Magnetic Reed Proximity Sensors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427268 | Date : Oct, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Magnetic Reed Proximity Sensors Market Size

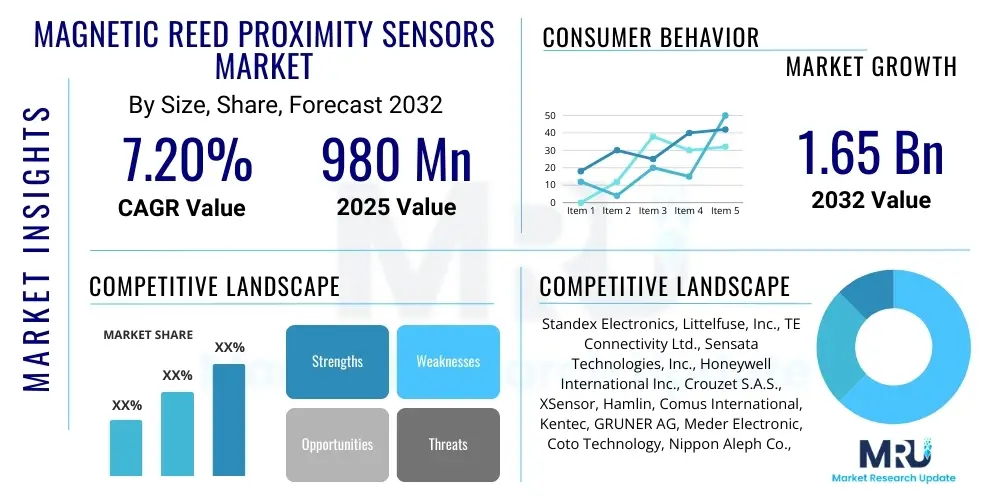

The Magnetic Reed Proximity Sensors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2025 and 2032. The market is estimated at USD 980 million in 2025 and is projected to reach USD 1.65 billion by the end of the forecast period in 2032. This growth is underpinned by increasing industrial automation, the expanding automotive sectors demand for reliable position sensing, and the pervasive integration of these sensors into various consumer electronics and security systems. The inherent durability and cost-effectiveness of magnetic reed proximity sensors continue to drive their adoption across diverse industries, ensuring a steady upward trajectory in market valuation.

Magnetic Reed Proximity Sensors Market introduction

The Magnetic Reed Proximity Sensors Market encompasses devices that detect the presence or absence of a magnetic field without physical contact, typically leveraging a hermetically sealed reed switch. These sensors consist of two ferromagnetic reeds enclosed in a glass tube, which, when exposed to a magnetic field, become magnetized and attract each other, completing an electrical circuit. This simple yet highly effective principle allows for reliable and long-lasting operation in challenging environments, making them a preferred choice for numerous applications requiring robust and precise position sensing.

The core product description highlights their non-contact operation, which minimizes wear and tear, leading to an extended operational lifespan. Major applications span industrial automation for position and limit sensing, the automotive industry for seatbelt buckles and gear position detection, security systems for door and window contacts, and a multitude of consumer electronics, including washing machines and refrigerators, for lid or door closure detection. The fundamental benefits of these sensors include their exceptional reliability, resistance to harsh environmental conditions such, as dust, dirt, and moisture due to their sealed nature, energy efficiency, and cost-effectiveness compared to more complex sensing technologies.

Driving factors propelling the markets expansion include the escalating global trend towards industrial automation and smart manufacturing, where accurate and durable proximity sensing is crucial for operational efficiency and safety. Furthermore, the burgeoning Internet of Things (IoT) ecosystem increasingly relies on simple, robust sensors for data collection and system control. The automotive sectors continuous innovation, particularly in electric vehicles and advanced driver-assistance systems (ADAS), also fuels demand for dependable position sensors. Additionally, the growing adoption of smart home technologies and security solutions contributes significantly to the markets sustained growth, solidifying the reed proximity sensors role as a foundational component in modern technological landscapes.

Magnetic Reed Proximity Sensors Market Executive Summary

The Magnetic Reed Proximity Sensors Market is experiencing dynamic business trends, characterized by a persistent drive towards miniaturization and enhanced integration capabilities, allowing these sensors to be incorporated into increasingly compact and sophisticated devices. Manufacturers are focusing on developing more specialized, application-specific designs that offer improved performance metrics such as faster response times and higher sensitivity, while also exploring new materials for increased durability and reliability in extreme operational conditions. There is a growing emphasis on smart sensor solutions that can seamlessly interface with digital control systems, contributing to the broader smart factory and smart home initiatives. The competitive landscape is marked by continuous innovation in manufacturing processes aimed at reducing costs and improving production efficiency, ensuring that these sensors remain a highly viable option against alternative sensing technologies, and fostering a robust market environment focused on both technological advancement and economic viability.

From a regional perspective, the Asia-Pacific region continues to emerge as a dominant force, primarily due to its expansive manufacturing base and rapid industrialization, particularly in countries like China, India, Japan, and South Korea, which are major producers and consumers of electronic components and automated machinery. Europe exhibits robust demand driven by its mature automotive industry and high adoption rates of industrial automation within its advanced manufacturing sectors, with Germany leading in precision engineering applications. North America is experiencing steady growth, propelled by significant investments in advanced manufacturing technologies, smart infrastructure projects, and a strong presence of key technology developers and early adopters of IoT solutions. Emerging markets in Latin America, the Middle East, and Africa are also showing promising growth, fueled by increasing foreign direct investment in manufacturing and infrastructure development, which necessitates reliable and cost-effective sensing solutions across various burgeoning sectors.

Segmentation trends reveal significant growth within the industrial automation segment, driven by the imperative for enhanced precision, safety, and efficiency in manufacturing processes. The automotive segment is also witnessing substantial expansion, particularly with the proliferation of electric vehicles and the increasing complexity of in-car systems requiring reliable position feedback. In terms of product types, normally open (NO) and normally closed (NC) configurations remain foundational, but advancements are leading to more sophisticated latching and programmable variants that offer greater flexibility. Material innovations are focusing on improving the hermetic sealing and longevity of reed switches, while the integration of these sensors into complete modules with accompanying electronics is becoming a key trend, offering easier implementation for system designers and end-users. These trends collectively underscore a market that is evolving to meet diverse and growing industrial and consumer needs, emphasizing adaptability and integration.

AI Impact Analysis on Magnetic Reed Proximity Sensors Market

Users frequently inquire about how Artificial Intelligence (AI) can enhance the capabilities and applications of traditional Magnetic Reed Proximity Sensors, especially concerning data processing, predictive maintenance, and seamless integration into intelligent automation systems. Common themes revolve around the potential for AI to interpret sensor data more effectively for condition monitoring, optimize system performance by predicting failures, and facilitate advanced decision-making in autonomous environments. There is significant interest in understanding how AI can overcome some of the inherent limitations of simple binary sensors, transforming them into more dynamic and intelligent components within a broader smart ecosystem. Users also express expectations regarding AIs role in improving the diagnostic capabilities and overall efficiency of systems that rely on these foundational sensors, thereby extending their utility and value in contemporary industrial and consumer applications.

- AI can analyze data from reed sensors to identify patterns indicative of impending mechanical failures, enabling predictive maintenance.

- Integration with AI-driven control systems allows for more adaptive and efficient process automation based on real-time sensor inputs.

- AI can filter out anomalous sensor readings, improving the reliability and accuracy of proximity detection in complex environments.

- Enhanced diagnostic capabilities through AI allow for rapid identification of sensor malfunctions or system deviations.

- Optimization of energy consumption in systems by AI, based on the operational states reported by reed sensors.

- Facilitates human-machine interaction by leveraging sensor data for context-aware responses in smart environments.

- Enables advanced anomaly detection for security applications, discerning between routine and suspicious activities.

DRO & Impact Forces Of Magnetic Reed Proximity Sensors Market

The Magnetic Reed Proximity Sensors Market is significantly influenced by a confluence of drivers, restraints, and opportunities, alongside broader market impact forces that shape its trajectory. Key drivers include the relentless global push for industrial automation, where these sensors provide reliable and cost-effective position and limit sensing critical for efficient manufacturing processes. The robust growth of the automotive sector, particularly with the advancements in electric vehicles and the increasing demand for safety features requiring precise sensing, further propels market expansion. Moreover, the enduring need for simple, durable, and energy-efficient non-contact switching solutions across various consumer and commercial applications underpins sustained demand. These factors collectively create a strong foundation for the markets continued upward growth, highlighting the irreplaceable role of these sensors in modern technological infrastructure.

However, the market also faces notable restraints that could temper its growth. The primary challenge stems from intense competition from alternative sensing technologies, such as Hall effect sensors, inductive sensors, and optical sensors, which often offer different advantages in terms of sensitivity, range, or integration complexity. Price sensitivity, particularly in high-volume consumer electronics markets, can also limit the adoption of more advanced or specialized reed sensor configurations. Additionally, the inherent limitations in sensing range and the binary nature of standard reed switches mean they may not be suitable for applications requiring continuous or highly precise analog measurement, thereby restricting their market penetration in certain high-end segments. Overcoming these competitive and technical limitations is crucial for sustained market leadership, compelling manufacturers to innovate constantly.

Despite these challenges, substantial opportunities exist for market expansion and innovation. The miniaturization of reed switches and the development of more compact sensor packages open new avenues in space-constrained applications, such as wearables and compact medical devices. The integration of magnetic reed sensors with intelligent electronics, enabling smart features and enhanced data processing capabilities, presents a significant opportunity to create more value-added solutions within the broader IoT ecosystem. Furthermore, the exploration of new materials and manufacturing techniques can lead to improved performance characteristics, such as higher switching speeds, increased current handling, and superior environmental resilience. Emerging markets, particularly in rapidly industrializing regions, offer untapped potential for widespread adoption as infrastructure and manufacturing capabilities continue to develop. These opportunities underscore a dynamic market environment ripe for innovation and strategic growth, leveraging foundational technology in new and advanced ways.

Segmentation Analysis

The Magnetic Reed Proximity Sensors Market is meticulously segmented to provide a comprehensive understanding of its diverse landscape and growth dynamics across various dimensions. These segmentations are critical for analyzing market trends, identifying lucrative niches, and formulating targeted business strategies. The categorization by type differentiates between normally open, normally closed, and latching configurations, reflecting distinct operational characteristics crucial for specific application requirements. Segmentation by application highlights the primary end-use industries, such as industrial automation, automotive, and consumer electronics, showcasing where these sensors provide the most significant value. Further breakdowns by end-user industry and material composition offer deeper insights into the specific needs and preferences of different market participants, enabling a granular view of the markets structure and potential for expansion in various sectors.

- By Type:

- Normally Open (NO)

- Normally Closed (NC)

- Latching

- By Application:

- Industrial Automation

- Automotive

- Consumer Electronics

- Medical Devices

- Security Systems

- White Goods

- HVAC Systems

- By End-User Industry:

- Manufacturing

- Automotive Assembly

- Building Automation

- Healthcare

- Consumer Appliance Manufacturing

- Energy & Utilities

- By Material:

- Glass (for reed encapsulation)

- Noble Metal (for contact plating, e.g., Rhodium, Ruthenium)

- Ferromagnetic Alloys (for reeds)

Magnetic Reed Proximity Sensors Market Value Chain Analysis

The value chain for the Magnetic Reed Proximity Sensors Market begins with the upstream analysis, which involves the sourcing of fundamental raw materials and specialized components essential for sensor manufacturing. This phase includes suppliers of high-purity glass for the hermetic encapsulation of reed switches, ferromagnetic alloys for the reed contacts themselves, and precious metals like rhodium or ruthenium for contact plating, crucial for ensuring reliability and longevity. Additionally, manufacturers of permanent magnets, which serve as the activating element for these sensors, are integral to this initial stage. The quality and availability of these specialized materials directly impact the performance and cost-effectiveness of the final sensor product, making supplier relationships and material innovation critical components of the upstream segment.

Moving downstream, the value chain progresses through the manufacturing and assembly processes, where raw reed switches are integrated into finished sensor packages, often incorporating additional circuitry, housing, and cabling. These completed sensors are then channeled to market through various distribution channels, which include both direct and indirect approaches. Direct distribution involves manufacturers selling directly to original equipment manufacturers (OEMs) or large industrial clients, fostering close relationships and often providing customized solutions. Indirect channels, on the other hand, rely on a network of distributors, wholesalers, and system integrators who aggregate products from multiple manufacturers and supply them to a broader customer base, including smaller businesses and end-users. Online marketplaces and e-commerce platforms are increasingly becoming significant indirect channels, offering greater reach and accessibility to a diverse clientele.

The final stage of the value chain involves the end-users who integrate these proximity sensors into their applications and products across diverse industries. This includes industrial automation companies utilizing them for machinery control, automotive manufacturers incorporating them into vehicles for safety and functional purposes, and consumer electronics companies deploying them in appliances. System integrators play a crucial role by combining reed sensors with other components to create complete solutions for specific applications, adding value through expertise and customization. Effective management of the entire value chain, from raw material procurement to end-user deployment, ensures efficient production, timely delivery, and responsive customer support, all of which are vital for maintaining competitive advantage and fostering market growth.

Magnetic Reed Proximity Sensors Market Potential Customers

Potential customers for Magnetic Reed Proximity Sensors span a broad spectrum of industries, driven by the inherent reliability, durability, and cost-effectiveness of these sensing solutions. In the industrial sector, manufacturing plants, automation system integrators, and machinery builders are primary end-users, requiring these sensors for precise position detection in assembly lines, conveyor systems, robotic arms, and safety interlocks. The ability of reed sensors to operate reliably in harsh industrial environments, often exposed to dust, moisture, and vibrations, makes them invaluable for ensuring operational efficiency and machine safety, directly contributing to streamlined production processes and reduced downtime across various manufacturing verticals.

The automotive industry represents another significant customer segment, where magnetic reed proximity sensors are extensively used for a multitude of applications. These include detecting seatbelt buckle engagement, monitoring door and trunk closure, sensing gear position in transmissions, and various other safety and convenience features within vehicles. As the automotive sector continues its evolution towards electric vehicles (EVs) and advanced driver-assistance systems (ADAS), the demand for robust and dependable sensors that can withstand vehicle operating conditions and contribute to overall system reliability is steadily increasing, positioning these sensors as essential components in modern automotive design and engineering.

Beyond industrial and automotive applications, a diverse array of other sectors constitute important customer bases. This includes manufacturers of consumer electronics and white goods, such as refrigerators, washing machines, and dishwashers, where reed sensors are used for lid or door closure detection, water level sensing, and safety cut-offs. The security industry relies on them for door and window contact sensors in alarm systems. Furthermore, HVAC (heating, ventilation, and air conditioning) system manufacturers use them for damper position feedback, while medical device manufacturers integrate them into equipment requiring reliable contact-less sensing. This wide-ranging adoption underscores the versatility and foundational utility of magnetic reed proximity sensors across a multitude of end-use applications, indicating a broad and sustained customer demand.

Magnetic Reed Proximity Sensors Market Key Technology Landscape

The key technology landscape of the Magnetic Reed Proximity Sensors Market is fundamentally centered around the advanced design and manufacturing of the hermetically sealed reed switch itself, which forms the core of these sensors. This involves meticulous engineering in creating the glass envelope to ensure a robust, vacuum-sealed or inert gas-filled environment, protecting the internal contacts from contamination and oxidation. Innovations in this area focus on developing stronger and more durable glass compositions capable of withstanding extreme temperatures and mechanical stresses, enhancing the sensors longevity and reliability in diverse operating conditions. The integrity of this hermetic seal is paramount to the sensors performance, preventing environmental degradation and ensuring consistent electrical contact over millions of cycles.

Another critical technological aspect lies in the composition and plating of the reed contacts. Modern reed switches often utilize high-quality ferromagnetic alloys for the reeds, which are then coated with noble metals such as rhodium, ruthenium, or iridium. These precious metal platings are essential for achieving low contact resistance, minimizing arc erosion during switching, and significantly extending the operational life of the switch. Ongoing research aims at developing new contact materials and plating techniques that can further improve current handling capabilities, reduce bounce, and increase switching speeds, making the sensors suitable for more demanding and high-frequency applications. These advancements are crucial for maintaining the competitive edge of reed sensors against alternative technologies.

Beyond the core reed switch, the broader technological landscape encompasses miniaturization techniques, allowing for the integration of these sensors into increasingly compact devices and complex assemblies without compromising performance. Surface-mount technology (SMT) integration of reed switches into printed circuit boards (PCBs) is also a significant trend, enabling more efficient manufacturing and space-saving designs. Furthermore, advancements in permanent magnet technology, which serves as the activating element for these sensors, directly influence their sensitivity and activation distance. The development of specialized housing materials and encapsulation methods ensures enhanced protection against environmental factors like shock, vibration, and chemical exposure, extending their applicability in harsh industrial and automotive settings. The continuous evolution in these areas ensures that magnetic reed proximity sensors remain a versatile and essential component in modern sensing solutions, adapting to evolving industry requirements.

Regional Highlights

- Asia-Pacific (APAC): Dominates the market due to rapid industrialization, extensive manufacturing hubs in China, Japan, and South Korea, and increasing adoption of automation and consumer electronics. Significant investments in infrastructure and smart factory initiatives further bolster market growth.

- Europe: A mature market driven by the robust automotive industry, high demand for industrial automation, and stringent safety regulations. Germany, in particular, showcases strong adoption owing to its advanced engineering and manufacturing capabilities.

- North America: Exhibits steady growth, fueled by technological advancements, strong R&D investments, and widespread adoption of IoT and advanced manufacturing processes. The automotive and aerospace sectors are key contributors to demand.

- South America: An emerging market with growing industrialization and infrastructure development projects. Increased foreign investment in manufacturing is gradually boosting the demand for reliable sensing solutions.

- Middle East & Africa: Showing promising growth, primarily driven by investments in industrial diversification, smart city initiatives, and the development of new manufacturing capabilities, particularly in the UAE and Saudi Arabia.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Magnetic Reed Proximity Sensors Market.- Standex Electronics (Standex International Corporation)

- Littelfuse, Inc.

- TE Connectivity Ltd.

- Sensata Technologies, Inc.

- Honeywell International Inc.

- Crouzet S.A.S. (InnoVista Sensors)

- XSensor (Tekscan)

- Hamlin (Littelfuse, Inc.)

- Comus International

- Kentec (Cynergy3 Components Ltd.)

- GRUNER AG

- Meder Electronic (Standex Electronics)

- Coto Technology

- Nippon Aleph Co., Ltd.

- Pangolin Photoelectron

Frequently Asked Questions

Analyze common user questions about the Magnetic Reed Proximity Sensors market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are Magnetic Reed Proximity Sensors?

Magnetic Reed Proximity Sensors are non-contact sensing devices that detect the presence or absence of a magnetic field. They typically consist of a hermetically sealed reed switch that changes its electrical state (opens or closes) when a magnetic field is brought into proximity, providing a simple yet reliable method for position detection or limit switching in various applications. Their design ensures durability and longevity by protecting the internal contacts from environmental contaminants.

How do Magnetic Reed Proximity Sensors work?

These sensors operate on the principle of magnetic induction. Inside a sealed glass tube, two ferromagnetic reeds are positioned with a small gap between them. When a permanent magnet approaches the sensor, its magnetic field induces magnetism in the reeds, causing them to attract each other and make physical contact. This closes an electrical circuit, thereby changing the sensors output state. When the magnet is removed, the reeds spring apart, breaking the circuit, which makes them highly effective for binary detection.

What are the primary applications of these sensors?

Magnetic Reed Proximity Sensors find widespread use across numerous industries. Key applications include industrial automation for position sensing in machinery and robotic systems, automotive applications for seatbelt detection, door closure monitoring, and gear position sensing. They are also integral to consumer electronics and white goods for lid/door status, security systems as door/window contacts, and medical devices where reliable non-contact switching is essential. Their versatility stems from their durability and ability to function in diverse environments.

What are the main advantages of using Magnetic Reed Proximity Sensors?

The primary advantages of Magnetic Reed Proximity Sensors include exceptional reliability and a long operational lifespan due to their non-contact nature and hermetically sealed construction, which protects them from dust, moisture, and corrosion. They offer cost-effectiveness compared to many alternative sensing technologies, consume minimal power, and are simple to install and operate. Their robust design makes them suitable for harsh industrial environments, and they provide clear, stable electrical signals, making them an excellent choice for straightforward binary detection tasks.

How is AI impacting the Magnetic Reed Proximity Sensors Market?

AI is increasingly impacting the Magnetic Reed Proximity Sensors Market by enhancing their utility beyond simple binary switching. AI can analyze data streams from multiple reed sensors to enable predictive maintenance, anticipating equipment failures by identifying subtle patterns in operational data. It also facilitates smarter integration into complex automation systems, allowing for more adaptive control and optimized performance. While the sensors themselves remain fundamental, AI provides the intelligence layer to interpret their outputs more effectively, leading to more efficient, intelligent, and responsive systems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager