Marine Selective Catalytic Reduction Systems Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427237 | Date : Oct, 2025 | Pages : 244 | Region : Global | Publisher : MRU

Marine Selective Catalytic Reduction Systems Market Size

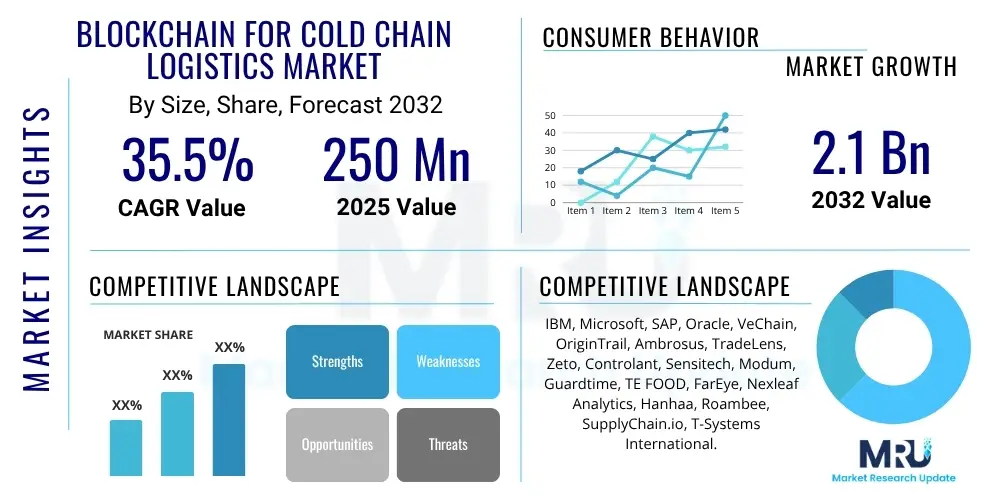

The Marine Selective Catalytic Reduction Systems Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2025 and 2032. The market is estimated at USD 1.2 Billion in 2025 and is projected to reach USD 2.1 Billion by the end of the forecast period in 2032.

Marine Selective Catalytic Reduction Systems Market introduction

The Marine Selective Catalytic Reduction (SCR) Systems market is experiencing robust growth driven by stringent global environmental regulations aimed at reducing nitrogen oxide (NOx) emissions from marine vessels. SCR systems are advanced post-combustion exhaust gas treatment technologies designed to convert harmful NOx into harmless diatomic nitrogen (N2) and water (H2O) using a catalyst and a liquid reductant, typically urea or ammonia. These systems are crucial for compliance with IMO Tier III NOx emission standards, which apply to vessels operating in Emission Control Areas (ECAs) and to all newbuild vessels globally depending on their keel-laying date and engine output. The primary product encompasses the entire system, including the reactor, catalyst modules, reductant injection system (e.g., urea tanks, pumps, dosing units), and sophisticated control and monitoring units that ensure optimal performance and compliance under varying engine loads and operating conditions. The increasing demand for sustainable shipping solutions, coupled with the expansion of global trade and maritime transport, underpins the markets trajectory.

Major applications for marine SCR systems span a wide range of vessel types, including container ships, tankers, cruise ships, bulk carriers, offshore support vessels, ferries, and naval vessels. These systems are integrated into both two-stroke and four-stroke marine engines, adapting to diverse engine sizes and operational profiles. The benefits of deploying marine SCR technology are multifaceted; they not only ensure regulatory compliance, thereby avoiding penalties and port restrictions, but also contribute significantly to environmental protection by mitigating air pollution, reducing acid rain, and improving air quality in coastal areas and port cities. Furthermore, efficient SCR systems can contribute to better engine performance and fuel efficiency in some integrated setups, extending engine life through reduced carbon buildup, although their primary role remains emissions reduction. The long-term operational cost savings associated with avoiding non-compliance and the enhanced public image of environmentally responsible shipping companies further bolster their adoption.

Driving factors for the marine SCR market primarily include the tightening of international and regional environmental regulations, particularly the IMO 2020 sulfur cap and the IMO Tier III NOx limits. As more areas are designated as ECAs, and as the global fleet ages and undergoes retrofitting or newbuild cycles, the installation of compliant exhaust gas treatment systems becomes imperative. The increasing awareness among shipowners and operators regarding environmental stewardship, coupled with growing pressure from investors, charterers, and consumers for sustainable practices, also plays a pivotal role. Technological advancements leading to more compact, efficient, and cost-effective SCR systems, alongside the development of reliable global supply chains for reductants like urea, are further propelling market expansion. The long operational lifespan of marine assets means that investments in future-proof emission control technologies are considered strategic, securing continuous access to international shipping routes and markets.

Marine Selective Catalytic Reduction Systems Market Executive Summary

The Marine Selective Catalytic Reduction Systems market is fundamentally shaped by evolving business trends centered on sustainability, operational efficiency, and regulatory adherence. A key business trend involves the increasing collaboration between engine manufacturers, SCR system suppliers, and shipyards to offer integrated, optimized solutions that streamline installation and commissioning for newbuilds and retrofits. There is a growing emphasis on modular designs and compact footprints to facilitate integration into vessels with limited space, a critical factor for the retrofit market. Furthermore, the market is witnessing a rise in service-level agreements and long-term maintenance contracts, reflecting shipowners desires for assured system performance and compliance over the operational life of their assets, thereby shifting towards total cost of ownership models rather than upfront capital expenditure alone. Digitalization trends are also influencing business models, with providers offering remote monitoring, predictive maintenance, and data analytics to optimize SCR system performance and reduce operational downtime, providing added value beyond mere compliance.

Regional trends are diverse, reflecting varying regulatory pressures and maritime activity levels. North America and Europe, with their established Emission Control Areas (ECAs) and stringent environmental policies, continue to be primary demand hubs for marine SCR systems, driven by a strong focus on air quality in coastal and port regions. Asia-Pacific, particularly shipbuilding giants like South Korea, China, and Japan, represents a significant growth region, propelled by a booming newbuild market, increasing internal shipping traffic, and a growing recognition of environmental responsibilities leading to the adoption of advanced emission controls. The region is also becoming a major manufacturing base for SCR components, benefiting from economies of scale. While other regions such as Latin America and the Middle East are currently smaller markets, they are anticipated to show gradual growth as global regulatory frameworks become more universal and as their maritime sectors expand and modernize, driven by both international trade and domestic environmental considerations.

Segmentation trends indicate a nuanced market landscape. By vessel type, demand is robust across all major categories, with large container ships, cruise liners, and tankers being significant consumers due to their extensive operational footprints and often high engine outputs. The retrofit market, driven by existing vessels needing to comply with newer regulations, continues to be a crucial segment alongside newbuild installations. In terms of engine type, both two-stroke and four-stroke engines are extensively fitted with SCR systems, with specific design considerations for each. The reductant type primarily revolves around urea-based solutions, which dominate the market due to their safety, availability, and ease of handling compared to ammonia, although research into alternative, more sustainable reductants is ongoing. The increasing complexity of maritime operations and the need for adaptable solutions are driving innovation within these segments, focusing on optimizing performance across various engine loads and fuel types, including dual-fuel and LNG-powered vessels, which still produce NOx emissions requiring abatement.

AI Impact Analysis on Marine Selective Catalytic Reduction Systems Market

The integration of Artificial Intelligence (AI) within the Marine Selective Catalytic Reduction Systems market addresses common user questions concerning operational efficiency, predictive maintenance, and optimal regulatory compliance. Users frequently inquire about how AI can enhance the performance and reliability of SCR systems, reduce operational costs associated with reductant consumption, and provide real-time insights into emission levels and system health. There is a strong expectation that AI will move beyond simple data monitoring to offer sophisticated analytics, anomaly detection, and decision support for ship operators, ensuring SCR systems function effectively under diverse and dynamic marine conditions. Furthermore, users are keen to understand how AI can assist in navigating complex and evolving environmental regulations by providing automated compliance reporting and optimizing system parameters to meet specific geographical or operational emission limits, thereby minimizing human error and maximizing operational uptime while ensuring environmental responsibility.

- AI-driven predictive maintenance optimizes SCR system uptime by analyzing sensor data to anticipate component failures, scheduling maintenance proactively, and reducing unscheduled downtime.

- Real-time performance optimization algorithms leverage AI to dynamically adjust reductant injection rates and catalyst temperatures, ensuring maximum NOx reduction efficiency under varying engine loads and fuel qualities, leading to significant urea consumption savings.

- Enhanced regulatory compliance and reporting are achieved through AI systems that automatically collect, process, and report emission data, flagging potential non-compliance issues before they occur and simplifying documentation for authorities.

- Advanced anomaly detection identifies unusual operational patterns or system malfunctions early, allowing for swift corrective action and preventing potential damage or severe emission breaches.

- AI supports integration with broader vessel management systems, enabling holistic operational optimization across propulsion, energy management, and emission control for overall vessel efficiency.

- Autonomous operation capabilities, while still nascent, suggest a future where AI could manage SCR systems with minimal human intervention, adapting to environmental conditions and regulatory zones automatically.

- Data analytics and machine learning provide deeper insights into fleet-wide SCR performance, identifying best practices, and informing future system designs and operational strategies.

DRO & Impact Forces Of Marine Selective Catalytic Reduction Systems Market

The Marine Selective Catalytic Reduction Systems market is profoundly influenced by a complex interplay of drivers, restraints, opportunities, and broader impact forces. Key drivers include the escalating stringency of global and regional environmental regulations, notably the IMO Tier III NOx emission standards, which mandate the use of advanced abatement technologies for vessels operating in Emission Control Areas (ECAs) and for all newbuilds. This regulatory push is compounded by increasing public and corporate pressure for sustainable maritime practices, pushing shipowners to adopt green technologies not just for compliance but for enhanced brand reputation and competitive advantage. The continuous growth in seaborne trade and the corresponding expansion of the global shipping fleet further amplify the demand for SCR systems, as more vessels are constructed or retrofitted to meet contemporary emission standards. Technological advancements, leading to more compact, efficient, and robust SCR solutions, also act as a significant driver, making these systems more attractive and viable for integration across diverse vessel types and operational profiles.

Segmentation Analysis

The Marine Selective Catalytic Reduction Systems market is extensively segmented to reflect the diverse operational landscape and technological requirements of the maritime industry. These segmentations allow for a granular understanding of demand patterns, technological preferences, and regional adoption rates across various vessel types, engine configurations, and system components. The market can be categorized by criteria such as vessel type (e.g., container ships, tankers, cruise ships, offshore vessels), which dictates engine size and operational cycles; engine type (two-stroke versus four-stroke), influencing SCR system design and integration; and reductant type, predominantly urea-based solutions, which are chosen for their efficacy and practical advantages. Further segmentation considers newbuild versus retrofit installations, reflecting different market dynamics and installation complexities, and application areas based on the specific operational zones (e.g., global shipping versus coastal operations) that inform regulatory compliance needs. This detailed segmentation is crucial for market players to tailor their product offerings, strategic investments, and marketing efforts to address specific needs within the highly specialized marine sector, optimizing market penetration and competitive positioning.

- By Vessel Type:

- Container Ships: Large vessels with high engine outputs, frequently traversing ECAs.

- Tankers: Oil and chemical carriers requiring robust, reliable systems for long voyages.

- Cruise Ships: Passenger vessels with strict environmental commitments, often operating near sensitive coastal areas.

- Bulk Carriers: High-capacity cargo ships operating globally, requiring durable solutions.

- Offshore Support Vessels (OSVs): Specialized ships for oil and gas industry, operating in specific, often regulated, offshore zones.

- Ferries: Regional and coastal vessels with frequent port calls and varying engine loads.

- Naval Ships: Military vessels requiring specialized, often stealthy, and highly reliable systems.

- Others: Including fishing vessels, tugboats, research vessels, and yachts.

- By Engine Type:

- Two-Stroke Engines: Predominantly used in large ocean-going vessels, characterized by high power output and long operational cycles.

- Four-Stroke Engines: Common in smaller and medium-sized vessels, including ferries, cruise ships, and offshore vessels, often with more variable operational profiles.

- By Reductant Type:

- Urea-based Solutions: Dominate the market due to their safety, availability, and ease of handling compared to ammonia.

- Ammonia-based Solutions: Less common in commercial marine due to safety concerns, but used in niche applications.

- By Installation Type:

- Newbuild: Systems integrated during the vessel construction phase, allowing for optimized design and placement.

- Retrofit: Installation of SCR systems on existing vessels to meet updated emission regulations, often requiring complex engineering and space considerations.

- By Component:

- Catalyst Reactors: The core unit where NOx reduction occurs, housing the catalyst elements.

- Catalyst Elements: Specialized materials designed for efficient NOx conversion, with varying compositions and geometries.

- Reagent Dosing and Injection Systems: Units responsible for precise delivery and atomization of the reductant (e.g., urea pump, injector nozzles, tanks).

- Control and Monitoring Systems: Sophisticated electronics and software to manage SCR operation, optimize performance, and ensure compliance.

- Piping and Ancillary Equipment: Including exhaust gas ducts, pumps, heat exchangers, and sensors.

Marine Selective Catalytic Reduction Systems Market Value Chain Analysis

The value chain for Marine Selective Catalytic Reduction Systems is a complex network of interconnected activities spanning from raw material sourcing to end-user operation and maintenance. Upstream analysis reveals that it begins with the procurement of specialized raw materials for catalysts (e.g., titanium dioxide, vanadium, tungsten, zeolite), steel alloys for reactor vessels, and high-precision components for dosing and control systems. Key suppliers in this segment focus on material purity, cost-effectiveness, and stable supply chains, often engaging in long-term contracts with catalyst manufacturers and system integrators. Catalyst development, a highly specialized field, involves advanced research and manufacturing processes to produce materials with optimal NOx conversion efficiency, durability, and resistance to sulfur poisoning. This upstream segment is characterized by a relatively concentrated base of technology providers and material specialists. The integration of advanced sensors and electronic components from specialized suppliers also forms a critical part of the upstream activities, ensuring the sophisticated monitoring and control capabilities essential for modern SCR systems.

The midstream of the value chain involves the design, engineering, and manufacturing of complete SCR systems. This segment is dominated by major marine equipment suppliers and specialized SCR system providers who integrate catalysts, reactors, dosing units, and control systems into comprehensive solutions. These companies invest heavily in R&D to develop compact, efficient, and robust systems tailored for the demanding marine environment and diverse vessel types. Downstream activities encompass the distribution, installation, commissioning, and after-sales support for SCR systems. Distribution channels are typically direct, involving sales teams working with shipyards for newbuild projects or directly with shipowners for retrofits. Indirect channels may include a network of authorized distributors, agents, or marine engineering firms who handle sales and project management in specific regions. Installation is a critical phase, requiring specialized expertise in marine engineering to integrate the SCR system seamlessly with the vessel’s existing exhaust and engine systems, often managed by shipyards or specialized installation contractors. After-sales support, including maintenance, spare parts supply, and performance monitoring, is crucial for ensuring the long-term operational effectiveness and regulatory compliance of the systems. The complexity of these systems necessitates ongoing technical support and periodic servicing, which forms a significant part of the downstream value proposition and creates recurring revenue streams for providers.

Marine Selective Catalytic Reduction Systems Market Potential Customers

The primary potential customers and end-users for Marine Selective Catalytic Reduction Systems are diverse entities within the global maritime industry, all driven by the imperative to comply with stringent environmental regulations and enhance their sustainability profile. Shipowners and operators represent the largest customer segment, encompassing a broad range from multinational shipping giants managing vast fleets of container ships, tankers, and bulk carriers, to smaller companies operating regional ferries, offshore support vessels, or specialized ships. These customers are driven by the need to ensure continuous access to international trade routes, avoid penalties for non-compliance in Emission Control Areas (ECAs), and maintain their social license to operate. The decision-making process for these customers often involves a comprehensive evaluation of capital expenditure, operational costs (including reductant consumption), system reliability, maintenance requirements, and the long-term implications for vessel resale value and charter rates. They seek solutions that offer high NOx reduction efficiency, a compact footprint, ease of integration, and robust after-sales support.

Another significant customer segment includes shipbuilding companies and shipyards, who integrate SCR systems into newbuild vessels as part of the initial design and construction phase. These entities work closely with engine manufacturers and SCR system suppliers to ensure seamless integration and optimized performance from the outset, aiming to deliver compliant and future-proof vessels to their clients. Naval forces and coast guards also constitute a specialized customer segment, often requiring bespoke SCR solutions that meet specific operational demands, including stealth, durability, and reliability in challenging environments, alongside emission reduction targets. Furthermore, governments and port authorities, through their regulatory powers, indirectly influence demand by setting and enforcing emission standards. For existing vessels, the retrofit market is a substantial opportunity, targeting shipowners of older vessels that need to be upgraded to meet current or upcoming regulations. The demand from these various customer groups is underpinned by a global shift towards decarbonization and environmental responsibility, making emission control technologies like SCR systems an indispensable investment for sustaining maritime operations.

Marine Selective Catalytic Reduction Systems Market Key Technology Landscape

The technology landscape for Marine Selective Catalytic Reduction Systems is characterized by continuous innovation aimed at enhancing efficiency, reducing footprint, and improving operational reliability under demanding marine conditions. The core of SCR technology revolves around the catalyst materials, which are typically composed of titanium dioxide (TiO2) as a base, impregnated with active components such as vanadium oxide (V2O5) or zeolites. Vanadium-based catalysts are widely used for their excellent NOx conversion efficiency and sulfur resistance, while zeolite-based catalysts offer higher temperature resistance and are increasingly favored for certain applications, especially where high exhaust gas temperatures are encountered. Recent advancements focus on developing more durable catalysts with extended lifespans, reduced susceptibility to fouling and poisoning from fuel impurities, and improved performance across a wider range of exhaust gas temperatures. This includes innovative catalyst geometries and coatings designed to maximize surface area and catalytic activity while minimizing pressure drop across the reactor, thereby improving overall engine efficiency. Research is also progressing into non-vanadium catalysts to address environmental concerns associated with vanadium disposal.

Beyond the catalyst, critical technologies include the reductant injection system, primarily utilizing urea-water solution (UWS), which requires precise dosing and atomization for optimal NOx reduction. Advanced injection technologies incorporate sophisticated nozzles and mixing units to ensure uniform distribution of the reductant within the exhaust gas stream, preventing "urea slip" (unreacted urea passing through the system) and minimizing ammonia slip. The control and monitoring systems are integral, leveraging advanced sensors (e.g., NOx sensors, ammonia sensors, temperature probes) and algorithms to continuously monitor exhaust gas conditions and SCR system performance. These systems dynamically adjust reductant injection rates based on engine load, exhaust gas temperature, and actual NOx levels, ensuring optimal performance and compliance while minimizing urea consumption. Integration with the vessels engine management system (EMS) and alarm monitoring system (AMS) is also a key technological aspect, enabling seamless operation and centralized control. Furthermore, the development of modular and compact SCR reactor designs, often utilizing innovative flow simulations and material science, is crucial for facilitating installation in space-constrained engine rooms, especially for retrofit projects. The ongoing evolution of these technologies is aimed at delivering systems that are not only compliant but also cost-effective, reliable, and adaptable to the future challenges of diverse marine fuels and operational requirements.

Regional Highlights

- Europe: A dominant market driven by stringent Emission Control Area (ECA) regulations in the North Sea and Baltic Sea. Strong demand from advanced shipbuilding nations and large ferry/cruise operators focused on environmental compliance and sustainability. Key countries include Germany, Norway, Finland, and Denmark, with robust R&D and manufacturing capabilities for marine technologies.

- North America: Significant market influence due to ECAs along the U.S. and Canadian coasts. Driven by environmental protection initiatives and a focus on reducing emissions in critical port areas. Demand primarily from cruise lines, offshore support vessels, and container shipping operating in these regulated zones, with ongoing investments in compliant fleets.

- Asia-Pacific: The fastest-growing region, propelled by major shipbuilding hubs in China, South Korea, and Japan, which integrate SCR systems into a large volume of newbuild vessels. Increasing domestic and international trade, coupled with rising environmental awareness and emerging regional emission controls, fuel demand. Australia and Singapore also contribute to the market with their active shipping lanes and port activities.

- Middle East & Africa: An emerging market with growing maritime activity, driven by oil and gas exploration, increasing trade routes, and infrastructure development. Demand is expected to rise as international regulations become more universally enforced and local environmental concerns grow. Investment in new port facilities and fleet modernization will likely drive future SCR adoption.

- Latin America: Gradual market expansion anticipated, influenced by increased commodity exports and regional trade. While current regulatory pressure is less intense than in ECAs, the need for compliance for international voyages and a growing focus on environmental stewardship will drive the adoption of SCR systems, particularly in countries with significant maritime trade such like Brazil and Panama.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Marine Selective Catalytic Reduction Systems Market.- Wärtsilä Corporation

- MAN Energy Solutions SE

- Yara Marine Technologies AS

- Caterpillar Inc. (MaK, Electro-Motive Diesel)

- Alfa Laval AB

- Johnson Matthey Plc

- Umoe Advanced Composites (UAC)

- Hug Engineering AG

- Eminox Ltd.

- Dinex A/S

- PureteQ A/S

- Mitsubishi Shipbuilding Co., Ltd.

- Hyundai Heavy Industries Co., Ltd.

- Saacke GmbH

- DEC Marine

Frequently Asked Questions

What are Marine Selective Catalytic Reduction (SCR) Systems and their primary function?

Marine SCR systems are advanced exhaust gas treatment technologies installed on vessels to significantly reduce harmful nitrogen oxide (NOx) emissions. They operate by injecting a liquid reductant, typically urea-water solution, into the exhaust gas stream, which then reacts with NOx over a catalyst to convert it into harmless nitrogen (N2) and water (H2O), ensuring compliance with international environmental regulations like IMO Tier III.

Why are Marine SCR Systems essential for the shipping industry?

Marine SCR systems are essential for the shipping industry primarily due to stringent global environmental regulations, such as the IMO Tier III NOx limits for Emission Control Areas (ECAs) and newbuilds. Their implementation enables vessels to operate legally in regulated zones, avoid substantial fines, enhance corporate environmental responsibility, and contribute to cleaner air quality in coastal regions and port cities.

What are the key components of a typical Marine SCR System?

A typical Marine SCR system comprises several key components, including the catalyst reactor housing the catalyst elements (e.g., vanadium or zeolite-based materials), a precise reductant dosing and injection system (e.g., urea pump, nozzles), a dedicated reductant storage tank, and a sophisticated control and monitoring unit. Ancillary equipment such as piping, sensors, and exhaust gas bypass lines are also integral to its operation.

How do Marine SCR Systems contribute to vessel operational efficiency?

While primarily for emissions reduction, modern Marine SCR systems contribute to operational efficiency through optimized design, reducing backpressure on engines and potentially improving fuel consumption in some integrated setups. Additionally, by ensuring regulatory compliance, they prevent operational restrictions and penalties, allowing vessels unrestricted access to global trade routes and minimizing unforeseen costs or delays, thus indirectly boosting overall fleet efficiency.

What is the outlook for Marine SCR System technology and market growth?

The outlook for Marine SCR System technology and market growth is positive, driven by ever-tightening environmental regulations, continued growth in global maritime trade, and ongoing technological advancements. Future innovations are expected to focus on more compact, energy-efficient designs, multi-fuel compatibility, longer-lasting catalysts, and enhanced integration with AI-driven predictive maintenance and autonomous control systems for optimized performance and reduced operational footprint.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager