Medical Non-woven Disposables Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428895 | Date : Oct, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Medical Non-woven Disposables Market Size

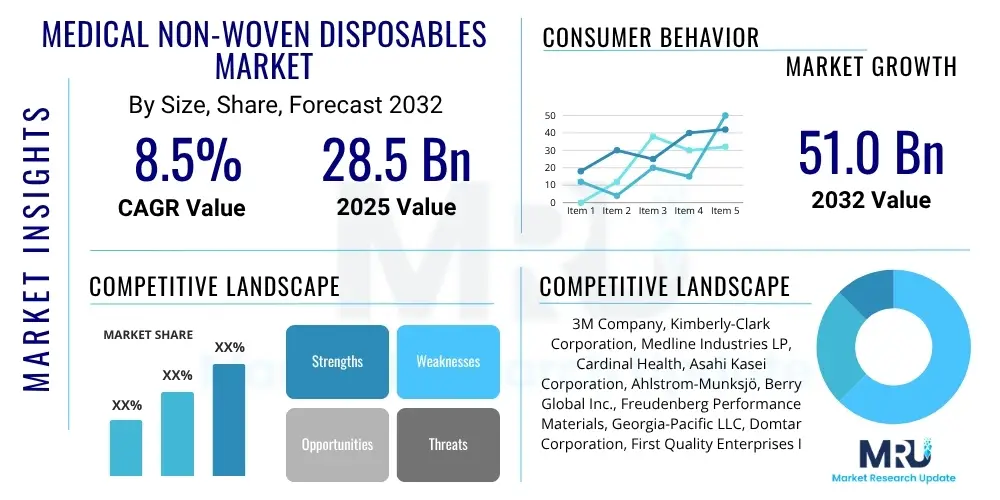

The Medical Non-woven Disposables Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2025 and 2032. The market is estimated at USD 28.5 billion in 2025 and is projected to reach USD 51.0 billion by the end of the forecast period in 2032.

Medical Non-woven Disposables Market introduction

The Medical Non-woven Disposables Market encompasses a wide array of single-use products crucial for infection control and patient safety within healthcare settings. These products are manufactured from non-woven fabrics, typically made from synthetic polymers like polypropylene, polyethylene, and polyester, or natural fibers such as rayon and wood pulp. Unlike traditional woven textiles, non-wovens are produced by bonding fibers together through mechanical, thermal, or chemical processes, resulting in materials with specific properties like fluid resistance, breathability, absorbency, and sterility, which are vital for medical applications.

Major applications of medical non-woven disposables include surgical drapes and gowns, face masks, sterilization wraps, wound dressings, caps, footwear, and various hygiene products like incontinence pads and wipes. The primary benefits of these disposables are enhanced infection prevention, cost-effectiveness through reduced laundry and sterilization expenses, and convenience for healthcare professionals. Key driving factors for market growth include the global rise in surgical procedures, increasing awareness of hospital-acquired infections (HAIs), the expanding geriatric population requiring frequent medical interventions, and robust regulatory frameworks promoting the use of sterile, single-use medical products to maintain hygiene standards and ensure patient safety across diverse healthcare environments.

Medical Non-woven Disposables Market Executive Summary

The Medical Non-woven Disposables Market is experiencing robust growth, primarily driven by an intensified focus on infection control and patient safety protocols globally. Business trends indicate a strong push towards product innovation, with manufacturers investing in advanced materials offering superior barrier protection, comfort, and breathability, alongside a growing emphasis on sustainable and biodegradable non-woven solutions to address environmental concerns. Strategic partnerships, mergers, and acquisitions are also prevalent, aimed at expanding product portfolios, enhancing manufacturing capabilities, and strengthening market presence in competitive landscapes.

Regional trends reveal that North America and Europe continue to hold significant market shares due to well-established healthcare infrastructures, high healthcare expenditure, and stringent regulatory environments favoring disposable medical products. However, the Asia Pacific region is anticipated to exhibit the fastest growth, fueled by rapidly developing healthcare facilities, a large patient pool, increasing medical tourism, and rising awareness regarding hygiene standards in countries like China and India. Latin America and the Middle East & Africa also present promising growth opportunities as healthcare access improves and disposable incomes rise.

Segment-wise, surgical drapes and gowns, along with face masks, represent dominant categories, propelled by the consistent volume of surgical procedures and ongoing public health imperatives. The wound care segment is also witnessing substantial growth, driven by an aging population prone to chronic wounds and the development of advanced wound care dressings. Material-wise, polypropylene remains a cornerstone due to its versatility and cost-effectiveness, while research into more sustainable and high-performance alternatives is gaining traction, reflecting a dynamic and evolving market landscape.

AI Impact Analysis on Medical Non-woven Disposables Market

User questions regarding AI's impact on the Medical Non-woven Disposables Market frequently revolve around efficiency gains, predictive capabilities, and enhanced product quality. Concerns are raised about how AI can optimize manufacturing processes, improve supply chain resilience, and contribute to the development of next-generation non-woven materials with tailored properties. Users are keen to understand AI's role in ensuring stringent quality control, minimizing waste, and offering personalized solutions, while also considering the challenges associated with data integration and the specialized nature of medical device manufacturing. The overarching expectation is that AI will drive significant improvements in operational efficiency and product innovation.

- AI can optimize manufacturing processes through predictive analytics, leading to higher efficiency and reduced downtime.

- Enhanced quality control systems utilizing AI for automated defect detection in non-woven production lines.

- Improved supply chain management and inventory forecasting, minimizing stockouts and overstocking of critical medical disposables.

- Acceleration of new material development by simulating properties and performance of non-woven fabrics with AI-powered design tools.

- Personalized product development, potentially allowing for customized fit or specific functional enhancements based on patient data.

- Predictive maintenance for manufacturing equipment, ensuring continuous production and reducing unexpected failures.

- Real-time monitoring of production parameters to maintain consistent product quality and adherence to strict medical standards.

DRO & Impact Forces Of Medical Non-woven Disposables Market

The Medical Non-woven Disposables Market is significantly shaped by a confluence of drivers, restraints, and opportunities. Key drivers include the escalating global prevalence of hospital-acquired infections (HAIs), which mandates the use of single-use, sterile barriers to prevent cross-contamination. Moreover, the increasing number of surgical procedures performed worldwide, coupled with a rapidly aging global population more susceptible to various health conditions, directly fuels the demand for medical disposables. Strict regulatory guidelines and infection control protocols enforced by health authorities further solidify the market's growth, making these products indispensable in clinical settings.

However, the market also faces notable restraints. Volatility in raw material prices, particularly for petrochemical-derived polymers like polypropylene, can impact manufacturing costs and product pricing. Environmental concerns related to the disposal of single-use plastics and non-biodegradable materials represent a significant challenge, pushing for research and development into sustainable alternatives. Intense competition among market players, coupled with the need for substantial capital investment in advanced manufacturing technologies, can also limit market entry and growth for smaller entities.

Opportunities for market expansion are abundant, particularly in emerging economies where healthcare infrastructure is rapidly developing and awareness regarding hygiene is increasing. The development of advanced non-woven materials with enhanced functionalities, such as antimicrobial properties, increased absorbency, or improved breathability, presents significant avenues for innovation. Additionally, the growing adoption of home healthcare services and the increasing demand for personal protective equipment (PPE) in non-clinical settings during health crises further broaden the application scope and growth potential for medical non-woven disposables. These impact forces collectively dictate market dynamics, influencing investment decisions, product development strategies, and overall market trajectory.

Segmentation Analysis

The Medical Non-woven Disposables Market is comprehensively segmented by product type, material type, and end-user, allowing for a detailed analysis of market dynamics and growth potential across various categories. Each segment reflects specific demands and applications within the healthcare industry, highlighting the diverse utility and specialized nature of these essential products. Understanding these segmentations is crucial for stakeholders to identify key growth areas, tailor product development, and refine market entry strategies.

- By Product Type:

- Surgical Drapes

- Surgical Gowns

- Surgical Masks

- Surgical Caps

- Surgical Footwear

- Sterilization Wraps

- Wound Dressings

- Incontinence Products

- Disposable Underpads

- Other Hygiene Products

- By Material Type:

- Polypropylene (PP)

- Polyethylene (PE)

- Polyester

- Rayon

- Wood Pulp

- Cotton

- Blends

- Bicomponent Fibers

- By End User:

- Hospitals

- Clinics

- Ambulatory Surgical Centers (ASCs)

- Long Term Care Facilities

- Home Healthcare Settings

- Research and Diagnostic Laboratories

Value Chain Analysis For Medical Non-woven Disposables Market

The value chain for the Medical Non-woven Disposables Market begins with upstream activities involving raw material procurement. This stage is dominated by chemical and fiber manufacturers who produce the synthetic polymers like polypropylene, polyethylene, and polyester, as well as suppliers of natural fibers such as wood pulp and cotton. These raw materials are then processed into non-woven fabrics by specialized non-woven fabric manufacturers using techniques like spunbond, meltblown, and SMS (spunbond-meltblown-spunbond) technologies. The quality and type of raw material significantly impact the final product's performance characteristics, such as barrier protection, absorbency, and softness.

Midstream activities involve the conversion of these non-woven fabrics into finished medical disposable products. This includes cutting, stitching, bonding, and often sterilization processes. Manufacturers of medical non-woven disposables then assemble these components into items like surgical gowns, drapes, masks, and wound dressings, adhering to stringent regulatory standards for medical devices. Quality control and packaging are critical steps at this stage to ensure product sterility, integrity, and shelf-life, preparing them for distribution to healthcare providers.

Downstream analysis focuses on the distribution channels and end-users. Products reach end-users primarily through both direct and indirect distribution channels. Direct sales involve manufacturers selling directly to large hospital networks or government procurement agencies. Indirect channels are more prevalent, utilizing a network of third-party distributors, wholesalers, and medical supply companies that have established relationships with hospitals, clinics, ambulatory surgical centers, and long-term care facilities. Online platforms and specialized medical e-commerce sites are also gaining traction, offering a streamlined procurement process. This intricate network ensures that a broad range of medical non-woven disposables are accessible to healthcare facilities globally, supporting patient care and infection control initiatives.

Medical Non-woven Disposables Market Potential Customers

The primary potential customers and end-users of medical non-woven disposables span a broad spectrum of healthcare facilities and related institutions that prioritize infection control, patient safety, and operational efficiency. Hospitals, being the largest consumers, utilize these products extensively across various departments, including operating rooms, intensive care units, emergency rooms, and general wards, for surgical procedures, patient care, and staff protection. The high volume of patient admissions and diverse medical interventions necessitate a constant supply of sterile drapes, gowns, masks, and wound dressings.

Ambulatory Surgical Centers (ASCs) and specialized clinics, such as dental clinics, ophthalmology clinics, and dermatology centers, represent another significant customer segment. These facilities, focusing on outpatient procedures, increasingly rely on medical non-woven disposables to maintain a sterile environment and minimize infection risks. The efficiency and cost-effectiveness of single-use items are particularly appealing to ASCs seeking to optimize operational costs without compromising patient safety standards.

Beyond traditional clinical settings, long-term care facilities, nursing homes, and home healthcare providers are rapidly expanding segments. The aging global population often requires continuous medical attention and hygiene support, driving demand for incontinence products, disposable underpads, and personal protective equipment for caregivers. Additionally, emergency medical services (EMS), research and diagnostic laboratories, and even pharmaceutical companies (for cleanroom environments) also constitute important potential customers, emphasizing the pervasive need for medical non-woven disposables across the entire healthcare ecosystem.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 28.5 billion |

| Market Forecast in 2032 | USD 51.0 billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, Kimberly-Clark Corporation, Medline Industries LP, Cardinal Health, Asahi Kasei Corporation, Ahlstrom-Munksjö, Berry Global Inc., Freudenberg Performance Materials, Georgia-Pacific LLC, Domtar Corporation, First Quality Enterprises Inc., Molnlycke Health Care AB, Lohmann & Rauscher GmbH & Co. KG, Hartmann AG, Smith & Nephew plc, DuPont de Nemours, Inc., Lydall, Inc., Fitesa S.A., Toray Industries Inc., P.M.I. Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Medical Non-woven Disposables Market Key Technology Landscape

The Medical Non-woven Disposables Market is underpinned by a dynamic technological landscape that continuously evolves to meet the stringent demands of healthcare. Core to this are the advanced non-woven manufacturing processes, primarily spunbond, meltblown, and SMS (spunbond-meltblown-spunbond) technologies. Spunbond produces strong, durable fabrics, while meltblown technology creates microfibers that excel in barrier and filtration properties. SMS combines these for versatile fabrics with excellent barrier, strength, and breathability, making them ideal for surgical drapes and gowns. Other methods like airlaid and wetlaid are also utilized for absorbent products like wound dressings and hygiene items.

Beyond fabric formation, innovations in material science play a crucial role. This includes the development of multi-layer structures, composite materials, and specialized fiber treatments to enhance specific properties. For instance, hydrophilic treatments improve absorbency, while antimicrobial agents can be incorporated directly into the fibers to reduce bacterial growth and enhance infection control. The focus is increasingly shifting towards sustainable materials, with research into biodegradable polymers, bio-based non-wovens, and more efficient recycling technologies gaining prominence to address environmental concerns associated with single-use products.

Furthermore, sterilization technologies are fundamental to ensuring the safety and efficacy of medical disposables. Common methods include Ethylene Oxide (EtO) sterilization, gamma radiation, and electron beam sterilization, each selected based on the material compatibility and product characteristics. Automation and advanced quality control systems, often integrated with AI and machine vision, are also becoming standard in manufacturing facilities. These technologies ensure consistent product quality, minimize defects, and optimize production efficiency, guaranteeing that medical non-woven disposables meet the rigorous standards required for healthcare applications.

Regional Highlights

- North America: This region holds a significant share of the global market, driven by its sophisticated healthcare infrastructure, high healthcare expenditure, increasing surgical procedures, and strong regulatory emphasis on infection control. The presence of major market players and a high adoption rate of advanced medical technologies further contribute to its dominance. The United States, in particular, is a major contributor.

- Europe: Europe represents another mature market with substantial growth, characterized by its well-established healthcare systems, growing geriatric population, and a strong focus on sustainable and eco-friendly disposable solutions. Countries like Germany, France, and the UK are key contributors, investing in advanced non-woven technologies and stringent quality standards.

- Asia Pacific (APAC): The APAC region is projected to be the fastest-growing market due to rapid improvements in healthcare infrastructure, increasing healthcare awareness, a massive and aging population, and rising medical tourism. Countries such as China, India, and Japan are at the forefront of this growth, driven by expanding access to healthcare services and increasing per capita income.

- Latin America: This region is an emerging market for medical non-woven disposables, propelled by improving economic conditions, increasing healthcare investments, and a rising prevalence of chronic diseases. Growth is particularly noted in countries like Brazil and Mexico, as they enhance their healthcare capabilities and adopt international standards for patient safety.

- Middle East and Africa (MEA): The MEA market is also experiencing steady growth, fueled by government initiatives to modernize healthcare facilities, increasing foreign investments in the healthcare sector, and a growing awareness of hygiene and infection prevention. Gulf Cooperation Council (GCC) countries are leading this expansion due to significant oil revenues and strategic healthcare development plans.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Medical Non-woven Disposables Market.- 3M Company

- Kimberly-Clark Corporation

- Medline Industries LP

- Cardinal Health

- Asahi Kasei Corporation

- Ahlstrom-Munksjö

- Berry Global Inc.

- Freudenberg Performance Materials

- Georgia-Pacific LLC

- Domtar Corporation

- First Quality Enterprises Inc.

- Molnlycke Health Care AB

- Lohmann & Rauscher GmbH & Co. KG

- Hartmann AG

- Smith & Nephew plc

- DuPont de Nemours, Inc.

- Lydall, Inc.

- Fitesa S.A.

- Toray Industries Inc.

- P.M.I. Corporation

Frequently Asked Questions

What are medical non-woven disposables?

Medical non-woven disposables are single-use healthcare products made from fabrics bonded together by chemical, mechanical, or thermal means, rather than weaving or knitting. They are crucial for infection control, offering properties like fluid resistance, breathability, and sterility, used in items such as surgical drapes, masks, and wound dressings.

Why are medical non-woven disposables important?

They are vital for preventing hospital-acquired infections (HAIs), enhancing patient safety, and ensuring healthcare worker protection. Their single-use nature eliminates cross-contamination risks and reduces the need for costly laundering and sterilization processes, contributing to operational efficiency in healthcare facilities.

What factors are driving the growth of this market?

Key drivers include the rising global prevalence of HAIs, an increase in surgical procedures, the expanding geriatric population, growing awareness of hygiene, and stringent regulatory standards mandating the use of sterile, single-use medical products to ensure patient and staff safety.

What are the primary challenges faced by the Medical Non-woven Disposables Market?

The market faces challenges such as volatility in raw material prices, environmental concerns regarding the disposal of non-biodegradable products, intense market competition, and the need for significant investments in research and development for sustainable and advanced materials.

How is AI impacting the Medical Non-woven Disposables Market?

AI is impacting the market by optimizing manufacturing processes for efficiency, enhancing quality control through automated defect detection, improving supply chain management and inventory forecasting, and accelerating the development of new materials with tailored properties, ultimately driving innovation and cost-effectiveness.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager