Machine Control Systems Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429804 | Date : Nov, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Machine Control Systems Market Size

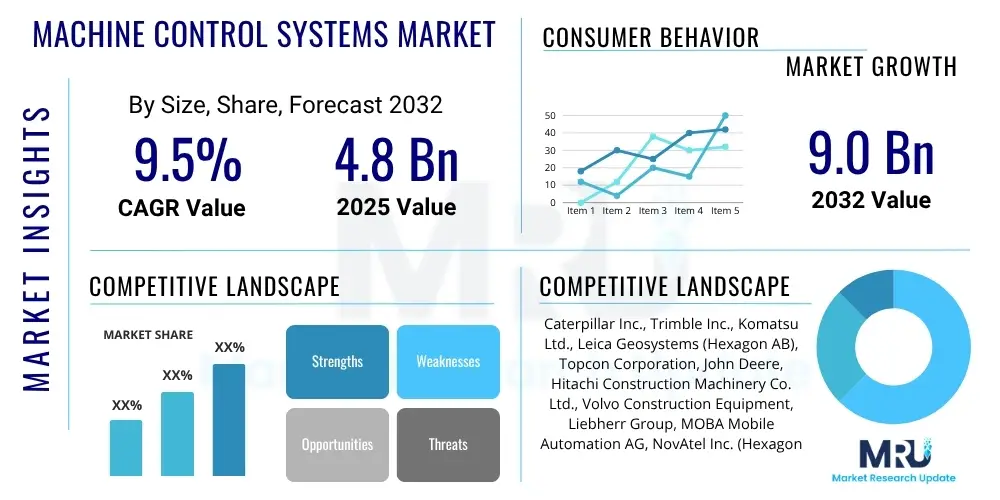

The Machine Control Systems Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2025 and 2032. The market is estimated at USD 4.8 billion in 2025 and is projected to reach USD 9.0 billion by the end of the forecast period in 2032.

Machine Control Systems Market introduction

The Machine Control Systems Market encompasses advanced technologies designed to enhance the precision, efficiency, and productivity of heavy machinery across various industries. These systems integrate hardware components such as GNSS receivers, total stations, sensors, and displays with sophisticated software to guide equipment operations automatically or semi-automatically. This technological convergence minimizes human error, optimizes material usage, and significantly reduces operational costs, offering a substantial return on investment for end-users.

Machine control systems are primarily utilized in applications requiring high positional accuracy, such as excavation, grading, paving, drilling, and piling. Key benefits include improved accuracy, leading to less rework and material waste; increased productivity through faster, more consistent operations; enhanced safety by reducing manual interaction in hazardous environments; and better data collection for project management and analysis. The market's growth is predominantly driven by the surging demand for infrastructure development globally, rapid technological advancements in automation and IoT, and the increasing adoption of digital construction methods to address skilled labor shortages and achieve environmental sustainability goals.

Machine Control Systems Market Executive Summary

The Machine Control Systems Market is poised for substantial expansion, driven by global infrastructure investments and the imperative for operational efficiency. Business trends indicate a strong shift towards integrated digital solutions, cloud-based platforms, and subscription models for software and data services. Companies are focusing on developing user-friendly interfaces and modular systems that can be easily integrated across diverse machine fleets, addressing the varied needs of small and large enterprises alike. Strategic collaborations and mergers and acquisitions are also prevalent, as companies seek to expand their technological portfolios and market reach, fostering innovation in areas like real-time data analytics and predictive maintenance.

Regionally, North America and Europe continue to lead in adoption due to robust construction sectors and early embracement of advanced technologies. However, the Asia Pacific region is rapidly emerging as a significant growth engine, fueled by extensive urbanization projects, increasing industrialization, and government initiatives promoting smart infrastructure development. Latin America, the Middle East, and Africa are also expected to witness steady growth as their respective construction and mining sectors modernize and invest in productivity-enhancing solutions. Segment-wise, GNSS-based systems dominate due to their precision and versatility, while software and control units are seeing strong demand as the central intelligence of these sophisticated systems. The construction and mining industries remain the primary end-users, with agriculture showing promising growth through precision farming applications.

AI Impact Analysis on Machine Control Systems Market

User inquiries regarding the impact of Artificial Intelligence on Machine Control Systems frequently revolve around how AI can enhance automation, improve predictive capabilities, and optimize operational workflows. Key themes include the potential for AI to enable fully autonomous machinery, refine data analysis for better decision-making, and address challenges such as integration complexity and data security. Users are keen to understand the tangible benefits AI can deliver, such as increased efficiency, reduced fuel consumption, and improved safety, while also expressing concerns about the skills gap required for AI-driven systems and the initial investment costs associated with these advanced technologies. Expectations are high for AI to transform machine control from reactive adjustments to proactive, intelligent operations, making machinery smarter and more adaptive to dynamic work environments.

- AI enables predictive maintenance, forecasting equipment failures before they occur, minimizing downtime.

- Optimized route planning and task execution through AI algorithms reduce fuel consumption and wear-and-tear.

- Enhanced sensor fusion and data interpretation, leading to more accurate real-time machine guidance.

- Facilitates advanced automation, moving towards fully autonomous operation for tasks like excavation and grading.

- Supports real-time decision-making, allowing systems to adapt to changing ground conditions or project requirements.

- Improves safety by identifying potential hazards and autonomously taking corrective actions.

- Enables sophisticated data analytics for project management, progress tracking, and performance optimization.

- Personalized operator assistance and training through AI-driven interfaces and simulations.

- Streamlines data integration from various sources for comprehensive operational insights.

DRO & Impact Forces Of Machine Control Systems Market

The Machine Control Systems Market is significantly influenced by a confluence of driving forces, inherent restraints, and emerging opportunities, all shaped by broader impact forces. Key drivers include global infrastructure development initiatives, particularly in developing economies, which necessitate efficient construction methods to meet ambitious timelines and budget constraints. The escalating demand for higher precision and accuracy in construction and mining operations, coupled with the rising cost of labor and a persistent shortage of skilled operators, further propels the adoption of these automated systems. Additionally, environmental regulations pushing for reduced waste and optimized resource utilization incentivize businesses to invest in technologies that offer greater efficiency and control.

However, the market faces several restraints, prominently the high initial investment required for implementing sophisticated machine control systems, which can be a barrier for small and medium-sized enterprises. The complexity associated with integrating these advanced technologies into existing fleets and the need for specialized training for operators and technicians also present significant challenges. Furthermore, concerns regarding data security and privacy for the vast amounts of operational data collected by these systems, along with the potential for technology obsolescence, temper rapid adoption. Despite these challenges, substantial opportunities exist, particularly in the expansion of these systems into emerging applications such as precision agriculture and waste management, and the development of more affordable, modular, and user-friendly solutions tailored for diverse market segments.

Impact forces such as rapid technological advancements in GPS/GNSS, IoT, and AI are continuously reshaping the market landscape, fostering innovation and creating new capabilities. Economic cycles and government policies related to infrastructure spending and digital transformation play a critical role in influencing market demand. The increasing focus on sustainability and smart city initiatives worldwide also acts as a powerful external force, pushing the industry towards more intelligent and eco-friendly operational practices. Geopolitical stability and global supply chain resilience are also crucial impact forces affecting the availability of components and the overall cost structure of machine control systems, thereby influencing market dynamics.

Segmentation Analysis

The Machine Control Systems market is comprehensively segmented to provide a detailed understanding of its diverse components and applications. This segmentation allows for precise market analysis, identifying distinct growth drivers, competitive landscapes, and customer needs across various categories. The market is typically broken down by components, types of technology, specific applications, and the end-use industries it serves, reflecting the specialized nature of these advanced solutions. This granular view assists stakeholders in strategic planning and product development tailored to specific market niches.

- By Type

- 2D Machine Control Systems

- 3D Machine Control Systems

- GNSS-based Systems

- Total Station-based Systems

- Laser-based Systems

- By Component

- Sensors (Tilt, Ultrasonic, Rotation)

- Displays/Control Panels

- Control Units

- Software

- GPS/GNSS Receivers

- Communication Systems (Radio, Cellular)

- Cameras

- By Application

- Excavators

- Dozers

- Graders

- Scrapers

- Pavers

- Compactors

- Drilling and Piling Machines

- Forestry Equipment

- By Industry

- Construction

- Mining

- Agriculture

- Waste Management

- Marine and Offshore

- Road Building

- By Technology

- Telematics

- Internet of Things (IoT)

- Artificial Intelligence (AI) and Machine Learning (ML)

- Cloud-based Solutions

- Augmented Reality (AR) and Virtual Reality (VR)

Value Chain Analysis For Machine Control Systems Market

The value chain for the Machine Control Systems market is intricate, involving multiple stages from raw material sourcing to end-user deployment and after-sales support. Upstream activities begin with the procurement of critical components and raw materials, including advanced semiconductors, optical sensors, GNSS chipsets, high-resolution displays, and durable casings. Key suppliers in this segment include specialized electronics manufacturers, sensor technology developers, and precision engineering firms that provide the foundational elements required for system assembly. These suppliers often operate within a global network, highlighting the importance of resilient supply chains for manufacturers of machine control systems.

Midstream activities primarily involve the research, development, manufacturing, and assembly of the machine control systems. This stage focuses on integrating various hardware components with proprietary software, developing advanced algorithms for precise positioning and control, and ensuring the interoperability of systems with a wide range of heavy machinery. Significant investments in R&D are common among market players to innovate new features, improve accuracy, and enhance user experience. Manufacturing processes adhere to stringent quality standards to ensure durability and reliability in challenging operational environments, often involving complex calibration and testing procedures.

Downstream analysis covers the distribution, sales, installation, and after-sales services for machine control systems. Distribution channels are typically a mix of direct sales forces, specialized dealers, and partnerships with heavy equipment manufacturers. Direct sales allow for closer customer relationships and customized solutions, while dealer networks provide broader geographic reach and local support. Indirect channels, such as OEMs integrating these systems into their new machinery, are also crucial. Post-sales support, including training, technical assistance, maintenance, and software updates, is a critical value-added service that enhances customer satisfaction and ensures long-term system performance. The overall efficiency and effectiveness of this value chain are paramount for delivering high-quality, reliable machine control solutions to the end-users.

Machine Control Systems Market Potential Customers

Potential customers for Machine Control Systems span a broad spectrum of industries that rely on heavy machinery for precision tasks, seeking to optimize operational efficiency, reduce costs, and enhance project accuracy. The primary end-users are entities engaged in large-scale infrastructure projects, such as national and regional governments, public works departments, and private construction firms responsible for building roads, bridges, railways, and commercial complexes. These customers benefit immensely from the systems' ability to streamline earthmoving, grading, and paving operations, ensuring projects are completed on time and within budget with minimal rework.

Beyond general construction, the mining industry represents a significant customer base, where machine control systems are employed for precise drilling, excavation, and material handling in both open-pit and underground operations. Mining companies utilize these technologies to improve safety, increase extraction efficiency, and manage vast quantities of material more effectively. Agricultural enterprises, particularly large-scale farms, are also emerging as key buyers, leveraging machine control for precision agriculture applications such as automated steering, variable rate application, and yield mapping to optimize crop yields and resource usage. Additionally, specialized contractors in sectors like waste management, marine construction, and forestry are increasingly adopting these systems to enhance the productivity and accuracy of their respective machinery fleets, expanding the market's reach into diverse operational environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.8 billion |

| Market Forecast in 2032 | USD 9.0 billion |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Caterpillar Inc., Trimble Inc., Komatsu Ltd., Leica Geosystems (Hexagon AB), Topcon Corporation, John Deere, Hitachi Construction Machinery Co. Ltd., Volvo Construction Equipment, Liebherr Group, MOBA Mobile Automation AG, NovAtel Inc. (Hexagon AB), Wirtgen Group (John Deere), Eos Positioning Systems, Carlson Software, Sokkia (Topcon Corporation), Case Construction Equipment (CNH Industrial), Doosan Infracore, Magellan Navigation, LiuGong Machinery Co. Ltd., XCMG Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Machine Control Systems Market Key Technology Landscape

The technological landscape of the Machine Control Systems market is characterized by rapid innovation and integration of advanced digital solutions, significantly enhancing the precision and automation capabilities of heavy machinery. Core to these systems are high-precision Global Navigation Satellite Systems (GNSS), including GPS, GLONASS, Galileo, and BeiDou, which provide centimeter-level positioning accuracy crucial for tasks like grading and paving. The evolution of GNSS technology, incorporating real-time kinematic (RTK) and network RTK corrections, has been pivotal in achieving the stringent accuracy requirements of modern construction and mining operations. This foundational technology is continually being refined with multi-constellation and multi-frequency receivers to improve signal robustness and availability in challenging environments.

Beyond GNSS, the market leverages a suite of complementary technologies. Inertial Measurement Units (IMUs) are increasingly integrated to provide highly stable and accurate orientation data, compensating for machine movements and vibrations, especially when GNSS signals are obstructed. LiDAR (Light Detection and Ranging) and 3D laser scanners are employed for highly accurate terrain mapping and real-time obstacle detection, generating detailed digital elevation models that guide machine operations. Telematics and the Internet of Things (IoT) play a crucial role in connecting machines, operators, and project managers, enabling real-time data exchange, remote monitoring, diagnostic capabilities, and predictive maintenance. This connectivity facilitates comprehensive fleet management and operational insights, transforming raw data into actionable intelligence.

Furthermore, the integration of Artificial Intelligence (AI) and Machine Learning (ML) algorithms is pushing the boundaries of autonomy and operational efficiency. AI is utilized for optimizing task execution, automating complex movements, and performing predictive analytics to prevent downtime and enhance safety. Cloud computing platforms support the vast data processing and storage needs, enabling collaborative project management and accessible data analysis from anywhere. The growing adoption of Augmented Reality (AR) in cab displays provides operators with enhanced visualization of design plans overlaid on the real-world environment, improving situational awareness and operational accuracy. These technological advancements collectively drive the market towards fully autonomous, intelligent, and highly efficient heavy machinery operations.

Regional Highlights

- North America

North America stands as a dominant force in the Machine Control Systems Market, largely due to its advanced technological infrastructure and a strong emphasis on automation across the construction, mining, and agriculture sectors. The region has been an early adopter of precision technologies, driven by a desire to optimize project timelines, mitigate labor shortages, and adhere to stringent safety and environmental regulations. Extensive investments in public and private infrastructure projects, coupled with a robust residential and commercial construction pipeline, continuously fuel the demand for sophisticated machine control solutions.

The presence of major market players and a culture of innovation contribute significantly to the market's maturity. Government initiatives promoting digital transformation in construction, such as Building Information Modeling (BIM) mandates, further accelerate the integration of these systems. The widespread adoption of telematics and IoT in fleet management, alongside a growing interest in autonomous heavy equipment, positions North America at the forefront of technological advancement in this domain.

- Europe

Europe represents another significant market for Machine Control Systems, characterized by a strong focus on high-quality engineering, sustainability, and technological integration. Countries such as Germany, the UK, and the Nordic nations are leaders in adopting these systems, primarily driven by strict environmental policies, a demand for sustainable construction practices, and an aging workforce that necessitates greater automation. The region's mature construction and infrastructure sectors, coupled with significant investments in renewable energy projects, create a consistent demand for precision equipment.

European market growth is also propelled by the increasing penetration of smart farming practices, where machine control systems enhance efficiency and reduce resource consumption in agricultural operations. The collaborative ecosystem between research institutions, technology providers, and end-users fosters continuous innovation, leading to specialized solutions tailored for various regional needs. Furthermore, strong regulatory frameworks and the European Union's digitalization agenda ensure that the market continues to evolve towards more integrated and data-driven solutions.

- Asia Pacific (APAC)

The Asia Pacific region is rapidly emerging as the fastest-growing market for Machine Control Systems, fueled by unprecedented rates of urbanization, industrialization, and massive government investments in infrastructure development. Countries like China, India, Japan, and Australia are undertaking mega-projects in transportation, energy, and commercial construction, which necessitate efficient and precise machinery. The burgeoning population and economic growth in these nations translate into a strong demand for advanced construction equipment and associated control systems.

The region benefits from increasing awareness regarding the long-term cost benefits of adopting automation, along with a growing emphasis on improving construction quality and project delivery timelines. While initial adoption rates might have been slower compared to Western counterparts, the rapid pace of technological absorption, coupled with competitive pricing strategies by local and international players, is driving significant market expansion. The digital transformation initiatives spearheaded by governments and the rise of smart city projects further solidify APAC's position as a key growth hub for machine control technologies.

- Latin America

Latin America's Machine Control Systems Market is experiencing steady growth, primarily influenced by ongoing infrastructure development and significant investments in the mining sector. Countries such as Brazil, Mexico, and Chile are prominent in this region, with their economies heavily reliant on resource extraction and public works projects. The adoption of machine control systems is driven by the need to enhance productivity in challenging terrains, reduce operational costs, and improve safety standards in both mining and construction environments.

While initial adoption may be slower due to economic volatility and budget constraints, the long-term benefits of increased efficiency and precision are increasingly recognized. The market is also seeing growth through partnerships between international technology providers and local distributors, aiming to make these advanced solutions more accessible. As infrastructure spending continues and awareness of advanced technologies penetrates deeper into regional industries, Latin America is poised for sustained expansion in the machine control systems sector.

- Middle East and Africa (MEA)

The Middle East and Africa region presents a dynamic yet diverse landscape for the Machine Control Systems Market. The Middle East, particularly the GCC countries, is witnessing substantial growth due to ambitious mega-projects, including new cities, extensive infrastructure networks, and diversified economic development initiatives. These projects demand high levels of precision and efficiency, making machine control systems indispensable. Significant government investments in diversifying economies away from oil also contribute to a robust construction pipeline.

In Africa, growth is more gradual but consistent, driven by infrastructure development projects, increasing mining activities, and agricultural modernization efforts. Challenges such as political instability, limited infrastructure, and a nascent technological ecosystem can restrain growth, but the long-term potential remains strong as economies mature. International companies are increasingly targeting these markets, offering tailored solutions and training programs to overcome regional specificities, aiming to capitalize on the vast untapped potential for automation and digital transformation in construction and resource management.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Machine Control Systems Market.- Caterpillar Inc.

- Trimble Inc.

- Komatsu Ltd.

- Leica Geosystems (Hexagon AB)

- Topcon Corporation

- John Deere

- Hitachi Construction Machinery Co. Ltd.

- Volvo Construction Equipment

- Liebherr Group

- MOBA Mobile Automation AG

- NovAtel Inc. (Hexagon AB)

- Wirtgen Group (John Deere)

- Eos Positioning Systems

- Carlson Software

- Sokkia (Topcon Corporation)

- Case Construction Equipment (CNH Industrial)

- Doosan Infracore

- Magellan Navigation

- LiuGong Machinery Co. Ltd.

- XCMG Group

Frequently Asked Questions

What are Machine Control Systems?

Machine Control Systems are advanced technologies that integrate hardware and software to guide heavy machinery with high precision. They use sensors, GPS/GNSS, and design data to automate or assist tasks like grading, excavation, and paving, improving accuracy and efficiency.

Which industries primarily use Machine Control Systems?

The primary industries utilizing Machine Control Systems include construction, mining, and agriculture. They are also increasingly adopted in waste management, road building, and marine construction for enhanced operational precision.

How do Machine Control Systems benefit construction projects?

Machine Control Systems significantly benefit construction projects by increasing accuracy, reducing rework, optimizing material usage, improving productivity, and enhancing site safety. They lead to faster project completion and lower overall costs.

What is the role of AI in Machine Control Systems?

AI in Machine Control Systems enables advanced automation, predictive maintenance, real-time decision-making, and optimized task execution. It enhances sensor data interpretation and facilitates fully autonomous machine operations, boosting efficiency and safety.

What are the key components of a Machine Control System?

Key components include GNSS receivers, total stations, sensors (e.g., tilt, laser), displays/control panels, control units, and specialized software. Communication systems and cameras are also integral for data exchange and situational awareness.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager