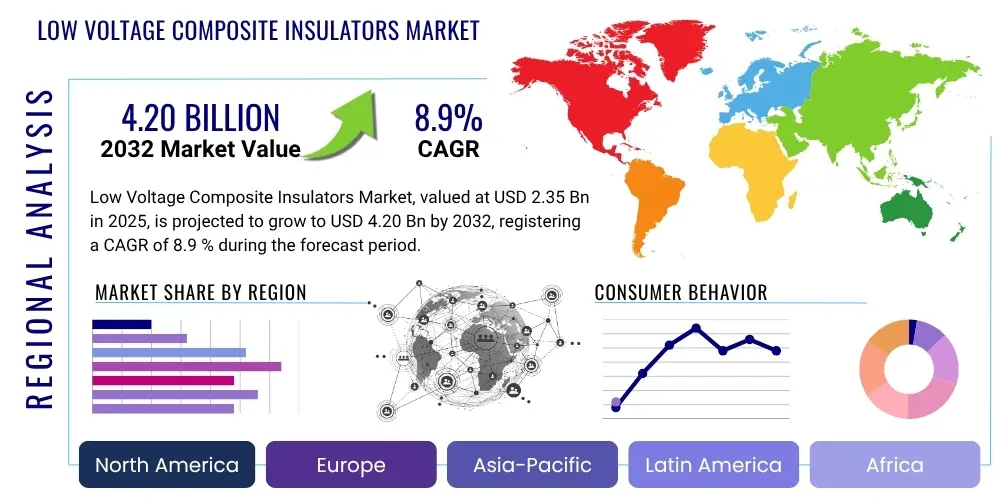

Low Voltage Composite Insulators Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427884 | Date : Oct, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Low Voltage Composite Insulators Market Size

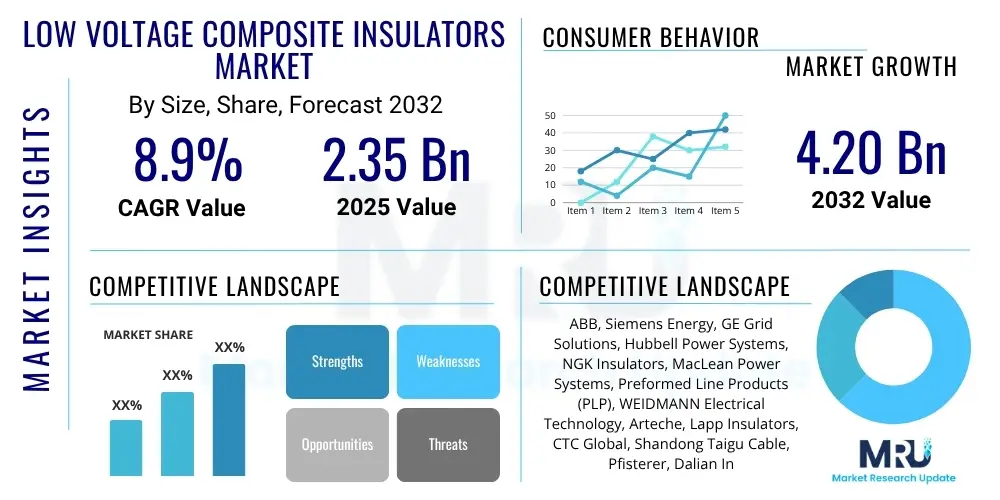

The Low Voltage Composite Insulators Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.9% between 2025 and 2032. The market is estimated at USD 2.35 Billion in 2025 and is projected to reach USD 4.20 Billion by the end of the forecast period in 2032. This growth trajectory is attributed to increasing global demand for reliable and efficient power distribution, coupled with advancements in material science offering enhanced performance characteristics for composite insulators in low voltage applications. The expanding electrification initiatives in developing economies and the continuous modernization of existing grid infrastructure in developed regions further bolster this significant market expansion, positioning low voltage composite insulators as a critical component in future power systems.

Low Voltage Composite Insulators Market introduction

The Low Voltage Composite Insulators Market encompasses the manufacturing, distribution, and application of insulators primarily designed for electricity transmission and distribution systems operating at voltage levels up to 1 kilovolt (kV). These modern insulators, often made from advanced polymer materials such as silicone rubber, EPDM, and various composites, offer significant advantages over traditional ceramic or glass insulators, including superior dielectric strength, lighter weight, enhanced resistance to vandalism, and improved performance in polluted environments. Their robust design minimizes flashover incidents, reduces maintenance requirements, and extends operational lifespans, contributing to greater grid reliability and operational efficiency. The market is driven by a global push towards grid modernization, infrastructure development, and the integration of renewable energy sources, all of which necessitate advanced insulation solutions for optimal performance.

Product Description: Low voltage composite insulators consist of a fiberglass rod core for mechanical strength, housing sheds (weathersheds) made from polymeric materials for insulation and hydrophobicity, and metal end fittings for attachment. These components are meticulously bonded to prevent moisture ingress and ensure long-term integrity. The design prioritizes resistance to tracking, erosion, and ultraviolet (UV) radiation, making them ideal for challenging environmental conditions. Their lightweight nature simplifies installation, reducing labor costs and safety risks compared to heavier traditional insulators. Furthermore, their non-brittle characteristics enhance resilience against impacts and vandalism, an increasingly important factor in both urban and remote installations.

Major Applications: Low voltage composite insulators find extensive application in overhead distribution lines, service connections to residential and commercial buildings, street lighting systems, railway electrification, and various industrial electrical installations where safety and reliability are paramount. They are crucial for isolating live conductors from ground and other support structures, ensuring the safe and continuous flow of electricity. The increasing demand for stable power supply in rapidly urbanizing areas, coupled with the expansion of mini-grids and decentralized energy systems, further amplifies their utility. Benefits of these insulators include enhanced safety due to reduced risk of shattering, superior resistance to environmental degradation, and a significantly longer operational life, which translates into lower lifecycle costs for utilities and industrial consumers.

Driving factors for the market's growth include the global impetus for electricity grid upgrades, particularly in regions prone to extreme weather or high pollution, where composite insulators outperform conventional materials. The proliferation of smart grid technologies, which demand more resilient and less maintenance-intensive components, also contributes significantly. Additionally, the growing adoption of renewable energy sources, such as solar and wind power, requires robust and reliable low voltage distribution infrastructure where composite insulators play a vital role. Regulatory support for advanced materials in power infrastructure further accelerates their market penetration. The inherent benefits of composite insulators, such as improved safety, reduced energy losses, and enhanced aesthetic appeal compared to bulky alternatives, continue to drive their widespread adoption across diverse applications.

Low Voltage Composite Insulators Market Executive Summary

The Low Voltage Composite Insulators Market is experiencing robust growth, propelled by a confluence of business trends, regional development initiatives, and evolving segment demands. Key business trends include a heightened focus on product innovation, with manufacturers investing in R&D to enhance material properties, extend operational lifespans, and improve environmental resistance. Strategic collaborations between material suppliers, insulator manufacturers, and utility companies are also becoming more prevalent, aiming to streamline supply chains and integrate advanced solutions more efficiently into grid infrastructure projects. Furthermore, a growing emphasis on sustainability and circular economy principles is driving manufacturers to explore more eco-friendly production processes and recyclable materials, influencing product design and market positioning. Companies are increasingly leveraging digital marketing and e-commerce platforms to reach a broader customer base, particularly for specialized or niche applications, thereby optimizing their market penetration strategies. This competitive landscape fosters continuous improvement and differentiation among market participants.

Regional trends indicate significant market expansion in emerging economies, particularly across Asia Pacific and parts of Latin America and Africa, where rapid urbanization and industrialization are driving extensive infrastructure development and electrification projects. Governments in these regions are allocating substantial budgets for grid expansion and modernization, creating a fertile ground for low voltage composite insulator adoption. Developed regions such such as North America and Europe, while having mature grids, are witnessing strong demand driven by grid refurbishment initiatives, the integration of distributed generation resources, and the need for more resilient infrastructure against climate change impacts. Regulatory frameworks in these regions often favor high-performance, low-maintenance components, further boosting the market for composite insulators. The Middle East also presents a promising market due to significant investments in smart city projects and industrial expansion, necessitating advanced power distribution systems.

Segment trends highlight a sustained demand for silicone rubber-based insulators due to their excellent hydrophobic properties and UV resistance, making them ideal for diverse environmental conditions. The market is also seeing an increase in adoption of specialized designs tailored for specific applications, such as railway electrification where vibration resistance and compact form factors are crucial, or in renewable energy installations requiring enhanced durability. By voltage rating, the segment of 1 kV to 36 kV, while technically not "low voltage" by strict definition (often considered medium voltage), often shares similar material and application drivers, showcasing demand for efficient insulation solutions across a broader spectrum of lower distribution voltages. Within the true low voltage (up to 1 kV) segment, a shift towards lighter, more resilient products for residential and commercial connections is noticeable, driven by ease of installation and reduced visual impact. The customization of insulators to meet specific climatic challenges and utility standards also represents a significant and growing trend within the market, indicating a move towards more bespoke and performance-optimized solutions.

AI Impact Analysis on Low Voltage Composite Insulators Market

User questions related to the impact of AI on the Low Voltage Composite Insulators Market often revolve around enhanced manufacturing efficiency, predictive maintenance capabilities, and optimization of grid performance. Users frequently inquire about how AI can contribute to the design and material selection process, leading to more durable and cost-effective insulators, or if AI can enable real-time monitoring of insulator health to prevent failures. There's also curiosity about AI's role in supply chain management for insulator components and its potential to optimize installation processes. Essentially, the overarching themes are about leveraging AI for improved reliability, reduced operational costs, and smarter infrastructure management throughout the lifecycle of low voltage composite insulators, indicating a strong expectation for technological integration that extends beyond traditional manufacturing processes into broader operational intelligence.

- AI can optimize manufacturing processes for composite insulators, predicting material flaws and enhancing quality control.

- Predictive maintenance analytics powered by AI can monitor environmental stress and operational loads on insulators, forecasting potential failures before they occur.

- AI-driven design tools can accelerate the development of new composite materials and insulator geometries, improving performance and cost-efficiency.

- Supply chain optimization using AI algorithms can streamline logistics, reduce lead times, and manage inventory for raw materials and finished insulators.

- AI in smart grid systems can integrate data from insulators to provide real-time network health assessments, improving grid stability and fault localization.

- Automated inspection systems utilizing AI and computer vision can quickly detect external damage or degradation on installed insulators, reducing manual labor and increasing accuracy.

- AI can analyze market trends and demand patterns to optimize production planning and inventory management for composite insulators, ensuring better responsiveness to utility needs.

DRO & Impact Forces Of Low Voltage Composite Insulators Market

The Low Voltage Composite Insulators Market is shaped by a complex interplay of Drivers, Restraints, Opportunities, and a variety of Impact Forces that dictate its growth trajectory and competitive landscape. Key drivers include the global imperative for modernizing aging electricity grids, particularly in developed nations where infrastructure is nearing its end-of-life, necessitating replacements with more resilient and efficient components. The rapid expansion of electrification projects in developing countries, fueled by population growth and industrialization, also significantly boosts demand. Furthermore, the inherent advantages of composite insulators over traditional materials, such as superior performance in harsh environments, lighter weight for easier installation, and reduced maintenance costs, make them an increasingly preferred choice for utilities. The integration of renewable energy sources into distribution networks, which requires stable and reliable low voltage infrastructure, further propels market expansion, as composite insulators offer enhanced protection against fluctuating loads and environmental stressors. These drivers collectively create a robust demand environment.

However, the market also faces several restraints that can impede its growth. One significant restraint is the relatively higher initial capital cost of composite insulators compared to conventional ceramic or glass alternatives, which can be a barrier for some budget-constrained utilities or smaller projects. Another challenge is the lack of standardized testing protocols and specifications across all regions, leading to a fragmented market and sometimes confusing procurement processes. The volatility in raw material prices, particularly for polymers and fiberglass, can impact manufacturing costs and consequently influence product pricing and profit margins for manufacturers. Additionally, a degree of resistance to change from traditional materials, rooted in long-standing relationships with ceramic insulator suppliers and a perceived lack of long-term performance data for composites in certain niche applications, can slow down adoption rates. Overcoming these restraints requires sustained efforts in cost-reduction, standardization, and demonstration of long-term benefits.

Opportunities within this market are abundant and varied, offering significant avenues for growth and innovation. The increasing global focus on smart grid development presents a substantial opportunity, as smart grids require highly reliable and low-maintenance components that can withstand dynamic operating conditions, a role perfectly suited for composite insulators. The expansion of mini-grids and off-grid electrification solutions, particularly in remote and rural areas, opens new application segments. Furthermore, the ongoing research and development into advanced polymer composites with even better fire resistance, self-cleaning properties, and extended durability offer future growth prospects. Niche applications, such as specialized insulators for high-altitude environments or regions with extremely corrosive industrial pollution, represent untapped market potential. The growing awareness about the environmental benefits of composites, including reduced energy consumption during manufacturing compared to ceramics and their contribution to a more resilient grid, also creates a favorable market environment. These opportunities position the market for continuous evolution and expansion.

- Drivers:

- Aging grid infrastructure and modernization initiatives.

- Rapid urbanization and industrialization in emerging economies.

- Superior performance characteristics (lightweight, pollution resistance, vandalism resistance) of composite materials.

- Increased integration of renewable energy sources into distribution grids.

- Growing demand for reliable and efficient power distribution systems.

- Restraints:

- Higher initial cost compared to traditional insulators.

- Lack of standardized regulations and specifications across all regions.

- Volatility in raw material prices (polymers, fiberglass).

- Resistance to change from conventional materials in some established markets.

- Opportunities:

- Development and adoption of smart grid technologies.

- Expansion of mini-grids and off-grid electrification solutions.

- Technological advancements in polymer science leading to enhanced insulator properties.

- Niche applications requiring specialized performance (e.g., high altitude, corrosive environments).

- Growing emphasis on sustainable and resilient infrastructure.

- Impact Forces:

- Technological advancements in materials and manufacturing processes.

- Government regulations and utility standards favoring modern insulation solutions.

- Economic growth and infrastructure spending in key regions.

- Environmental concerns driving demand for durable and low-maintenance solutions.

- Competitive landscape and pricing strategies among manufacturers.

Segmentation Analysis

The Low Voltage Composite Insulators Market is comprehensively segmented based on various critical parameters including material, type, voltage rating, application, and end-user. This intricate segmentation allows for a detailed analysis of market dynamics, identifying specific growth pockets and competitive advantages within each category. Understanding these segments is crucial for manufacturers to tailor their product offerings, for distributors to optimize their supply chains, and for end-users to make informed purchasing decisions based on their specific technical requirements and operational environments. The market's diverse applications, from overhead distribution lines to industrial machinery, necessitate a wide range of insulator specifications, each catered to by distinct segments. The evolving material science also contributes to the continuous diversification of product offerings across these segments, enhancing overall market agility and responsiveness to emerging demands.

- By Material:

- Silicone Rubber: Known for excellent hydrophobicity, UV resistance, and pollution performance.

- EPDM Rubber: Offers good thermal stability and resistance to ozone and weathering.

- Polymer Concrete: Provides robust mechanical strength, often used in specialized applications.

- Others: Includes hybrid materials and novel polymer formulations currently under development or in niche use.

- By Type:

- Pin Type: Commonly used for supporting conductors on overhead lines.

- Post Type: Offers higher mechanical strength and often used in substations and heavy-duty applications.

- Suspension Type: Used for suspending transmission and distribution lines from towers.

- Spool Type: Typically found in low voltage distribution for dead-ending or turning angles.

- Shackle Type: Similar to spool but often used for supporting and dead-ending low voltage lines.

- By Voltage Rating:

- Up to 1 kV: Primarily for residential, commercial, and service drop applications.

- 1 kV to 36 kV: While sometimes considered medium voltage, this range often shares similar manufacturing technologies and application drivers with true low voltage in terms of composite material use and is critical for primary and secondary distribution.

- By Application:

- Distribution Lines: Overhead and underground systems for power delivery.

- Railway Electrification: Specialized insulators for catenary systems and rail power.

- Industrial Applications: Factories, mining operations, and heavy machinery.

- Building and Construction: Internal and external wiring, electrical panels.

- Utilities: Power generation, transmission, and distribution companies.

- Telecommunications: Supporting communication lines and associated power.

- Renewable Energy Systems: Solar farms, wind turbines, and energy storage connections.

- By End-User:

- Power Utilities: Major purchasers for grid infrastructure.

- Industrial Sector: Manufacturing, processing, and heavy industries.

- Commercial Sector: Office buildings, retail establishments, data centers.

- Residential Sector: Home connections, local distribution networks.

Value Chain Analysis For Low Voltage Composite Insulators Market

The value chain for the Low Voltage Composite Insulators Market is a complex and interconnected network encompassing raw material extraction, component manufacturing, assembly, distribution, and end-user application. Upstream activities begin with the sourcing of specialized raw materials, primarily high-performance polymers such as silicone rubber, EPDM, and fiberglass rods, along with various metal components for end fittings. These raw materials are often sourced from a global network of chemical and metallurgy companies that specialize in providing high-grade, consistent quality inputs. The quality and availability of these materials are paramount, as they directly influence the performance, durability, and cost-effectiveness of the final insulator product. Any disruptions in the supply of these critical raw materials can significantly impact the entire value chain, leading to production delays and increased costs. Furthermore, the technological expertise required to produce these specialized materials also adds a layer of complexity to the upstream segment.

Midstream activities involve the intricate manufacturing and assembly processes. This stage includes the extrusion or molding of the polymeric housing sheds, pultrusion of fiberglass rods, casting or forging of metal end fittings, and the critical bonding process that integrates these components into a finished composite insulator. Manufacturers often employ advanced automation and quality control systems to ensure product consistency, compliance with international standards, and optimal performance under various operating conditions. Research and development plays a vital role here, as manufacturers continuously seek to innovate materials and designs to improve insulation properties, mechanical strength, and environmental resistance. The assembly process is highly specialized, requiring precision engineering to prevent defects such as voids or improper bonding, which could compromise the insulator's integrity and lead to premature failure in the field. This phase also involves rigorous testing protocols to validate product specifications and reliability, adhering to industry standards like IEC and ANSI.

Downstream analysis focuses on the distribution channels and end-user engagement. Finished low voltage composite insulators are distributed through a combination of direct and indirect channels. Direct sales often involve large-scale contracts with national power utilities, major industrial clients, or government-backed infrastructure projects, where manufacturers might engage directly with procurement departments. This allows for customized solutions and strong relationship building. Indirect channels include a network of authorized distributors, wholesalers, and electrical equipment suppliers who cater to a broader range of smaller utilities, commercial enterprises, contractors, and local distributors. These intermediaries play a crucial role in market penetration, providing logistics, localized technical support, and inventory management. The distribution network must be efficient to ensure timely delivery to diverse geographical locations, especially in rapidly developing regions where infrastructure projects are often time-sensitive. The final stage involves the installation and application by end-users, where factors like ease of installation, maintenance requirements, and overall product lifespan become critical considerations for sustained market preference.

Direct and indirect distribution channels play distinct yet complementary roles in the Low Voltage Composite Insulators Market. Direct sales are typically characterized by large volume transactions, direct negotiation, and often involve bespoke product specifications tailored to specific utility requirements or major infrastructure projects. This channel allows manufacturers to maintain direct control over pricing, quality assurance, and customer relationships, fostering long-term partnerships. For instance, a major national utility undertaking a grid modernization project might procure thousands of specialized insulators directly from a manufacturer. Indirect channels, on the other hand, provide broader market reach and cater to smaller, more fragmented demand. Electrical wholesalers and distributors maintain inventories, offer localized customer service, and facilitate sales to independent contractors, smaller municipal utilities, and industrial clients who require smaller quantities or a variety of products. This multi-channel approach ensures that the market effectively serves both large-scale strategic buyers and a diverse array of smaller, geographically dispersed customers, maximizing market coverage and accessibility. Both channels are vital for the continuous growth and widespread adoption of low voltage composite insulators across different market segments and regions.

Low Voltage Composite Insulators Market Potential Customers

The Low Voltage Composite Insulators Market caters to a diverse range of potential customers, primarily end-users and buyers involved in the generation, transmission, and distribution of electrical power, as well as various industrial and commercial applications. The largest and most significant customer segment comprises national and regional power utilities. These entities are responsible for maintaining and expanding vast electricity grids, and they require high volumes of reliable insulators for overhead distribution lines, substations, and service connections. Their purchasing decisions are heavily influenced by product reliability, compliance with regulatory standards, long-term performance, and total cost of ownership, including maintenance expenses. Utilities are continuously upgrading aging infrastructure and expanding grids to meet growing energy demands, making them perennial and substantial consumers of low voltage composite insulators. Their procurement processes often involve stringent qualification criteria and long-term supply agreements, ensuring consistent demand for established manufacturers.

Beyond traditional utilities, the industrial sector represents a substantial customer base. Manufacturing plants, mining operations, oil and gas facilities, and heavy industries require robust electrical systems to power their operations. In these environments, composite insulators are valued for their durability, resistance to harsh industrial pollutants, and enhanced safety features, which are critical for preventing costly downtime and ensuring worker safety. Industrial customers often have specific environmental challenges, such as corrosive atmospheres or high vibration, where the superior material properties of composite insulators provide a distinct advantage over traditional alternatives. Their purchasing decisions are driven by the need for reliable power supply to maintain production continuity, minimize operational risks, and comply with strict safety regulations, making the long-term performance and low maintenance characteristics of composite insulators highly appealing. The demand from this sector is often project-based, linked to new facility construction or upgrades to existing electrical infrastructure.

The commercial and residential sectors also constitute significant end-users, albeit often through indirect channels. Commercial establishments, including office buildings, retail complexes, and data centers, require dependable low voltage insulation for internal wiring, service drops, and local distribution networks. Similarly, the residential sector, driven by new housing developments and electrification initiatives, consumes large quantities of low voltage composite insulators for connecting homes to the grid. While individual residential or small commercial entities typically do not directly purchase insulators from manufacturers, their demand is aggregated through electrical contractors, builders, and local distribution companies who then procure from wholesalers and distributors. The increasing global population and ongoing urbanization trends directly translate into increased construction activities and demand for electricity, thereby ensuring a steady and growing market for low voltage composite insulators across these segments. The emphasis in these sectors is often on cost-effectiveness, ease of installation, and compliance with local building codes.

| Report Attributes | Report Details | |

|---|---|---|

| Market Size in 2025 | USD 2.35 Billion | |

| Market Forecast in 2032 | USD 4.20 Billion | |

| Growth Rate | 8.9% CAGR | |

| Historical Year | 2019 to 2023 | |

| Base Year | 2024 | |

| Forecast Year | 2025 - 2032 | |

| DRO & Impact Forces |

| |

| Segments Covered |

| |

| Key Companies Covered | ABB, Siemens Energy, GE Grid Solutions, Hubbell Power Systems, NGK Insulators, MacLean Power Systems, Preformed Line Products (PLP), WEIDMANN Electrical Technology, Arteche, Lapp Insulators, CTC Global, Shandong Taigu Cable, Pfisterer, Dalian Insulator Group, TE Connectivity, Sicame Group, Bonomi Group, Hindustan Vidyut Products (HVPL), ESI Group | |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) | |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Low Voltage Composite Insulators Market Key Technology Landscape

The Low Voltage Composite Insulators Market is characterized by a dynamic technology landscape driven by continuous advancements in material science, manufacturing processes, and smart grid integration capabilities. A primary technological focus revolves around the development of advanced polymeric materials, especially next-generation silicone rubbers and EPDM compounds, that offer enhanced hydrophobic recovery, superior resistance to tracking and erosion, and improved long-term UV stability. Innovations in nanotechnology are also being explored to incorporate nanofillers into polymer matrices, aiming to boost dielectric strength, mechanical toughness, and thermal performance, thereby creating more resilient insulators capable of withstanding extreme environmental conditions and pollution levels. These material science breakthroughs are crucial for extending the lifespan of insulators and reducing maintenance frequency in the field, providing a significant advantage over conventional materials. Furthermore, research into flame-retardant polymers for enhanced safety in critical applications is a growing area, addressing concerns related to fire hazards in electrical installations.

In terms of manufacturing processes, advancements in injection molding, extrusion, and pultrusion techniques are critical. These technologies enable precise control over the geometric design and material distribution within the insulator, ensuring optimal performance and consistent quality across large production batches. Automated assembly lines are becoming more sophisticated, incorporating robotics and AI-driven quality control systems that can detect micro-defects invisible to the human eye, thereby enhancing product reliability and reducing manufacturing costs. The development of seamless bonding technologies between the fiberglass core, polymer sheds, and metal end fittings is also vital, as the integrity of these interfaces is crucial for preventing moisture ingress and ensuring the insulator's long-term performance. Additionally, specialized coatings are being developed to further enhance surface hydrophobicity and resistance to icing and salt fog, expanding the applicability of composite insulators to even harsher climates and coastal regions. These manufacturing innovations contribute significantly to both the performance and cost-effectiveness of the final product.

Another significant aspect of the technology landscape involves the integration of smart features and diagnostic capabilities. While not as prevalent in low voltage as in high voltage applications, there is a growing trend towards embedding sensors within composite insulators or developing external monitoring solutions for real-time performance assessment. These smart insulators could potentially provide data on temperature, humidity, leakage currents, and mechanical stress, allowing utilities to implement predictive maintenance strategies and optimize grid operations. The incorporation of IoT (Internet of Things) principles could enable these insulators to communicate their status directly to grid management systems, facilitating proactive intervention before failures occur. Furthermore, advancements in digital twin technology allow for virtual modeling and simulation of insulator performance under various conditions, aiding in design optimization and failure analysis. These technological integrations not only enhance the functionality of low voltage composite insulators but also position them as integral components of future smart and resilient electricity grids, capable of adapting to dynamic operational demands and environmental challenges. This forward-looking approach ensures that the market for these insulators remains robust and responsive to emerging technological paradigms.

Regional Highlights

- North America: This region is characterized by aging grid infrastructure and a strong focus on grid modernization and smart grid initiatives. The demand for low voltage composite insulators is robust, driven by utility upgrades, integration of distributed energy resources, and stringent reliability standards. Canada and the United States are significant markets, emphasizing durable, low-maintenance solutions suitable for diverse weather conditions.

- Europe: European countries are actively investing in enhancing grid resilience and integrating renewable energy sources, fueling the demand for composite insulators. Strict environmental regulations and a focus on reducing carbon footprint also favor the adoption of advanced, lightweight materials. Western European nations, particularly Germany, France, and the UK, are key contributors, with Eastern Europe showing increasing adoption rates in infrastructure development projects.

- Asia Pacific (APAC): APAC is the fastest-growing market, primarily due to rapid urbanization, industrial expansion, and extensive rural electrification programs in countries like China, India, and Southeast Asian nations. Massive investments in new power infrastructure and grid expansion, coupled with a focus on improving electricity access and reliability, are propelling the demand for low voltage composite insulators. Cost-effectiveness and performance in challenging environments are key drivers here.

- Latin America: This region is experiencing significant investments in grid expansion and refurbishment, particularly in countries like Brazil, Mexico, and Argentina. The need for reliable power distribution in remote areas and urban centers, often characterized by challenging terrain and weather, makes composite insulators an attractive solution. Economic development and infrastructure projects are key growth catalysts.

- Middle East and Africa (MEA): The MEA region is witnessing substantial infrastructure development, driven by smart city projects, industrialization, and efforts to expand electricity access. Countries in the GCC (Gulf Cooperation Council) are investing heavily in modernizing their power grids. In Africa, rural electrification initiatives and the expansion of mini-grids create significant opportunities for low voltage composite insulators, valued for their durability and ease of installation in diverse climates.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Low Voltage Composite Insulators Market.- ABB

- Siemens Energy

- GE Grid Solutions

- Hubbell Power Systems

- NGK Insulators

- MacLean Power Systems

- Preformed Line Products (PLP)

- WEIDMANN Electrical Technology

- Arteche

- Lapp Insulators

- CTC Global

- Shandong Taigu Cable

- Pfisterer

- Dalian Insulator Group

- TE Connectivity

- Sicame Group

- Bonomi Group

- Hindustan Vidyut Products (HVPL)

- ESI Group

- Raychem RPG (P) Ltd.

Frequently Asked Questions

What are the primary benefits of low voltage composite insulators compared to traditional ceramic ones?

Low voltage composite insulators offer superior advantages such as lighter weight for easier installation, enhanced resistance to pollution and UV radiation, greater mechanical strength, and improved performance in harsh environments. They are also less prone to vandalism and shattering, leading to reduced maintenance and extended operational lifespan, ultimately lowering the total cost of ownership for utilities.

How is the adoption of renewable energy impacting the demand for low voltage composite insulators?

The increasing integration of renewable energy sources like solar and wind power necessitates robust and reliable low voltage distribution infrastructure. Composite insulators are crucial for these systems due to their durability, resilience to environmental stressors, and ability to ensure stable power flow, directly boosting their demand in renewable energy applications and associated grid extensions.

What role does AI play in the manufacturing and performance of composite insulators?

AI is increasingly used to optimize manufacturing processes, predict material defects, and enhance quality control in composite insulator production. Furthermore, AI-driven analytics can enable predictive maintenance by monitoring insulator health in real-time, forecasting potential failures, and optimizing grid stability, thereby improving overall reliability and reducing operational costs.

Which geographical regions are expected to drive the most growth in the Low Voltage Composite Insulators Market?

The Asia Pacific region, particularly countries like China and India, is projected to be the fastest-growing market due to rapid urbanization, extensive infrastructure development, and significant investments in rural electrification. North America and Europe will also see sustained demand driven by grid modernization and renewable energy integration efforts, while Latin America and MEA are emerging as key growth areas.

What are the main types of materials used in low voltage composite insulators?

The primary materials used include silicone rubber and EPDM rubber for the housing sheds, known for their excellent hydrophobic properties and environmental resistance. A fiberglass rod core provides the necessary mechanical strength, and metal end fittings (e.g., galvanized steel, aluminum) are used for attachment to structures. Advanced polymer concrete is also used in specialized applications requiring high mechanical integrity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager