throughout the supply chain.

- Other Manufacturing Industries: Including automotive component manufacturers, textile producers, toy manufacturers, and agricultural enterprises leveraging litho laminated solutions for their specific packaging needs.

Value Chain Analysis For Litho Laminated Packaging Market

The value chain of the Litho Laminated Packaging Market commences with critical upstream activities, primarily involving the sourcing and procurement of essential raw materials. This initial stage is dominated by suppliers of various grades of paperboard, which forms the fundamental structural component of the packaging, ranging from virgin fiber to recycled content. Concurrently, highly specialized printing inks, coatings, and adhesives, crucial for achieving the high-quality lithographic printing and ensuring robust lamination, are sourced from chemical and specialty materials manufacturers. The performance, consistency, and cost-effectiveness of these inputs directly dictate the quality, durability, and final pricing of the litho laminated products. Strategic, long-term relationships with these upstream suppliers are vital for ensuring a stable supply chain, maintaining consistent product quality, and fostering innovation in material science, particularly regarding sustainable alternatives and advanced functional properties.

Moving further along the value chain, the manufacturing and conversion processes constitute the core transformation stage. This segment is characterized by specialized converters and packaging producers who undertake the intricate task of transforming raw materials into finished litho laminated solutions. This involves several sophisticated steps: first, high-resolution graphic images are lithographically printed onto thin paper sheets. Subsequently, these printed sheets are precisely laminated onto corrugated board using advanced adhesive systems and high-speed lamination machinery, ensuring a strong, permanent bond. Following lamination, the combined sheets undergo precision die-cutting, scoring, folding, and gluing to form the final packaging structures, which can range from simple boxes to complex retail display units. This stage demands significant capital investment in advanced machinery, sophisticated control systems, and a highly skilled workforce to ensure exceptional precision, operational efficiency, and consistent quality across diverse product specifications and production volumes.

The downstream segment of the value chain focuses on the effective distribution and ultimate delivery of finished litho laminated packaging to its end-users. This typically occurs through a combination of direct and indirect distribution channels. Large-scale packaging manufacturers often engage in direct sales, supplying customized packaging solutions directly to major brand owners, global consumer goods companies, and large industrial clients who require significant volumes and specific technical expertise. Alternatively, indirect channels involve a network of distributors, wholesalers, and packaging brokers who cater to smaller businesses, provide localized inventory, or offer a broader regional reach. The ultimate end-users are diverse industries, including food and beverage, electronics, personal care, pharmaceuticals, and e-commerce retailers, who integrate these specialized packages into their own product lines. The efficiency and reliability of both direct and indirect distribution channels are paramount for timely delivery, ensuring that packaging solutions meet the demanding production schedules and logistics requirements of various fast-moving consumer goods (FMCG) and industrial sectors globally, thereby influencing market penetration and customer satisfaction.

Litho Laminated Packaging Market Potential Customers

The primary potential customers and end-users of litho laminated packaging solutions encompass a broad spectrum of industries that critically depend on packaging to achieve dual objectives: superior product protection and high-impact visual branding. Consumer Packaged Goods (CPG) companies, particularly those within the expansive food and beverage sector, represent a cornerstone of the customer base. They extensively utilize this packaging for a wide array of products, including frozen meals, confectionery, baked goods, premium beverages, and dairy items, where compelling shelf appeal, product freshness, and robust protection during distribution are non-negotiable. The capability of litho laminated packaging to display vibrant, high-definition graphics and intricate branding makes it an indispensable choice for products aiming to capture immediate consumer attention and differentiate themselves effectively in crowded retail environments.

Another profoundly significant segment of potential customers includes electronics manufacturers, ranging from global giants to specialized component producers. Companies involved in manufacturing consumer electronics such as smartphones, laptops, and gaming consoles, alongside home appliances and sensitive IT peripherals, rely heavily on litho laminated packaging. Its robust structural qualities are crucial for safeguarding delicate and high-value items against impact, vibration, and environmental factors during shipping and handling. Concurrently, the sophisticated aesthetic appeal provided by the litho printing conveys the premium quality and innovative nature of the enclosed electronic devices, significantly influencing consumer perception and purchase decisions. Furthermore, the rapidly expanding e-commerce sector, encompassing a vast array of product categories, is increasingly adopting litho laminated packaging due to the escalating need for durable, attractive, and memorable packaging solutions that can withstand the rigors of complex logistical networks while delivering an enhanced and personalized unboxing experience for online shoppers.

Beyond these dominant segments, a diverse array of other industries also constitutes key potential customers for litho laminated packaging. The personal care and cosmetics industry extensively employs these solutions for luxury skincare products, high-end fragrances, and premium makeup lines, where packaging serves as a critical extension of brand identity and perceived value. Automotive parts manufacturers utilize litho laminated packaging for replacement parts and accessories, benefiting from its strength for heavy items and its branding capabilities for distinguishing genuine parts. Even certain segments of the pharmaceutical industry are increasingly seeking sophisticated litho laminated packaging for over-the-counter medications, medical devices, and health supplements. This is driven by the need for packaging that offers tamper evidence, clear and attractive labeling for crucial product information, and a sense of reliability and trust for consumers, alongside meeting stringent regulatory requirements for product integrity and presentation.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 18.5 Billion |

| Market Forecast in 2032 | USD 27.3 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | WestRock Company, Smurfit Kappa Group, International Paper Company, DS Smith Plc, Mondi Group, Georgia-Pacific LLC, Oji Holdings Corporation, Packaging Corporation of America, Hood Container Corporation, Graphic Packaging International LLC, BillerudKorsnas AB, Stora Enso Oyj, Sonoco Products Company, Pratt Industries Inc., Acme Corrugated Box Co. Inc., Green Bay Packaging Inc., CEFPI S.p.A., Alliance Packaging, Custom Packaging & Products Inc., Lihua Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Litho Laminated Packaging Market Key Technology Landscape

The Litho Laminated Packaging Market is continuously being reshaped by the rapid adoption and integration of cutting-edge technologies, all aimed at significantly enhancing efficiency, elevating product quality, and promoting sustainability throughout the production lifecycle. Digital printing technology stands as a transformative force, enabling unprecedented capabilities for high-resolution graphics, variable data printing, and cost-effective shorter production runs. This innovation directly addresses the escalating demand for customized and personalized packaging solutions, which is particularly vital for the dynamic e-commerce sector and targeted promotional campaigns requiring swift turnarounds and diverse Stock Keeping Units (SKUs). The exceptional precision and vibrant color reproduction offered by digital lithography dramatically improve brand appeal and shelf impact, allowing for more intricate and responsive marketing strategies.

Automation and advanced robotics are playing an increasingly crucial role in modern litho lamination facilities, revolutionizing various stages of the manufacturing process. These technologies are extensively employed in critical operations such as precise sheet feeding, ensuring accurate registration of the intricately printed sheets onto the corrugated boards, and facilitating automated die-cutting, folding, and gluing procedures. High-speed lamination machines, equipped with sophisticated control systems and sensors, ensure consistent bond strength, prevent delamination defects, and significantly increase overall production throughput while simultaneously reducing labor costs and minimizing human error. Furthermore, the integration of entire production lines, capable of seamlessly handling multiple steps from initial printing to final finishing, streamlines the manufacturing process, contributing substantially to overall operational efficiency, consistency in product quality, and the ability to scale production for large volumes.

Innovations in materials science and smart packaging technologies are also pivotal in driving market advancements. There is a strong focus on developing more sustainable and high-performance inks, coatings, and adhesives that are biodegradable, recyclable, or derived from renewable biological resources. Water-based and UV-curable inks are rapidly gaining traction due to their significantly lower volatile organic compound (VOC) emissions, faster drying times, and improved print quality. Simultaneously, the integration of smart packaging features, such as embedded QR codes, Near Field Communication (NFC) tags, and augmented reality (AR) experiences accessible via smartphones, is emerging as a significant trend. These cutting-edge technologies enhance consumer engagement, provide critical product traceability information, enable interactive marketing campaigns, and offer valuable post-purchase insights, thereby adding new dimensions to the functional and marketing capabilities of litho laminated packaging far beyond its traditional roles of mere protection and branding.

Regional Highlights

- North America: This region constitutes a mature and highly innovative market for litho laminated packaging, driven by a strong consumer goods sector, robust e-commerce growth, and a high demand for premium and visually appealing packaging. Manufacturers here continuously invest in advanced printing technologies and automation to meet stringent quality standards and consumer preferences for both aesthetics and sustainability. The United States and Canada are leading adopters, particularly in the food and beverage, electronics, and personal care segments, with a growing focus on circular economy principles and recyclable packaging solutions to address environmental concerns.

- Europe: The European market is significantly shaped by its stringent environmental regulations, a strong consumer emphasis on sustainability, and a pervasive demand for eco-friendly and highly recyclable packaging. Countries such as Germany, the UK, France, and Italy are key contributors, consistently investing in cutting-edge printing, lamination, and finishing technologies to meet diverse consumer demands for both superior aesthetic appeal and robust environmental responsibility. The food, confectionery, personal care, and automotive industries are major drivers of market growth, with a continuous push towards innovative and resource-efficient packaging designs.

- Asia Pacific (APAC): APAC stands out as the fastest-growing region in the litho laminated packaging market, propelled by rapid industrialization, burgeoning urbanization, and a rapidly expanding middle-class population across key economies like China, India, Japan, and Southeast Asian nations. The region's expanding consumer base, coupled with increasing disposable incomes and a rising awareness of brand value, are collectively fueling the accelerated adoption of high-quality litho laminated packaging solutions. This demand spans a diverse range of industries, most notably food and beverage, electronics manufacturing, and the burgeoning retail and e-commerce sectors, making it a pivotal growth engine for the global market.

- Latin America: The market in Latin America is experiencing steady growth, primarily stimulated by expanding retail infrastructures, increasing foreign direct investment in manufacturing, and a rising middle-class population with growing purchasing power. Countries such as Brazil, Mexico, and Argentina are leading the adoption curve, with strong demand emanating from the food and beverage and personal care industries. Economic stabilization, coupled with an increasing preference for packaged and branded goods, are key factors supporting market expansion, often with a focus on cost-effective yet visually appealing packaging solutions tailored to local consumer preferences.

- Middle East and Africa (MEA): This region offers substantial untapped growth potential within the litho laminated packaging market, driven by significant infrastructure development projects, ongoing economic diversification efforts, and a rapidly increasing consumption of packaged goods. The Gulf Cooperation Council (GCC) countries, in particular, are at the forefront of adopting modern packaging solutions, supported by considerable investments in local manufacturing capabilities. The market's expansion is predominantly propelled by growth in the food and beverage, retail, and pharmaceutical sectors, all seeking to enhance product presentation, extend shelf life, and ensure product integrity amidst evolving consumer preferences and increasing urbanization.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Litho Laminated Packaging Market.- WestRock Company

- Smurfit Kappa Group

- International Paper Company

- DS Smith Plc

- Mondi Group

- Georgia-Pacific LLC

- Oji Holdings Corporation

- Packaging Corporation of America

- Hood Container Corporation

- Graphic Packaging International LLC

- BillerudKorsnas AB

- Stora Enso Oyj

- Sonoco Products Company

- Pratt Industries Inc.

- Acme Corrugated Box Co. Inc.

- Green Bay Packaging Inc.

- CEFPI S.p.A.

- Alliance Packaging

- Custom Packaging & Products Inc.

- Lihua Group

- Klabin S.A.

- Segezha Group

- Mayr-Melnhof Karton AG

- Cascades Inc.

- Daio Paper Corporation

Frequently Asked Questions

What precisely defines litho laminated packaging?

Litho laminated packaging is a premium solution that merges high-quality lithographic printing, typically applied to a thin paper sheet, with the structural strength of corrugated cardboard. This combination yields packaging with vibrant, detailed graphics and superior protection, making it ideal for products that require both strong visual appeal and robust physical integrity, especially in retail and shipping contexts.

What are the primary advantages of opting for litho laminated packaging?

The foremost advantages include significantly enhanced brand visibility through rich, high-definition graphics, crucial product differentiation in crowded markets, and exceptional protection for goods due to the corrugated base. It also offers extensive design flexibility, allowing for custom shapes and sizes that reinforce brand identity and improve shelf appeal, directly contributing to consumer purchase decisions.

Which industrial sectors are the most significant consumers of litho laminated packaging solutions?

The food and beverage industry represents the largest consumer base, utilizing this packaging for everything from confectionery to frozen foods. Other major sectors include electronics manufacturing, personal care and cosmetics, and consumer durables. Additionally, the rapid expansion of e-commerce across various categories substantially drives demand for durable and aesthetically pleasing shipping packaging.

How are sustainability concerns being addressed within the litho laminated packaging market?

Sustainability efforts are multi-faceted, focusing on the increased use of recyclable paperboard materials, the development of eco-friendly inks and adhesives (e.g., water-based), and advanced manufacturing processes that optimize material usage to reduce waste. Furthermore, ongoing innovations in lightweighting, adopting circular economy principles, and exploring biodegradable or compostable alternatives are key strategies to minimize environmental impact.

What key technological advancements are currently influencing this market's evolution?

Significant technological advancements include the widespread adoption of digital printing for superior customization and efficient short production runs, advanced automation and robotics in lamination and finishing processes for enhanced operational efficiency, and the integration of smart packaging features like QR codes and NFC tags, which facilitate enhanced consumer engagement, product traceability, and interactive marketing experiences.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager