Low Voltage Drives Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428928 | Date : Oct, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Low Voltage Drives Market Size

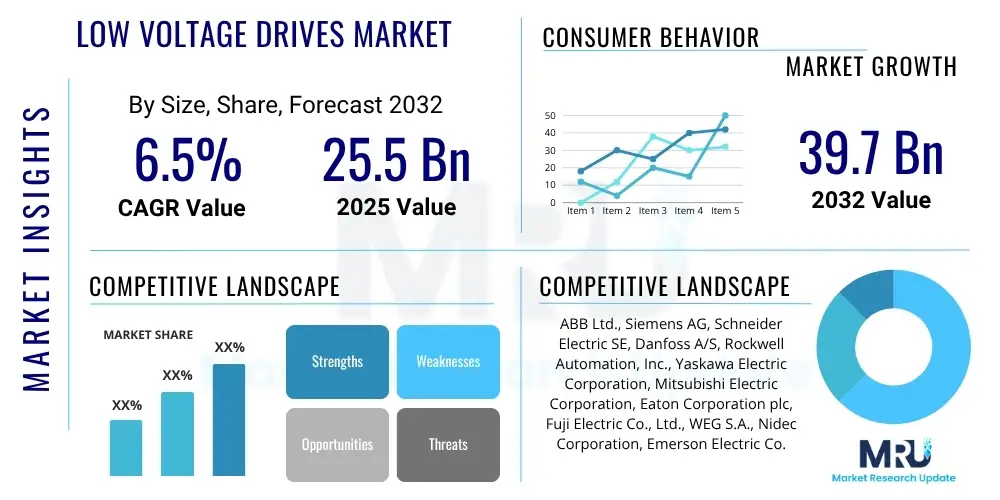

The Low Voltage Drives Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032. The market is estimated at $25.5 Billion in 2025 and is projected to reach $39.7 Billion by the end of the forecast period in 2032.

Low Voltage Drives Market introduction

The Low Voltage Drives market encompasses a critical segment of industrial automation, providing essential control over electric motors operating at voltages typically below 1000V. These drives, also known as Variable Frequency Drives (VFDs) or Adjustable Speed Drives (ASDs), regulate the speed and torque of AC motors by varying the frequency and voltage of the power supplied to them. This precise control not only optimizes industrial processes but also significantly enhances energy efficiency, reduces mechanical stress, and improves overall system reliability. The inherent ability of low voltage drives to match motor speed to process requirements minimizes energy waste, a key benefit in an era focused on sustainable industrial operations and cost reduction.

The product description for low voltage drives highlights their sophisticated electronic components, including rectifiers, DC link capacitors, and inverters, which transform incoming AC power into variable frequency and voltage output. Modern low voltage drives incorporate advanced control algorithms, communication interfaces, and diagnostic capabilities, enabling seamless integration into complex industrial networks and offering real-time performance monitoring. They are designed for robustness, capable of operating in diverse industrial environments, from clean manufacturing facilities to harsh outdoor applications. The continuous evolution in power electronics and digital control technologies further enhances their performance, making them more compact, reliable, and feature-rich.

Major applications of low voltage drives span across a multitude of industries, including HVAC systems, pumping stations, fan control, conveyors, compressors, and various manufacturing processes such as food and beverage, pulp and paper, textiles, and metals. The benefits derived from their implementation are substantial, primarily energy savings, which can be as high as 30-50% in certain applications, extended equipment lifespan due to reduced mechanical wear, improved process control leading to higher product quality, and enhanced operational flexibility. The market is primarily driven by escalating energy costs, stringent energy efficiency regulations, the widespread adoption of industrial automation, and the need for optimized production processes across manufacturing and infrastructure sectors globally. These factors collectively underpin the sustained growth and strategic importance of the low voltage drives market.

Low Voltage Drives Market Executive Summary

The Low Voltage Drives market is experiencing robust expansion, driven by a confluence of factors including increasing industrial automation, a global emphasis on energy efficiency, and the modernization of industrial infrastructure. Business trends indicate a shift towards smart, connected drives equipped with advanced functionalities such as predictive maintenance, remote monitoring, and integration with Industrial Internet of Things (IIoT) platforms. Manufacturers are focusing on developing compact, modular designs that offer greater flexibility and ease of installation, catering to the growing demand for customized solutions. Strategic collaborations, mergers, and acquisitions are also prevalent, as key players seek to expand their product portfolios, technological capabilities, and geographical reach, consolidating market leadership and fostering innovation.

Regional trends highlight significant growth opportunities in emerging economies, particularly in Asia Pacific, due to rapid industrialization, infrastructure development, and substantial investments in manufacturing capabilities. Countries like China and India are at the forefront of this growth, driven by their vast industrial bases and governmental initiatives promoting energy conservation. North America and Europe, while mature markets, continue to demonstrate steady demand, propelled by the need for industrial upgrades, stringent environmental regulations, and the adoption of advanced automation technologies in existing facilities. Latin America, the Middle East, and Africa are also showing promising growth, albeit from a smaller base, as industrialization efforts gain momentum and awareness of energy efficiency benefits increases across these regions.

Segment trends reveal a strong inclination towards drives with higher protection ratings and enhanced communication protocols, crucial for demanding industrial environments and seamless integration into enterprise-wide systems. The demand for specific power ranges is also evolving, with an increasing focus on drives for medium to high-power low voltage applications as industrial processes become more power-intensive. End-user industries such as power generation, oil and gas, metals and mining, and water and wastewater treatment are key contributors to market growth, driven by their critical need for reliable motor control and substantial energy savings. The continuous innovation in semiconductor technology, particularly in wide-bandgap materials like SiC and GaN, is also influencing drive design, leading to more efficient, smaller, and higher-performing units, further shaping segment dynamics and market competitiveness.

AI Impact Analysis on Low Voltage Drives Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Low Voltage Drives market frequently revolve around how AI can enhance efficiency, enable predictive maintenance, and facilitate more autonomous operations. Users are keen to understand if AI will lead to smarter, self-optimizing drives, what data is required for effective AI integration, and the cybersecurity implications of connecting these advanced systems. There is also significant interest in the potential for AI to personalize drive performance to specific application needs and to integrate seamlessly with broader IIoT and cloud-based analytical platforms. The overarching theme is the transformation of traditional motor control into an intelligent, proactive, and highly optimized process, raising expectations for improved operational uptime and reduced maintenance costs.

- AI enables predictive maintenance by analyzing operational data from drives, anticipating failures, and scheduling maintenance proactively.

- Optimized energy consumption through AI algorithms that learn and adapt drive performance to fluctuating load conditions and process requirements.

- Enhanced fault detection and diagnostics capabilities, allowing for quicker identification and resolution of operational anomalies.

- Integration with broader industrial automation systems and IIoT platforms for centralized monitoring, control, and data analytics.

- Development of self-optimizing drives that can autonomously adjust parameters for peak performance and efficiency based on real-time feedback.

- Improved process control through AI-driven adaptive control loops, leading to higher product quality and reduced waste.

- Facilitates remote management and troubleshooting, reducing the need for on-site interventions and improving response times.

- Potential for cybersecurity risks due to increased connectivity and data exchange, requiring robust security measures in AI-enabled drives.

- Personalized drive configurations and performance tuning based on specific application profiles and historical operational data.

DRO & Impact Forces Of Low Voltage Drives Market

The Low Voltage Drives market is significantly influenced by various Driving forces, Restraints, Opportunities, and broader Impact forces that shape its trajectory. Key drivers include the global imperative for energy efficiency and sustainability, compelling industries to adopt advanced motor control solutions that reduce power consumption and carbon footprint. The accelerating pace of industrial automation across sectors, coupled with the expansion of smart factory initiatives and the Industrial Internet of Things (IIoT), further fuels demand for intelligent and connected low voltage drives. Additionally, the increasing cost of energy worldwide acts as a direct financial incentive for businesses to invest in energy-saving technologies like VFDs. The replacement of older, less efficient motor control systems with modern low voltage drives also contributes substantially to market growth, driven by operational cost savings and improved reliability.

However, the market also faces several restraints. The high initial capital investment required for implementing sophisticated low voltage drive systems can be a deterrent, particularly for small and medium-sized enterprises (SMEs) with limited budgets. A lack of awareness or technical expertise regarding the benefits and proper application of these drives in certain regions or industries can also hinder adoption. Furthermore, the complexity of integrating advanced drives into existing legacy systems sometimes presents technical challenges, requiring specialized skills and additional investment in system upgrades. Economic uncertainties and geopolitical instabilities can also impact industrial spending, leading to delayed or reduced investments in automation technologies, thereby restraining market expansion in affected regions.

Despite these challenges, numerous opportunities abound for growth and innovation within the low voltage drives market. The burgeoning demand for electric vehicles and renewable energy systems (solar, wind) presents new application areas for precise motor control solutions. The continuous technological advancements in power electronics, such as Wide Bandgap (WBG) semiconductors (SiC, GaN), promise to deliver more efficient, compact, and cost-effective drives, opening new market segments. The growing trend towards digitalization and cloud-based services offers opportunities for developing value-added services like predictive analytics, remote diagnostics, and energy management platforms, creating new revenue streams for manufacturers. Moreover, expanding into underserved markets and offering customized solutions tailored to specific industry needs can unlock significant untapped potential. These impact forces collectively define the dynamic environment in which the low voltage drives market operates, necessitating strategic adaptation and continuous innovation from market participants.

Segmentation Analysis

The Low Voltage Drives market is extensively segmented across various parameters, including voltage type, power rating, application, and end-user industry, providing a granular view of market dynamics and opportunities. This detailed segmentation allows manufacturers to tailor their product offerings to specific needs and helps stakeholders understand the diverse demands within the market. Each segment exhibits unique growth patterns and drivers, reflecting varying levels of industrialization, technological adoption, and regulatory landscapes across different regions and sectors. Understanding these segmentations is crucial for developing targeted marketing strategies and product development roadmaps.

- Voltage Type

- AC Drives

- DC Drives

- Power Rating

- Micro Drives (Up to 5 kW)

- Low Power Drives (5.1 kW - 50 kW)

- Medium Power Drives (50.1 kW - 200 kW)

- High Power Drives (Above 200 kW)

- Application

- Pumps

- Fans

- Compressors

- Conveyors

- Extruders

- Cranes & Hoists

- HVAC Systems

- Others (e.g., Mixers, Grinders)

- End-User Industry

- Oil & Gas

- Water & Wastewater Treatment

- Power Generation

- Metals & Mining

- Food & Beverages

- Pulp & Paper

- Textile

- Automotive

- Building Automation

- Chemicals & Petrochemicals

- Pharmaceuticals

- Semiconductors

- Marine

- Others (e.g., Cement, Rubber, Glass)

- Technology

- Variable Voltage and Frequency (VVF)

- Vector Control

- Direct Torque Control (DTC)

Value Chain Analysis For Low Voltage Drives Market

The value chain for the Low Voltage Drives market is a complex network involving multiple stages, from raw material procurement to end-user consumption and post-sales support. Upstream analysis reveals that key raw materials and components, such as semiconductors (IGBTs, MOSFETs), capacitors, microcontrollers, PCBs, and various metals for enclosures, are sourced from specialized suppliers. Research and development plays a crucial role at this stage, focusing on innovation in power electronics, control algorithms, and software to enhance drive performance, efficiency, and connectivity. Manufacturers then engage in the design, assembly, and testing of these drives, often integrating advanced automation processes to ensure quality and cost-effectiveness. The manufacturing process is highly specialized, requiring significant capital investment in production facilities and skilled labor for intricate assembly and rigorous quality control.

The distribution channel for low voltage drives is multifaceted, encompassing both direct and indirect sales approaches. Direct distribution often involves manufacturers selling directly to large industrial clients, original equipment manufacturers (OEMs), or engineering, procurement, and construction (EPC) contractors through their own sales force or dedicated project teams. This approach allows for direct technical consultation, customized solutions, and stronger client relationships, especially for complex or large-scale projects. Indirect distribution, on the other hand, relies heavily on a network of authorized distributors, system integrators, value-added resellers (VARs), and electrical wholesalers. These intermediaries play a vital role in reaching a broader customer base, particularly SMEs, by providing localized sales support, inventory management, and often initial technical support and installation services. The choice between direct and indirect channels often depends on market size, geographic reach, customer type, and the complexity of the product or project.

Downstream analysis focuses on the installation, commissioning, operation, and maintenance of low voltage drives at the end-user facilities. This stage involves system integrators who connect the drives to motors and control systems, ensuring seamless operation within the industrial plant. Post-sales services, including technical support, training, troubleshooting, spare parts supply, and maintenance contracts, are critical for ensuring long-term customer satisfaction and operational reliability. As drives become more intelligent and connected, digital services such as remote monitoring, predictive maintenance, and energy management analytics are gaining prominence, creating new service-based revenue opportunities for manufacturers. The efficient functioning of this entire value chain is essential for the sustained growth and competitiveness of the Low Voltage Drives market, requiring strong collaboration and coordination among all participants to deliver value to the end customer.

Low Voltage Drives Market Potential Customers

Potential customers and end-users of Low Voltage Drives span a broad spectrum of industries, driven by the universal need for efficient motor control in various applications. These drives are indispensable for any industrial or commercial operation that utilizes electric motors for processes such as pumping, ventilation, conveying, mixing, or precise machinery operation. Industries with substantial motor populations, such as manufacturing, infrastructure, and utilities, represent the largest customer base. This includes original equipment manufacturers (OEMs) who integrate drives into their machinery and equipment before selling to end-users, as well as direct industrial end-users seeking to optimize their existing processes or upgrade their facilities for energy efficiency and enhanced productivity.

Specifically, the Water and Wastewater Treatment sector is a significant consumer, utilizing drives to control pumps and blowers for efficient fluid management, filtration, and aeration processes, crucial for minimizing energy consumption in continuous operations. The Oil and Gas industry employs low voltage drives for various applications, including pumping crude oil, operating compressors in refineries, and controlling drilling equipment, where reliability and precise control are paramount in often harsh environments. The Metals and Mining sector relies on these drives for conveyors, crushers, grinders, and other heavy-duty machinery, benefiting from improved torque control and energy savings in demanding applications. The Food and Beverage industry uses low voltage drives for precise speed control in packaging, processing, and material handling, ensuring product quality and sanitation standards while optimizing throughput.

Furthermore, the Power Generation industry, encompassing traditional and renewable energy sources, uses drives for auxiliary equipment like boiler feed pumps, cooling fans, and fuel handling systems, contributing to overall plant efficiency. The Building Automation sector is another key end-user, with drives integrated into HVAC systems, elevators, and escalators to optimize energy consumption and provide comfortable indoor environments. Other crucial end-users include the Pulp and Paper industry, for controlling large machinery; the Textile industry, for precise fabric production; and the Automotive industry, for various manufacturing processes. This diverse customer landscape underscores the fundamental role of low voltage drives across the global industrial ecosystem, reflecting their critical utility in enhancing efficiency, productivity, and sustainability for a wide array of industrial processes and applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $25.5 Billion |

| Market Forecast in 2032 | $39.7 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., Siemens AG, Schneider Electric SE, Danfoss A/S, Rockwell Automation, Inc., Yaskawa Electric Corporation, Mitsubishi Electric Corporation, Eaton Corporation plc, Fuji Electric Co., Ltd., WEG S.A., Nidec Corporation, Emerson Electric Co., Hitachi, Ltd., Lenze SE, Parker Hannifin Corporation, Delta Electronics, Inc., Inovance Technology, Vacon (now part of Danfoss), Keb Automation KG, GE Digital |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Low Voltage Drives Market Key Technology Landscape

The Low Voltage Drives market is characterized by a dynamic and evolving technology landscape, continuously driven by advancements in power electronics, control algorithms, and communication protocols. At its core, the technology relies on the conversion of fixed-frequency AC power into variable frequency and voltage AC power to precisely control motor speed and torque. This is primarily achieved through sophisticated power semiconductor devices, with Insulated Gate Bipolar Transistors (IGBTs) being a dominant technology due to their high power handling capabilities and fast switching speeds. The continuous development of these semiconductor devices, including improvements in efficiency and reduction in size, directly translates into more compact and energy-efficient drives. Furthermore, the emergence of Wide Bandgap (WBG) semiconductors, such as Silicon Carbide (SiC) and Gallium Nitride (GaN), is set to revolutionize the market by enabling even higher switching frequencies, greater power density, and significantly lower energy losses, leading to smaller form factors and enhanced performance for future low voltage drive solutions.

Beyond the power stage, the intelligence of low voltage drives is largely determined by their digital control systems and embedded software. Advanced control algorithms like Vector Control (Field Oriented Control) and Direct Torque Control (DTC) are critical for achieving high-performance motor control, offering precise speed and torque regulation across a wide operating range, even under dynamic load conditions. These algorithms require powerful microcontrollers and digital signal processors (DSPs) to execute complex computations in real-time. The integration of advanced communication protocols, such as EtherNet/IP, PROFINET, Modbus TCP, and OPC UA, is paramount, enabling seamless connectivity with broader industrial automation systems, programmable logic controllers (PLCs), and supervisory control and data acquisition (SCADA) systems. This connectivity supports centralized control, data exchange, and remote diagnostics, aligning with the principles of Industry 4.0 and the Industrial Internet of Things (IIoT).

The ongoing trend towards digitalization also incorporates features like integrated sensors for real-time monitoring of various operational parameters, cloud connectivity for data analytics, and embedded cybersecurity measures to protect against unauthorized access and cyber threats. Drive manufacturers are increasingly incorporating artificial intelligence (AI) and machine learning (ML) capabilities to enable predictive maintenance, self-optimization of drive parameters, and advanced fault detection, transforming drives from mere control devices into intelligent assets. This technological evolution extends to user interfaces, with intuitive human-machine interfaces (HMIs) and mobile applications for commissioning, monitoring, and troubleshooting. The cumulative effect of these technological advancements is leading to low voltage drives that are not only more efficient and reliable but also smarter, more connected, and highly adaptable to the complex demands of modern industrial environments, significantly enhancing operational intelligence and overall system performance for end-users.

Regional Highlights

- North America: A mature market characterized by significant adoption of advanced automation technologies, stringent energy efficiency regulations, and a strong focus on upgrading existing industrial infrastructure. The region demonstrates steady demand, particularly in the automotive, oil and gas, and HVAC sectors, driven by modernization and sustainability initiatives.

- Europe: Similar to North America, Europe is a well-established market with a high emphasis on energy savings and environmental compliance. Germany, Italy, and France are key contributors, driven by manufacturing excellence, robust R&D, and the widespread implementation of Industry 4.0 principles across diverse industries like machinery, food and beverage, and water utilities.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, burgeoning manufacturing sectors in countries like China, India, Japan, and South Korea, and substantial investments in infrastructure development. Government initiatives promoting energy conservation and increasing foreign direct investment in manufacturing facilities are key drivers.

- Latin America: An emerging market exhibiting promising growth, primarily led by industrial expansion in countries such as Brazil and Mexico. Investments in mining, oil and gas, and food processing industries are contributing to the increased adoption of low voltage drives as companies seek to improve operational efficiency and competitiveness.

- Middle East and Africa (MEA): This region is experiencing considerable growth due to diversification efforts away from oil-dependent economies, leading to investments in infrastructure, manufacturing, and renewable energy projects. Countries like Saudi Arabia, UAE, and South Africa are key markets, driven by large-scale industrial projects and the need for energy optimization in resource-intensive sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Low Voltage Drives Market.- ABB Ltd.

- Siemens AG

- Schneider Electric SE

- Danfoss A/S

- Rockwell Automation, Inc.

- Yaskawa Electric Corporation

- Mitsubishi Electric Corporation

- Eaton Corporation plc

- Fuji Electric Co., Ltd.

- WEG S.A.

- Nidec Corporation

- Emerson Electric Co.

- Hitachi, Ltd.

- Lenze SE

- Parker Hannifin Corporation

- Delta Electronics, Inc.

- Inovance Technology

- Vacon (now part of Danfoss)

- Keb Automation KG

- GE Digital

Frequently Asked Questions

What are Low Voltage Drives and why are they important?

Low Voltage Drives, often called Variable Frequency Drives (VFDs) or Adjustable Speed Drives (ASDs), are electronic devices that control the speed and torque of AC motors by varying the frequency and voltage of their power supply. They are crucial for improving energy efficiency, optimizing industrial processes, and extending the lifespan of motor-driven equipment across various sectors.

How do Low Voltage Drives contribute to energy savings?

Low Voltage Drives save energy by allowing motors to operate only at the speed and torque required for a specific process, rather than constantly running at full speed. This precise control significantly reduces wasted energy, especially in applications like pumps and fans where demand fluctuates, leading to substantial electricity cost reductions.

Which industries are the primary users of Low Voltage Drives?

Low Voltage Drives are widely used across numerous industries including water and wastewater treatment, oil and gas, power generation, metals and mining, food and beverages, pulp and paper, textiles, automotive, and building automation for HVAC systems, due to their universal application in motor control.

What are the key technological trends influencing the Low Voltage Drives market?

Key technological trends include the integration of AI and machine learning for predictive maintenance and self-optimization, the adoption of Wide Bandgap (WBG) semiconductors (SiC, GaN) for higher efficiency and smaller sizes, enhanced connectivity through IIoT and industrial communication protocols, and advanced control algorithms like Vector Control and DTC.

What is the projected growth rate for the Low Voltage Drives market?

The Low Voltage Drives market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032, driven by increasing industrial automation, global energy efficiency mandates, and technological advancements.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Low Voltage Drives Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Automotive Low Voltage Drives Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager