Marine Electrostatic Precipitator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429984 | Date : Nov, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Marine Electrostatic Precipitator Market Size

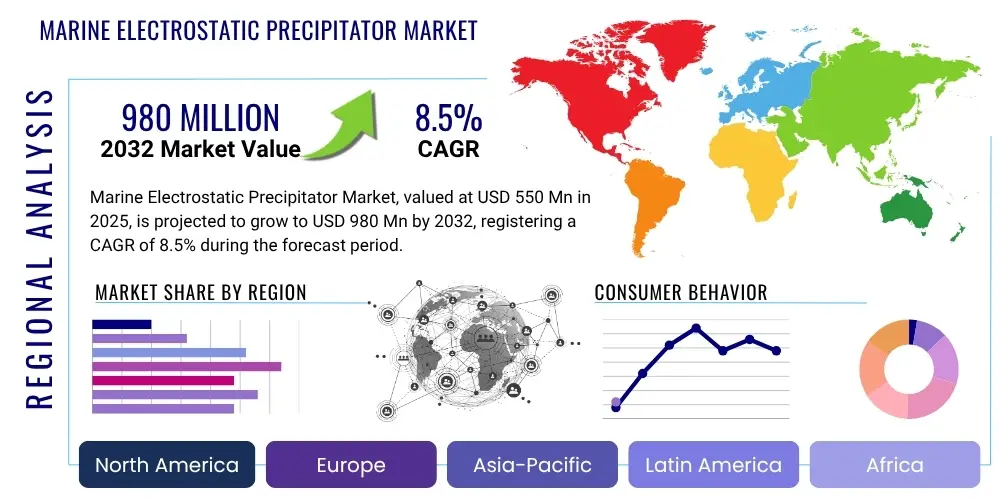

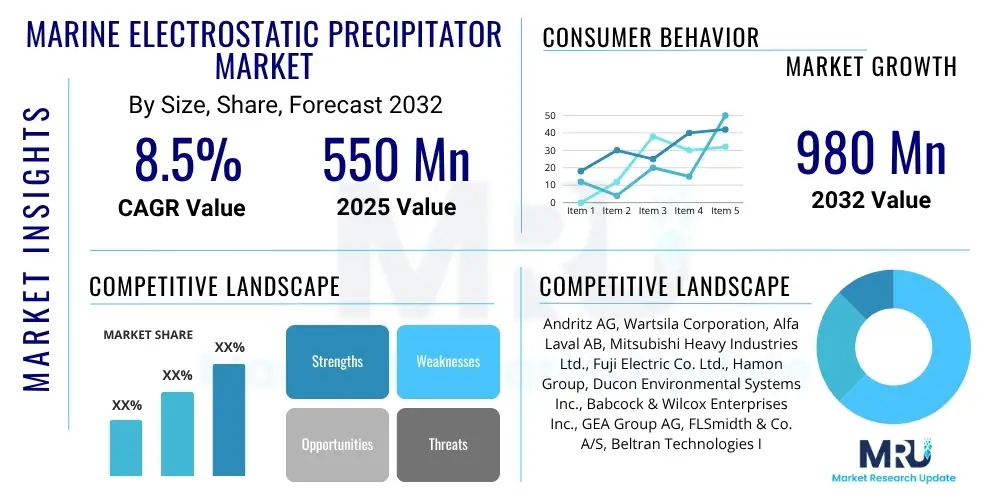

The Marine Electrostatic Precipitator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2025 and 2032. The market is estimated at $550 million in 2025 and is projected to reach $980 million by the end of the forecast period in 2032.

Marine Electrostatic Precipitator Market introduction

The Marine Electrostatic Precipitator (ESP) Market is experiencing significant growth driven by stringent global environmental regulations aimed at reducing air pollution from marine vessels. Marine ESPs are advanced air pollution control devices designed to remove fine particulate matter, including soot, ash, and unburnt hydrocarbons, from exhaust gases emitted by ship engines. These systems operate by electrically charging the particulate matter and then collecting it on oppositely charged plates, ensuring cleaner emissions into the atmosphere. The increasing demand for cleaner marine operations and the imperative to comply with international maritime organization (IMO) mandates are pivotal in shaping the market trajectory.

The primary function of a Marine ESP is to enhance air quality by drastically minimizing the discharge of harmful pollutants from marine engine exhaust. This technology is becoming indispensable across various maritime applications, ranging from large commercial cargo vessels and oil tankers to luxurious cruise ships and specialized offshore support vessels, as well as naval fleets. The benefits extend beyond regulatory compliance, encompassing improved vessel operational efficiency, reduced maintenance intervals for downstream exhaust components, and a positive environmental footprint. Key driving factors for this market include the growing global concern over climate change, the expansion of the global shipping fleet, and continuous technological advancements making ESP systems more compact, efficient, and cost-effective for marine installations.

Marine Electrostatic Precipitator Market Executive Summary

The Marine Electrostatic Precipitator market is undergoing a transformative phase, characterized by strong business trends focusing on innovation and sustainability. Manufacturers are investing heavily in research and development to produce more compact, modular, and energy-efficient ESP systems that can be easily integrated into both new builds and existing vessel retrofits. A notable business trend involves strategic partnerships and collaborations between ESP manufacturers, shipyards, and engine makers to offer integrated solutions, streamlining the installation and maintenance processes for vessel owners. Furthermore, there is a growing emphasis on smart ESP systems equipped with advanced monitoring and control capabilities to optimize performance and ensure continuous compliance.

Regionally, the market exhibits dynamic growth, with Asia Pacific emerging as a dominant region due to its expansive shipbuilding industry and large maritime fleet. Countries like China, South Korea, and Japan are at the forefront of adopting and manufacturing these technologies. Europe and North America also represent significant markets, driven by their proactive environmental policies and a strong push towards green shipping initiatives. These regions are witnessing increased retrofitting activities for older vessels to meet updated emissions standards. Segment-wise, the market is primarily driven by demand from commercial vessels, particularly container ships and bulk carriers, which constitute a large portion of global maritime traffic. The retrofit segment is expected to outpace new installations in the short term, fueled by the urgent need for older vessels to achieve compliance with current environmental regulations. The continuous evolution of regulatory landscapes globally remains a primary catalyst for sustained market expansion and technological innovation.

AI Impact Analysis on Marine Electrostatic Precipitator Market

User inquiries regarding the impact of Artificial Intelligence on the Marine Electrostatic Precipitator market frequently revolve around how AI can enhance operational efficiency, optimize maintenance schedules, and improve compliance monitoring. Common themes include the potential for AI algorithms to analyze real-time operational data for predictive maintenance, thereby reducing downtime and extending equipment lifespan. Users are also keen to understand how AI can fine-tune ESP performance parameters in response to varying engine loads and fuel types, ensuring optimal pollutant removal under diverse conditions. Furthermore, concerns about the integration complexity, data privacy, and the need for specialized AI expertise within the maritime sector are often raised, alongside expectations for AI to automate regulatory reporting and provide advanced diagnostics.

- AI driven predictive maintenance of ESP components, minimizing unplanned downtime and reducing operational costs.

- Real-time optimization of ESP operating parameters based on exhaust gas composition, vessel speed, and environmental conditions.

- Enhanced compliance monitoring through AI powered data analytics, automating reporting and alerting on potential deviations.

- Integration with broader vessel management systems for holistic energy efficiency and emissions control.

- Advanced fault detection and diagnostics, pinpointing issues with greater accuracy and recommending specific corrective actions.

- Development of self learning ESP systems that adapt to changes in fuel quality and engine performance over time.

DRO & Impact Forces Of Marine Electrostatic Precipitator Market

The Marine Electrostatic Precipitator market is profoundly influenced by a complex interplay of drivers, restraints, and opportunities, all shaped by significant impact forces. A primary driver is the escalating pressure from international and regional environmental regulations, notably the International Maritime Organization's (IMO) stringent limits on particulate matter and sulfur oxide emissions (IMO 2020 and beyond). This regulatory push compels vessel operators worldwide to adopt advanced exhaust gas cleaning technologies. Furthermore, the increasing global awareness of marine pollution and its impact on human health and ecosystems is fostering a corporate responsibility culture, prompting shipping companies to voluntarily invest in greener technologies. The continuous expansion of the global shipping fleet, driven by international trade, also contributes to a growing demand for effective emission control solutions for newbuilds and retrofits.

However, the market faces several formidable restraints. The high initial capital expenditure associated with purchasing and installing Marine ESP systems can be a significant deterrent for many vessel owners, especially for smaller operators or those with older fleets. The complexity of integrating these sophisticated systems into existing vessel infrastructure, coupled with the need for specialized maintenance expertise, further adds to the operational challenges. Space constraints on board various vessel types can also limit the feasibility of ESP installations, as these units can be bulky. Competition from alternative exhaust gas cleaning technologies, such as marine scrubbers (SOx scrubbers), presents another restraint, offering a different pathway to compliance that some operators might prefer based on cost or operational considerations.

Despite these challenges, substantial opportunities exist within the market. The significant retrofit market for the vast existing global fleet presents a continuous revenue stream as older vessels are upgraded to meet new regulations. Moreover, advancements in material science and modular design are leading to the development of more compact, lightweight, and efficient ESP systems that are easier to install and maintain, making them more appealing to a broader range of vessel types. The increasing demand for "green shipping" solutions and the potential for hybridization of ESPs with other emission control technologies, or their integration into smart vessel ecosystems, open avenues for innovation and market expansion. The development of next-generation ESPs that can handle diverse fuel types and variable engine loads will further enhance their appeal and broaden their application scope, capitalizing on emerging environmental demands.

Segmentation Analysis

The Marine Electrostatic Precipitator market is comprehensively segmented to provide a detailed understanding of its diverse components and drivers. These segments allow for a nuanced analysis of market dynamics, revealing specific growth areas and investment opportunities within the broader maritime environmental technology landscape. The segmentation typically considers the technological variations of ESP systems, their application across different vessel types, the lifecycle stage of the vessel (new build vs. retrofit), and the capacity of the ESP unit.

- By Type

- Dry Electrostatic Precipitator

- Wet Electrostatic Precipitator

- By Application

- Commercial Vessels

- Offshore Vessels

- Naval Vessels

- Cruise Ships

- Specialized Vessels

- By End User

- New Builds

- Retrofits

- By Capacity

- Small Capacity ESPs (less than 10,000 m3/h)

- Medium Capacity ESPs (10,000 to 50,000 m3/h)

- Large Capacity ESPs (greater than 50,000 m3/h)

Value Chain Analysis For Marine Electrostatic Precipitator Market

The value chain for the Marine Electrostatic Precipitator market encompasses a series of interconnected stages, from raw material sourcing to the final deployment and maintenance of the systems on marine vessels. Upstream activities involve suppliers of critical raw materials such as specialized metals (e.g., stainless steel, corrosion-resistant alloys), ceramics for insulators, and various electronic components for power supplies and control units. Component manufacturers then transform these materials into electrodes, collecting plates, high-voltage rectifiers, and control systems, which are essential building blocks of the ESP unit. These suppliers often specialize in high-precision engineering and materials science tailored for harsh marine environments.

Midstream in the value chain, manufacturers of Marine ESP systems assemble these components into complete units, conducting rigorous testing to ensure performance and compliance with maritime standards. This stage involves significant R&D to innovate designs, enhance efficiency, and reduce the footprint of the units. Downstream activities are centered around the installation, integration, and ongoing maintenance of the ESP systems. This includes shipyards, which install ESPs on new vessels, and marine service providers, who handle retrofits and provide after-sales support, including spare parts, troubleshooting, and scheduled maintenance for existing fleets. System integrators play a crucial role in ensuring seamless integration of ESPs with a vessel's existing exhaust and control systems.

Distribution channels for Marine ESPs are typically a mix of direct and indirect approaches. Major manufacturers often engage in direct sales to large shipping companies, naval forces, and prominent shipyards, allowing for customized solutions and direct technical support. Indirect channels involve collaboration with marine equipment distributors, third-party system integrators, and specialized marine engineering firms that can bundle ESP solutions with other maritime technologies or services. These indirect channels extend market reach, particularly to smaller vessel operators or regions where manufacturers do not have a direct presence, facilitating broader market penetration and ensuring comprehensive service delivery throughout the product lifecycle.

Marine Electrostatic Precipitator Market Potential Customers

The Marine Electrostatic Precipitator market serves a diverse range of potential customers, primarily comprising various entities within the global maritime industry that operate vessels requiring compliance with stringent environmental emission regulations. The core end-users and buyers of these advanced pollution control systems include major international shipping companies that operate large fleets of container ships, bulk carriers, oil tankers, and chemical tankers. These operators are under constant pressure to meet global and regional air quality standards, making ESPs a crucial investment for both new builds and the modernization of existing vessels. Their purchasing decisions are driven by regulatory compliance, operational efficiency, and a commitment to environmental stewardship.

Beyond commercial cargo transport, other significant customer segments include cruise line operators, who must maintain a high environmental image and adhere to strict emission limits, especially when operating in environmentally sensitive areas or near populous coastlines. Naval forces and coast guards also represent a notable customer base, requiring ESP systems for their diverse fleets to ensure compliance and reduce their environmental footprint during routine operations and deployments. Additionally, offshore drilling and support vessel operators, along with ferry and specialized vessel owners, constitute growing segments as environmental regulations increasingly extend to all types of marine activities, driving demand for tailored ESP solutions that can operate effectively under varied and often demanding conditions at sea. These customers prioritize reliability, durability, and robust performance to ensure uninterrupted operations and long-term cost effectiveness.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $550 million |

| Market Forecast in 2032 | $980 million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Andritz AG, Wartsila Corporation, Alfa Laval AB, Mitsubishi Heavy Industries Ltd., Fuji Electric Co. Ltd., Hamon Group, Ducon Environmental Systems Inc., Babcock & Wilcox Enterprises Inc., GEA Group AG, FLSmidth & Co. A/S, Beltran Technologies Inc., JOVYATLAS TECH GmbH, KCH Group, CTP Air Pollution Control, Envitech Inc., Sanken Electric Co. Ltd., Elex AG, Sumitomo Heavy Industries, Clyde Process Solutions, CECO Environmental |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Marine Electrostatic Precipitator Market Key Technology Landscape

The Marine Electrostatic Precipitator market is characterized by a dynamic technology landscape continually evolving to meet stricter environmental standards and operational demands. Key technological advancements center around optimizing the efficiency of particulate matter removal, reducing energy consumption, and enhancing the durability and maintainability of ESP units in the harsh marine environment. Innovations include the development of advanced electrode designs, such as those with improved discharge characteristics and enhanced corona stability, which lead to higher collection efficiencies for ultra-fine particulates. Furthermore, the use of modular construction allows for greater flexibility in installation, enabling manufacturers to offer customizable solutions that fit the varied space constraints of different vessel types, from compact units for smaller ships to larger systems for cruise liners and cargo vessels.

Another significant aspect of the technology landscape is the integration of sophisticated control and monitoring systems. Modern Marine ESPs are often equipped with real-time sensors and automated control algorithms that can adjust operating parameters based on exhaust gas flow rates, temperature, and particulate loading. This ensures optimal performance across varying engine loads and fuel types, minimizing energy usage while maximizing pollutant removal. Materials science also plays a crucial role, with ongoing research into corrosion-resistant alloys and ceramics that can withstand high temperatures and acidic exhaust gases, thereby extending the operational lifespan and reducing the maintenance frequency of ESP components. Automated cleaning systems, such as rapper systems for dry ESPs or water washing for wet ESPs, are also being refined to improve efficiency and reduce manual intervention.

The convergence of digital technologies, particularly the Internet of Things (IoT) and artificial intelligence (AI), is also transforming the Marine ESP landscape. These technologies facilitate predictive maintenance capabilities, remote diagnostics, and data analytics that can inform operational adjustments and compliance reporting. The development of hybrid systems, combining ESP technology with other exhaust gas treatment methods, represents another frontier, aiming for even more comprehensive emission control for multiple pollutants. This continuous drive for innovation is not only addressing the immediate regulatory challenges but also paving the way for a new generation of smart, efficient, and environmentally friendly marine propulsion systems that contribute to a cleaner global maritime industry.

Regional Highlights

- Asia Pacific: This region is a powerhouse in shipbuilding and a major hub for global maritime traffic, making it the largest market for Marine ESPs. Countries like China, South Korea, and Japan lead in both manufacturing and adoption, driven by vast fleets and growing environmental regulations.

- Europe: With its stringent environmental policies, particularly from the European Union, Europe is a significant market for Marine ESPs. Countries such as Germany, Norway, the Netherlands, and the UK are actively investing in green shipping technologies and retrofitting existing fleets to comply with regional emission control areas (ECAs).

- North America: The United States and Canada are critical markets, propelled by robust environmental legislation from agencies like the EPA and a strong focus on sustainable shipping practices. Demand stems from both new vessel constructions and the retrofitting of a substantial domestic fleet.

- Latin America: This region presents emerging opportunities as maritime trade grows and environmental awareness increases. While adoption rates are currently lower than in developed regions, ongoing port development and fleet modernization efforts are expected to drive future demand.

- Middle East and Africa (MEA): The MEA region is characterized by significant oil and gas shipping activities and developing maritime infrastructure. Investment in Marine ESPs is expected to increase as environmental regulations are enforced more rigorously and as port states demand cleaner operations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Marine Electrostatic Precipitator Market.- Andritz AG

- Wartsila Corporation

- Alfa Laval AB

- Mitsubishi Heavy Industries Ltd.

- Fuji Electric Co. Ltd.

- Hamon Group

- Ducon Environmental Systems Inc.

- Babcock & Wilcox Enterprises Inc.

- GEA Group AG

- FLSmidth & Co. A/S

- Beltran Technologies Inc.

- JOVYATLAS TECH GmbH

- KCH Group

- CTP Air Pollution Control

- Envitech Inc.

- Sanken Electric Co. Ltd.

- Elex AG

- Sumitomo Heavy Industries

- Clyde Process Solutions

- CECO Environmental

Frequently Asked Questions

What are Marine Electrostatic Precipitators (ESPs)?

Marine Electrostatic Precipitators are advanced air pollution control devices installed on ships to remove particulate matter, such as soot and fine dust, from exhaust gases by using an electric field to charge and collect the particles, ensuring cleaner emissions into the atmosphere.

Why are Marine ESPs becoming increasingly important?

Marine ESPs are crucial for environmental compliance, primarily driven by stringent international regulations from the IMO (International Maritime Organization) aimed at reducing air pollution from shipping. They help vessels meet these emission limits, improve air quality, and enhance the shipping industry's environmental sustainability.

What are the main types of Marine ESPs available in the market?

The Marine ESP market primarily features two types: Dry Electrostatic Precipitators, which collect dry particulate matter, and Wet Electrostatic Precipitators, which use water sprays to collect particles and often simultaneously remove acid gases, offering versatile solutions for different vessel requirements.

What are the primary challenges associated with adopting Marine ESPs?

Key challenges include the high initial investment cost for purchasing and installing the systems, the complexity of integration into existing vessel infrastructure, potential space constraints on board, and the need for specialized maintenance expertise. Competition from alternative exhaust treatment technologies also presents a challenge.

How does AI impact the performance and efficiency of Marine ESPs?

AI enhances Marine ESPs by enabling predictive maintenance, optimizing operating parameters in real time based on exhaust conditions, improving compliance monitoring through automated data analysis, and integrating with broader vessel management systems for overall energy and emissions efficiency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager