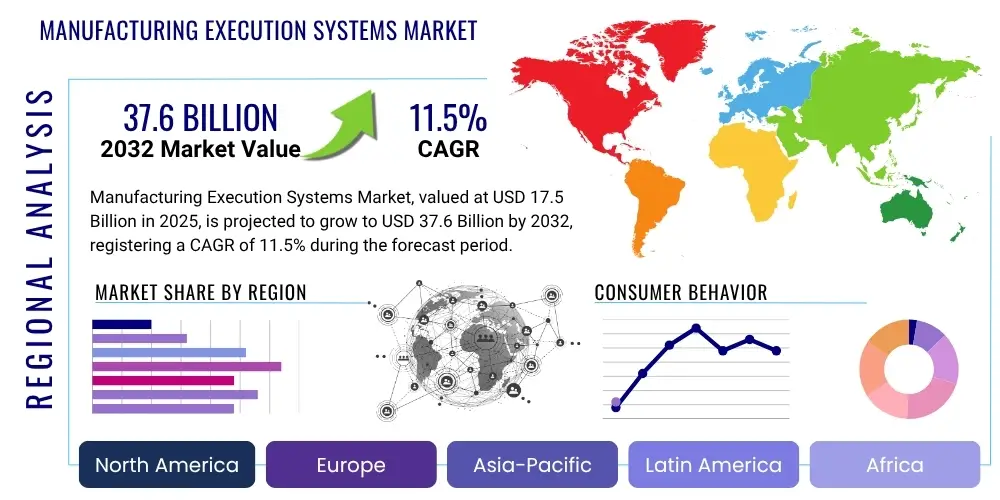

Manufacturing Execution Systems Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429170 | Date : Oct, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Manufacturing Execution Systems Market Size

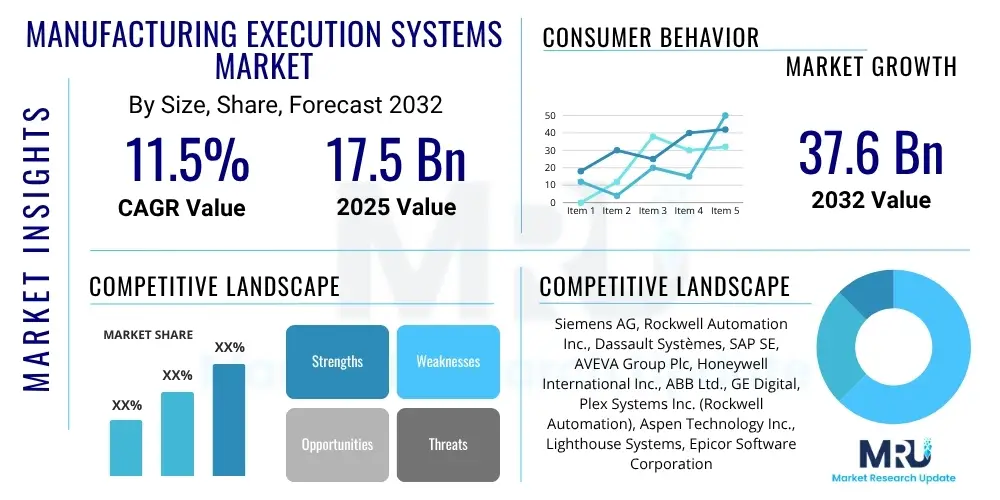

The Manufacturing Execution Systems Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 11.5% between 2025 and 2032. The market is estimated at USD 17.5 Billion in 2025 and is projected to reach USD 37.6 Billion by the end of the forecast period in 2032.

Manufacturing Execution Systems Market introduction

The Manufacturing Execution Systems (MES) market encompasses software and hardware solutions designed to monitor, track, document, and control the entire manufacturing process from raw materials to finished goods. An MES acts as a critical intermediary between enterprise resource planning (ERP) systems and process control systems, providing real-time data and functionalities that optimize production operations. Its primary objective is to enhance operational efficiency, reduce waste, improve product quality, and ensure regulatory compliance by offering a comprehensive view and control over shop floor activities. This integration facilitates better decision-making and responsiveness to dynamic production environments, bridging the gap between planning and execution.

Manufacturing Execution Systems are sophisticated information systems that connect, monitor, and control complex manufacturing processes and data flows on the factory floor. They manage various production elements, including work orders, equipment statuses, material tracking, and labor allocation, ensuring that production schedules are met efficiently and effectively. Product descriptions often highlight modularity, allowing businesses to implement specific functionalities such as production scheduling, quality management, data collection, and performance analysis as needed. These systems are crucial for achieving lean manufacturing principles and smart factory initiatives under the broader umbrella of Industry 4.0, enabling a higher degree of automation and data-driven operational intelligence across diverse industrial sectors.

Major applications of MES span across industries such as automotive, aerospace and defense, pharmaceuticals and biotechnology, food and beverage, chemicals, and consumer packaged goods. The benefits derived from implementing MES are substantial, including improved throughput, reduced lead times, enhanced inventory accuracy, real-time visibility into production, and better traceability for compliance and quality control. Key driving factors propelling market growth include the increasing adoption of Industry 4.0 technologies, the imperative for digital transformation, rising demand for operational efficiency and cost reduction, stringent regulatory requirements, and the growing complexity of global supply chains. These factors collectively underscore the vital role MES plays in modern manufacturing, enabling competitive advantages and sustainable growth.

Manufacturing Execution Systems Market Executive Summary

The Manufacturing Execution Systems (MES) market is currently experiencing robust growth, driven by an accelerating trend towards digital transformation and the widespread adoption of Industry 4.0 initiatives across global manufacturing sectors. Businesses are increasingly investing in MES solutions to gain real-time visibility into their production processes, enhance operational efficiency, and improve product quality while reducing overall production costs. A key business trend shaping the market is the shift towards cloud-based MES solutions, which offer greater scalability, flexibility, and reduced upfront infrastructure investments compared to traditional on-premise deployments. This transition is particularly appealing to small and medium-sized enterprises (SMEs) seeking to leverage advanced manufacturing capabilities without extensive capital expenditure, fostering broader market penetration and innovation in deployment models.

Regionally, the Asia Pacific (APAC) market is poised for significant expansion, fueled by rapid industrialization, increasing foreign direct investment in manufacturing, and government initiatives promoting smart factories in countries like China, India, and Japan. North America and Europe, while more mature markets, continue to demonstrate steady growth, driven by modernization efforts, the integration of advanced analytics, and a strong emphasis on regulatory compliance in sectors such as pharmaceuticals and aerospace. Latin America and the Middle East and Africa (MEA) are emerging markets, showing considerable potential due to nascent industrial growth and increasing awareness of the benefits associated with manufacturing digitalization. The competitive landscape reflects a blend of established global players and innovative regional vendors, all striving to offer comprehensive, integrated solutions that cater to specific industry requirements and technological advancements.

In terms of segmentation trends, the software segment continues to dominate, with a growing emphasis on modular and configurable solutions that can be tailored to diverse manufacturing environments. Services, including implementation, consulting, and maintenance, are also witnessing substantial demand as manufacturers seek expert guidance for successful MES deployment and optimization. From an industry perspective, discrete manufacturing (e.g., automotive, aerospace, industrial machinery) holds a larger market share due to its complex assembly processes and high demand for precision and traceability. However, process manufacturing (e.g., food and beverage, chemicals, pharmaceuticals) is experiencing accelerated adoption driven by strict regulatory mandates and the need for continuous process optimization. The overarching trend across all segments is the increasing integration of MES with other enterprise systems like ERP, PLM (Product Lifecycle Management), and SCM (Supply Chain Management) to create a truly interconnected and intelligent manufacturing ecosystem.

AI Impact Analysis on Manufacturing Execution Systems Market

Common user questions regarding AI's impact on Manufacturing Execution Systems (MES) often revolve around how AI can enhance efficiency, improve decision-making, and what practical applications exist for AI within MES. Users frequently inquire about AI's role in predictive maintenance, real-time anomaly detection, quality control, and optimizing production schedules. There is also significant interest in understanding the challenges associated with integrating AI into existing MES infrastructure, such as data privacy, system compatibility, and the need for specialized skillsets. Concerns often touch upon the return on investment (ROI) and the tangible benefits AI can deliver in tangible operational improvements and cost savings, underscoring a desire for clear, measurable outcomes and practical implementation guidance.

- AI-driven predictive maintenance significantly reduces equipment downtime by foreseeing potential failures.

- Enhanced real-time process optimization through AI algorithms leading to improved throughput and reduced waste.

- Advanced quality control systems leveraging AI for automated visual inspection and defect detection.

- Dynamic production scheduling and resource allocation, optimizing workloads and minimizing bottlenecks.

- Intelligent data analysis providing deeper insights into operational performance and root cause analysis.

- AI-powered augmented reality (AR) for technician assistance and training on the shop floor.

- Improved traceability and compliance through AI-assisted data validation and anomaly detection in production logs.

DRO & Impact Forces Of Manufacturing Execution Systems Market

The Manufacturing Execution Systems (MES) market is significantly shaped by a confluence of drivers, restraints, and opportunities, collectively acting as powerful impact forces. A primary driver is the accelerating adoption of Industry 4.0 and smart factory initiatives globally. Manufacturers are increasingly recognizing the necessity of digitalizing their operations to maintain competitiveness, leading to widespread investments in MES as the foundational layer for real-time production control and data integration. The relentless pursuit of operational efficiency, cost reduction, and improved product quality further fuels this demand, as MES solutions offer tangible benefits in these areas by optimizing resource utilization, minimizing waste, and streamlining production workflows. Moreover, stringent regulatory compliance requirements, particularly in industries like pharmaceuticals, food and beverage, and aerospace, necessitate robust traceability and data management capabilities that MES inherently provides, pushing manufacturers towards adoption.

Despite these strong drivers, the MES market faces several notable restraints. High initial implementation costs, encompassing software licenses, hardware upgrades, and extensive integration services, often deter smaller enterprises or those with limited capital budgets. The complexity involved in integrating MES with existing legacy systems (e.g., ERP, PLM, SCADA) poses a significant challenge, requiring substantial technical expertise and potentially disrupting ongoing operations during the transition phase. Furthermore, concerns regarding data security and privacy, especially with the rise of cloud-based MES and increased connectivity, represent a critical restraint. Manufacturers are apprehensive about protecting sensitive production data from cyber threats and ensuring compliance with evolving data protection regulations, leading to cautious adoption strategies and a demand for robust cybersecurity features within MES solutions.

Opportunities within the MES market are abundant and promising, driven largely by technological advancements and evolving industry needs. The growing trend towards cloud-based and Software-as-a-Service (SaaS) MES solutions offers significant growth potential, providing greater flexibility, scalability, and reduced total cost of ownership, making advanced MES accessible to a wider range of businesses. The increasing integration of Artificial Intelligence (AI) and Machine Learning (ML) capabilities into MES platforms presents a transformative opportunity, enabling predictive analytics, proactive maintenance, real-time optimization, and intelligent decision-making that can revolutionize manufacturing processes. Furthermore, the expansion of the Internet of Things (IoT) in manufacturing provides MES with unprecedented access to real-time data from shop floor equipment, sensors, and devices, creating opportunities for more precise monitoring, control, and automation. The rising demand for customized products and shorter product lifecycles also necessitates agile and responsive manufacturing systems, positioning MES as a crucial enabler for flexibility and rapid adaptation in production.

Segmentation Analysis

The Manufacturing Execution Systems (MES) market is comprehensively segmented to address the diverse needs and operational structures across various industries and business sizes. This segmentation allows for a detailed understanding of market dynamics, identifies specific growth opportunities, and helps solution providers tailor their offerings more effectively. The market is primarily analyzed across dimensions such as component, deployment model, enterprise size, industry vertical, and application. Each segment reflects unique characteristics in terms of adoption rates, technology preferences, and integration complexities, contributing to a granular view of the MES landscape and its evolutionary trajectory, especially as digital transformation continues to reshape global manufacturing paradigms.

- By Component:

- Software

- Services (Consulting, Implementation, Support & Maintenance)

- By Deployment Model:

- On-premise

- Cloud-based

- Hybrid

- By Enterprise Size:

- Large Enterprises

- Small and Medium-sized Enterprises (SMEs)

- By Industry Vertical:

- Discrete Manufacturing (Automotive, Aerospace & Defense, Industrial Machinery, Medical Devices, Electronics)

- Process Manufacturing (Chemicals, Food & Beverage, Pharmaceuticals & Biotechnology, Oil & Gas, Pulp & Paper)

- By Application:

- Production Process Management

- Quality Management

- Labor Management

- Inventory Management

- Data Collection & Acquisition

- Performance Analysis

- Maintenance Management

Value Chain Analysis For Manufacturing Execution Systems Market

The value chain for the Manufacturing Execution Systems (MES) market begins with upstream activities, primarily involving software developers, hardware component manufacturers, and technology providers specializing in industrial automation. Software developers are at the core, creating the sophisticated platforms and modular applications that constitute MES solutions, investing heavily in research and development to incorporate new technologies like AI, IoT, and cloud computing. Hardware vendors supply the necessary industrial computers, sensors, networking equipment, and HMI (Human Machine Interface) devices that facilitate data collection and interaction on the shop floor. Technology providers contribute specialized functionalities such as cybersecurity tools, data analytics engines, and integration middleware, forming the foundational technological building blocks upon which MES solutions are constructed. These upstream players often engage in strategic partnerships to ensure compatibility and comprehensive offerings.

Moving downstream, the value chain encompasses solution integrators, consultants, and value-added resellers (VARs) who play a critical role in delivering and customizing MES solutions to end-user specifications. Integrators are responsible for the complex task of integrating MES platforms with existing enterprise systems like ERP, PLM, and SCADA, ensuring seamless data flow and operational synergy. Consulting firms provide expert advice on system selection, process optimization, and change management, guiding manufacturers through their digital transformation journey. VARs, equipped with deep industry knowledge, not only sell MES software but also offer tailored services, localized support, and specialized training, making advanced MES solutions accessible to a broader market, particularly SMEs. This downstream segment is crucial for successful deployment and realizing the full benefits of MES investments.

Distribution channels for MES solutions are typically a mix of direct and indirect approaches. Direct sales involve MES vendors selling their solutions directly to large enterprises, often engaging in complex, long-term contracts that include extensive customization, implementation, and support services. This direct model allows vendors to build strong relationships with key clients and ensure alignment with their strategic objectives. Indirect channels leverage a network of system integrators, value-added resellers, and channel partners who extend the market reach of MES providers, especially into niche industries or geographical regions where direct presence might be limited. Cloud marketplaces are also emerging as significant indirect channels for SaaS-based MES solutions, offering simplified procurement and deployment models. The effectiveness of these channels is contingent on robust partner programs, comprehensive training, and continuous technical and sales support to ensure consistent service delivery and market penetration.

Manufacturing Execution Systems Market Potential Customers

The potential customers for Manufacturing Execution Systems (MES) span a wide array of industries that are heavily reliant on efficient and controlled production processes. These end-users, or buyers, primarily include manufacturing companies ranging from large multinational corporations to small and medium-sized enterprises (SMEs) that are seeking to optimize their operational performance, enhance product quality, and achieve greater regulatory compliance. Industries such as automotive, aerospace and defense, pharmaceuticals, food and beverage, chemicals, consumer packaged goods, and electronics represent significant customer bases due to their complex production lines, stringent quality requirements, and the necessity for detailed traceability and real-time data visibility. These sectors often face intense global competition and tight margins, making MES a crucial tool for maintaining a competitive edge.

Within these industries, the buyers of MES solutions are typically production managers, plant managers, operations directors, IT managers, and increasingly, chief digital officers (CDOs) or innovation leads. These stakeholders are primarily concerned with improving key performance indicators (KPIs) such as overall equipment effectiveness (OEE), throughput rates, defect rates, and inventory turns. They seek solutions that can integrate seamlessly with existing enterprise resource planning (ERP) systems and industrial control systems (SCADA, PLC), providing a unified platform for managing the entire production lifecycle. The decision to invest in an MES is often driven by strategic imperatives to adopt Industry 4.0 principles, implement lean manufacturing, or respond to market demands for greater product customization and faster time-to-market.

Furthermore, an expanding segment of potential customers includes contract manufacturers and specialized component producers who require sophisticated MES capabilities to manage diverse client specifications, fluctuating order volumes, and strict quality assurance protocols. Even small and medium-sized enterprises are becoming increasingly viable customers, particularly with the proliferation of cost-effective, cloud-based MES solutions that lower the barrier to entry. These SMEs are motivated by the desire to scale operations, comply with supply chain mandates from larger clients, and improve their competitiveness through enhanced efficiency and data-driven decision-making. The evolving landscape suggests that any manufacturing entity looking to move beyond manual processes and towards automated, data-centric, and intelligent production will be a potential customer for MES solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 17.5 Billion |

| Market Forecast in 2032 | USD 37.6 Billion |

| Growth Rate | 11.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, Rockwell Automation Inc., Dassault Systèmes, SAP SE, AVEVA Group Plc, Honeywell International Inc., ABB Ltd., GE Digital, Plex Systems Inc. (Rockwell Automation), Aspen Technology Inc., Lighthouse Systems, Epicor Software Corporation, QAD Inc., Eyelit Inc., Critical Manufacturing, Infor, Parsec Corporation, Andea Solutions, Savigent Software, Apriso (Dassault Systèmes) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Manufacturing Execution Systems Market Key Technology Landscape

The Manufacturing Execution Systems (MES) market is rapidly evolving, driven by the integration of several transformative technologies that enhance its capabilities and extend its reach. A cornerstone of this evolution is the widespread adoption of the Internet of Things (IoT). IoT devices, including sensors, smart machines, and connected tools, provide MES with a continuous stream of real-time operational data from the factory floor. This influx of granular data enables precise monitoring of equipment performance, environmental conditions, and material flow, facilitating immediate intervention and optimization. The ability of MES to leverage IoT data allows manufacturers to move from reactive to proactive strategies, particularly in maintenance and quality control, laying the groundwork for truly intelligent manufacturing environments.

Cloud computing and Software-as-a-Service (SaaS) models are fundamentally reshaping the deployment and accessibility of MES. Cloud-based MES offers unparalleled flexibility, scalability, and reduced infrastructure overheads, making advanced manufacturing capabilities available to a broader range of enterprises, including small and medium-sized businesses. This shift democratizes access to sophisticated MES functionalities, enabling quicker implementation, easier updates, and remote accessibility, which is crucial for distributed manufacturing operations and global supply chains. Furthermore, the robust computing power of the cloud supports the intensive data processing required for advanced analytics and artificial intelligence applications, making it an indispensable technological backbone for modern MES.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) stands as a pivotal advancement in the MES technology landscape. AI/ML algorithms analyze the vast datasets collected by MES, identifying patterns, predicting outcomes, and generating actionable insights that far surpass human analytical capabilities. This enables predictive maintenance, real-time quality anomaly detection, dynamic production scheduling optimization, and intelligent resource allocation. Digital Twins, virtual replicas of physical assets or processes, are also gaining traction. When integrated with MES, Digital Twins allow manufacturers to simulate various production scenarios, test changes, and predict performance before implementation, significantly reducing risks and improving efficiency. Concurrently, Big Data Analytics and Business Intelligence (BI) tools are becoming integral, providing dashboards and reports that translate complex operational data into digestible, actionable information for strategic decision-making, thus completing the technological ecosystem that defines contemporary MES solutions.

Regional Highlights

- North America: This region represents a mature MES market, characterized by early adoption of advanced manufacturing technologies and a strong presence of key industry players. Growth is primarily driven by the ongoing modernization of existing infrastructure, a robust push towards digital transformation in automotive, aerospace, and pharmaceutical sectors, and stringent regulatory compliance requirements that necessitate sophisticated traceability and data management systems. The market here is further propelled by substantial investments in research and development, particularly in integrating AI, IoT, and cloud solutions into MES platforms.

- Europe: Europe is another well-established market for MES, heavily influenced by initiatives like Industry 4.0 and smart factory mandates from the European Union. Countries such as Germany, the UK, and France are at the forefront of adopting MES solutions, especially in their highly automated automotive, machinery, and food and beverage industries. The region emphasizes sustainable manufacturing practices, high-quality production, and cybersecurity, leading to demand for MES solutions that can deliver on these complex requirements, often favoring integrated and comprehensive systems.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region in the MES market, fueled by rapid industrialization, burgeoning manufacturing sectors in China, India, and Southeast Asian countries, and increasing foreign direct investment. Government support for manufacturing digitalization, coupled with a growing awareness among local enterprises about the benefits of operational efficiency, drives substantial adoption. The region's diverse manufacturing base, from high-tech electronics to textiles, creates a vast opportunity for scalable and cost-effective MES solutions, with a particular interest in cloud-based deployments for quick implementation and flexibility.

- Latin America: The MES market in Latin America is in an emerging phase, with increasing adoption driven by industrial expansion and the modernization of manufacturing facilities, particularly in Brazil, Mexico, and Argentina. Manufacturers in this region are increasingly recognizing the need for greater efficiency and improved quality to compete on a global scale. While initial investments can be a barrier, the push towards adopting global manufacturing standards and optimizing supply chain operations is gradually increasing the demand for MES solutions, often starting with modular and essential functionalities.

- Middle East and Africa (MEA): MEA is another emerging market for MES, characterized by significant investments in industrial infrastructure and diversification away from reliance on oil and gas sectors. Countries like Saudi Arabia, UAE, and South Africa are leading the charge in digitalizing their manufacturing processes, driven by national visions for economic transformation and industrial growth. The demand for MES is growing in sectors such as chemicals, food processing, and defense, as enterprises seek to enhance operational visibility, improve asset utilization, and comply with international quality standards, though challenges related to digital infrastructure and skilled workforce remain.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Manufacturing Execution Systems Market.- Siemens AG

- Rockwell Automation Inc.

- Dassault Systèmes

- SAP SE

- AVEVA Group Plc

- Honeywell International Inc.

- ABB Ltd.

- GE Digital

- Plex Systems Inc. (Rockwell Automation)

- Aspen Technology Inc.

- Lighthouse Systems

- Epicor Software Corporation

- QAD Inc.

- Eyelit Inc.

- Critical Manufacturing

- Infor

- Parsec Corporation

- Andea Solutions

- Savigent Software

- Apriso (Dassault Systèmes)

Frequently Asked Questions

What is a Manufacturing Execution System (MES) and why is it important?

A Manufacturing Execution System (MES) is a comprehensive IT solution that manages, monitors, and synchronizes the real-time execution of manufacturing operations. It is crucial for bridging the gap between enterprise-level planning (ERP) and shop-floor control systems, providing vital data for improving operational efficiency, product quality, regulatory compliance, and overall production visibility. MES optimizes production flows, tracks materials, manages labor, and ensures equipment effectiveness, directly impacting a manufacturer's profitability and competitiveness.

How does MES contribute to Industry 4.0 and digital transformation?

MES is a foundational pillar of Industry 4.0, serving as the central nervous system for smart factories. It enables digital transformation by providing real-time data collection, analytics, and control over manufacturing processes, integrating various operational technologies (OT) with information technologies (IT). This integration facilitates automation, predictive analytics, and autonomous decision-making, supporting the creation of interconnected, intelligent, and flexi

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager