Lotion Pump Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427227 | Date : Oct, 2025 | Pages : 244 | Region : Global | Publisher : MRU

Lotion Pump Market Size

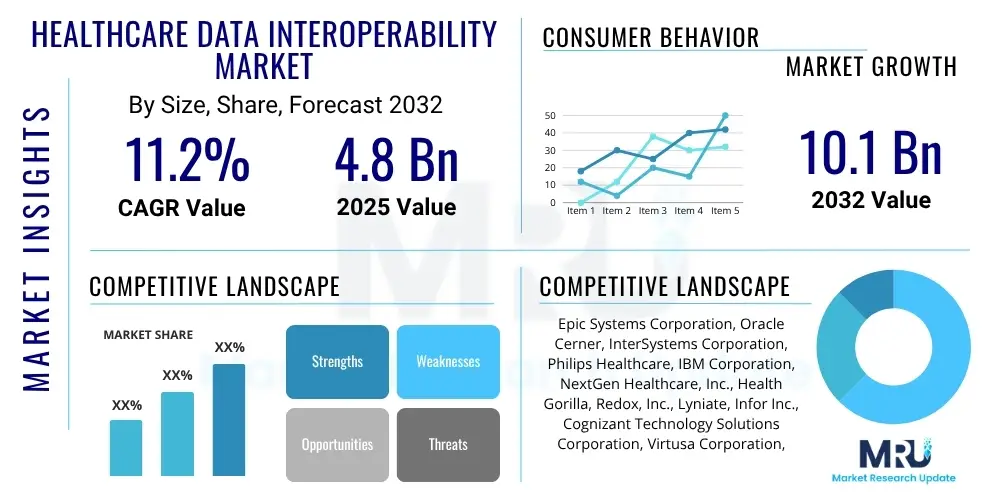

The Lotion Pump Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 3.5 billion in 2025 and is projected to reach USD 5.6 billion by the end of the forecast period in 2032.

Lotion Pump Market introduction

The lotion pump market represents a critical segment within the broader packaging industry, providing essential dispensing solutions for a diverse range of liquid and semi-liquid products. These mechanical dispensing devices are designed for precise and controlled dosage, enhancing user convenience and product integrity. Typically comprising a pump head, actuator, closure, piston, spring, and dip tube, lotion pumps are engineered to deliver a consistent amount of product with each depression, preventing contamination and reducing waste. Their functionality is paramount in maintaining product hygiene and extending shelf life, making them indispensable across various sectors. The inherent design of lotion pumps facilitates easy and mess-free application, which is a significant driver of consumer preference, particularly in fast-moving consumer goods.

Major applications for lotion pumps span across personal care, cosmetics, pharmaceuticals, and household products. In the personal care sector, they are extensively used for lotions, creams, shampoos, conditioners, and liquid soaps, offering hygienic dispensing and user-friendly experience. The cosmetics industry leverages lotion pumps for foundation, primers, and serums, where precise dosing and product protection are crucial. Pharmaceutical applications include dispensing topical medications and sanitizers, emphasizing sterility and accurate delivery. Furthermore, household cleaning products like dish soap and surface cleaners frequently employ lotion pumps for controlled and efficient use. The versatility of these pumps allows for adaptation to various product viscosities and container designs, making them a preferred choice for manufacturers seeking functional and aesthetically pleasing packaging solutions.

The markets expansion is significantly driven by a confluence of factors, including the surging demand for personal care and cosmetic products globally, heightened consumer awareness regarding hygiene, and the convenience offered by pump dispensers. The rise of e-commerce platforms has also contributed to market growth, as manufacturers prioritize robust and leak-proof packaging for shipping. Moreover, benefits such as improved product preservation, reduced product waste, and enhanced user experience continually fuel adoption. Innovations in material science, focusing on sustainable and recyclable options, further contribute to market dynamism, addressing growing environmental concerns and regulatory pressures. The continuous evolution in consumer lifestyles favoring convenience and efficiency positions the lotion pump market for sustained growth over the forecast period.

Lotion Pump Market Executive Summary

The global lotion pump market is characterized by robust business trends driven by innovation in sustainable packaging, customization, and advanced dispensing technologies. Manufacturers are increasingly investing in research and development to introduce pumps made from post-consumer recycled (PCR) plastics, bio-based materials, and mono-material designs to enhance recyclability and reduce environmental impact. The demand for aesthetically appealing and highly functional pumps has led to a surge in customization options, including different colors, finishes, and ergonomic designs that align with brand aesthetics and consumer preferences. Additionally, there is a growing trend towards incorporating smart dispensing features, such as dosage control mechanisms and anti-leak technologies, to improve user experience and product integrity. The competitive landscape is marked by strategic collaborations and mergers and acquisitions aimed at expanding product portfolios and geographical reach, alongside a focus on optimizing manufacturing processes for cost-efficiency and scalability.

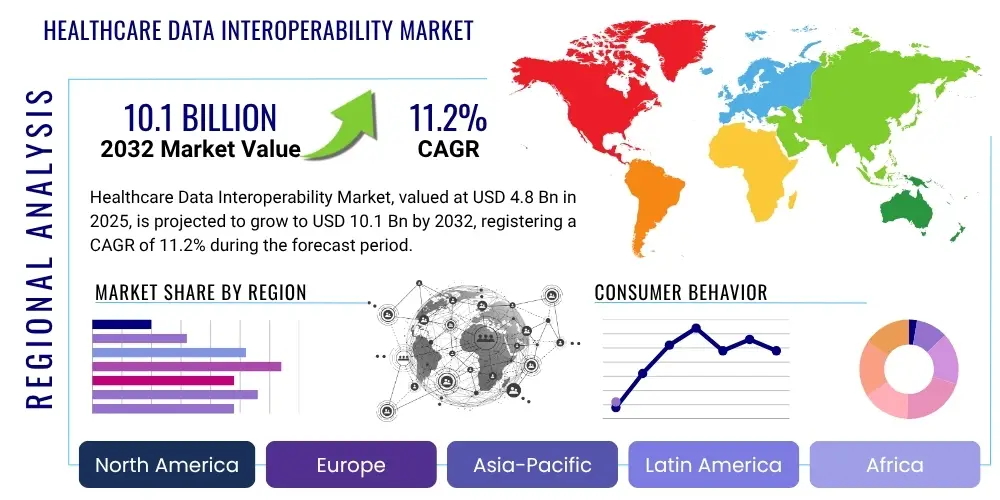

Regionally, the market exhibits varied dynamics, with Asia-Pacific emerging as the dominant and fastest-growing region, primarily due to rapid urbanization, increasing disposable incomes, and the burgeoning personal care and cosmetics industries in countries like China and India. North America and Europe, while mature markets, continue to demonstrate stable growth, driven by a strong emphasis on premium, high-performance, and sustainable packaging solutions. These regions are also at the forefront of adopting advanced dispensing technologies and compliant packaging that meets stringent regulatory standards. Latin America, the Middle East, and Africa are experiencing steady growth fueled by rising awareness of personal hygiene, increasing product penetration, and expanding retail infrastructure. The diverse regional trends underscore the global nature of the lotion pump market, influenced by localized consumer preferences, economic conditions, and regulatory environments.

Segmentation trends within the lotion pump market highlight key shifts in demand across different product types, materials, and applications. The personal care and cosmetics segments remain the largest application areas, benefiting from continuous product innovation and consumer spending on beauty and grooming. However, the pharmaceutical sector is witnessing significant growth, driven by the increasing need for sterile and precise dispensing of topical medications and sanitizers. In terms of materials, plastic pumps, particularly those made from PP (polypropylene) and PE (polyethylene), continue to dominate due to their cost-effectiveness and versatility, although there is a discernible shift towards sustainable plastic alternatives. Airless pump technology is gaining traction, especially in the premium cosmetics and pharmaceutical segments, for its ability to protect sensitive formulations from air exposure and minimize product waste, signifying a premiumization trend within specific market niches.

AI Impact Analysis on Lotion Pump Market

The integration of Artificial Intelligence (AI) into the lotion pump market is poised to revolutionize various aspects, from manufacturing efficiency to supply chain optimization and even product development. Common user inquiries frequently center on how AI can enhance the precision and speed of production lines, improve quality control to minimize defects, and optimize inventory management to reduce waste and costs. Stakeholders are keen to understand AIs potential in predicting maintenance needs for machinery, thereby reducing downtime, and its role in analyzing vast datasets for market trends to inform new product designs or customizations. Theres also growing interest in how AI could facilitate more sustainable practices by optimizing material usage and improving recycling processes, aligning with broader industry goals for environmental responsibility and resource efficiency.

Moreover, consumers and brands are beginning to explore the concept of AI-driven personalized dispensing, where smart pumps could potentially learn user preferences or integrate with smart home systems to optimize dosage or even suggest product refills based on usage patterns. This futuristic vision suggests a shift towards more intelligent and responsive packaging solutions that cater directly to individual needs, offering unparalleled convenience and efficiency. Concerns also arise regarding the investment required for AI implementation, data privacy for personalized usage, and the need for a skilled workforce to manage these advanced systems. Overall, the prevailing themes indicate an anticipation of significant operational improvements, enhanced product innovation, and a move towards more intelligent, customer-centric, and sustainable packaging solutions through the strategic application of AI technologies.

- Predictive Maintenance: AI algorithms analyze sensor data from manufacturing equipment to forecast potential failures, enabling proactive maintenance and minimizing production downtime.

- Automated Quality Control: AI-powered vision systems detect microscopic defects in pump components and assembled units with higher accuracy and speed than manual inspection, ensuring consistent product quality.

- Supply Chain Optimization: AI tools analyze demand forecasts, logistics data, and raw material availability to optimize inventory levels, route planning, and warehouse management, reducing operational costs and lead times.

- Personalized Dispensing: Future iterations may involve AI-enabled smart pumps that learn user habits to dispense customized dosages or integrate with IoT devices for reordering and product tracking.

- Data-Driven Product Development: AI analyzes market trends, consumer feedback, and material properties to inform the design of new, more efficient, and sustainable lotion pump solutions, accelerating innovation cycles.

- Manufacturing Process Optimization: AI algorithms fine-tune parameters in injection molding and assembly lines, leading to improved material utilization, reduced waste, and higher production yields.

DRO & Impact Forces Of Lotion Pump Market

The lotion pump market is significantly shaped by a dynamic interplay of drivers, restraints, opportunities, and broader impact forces. Key drivers propelling market growth include the escalating global demand for personal care and cosmetic products, fueled by rising disposable incomes and changing lifestyle patterns, particularly in emerging economies. Enhanced consumer awareness regarding hygiene and sanitation, intensified by global health concerns, has further cemented the need for hygienic dispensing solutions. The rapid expansion of e-commerce platforms also plays a crucial role, as manufacturers require robust, leak-proof, and aesthetically pleasing packaging that can withstand the rigors of shipping, making lotion pumps an ideal choice. Moreover, continuous innovation in pump design, focusing on precision, convenience, and functionality, alongside advancements in material science enabling more sustainable options, actively drives market expansion.

However, the market also faces considerable restraints that temper its growth trajectory. The volatility in raw material prices, primarily petroleum-derived plastics, poses a significant challenge to manufacturers, impacting production costs and profit margins. Environmental concerns related to plastic waste and pollution continue to exert pressure on the industry, leading to increased scrutiny and demand for eco-friendly alternatives. Stringent regulations pertaining to packaging materials, product safety, and recyclability in various regions necessitate substantial investment in compliance and R&D for new materials. Furthermore, the high initial investment required for advanced manufacturing machinery and sustainable material processing can be a barrier for smaller players, limiting market entry and competition.

Despite these challenges, the lotion pump market presents numerous lucrative opportunities. The growing emphasis on sustainable packaging offers a vast avenue for innovation, including the development and adoption of pumps made from post-consumer recycled (PCR) plastics, bio-based polymers, and mono-materials for enhanced recyclability. The emergence of smart pump technologies, integrating features like dosage control, IoT connectivity, and anti-counterfeiting measures, represents a significant opportunity for premiumization and technological differentiation. Untapped potential in emerging markets, characterized by increasing urbanization and evolving consumer preferences, provides fertile ground for market penetration and expansion. Additionally, the pharmaceutical sector, with its stringent requirements for sterile and precise dispensing, offers a niche yet high-value growth opportunity for specialized lotion pump solutions, including airless systems for sensitive formulations.

Segmentation Analysis

The lotion pump market is meticulously segmented across various parameters, allowing for a granular understanding of its dynamics and evolving consumer preferences. These segmentations typically include material type, closure type, dosage volume, and end-use application, each reflecting distinct market demands and technological advancements. The diversity in segmentation underscores the versatility of lotion pumps, catering to a wide array of products from viscous creams to lighter liquids, and meeting diverse industry standards regarding hygiene, precision, and aesthetic appeal. Understanding these segments is crucial for manufacturers to tailor their product offerings, for brands to select optimal packaging, and for market analysts to identify key growth areas and competitive landscapes within the broader packaging industry.

- By Material: This segment differentiates pumps based on the primary material used in their construction.

- Plastic: Dominant segment, including Polypropylene (PP), Polyethylene (PE), and other polymers, valued for cost-effectiveness, versatility, and ease of molding.

- Metal: Less common but used for premium or specialized applications, offering a luxury feel and enhanced durability, often for cosmetic or high-end personal care products.

- Others: Encompasses bio-based plastics, glass, or composite materials, driven by sustainability trends and specific product requirements.

- By Closure Type: Categorizes pumps based on how they attach to the container, impacting ease of use and sealing integrity.

- Screw-on: Most prevalent, offering a secure seal and reusability, commonly found on bottles for lotions, soaps, and shampoos.

- Snap-on: Used for simpler, often single-use applications or where quick assembly is prioritized, providing a tight but permanent seal.

- Crimp-on: Typically found in pharmaceutical or high-security applications where tamper-evidence and airtight sealing are critical.

- By Dosage: Segments pumps based on the volume of product dispensed per actuation, crucial for precise application and product value.

- Less than 1.0 ml: Ideal for facial serums, concentrated cosmetics, or pharmaceutical products requiring very small, controlled doses.

- 1.0 ml - 2.0 ml: Standard range for hand soaps, body lotions, and many personal care products, offering a balance of dispense volume and control.

- More than 2.0 ml: Suitable for bulkier products like shampoos, conditioners, or household cleaners where a larger dispense volume per pump is desired.

- By Application: Classifies the market based on the end-use industry where lotion pumps are deployed, reflecting diverse product requirements.

- Personal Care: Largest segment, including lotions, creams, liquid soaps, hand sanitizers, and body washes, driven by daily consumer usage.

- Cosmetics: Encompasses foundations, primers, serums, and other beauty products where precise, hygienic, and airless dispensing is often preferred.

- Pharmaceuticals: Critical for topical medications, ointments, and medical liquids, requiring sterile, accurate, and often tamper-evident dispensing.

- Household: Includes dish soaps, cleaning solutions, and air fresheners, prioritizing durability, cost-effectiveness, and adequate dispense volume.

- Others: Covers niche applications such as pet care products, automotive detailing liquids, and industrial solutions.

Lotion Pump Market Value Chain Analysis

A comprehensive value chain analysis of the lotion pump market elucidates the intricate stages from raw material procurement to the final consumer, highlighting the various stakeholders and processes that add value. The upstream segment of the value chain is predominantly concerned with the sourcing and processing of raw materials. This primarily involves the chemical industry supplying plastic resins such as polypropylene (PP), polyethylene (PE), and acrylonitrile butadiene styrene (ABS), which form the bulk of pump components. Metal suppliers provide stainless steel for springs, and other specialized suppliers offer elastomers for seals and gaskets. These raw material providers are crucial as their product quality and pricing directly impact the cost-effectiveness and performance of the final lotion pump. Innovation in this upstream segment, particularly concerning sustainable and recycled materials, is becoming increasingly vital to address environmental concerns and meet evolving regulatory requirements, influencing the entire value chain.

Further down the value chain, component manufacturing and pump assembly represent the core transformation processes. Specialized manufacturers employ precision injection molding, extrusion, and automated assembly lines to produce the various intricate parts of a lotion pump, including actuators, closures, pistons, dip tubes, and the housing. These manufacturers often specialize in high-volume production, leveraging advanced machinery and quality control systems to ensure consistency and reliability. Post-assembly, the pumps are then distributed to brand owners and filling companies. The distribution channels are multifaceted, comprising both direct and indirect approaches. Large-scale lotion pump manufacturers often engage in direct sales with major global personal care, cosmetic, and pharmaceutical brands, establishing long-term supply agreements and customizing solutions to meet specific brand requirements and packaging designs. This direct relationship facilitates closer collaboration on R&D and quality assurance, ensuring seamless integration into the brands production lines.

Indirect distribution channels typically involve a network of wholesalers, distributors, and packaging solution providers who cater to smaller and medium-sized enterprises (SMEs) or regional brands that may not have the capacity for direct procurement from large manufacturers. These intermediaries offer a wider range of stock products, flexible order quantities, and localized support, making lotion pumps accessible to a broader market segment. Online B2B platforms are also emerging as significant indirect channels, connecting manufacturers with a global base of potential buyers, particularly for standardized or semi-customized pump solutions. The final stage involves the filling companies and brand owners integrating these pumps into their product packaging, followed by retail distribution to end-consumers. The efficiency and reliability of the entire value chain are paramount for timely product delivery, cost optimization, and ensuring that high-quality, functional lotion pumps ultimately reach the hands of the end-users, thus fulfilling consumer expectations for convenience and product integrity.

Lotion Pump Market Potential Customers

The lotion pump market serves a broad and diverse spectrum of potential customers, essentially encompassing any industry that requires precise, hygienic, and convenient dispensing of liquid or semi-liquid products. At the forefront are major players in the personal care industry, including global conglomerates and niche brands producing body lotions, hand creams, liquid soaps, shampoos, conditioners, and hand sanitizers. These companies prioritize pumps that offer consistent dosage, prevent product contamination, and enhance the overall user experience, often seeking customization options to align with their brand identity and bottle designs. The sheer volume and continuous demand in this sector make personal care brands the largest and most consistent buyers of lotion pumps, driving innovation in both functionality and aesthetics to meet evolving consumer preferences for hygiene, convenience, and sustainability.

Another significant customer segment is the cosmetics industry, which relies heavily on lotion pumps for foundations, primers, serums, and various liquid beauty products. For cosmetic brands, precision in dispensing is paramount, especially for expensive or potent formulations where accurate dosage is crucial for efficacy and minimizing waste. Airless pump technology is particularly attractive to this segment, as it protects sensitive ingredients from oxidation and extends product shelf life, while also providing a premium look and feel. Pharmaceutical companies also constitute a critical customer base, utilizing lotion pumps for topical medications, gels, and sanitizers. In this sector, the demand is not only for precise dosage but also for strict adherence to regulatory standards, material compatibility, and often, sterile or tamper-evident dispensing mechanisms, making specialized, high-quality pumps indispensable for patient safety and product integrity.

Beyond these primary sectors, the household products industry represents a substantial customer segment, with manufacturers of dish soaps, surface cleaners, fabric softeners, and other liquid household essentials. For these applications, durability, cost-effectiveness, and appropriate dispense volume are key considerations, allowing for efficient and easy use by consumers. Furthermore, the hospitality sector, including hotels, spas, and public facilities, increasingly purchases lotion pumps for bulk dispensers of hand soap, shampoo, and body wash, emphasizing hygiene and user convenience. Emerging markets and specialty industries such such as pet care, automotive detailing products, and even certain food packaging applications also present growing opportunities for lotion pump manufacturers, showcasing the expansive and varied customer landscape that relies on these essential dispensing solutions for product delivery and consumer satisfaction.

Lotion Pump Market Key Technology Landscape

The technological landscape of the lotion pump market is characterized by continuous innovation aimed at enhancing functionality, precision, sustainability, and user experience. A foundational technology remains precision injection molding, which is crucial for producing the intricate components of lotion pumps with high accuracy and consistency. Advancements in molding techniques allow for complex designs, tighter tolerances, and the use of diverse materials, including multi-shot molding for integrated components. Material science plays a pivotal role, with ongoing research into lightweight, durable, and chemically resistant plastics, as well as the increasing adoption of sustainable materials such as post-consumer recycled (PCR) resins, bio-plastics, and mono-materials to facilitate easier recycling. These material innovations are driven by both consumer demand for eco-friendly products and stringent environmental regulations globally, pushing manufacturers towards more responsible production practices.

Further technological advancements include sophisticated dispensing mechanisms designed for specific product viscosities and dosage requirements. Airless pump technology is a prominent innovation, particularly for premium cosmetics and pharmaceutical products. These systems prevent air from entering the container, protecting oxygen-sensitive formulations from oxidation, extending shelf life, and ensuring nearly 100% product evacuation, thus minimizing waste. Anti-siphon and anti-leak mechanisms are also critical, employing advanced valve designs and sealing technologies to prevent product leakage during transit and use, which is essential for e-commerce and consumer satisfaction. Additionally, the integration of child-resistant or tamper-evident features in pump designs addresses safety and regulatory compliance concerns, especially for pharmaceutical and household cleaning products.

Looking ahead, the market is beginning to explore the integration of smart technologies and IoT (Internet of Things) capabilities into lotion pumps. While still nascent, concepts include smart dispensers that can track usage, remind users for refills, or even communicate with smart home systems to manage inventory. This represents a significant shift towards interactive and intelligent packaging, offering enhanced convenience and personalized experiences. Furthermore, advancements in automated assembly and quality control systems, often leveraging AI and machine vision, are improving manufacturing efficiency, reducing defects, and accelerating production cycles. These technological developments collectively aim to deliver more efficient, reliable, sustainable, and user-friendly dispensing solutions that meet the evolving demands of both industry and consumers in a highly competitive global market.

Regional Highlights

- Asia-Pacific: This region stands as the largest and fastest-growing market for lotion pumps, primarily driven by rapid urbanization, increasing disposable incomes, and the expansion of the personal care, cosmetics, and pharmaceutical industries in populous countries like China, India, and Japan. The burgeoning middle class and growing awareness of personal hygiene are significant factors contributing to the high consumption of products utilizing lotion pumps. Local manufacturing capabilities are robust, leading to competitive pricing and innovative product development tailored to regional preferences.

- North America: A mature market characterized by a strong emphasis on premium products, advanced dispensing technologies, and sustainable packaging solutions. Consumers in this region often prioritize convenience, product efficacy, and environmentally friendly options, driving demand for airless pumps, PCR materials, and aesthetically pleasing designs. Stringent regulatory standards for product safety and packaging further influence market dynamics, pushing manufacturers towards high-quality and compliant solutions.

- Europe: This region represents a significant market with a strong focus on sustainability, innovation, and compliance with strict environmental regulations. European consumers and brands show a high preference for eco-friendly packaging, including pumps made from recycled plastics or bio-based materials, and those designed for refillability. The market is also driven by demand for high-performance pumps for luxury cosmetics and pharmaceutical applications, supported by advanced manufacturing capabilities and a robust R&D ecosystem.

- Latin America: An emerging market experiencing steady growth attributed to rising urbanization, increasing disposable incomes, and evolving consumer preferences for branded personal care and cosmetic products. Brazil and Mexico are key markets within this region, showing a growing adoption of lotion pumps as consumers become more aware of hygiene and seek convenient product dispensing. Local and international players are investing in the region to tap into its growing consumer base.

- Middle East & Africa (MEA): This region is projected to witness considerable growth, driven by increasing awareness of health and hygiene, expanding retail infrastructure, and a rise in beauty and personal care spending. The demand for lotion pumps is accelerating with the influx of international brands and the development of local manufacturing capabilities. Economic diversification and a growing young population contribute to the positive outlook for the market in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Lotion Pump Market.- AptarGroup, Inc.

- Silgan Dispensing Systems

- Albea SA

- Rieke Packaging Systems (part of TriMas)

- Guala Dispensing

- Quadpack Industries

- Berry Global Inc. (includes RPC Group)

- Zhejiang JM Plastic Co., Ltd.

- Ningbo Sun-Rain Plastics Co., Ltd.

- Raepak Ltd.

- Pumpspecs (UK) Ltd.

- Yiwu Global Packaging Co., Ltd.

- Frapak Packaging B.V.

- Shya Hsin Packaging Industry Co., Ltd.

- Taixing K.K. Plastic Co., Ltd.

- C.L. Smith Company

- Vison Pack Co., Ltd.

- Shanghai BrotherPack Co., Ltd.

- Guangzhou Jianxin Plastic Products Co., Ltd.

Frequently Asked Questions

What are the primary drivers for the growth of the lotion pump market?

The lotion pump market growth is primarily driven by the expanding global demand for personal care and cosmetic products, increasing consumer awareness regarding hygiene and sanitation, and the significant rise of e-commerce platforms requiring secure and convenient packaging. Additionally, ongoing innovations in pump design and sustainable materials further fuel market expansion.

Which application segment holds the largest share in the lotion pump market?

The personal care segment consistently holds the largest share in the lotion pump market. This dominance is attributed to the widespread use of lotion pumps for products such as body lotions, hand soaps, shampoos, and conditioners, driven by daily consumer usage and continuous product innovation in the personal grooming sector.

What role do sustainable materials play in the lotion pump market?

Sustainable materials, including post-consumer recycled (PCR) plastics, bio-based polymers, and mono-materials for enhanced recyclability, play an increasingly critical role. They address growing environmental concerns, meet stringent regulatory standards, and cater to consumer preferences for eco-friendly packaging, driving significant innovation and investment in the market.

How does AI impact the manufacturing of lotion pumps?

AI significantly impacts lotion pump manufacturing by enabling predictive maintenance for machinery, optimizing production processes for efficiency and material usage, and enhancing automated quality control systems. This leads to reduced downtime, minimized defects, and overall cost savings, while also informing data-driven product design and supply chain management.

What are the main challenges faced by the lotion pump market?

The main challenges for the lotion pump market include the volatility of raw material prices, particularly for plastics, which impacts production costs. Environmental concerns related to plastic waste and increasing regulatory pressures for sustainable packaging also pose significant hurdles. High initial investment for advanced manufacturing technologies can further restrict market entry for smaller players.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager