Medium Voltage Drives Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431171 | Date : Nov, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Medium Voltage Drives Market Size

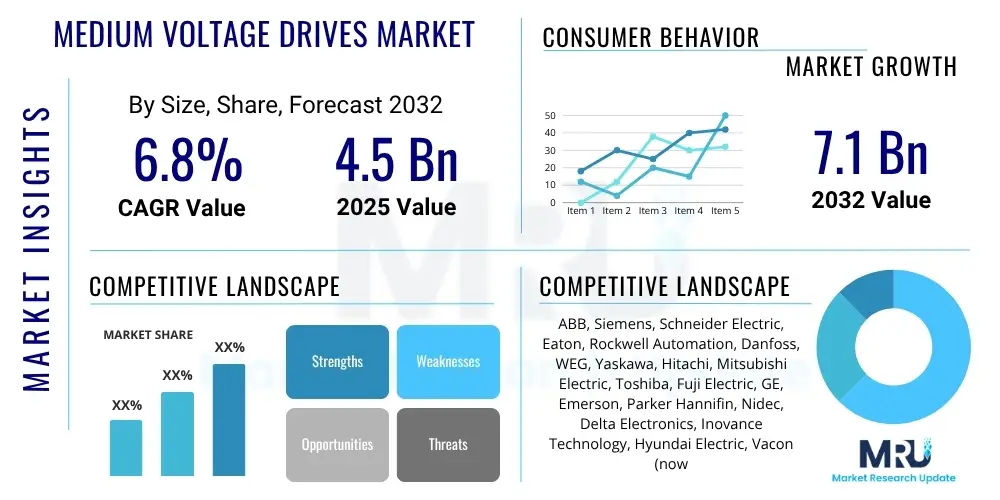

The Medium Voltage Drives Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 4.5 billion in 2025 and is projected to reach USD 7.1 billion by the end of the forecast period in 2032.

Medium Voltage Drives Market introduction

Medium Voltage Drives (MVDs) are sophisticated electronic devices designed to control the speed and torque of alternating current (AC) motors operating at medium voltage levels, typically ranging from 1 kV to 10 kV. These drives achieve precise motor control by varying the frequency and voltage supplied to the motor, enabling optimal performance for a wide array of industrial applications. The fundamental product description involves an input rectifier, a DC link, and an output inverter, which collectively convert fixed frequency AC power into variable frequency and voltage AC power, providing unparalleled operational flexibility and efficiency. Their robust design allows them to handle high power applications, making them indispensable in heavy industries.

Major applications for Medium Voltage Drives span across critical sectors such as oil and gas, power generation, mining, metals, cement, water and wastewater treatment, and marine. In these industries, MVDs are primarily employed to manage large pumps, fans, compressors, conveyors, and mill drives, where precise control, energy efficiency, and extended equipment lifespan are paramount. The benefits derived from deploying MVDs are substantial, including significant energy savings through optimized motor speed, enhanced process control, reduced mechanical stress on equipment, and lower maintenance costs due to smoother operation. These advantages directly contribute to improved operational efficiency and reduced environmental footprint, aligning with global sustainability initiatives.

The market for Medium Voltage Drives is currently being driven by several key factors. A surging global demand for energy efficiency in industrial operations is a primary catalyst, as MVDs can dramatically cut energy consumption in motor-driven systems. Simultaneously, the accelerating trend of industrial automation and digitalization across manufacturing and process industries necessitates advanced motor control solutions. Furthermore, increasing investments in infrastructure development, particularly in emerging economies, alongside the modernization of existing industrial facilities, further propels the adoption of MVDs. Strict environmental regulations and government mandates promoting energy conservation also play a crucial role in expanding the market's reach.

Medium Voltage Drives Market Executive Summary

The Medium Voltage Drives market is experiencing robust growth, primarily fueled by a global emphasis on energy efficiency, escalating industrial automation, and substantial infrastructure development across various sectors. Business trends highlight a strong shift towards intelligent and connected drives, integrating advanced analytics, Internet of Things (IoT), and artificial intelligence (AI) for enhanced predictive maintenance, operational optimization, and real-time monitoring. Manufacturers are increasingly focusing on modular designs, higher power density, and more compact footprints to meet diverse industrial requirements. Furthermore, sustainability initiatives are prompting industries to invest in regenerative drives and solutions that minimize energy waste, thereby boosting market expansion and fostering innovation.

Regional trends indicate that Asia Pacific is emerging as the dominant growth region, driven by rapid industrialization, burgeoning manufacturing sectors, and extensive infrastructure projects, particularly in countries like China, India, and Southeast Asian nations. North America and Europe, while mature markets, are witnessing steady demand, primarily from the modernization and upgrading of existing industrial facilities, stringent energy efficiency regulations, and the adoption of advanced automation technologies in sectors such as power generation and water treatment. Latin America and the Middle East and Africa regions are also showing promising growth, attributed to investments in oil and gas, mining, and renewable energy projects, necessitating robust and efficient motor control solutions.

Segmentation trends within the Medium Voltage Drives market reveal a significant demand for Variable Voltage Source Inverter (VVSI) and Current Source Inverter (CSI) types, favored for their reliability and performance across various power ranges. The oil and gas, power generation, water and wastewater, and metals and mining industries remain the largest end-user segments, consistently investing in MVDs for their critical applications. There is a growing inclination towards drives that offer advanced connectivity features and compatibility with industrial communication protocols, facilitating seamless integration into broader industrial control systems. This trend underscores the market's evolution towards more integrated and data-driven operational environments, enhancing efficiency and reducing downtime.

AI Impact Analysis on Medium Voltage Drives Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Medium Voltage Drives market typically revolve around how AI can enhance operational efficiency, extend equipment lifespan, and optimize energy consumption. Users frequently inquire about the feasibility of AI-driven predictive maintenance, asking if AI algorithms can accurately foresee potential drive failures and recommend proactive interventions. There is also significant interest in AI's role in optimizing motor control parameters in real-time to maximize energy savings and improve process stability. Furthermore, questions often arise about the integration of AI with existing Industrial IoT (IIoT) platforms for comprehensive system monitoring and autonomous adjustments, as well as concerns regarding data security and the complexity of implementing AI solutions within legacy industrial infrastructures.

These inquiries highlight a collective expectation that AI will transform MVD operations from reactive to proactive, providing a new layer of intelligence that transcends traditional control mechanisms. The key themes emerging from this analysis include the potential for AI to dramatically improve diagnostics, enable highly accurate predictive maintenance, and facilitate dynamic energy optimization. Users anticipate that AI will lead to more intelligent, self-optimizing drive systems capable of adapting to changing load conditions and environmental factors, thereby minimizing downtime and operational costs. However, there is also an underlying concern about the technical expertise required for implementation and the need for robust cybersecurity measures to protect sensitive operational data.

- Enhanced Predictive Maintenance: AI algorithms analyze operational data from MVDs to predict potential failures, reducing unplanned downtime and maintenance costs.

- Optimized Energy Consumption: AI dynamically adjusts drive parameters in real-time based on load, process requirements, and energy prices, maximizing efficiency.

- Real-time Diagnostics and Anomaly Detection: AI identifies unusual operating patterns or deviations from baseline performance, enabling early intervention.

- Autonomous Operation and Self-Optimization: AI allows MVDs to adapt and optimize their performance without constant human intervention, improving overall system resilience.

- Improved Process Control: AI-driven insights enable finer control over motor speed and torque, leading to higher product quality and consistency in manufacturing processes.

- Remote Monitoring and Management: AI facilitates advanced remote monitoring capabilities, providing operators with actionable insights and control from anywhere.

- Cybersecurity Enhancements: AI can be employed to detect and respond to cybersecurity threats within networked drive systems, protecting industrial control environments.

- Reduced Human Error: Automation of complex decision-making processes through AI minimizes the potential for human error in MVD operation and maintenance.

DRO & Impact Forces Of Medium Voltage Drives Market

The Medium Voltage Drives market is significantly influenced by a confluence of drivers, restraints, and opportunities that shape its growth trajectory and competitive landscape. Key drivers include the escalating global demand for energy-efficient solutions in industrial processes, propelled by rising energy costs and stringent environmental regulations aimed at reducing carbon emissions. The continuous push for industrial automation and digitalization across sectors such as manufacturing, oil and gas, and power generation further stimulates the adoption of MVDs for precise motor control and operational optimization. Additionally, substantial investments in infrastructure development, particularly in emerging economies, and the modernization of aging industrial facilities in developed regions, contribute significantly to market expansion. The inherent benefits of MVDs, such as extended equipment lifespan and reduced maintenance costs, also act as strong motivators for their deployment.

However, the market also faces considerable restraints that could impede its growth. The high initial capital investment required for Medium Voltage Drives, compared to conventional motor starters, can be a significant deterrent for small and medium-sized enterprises. The technical complexity associated with the installation, commissioning, and maintenance of MVDs necessitates a highly skilled workforce, which can be a limiting factor in regions with labor shortages or insufficient technical expertise. Furthermore, economic slowdowns, geopolitical uncertainties, and fluctuating raw material prices can impact manufacturing costs and project investments, thus slowing market progression. The integration challenges with legacy systems and the perceived reliability risks associated with sophisticated electronics also pose barriers to widespread adoption in some industries.

Despite these challenges, numerous opportunities exist to propel the Medium Voltage Drives market forward. The increasing focus on retrofitting existing industrial infrastructure with MVDs to enhance efficiency and extend asset life presents a lucrative avenue for growth. The integration of MVDs with renewable energy generation systems, such as wind turbines and solar power plants, represents another significant opportunity as the world transitions towards sustainable energy sources. Furthermore, advancements in power electronics, such as the development of silicon carbide (SiC) and gallium nitride (GaN) technologies, offer pathways for more efficient, compact, and cost-effective drives. The expansion into untapped emerging markets, combined with the continuous innovation in intelligent drive solutions featuring AI and IoT capabilities, provides substantial potential for market players to diversify their offerings and capture new customer segments. These impact forces collectively dictate the market dynamics, influencing strategic decisions and competitive strategies.

Segmentation Analysis

The Medium Voltage Drives market is extensively segmented based on various critical parameters, including type, voltage, power rating, application, and end-user industry. This comprehensive segmentation provides a detailed understanding of market dynamics, identifies high-growth areas, and enables stakeholders to tailor their strategies effectively. Each segment reflects specific technological requirements, operational preferences, and industrial demands, contributing to a diverse and evolving market landscape. Analyzing these segments helps in comprehending regional consumption patterns, technological adoption rates, and the competitive environment.

Understanding the interplay between these segments is crucial for market participants. For instance, the choice of drive type (e.g., VVSI vs. CSI) often depends on the specific application's power demands and performance requirements, while voltage and power ratings are determined by the size and operational characteristics of the motor. End-user industries, in turn, drive the demand for specific types and configurations of MVDs based on their unique operational challenges and regulatory environments. This granular view assists in forecasting market trends, identifying niche opportunities, and developing targeted marketing and product development initiatives across the global market. The market's complexity and technological diversity are well-captured through this multi-dimensional segmentation approach, offering clarity on its structure and potential.

- Type:

- Variable Voltage Source Inverter (VVSI)

- Current Source Inverter (CSI)

- Load Commutated Inverter (LCI)

- Others (e.g., Matrix Converters, Multi-level Inverters)

- Voltage Range:

- 1 kV - 3 kV

- 3 kV - 6 kV

- Above 6 kV

- Power Rating:

- Low Power (up to 500 kW)

- Medium Power (501 kW - 5 MW)

- High Power (above 5 MW)

- Application:

- Pumps

- Fans

- Compressors

- Extruders

- Conveyors

- Mill Drives

- Others (e.g., Mixers, Grinders)

- End-User Industry:

- Oil & Gas

- Power Generation (Thermal, Hydro, Nuclear, Renewables)

- Water & Wastewater

- Metals & Mining

- Cement

- Marine

- Chemical & Petrochemical

- Pulp & Paper

- Others (e.g., Food & Beverage, Automotive)

Value Chain Analysis For Medium Voltage Drives Market

The value chain for the Medium Voltage Drives market is a complex ecosystem involving various stages from raw material sourcing to end-user consumption and after-sales support. At the upstream end, the value chain commences with the procurement of critical raw materials and components, including power semiconductors (IGBTs, SiC, GaN), microcontrollers, capacitors, inductors, cooling systems, and various metals and plastics. These components are supplied by specialized manufacturers globally, forming the foundational layer of the drive's construction. The quality and availability of these components directly impact the performance, reliability, and cost-effectiveness of the final MVD product. Strong supplier relationships and efficient inventory management are crucial for manufacturers at this stage to ensure a stable and cost-effective production process, minimizing lead times and mitigating supply chain risks.

Midstream activities involve the design, manufacturing, assembly, and testing of Medium Voltage Drives by original equipment manufacturers (OEMs) and specialized drive manufacturers. This stage requires significant investment in research and development to incorporate advanced power electronics, control algorithms, and communication interfaces. Manufacturers often engage in vertical integration to control key component production or collaborate with technology partners for specific innovations. The manufacturing process involves precision engineering, quality control, and rigorous testing to ensure the drives meet stringent industry standards for performance, safety, and reliability. Differentiation at this stage often comes from proprietary technology, intellectual property, and adherence to specific industry certifications.

Downstream analysis of the Medium Voltage Drives market primarily focuses on distribution channels, installation, system integration, and end-user support. Distribution channels can be direct, where manufacturers sell directly to large industrial clients or system integrators, or indirect, through a network of authorized distributors, agents, and value-added resellers. System integrators play a pivotal role in designing, installing, and commissioning MVDs into complex industrial systems, often customizing solutions to specific application requirements. After-sales support, including maintenance services, spare parts supply, and technical training, is critical for customer satisfaction and long-term relationships, forming a significant part of the revenue stream. The effectiveness of these distribution and service networks is paramount for market penetration and customer retention, as they directly influence the accessibility and operational lifespan of MVD products.

Medium Voltage Drives Market Potential Customers

The potential customers for Medium Voltage Drives are primarily large-scale industrial enterprises and utility companies that operate extensive facilities requiring precise and efficient control of high-power electric motors. These end-users typically invest in MVDs to enhance operational efficiency, reduce energy consumption, improve process control, and extend the lifespan of their critical equipment. Industries such as oil and gas, for instance, rely heavily on MVDs for applications like pipeline pumps, compressors, and drilling rigs, where uninterrupted operation and energy savings are paramount. Similarly, power generation plants utilize MVDs for large boiler feed pumps, cooling tower fans, and induced draft/forced draft fans, contributing to stable and efficient power production.

Beyond the core energy and heavy industry sectors, significant demand for Medium Voltage Drives originates from the water and wastewater treatment sector, where MVDs control large pumps and blowers essential for municipal water supply and effluent management, ensuring reliable and cost-effective operations. The metals and mining industry also represents a substantial customer base, deploying MVDs for mill drives, crushers, conveyors, and smelter fans to handle massive material volumes and withstand harsh operating conditions. The cement industry uses MVDs for kiln drives, fan drives, and grinding mill applications to manage the energy-intensive processes involved in cement production. Marine applications, including propulsion systems and large auxiliary equipment on ships, also increasingly adopt MVDs for enhanced fuel efficiency and maneuverability.

Ultimately, the typical buyers of Medium Voltage Drives are facility managers, plant engineers, procurement specialists, and executive decision-makers within these heavy industries who are focused on optimizing operational expenditures, complying with environmental regulations, and ensuring the reliability and longevity of their motor-driven systems. Their purchasing decisions are influenced by factors such as the total cost of ownership, energy efficiency gains, product reliability, manufacturer reputation, after-sales service quality, and the ability of the drives to seamlessly integrate with existing control systems. The market is characterized by long sales cycles and a strong emphasis on technical specifications and customized solutions to meet the unique demands of diverse industrial applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.5 billion |

| Market Forecast in 2032 | USD 7.1 billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB, Siemens, Schneider Electric, Eaton, Rockwell Automation, Danfoss, WEG, Yaskawa, Hitachi, Mitsubishi Electric, Toshiba, Fuji Electric, GE, Emerson, Parker Hannifin, Nidec, Delta Electronics, Inovance Technology, Hyundai Electric, Vacon (now Danfoss) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Medium Voltage Drives Market Key Technology Landscape

The technological landscape of the Medium Voltage Drives market is characterized by continuous innovation aimed at enhancing efficiency, reliability, and control capabilities. Key advancements revolve around power semiconductor devices, where the transition from traditional silicon-based Insulated Gate Bipolar Transistors (IGBTs) to wide-bandgap materials like Silicon Carbide (SiC) and Gallium Nitride (GaN) is gaining traction. These newer materials enable higher switching frequencies, leading to smaller, lighter, and more efficient drive designs with reduced cooling requirements and power losses. The evolution of multi-level inverter topologies, such as neutral-point clamped (NPC) and cascaded H-bridge (CHB) configurations, is also prominent, allowing for smoother output waveforms, lower harmonic distortion, and improved voltage sharing at higher power ratings, which directly benefits motor longevity and system performance.

Further technological developments include the integration of advanced control algorithms and digital signal processing (DSP) capabilities. Sensorless vector control, for example, eliminates the need for physical speed sensors, reducing complexity and maintenance while maintaining high-performance torque and speed control. Active Front-End (AFE) technology is another significant innovation, allowing for regenerative braking, which feeds energy back into the grid, and significantly improves power factor correction, thereby reducing energy consumption and grid disturbances. The increasing adoption of modular designs facilitates easier installation, maintenance, and scalability of MVDs, enabling industries to customize solutions according to specific operational needs and simplifying upgrades.

The advent of Industrial Internet of Things (IIoT) and cloud connectivity is profoundly shaping the MVD market, transforming drives into intelligent, connected assets. Modern MVDs are now equipped with integrated sensors, communication modules, and edge computing capabilities, allowing for real-time data collection, remote monitoring, predictive maintenance, and advanced diagnostics. This connectivity enables seamless integration with plant-wide control systems and enterprise resource planning (ERP) systems, providing comprehensive insights into operational performance and energy usage. Furthermore, cybersecurity features are becoming increasingly crucial to protect these connected drives from potential cyber threats, ensuring the integrity and reliability of industrial operations. These technological advancements collectively contribute to making MVDs more intelligent, efficient, and integral to smart industrial environments.

Regional Highlights

- North America: A mature market characterized by stringent energy efficiency regulations and a strong emphasis on industrial automation and modernization projects. Key demand drivers include upgrades of aging infrastructure in sectors like power generation, oil and gas, and water and wastewater. The region also sees significant adoption of advanced MVD technologies for optimizing existing facilities.

- Europe: Driven by robust environmental policies, high energy costs, and a focus on sustainable manufacturing practices. Countries like Germany, the UK, and France are leading the adoption of MVDs, particularly in industries such as chemical, pulp and paper, and manufacturing, aiming for reduced carbon footprints and enhanced operational efficiency.

- Asia Pacific (APAC): The fastest-growing region due to rapid industrialization, massive infrastructure development, and increasing investments in manufacturing capabilities, particularly in China, India, Japan, and South Korea. The burgeoning demand from power generation, metals and mining, cement, and chemical industries fuels market expansion, with a strong focus on new project installations.

- Latin America: Characterized by growth in resource-intensive industries such as mining, oil and gas, and agriculture. Countries like Brazil, Mexico, and Chile are key markets, investing in MVDs to enhance productivity and energy efficiency in their core industrial operations. Infrastructure development projects also contribute to demand.

- Middle East and Africa (MEA): Growth is propelled by significant investments in the oil and gas sector, petrochemicals, and large-scale infrastructure projects, including power plants and desalination facilities. The need for reliable and efficient motor control in harsh operating environments drives the adoption of robust MVD solutions, particularly in GCC countries and South Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Medium Voltage Drives Market.- ABB

- Siemens

- Schneider Electric

- Eaton

- Rockwell Automation

- Danfoss

- WEG

- Yaskawa Electric Corporation

- Hitachi Ltd.

- Mitsubishi Electric Corporation

- Toshiba International Corporation

- Fuji Electric Co., Ltd.

- General Electric (GE)

- Emerson Electric Co.

- Parker Hannifin Corporation

- Nidec Corporation

- Delta Electronics, Inc.

- Inovance Technology Co., Ltd.

- Hyundai Electric & Energy Systems Co., Ltd.

- Vacon (now part of Danfoss)

Frequently Asked Questions

What are Medium Voltage Drives?

Medium Voltage Drives (MVDs) are power electronic devices that control the speed and torque of AC motors operating at voltages typically ranging from 1 kV to 10 kV. They achieve this by varying the frequency and voltage supplied to the motor, enabling precise control and optimizing energy consumption in industrial applications.

Why are MVDs important for industrial applications?

MVDs are crucial for industrial applications because they provide precise motor control, leading to significant energy savings, enhanced process stability, reduced mechanical stress on equipment, and extended equipment lifespan. They are essential for managing large motors in heavy industries like oil & gas, mining, and power generation.

How do MVDs contribute to energy efficiency?

MVDs contribute to energy efficiency by allowing motors to operate only at the required speed and torque, rather than at full capacity continuously. This variable speed operation significantly reduces power consumption, especially in pump and fan applications, aligning with global energy conservation mandates and reducing operational costs.

What are the key technological advancements in MVDs?

Key technological advancements include the use of wide-bandgap semiconductors (SiC, GaN) for higher efficiency, multi-level inverter topologies for smoother power output, advanced control algorithms like sensorless vector control, and integration with Industrial IoT (IIoT) for predictive maintenance and remote monitoring. Active Front-End (AFE) technology also enables regenerative braking and improved power factor.

What industries primarily benefit from MVDs?

Industries that primarily benefit from MVDs include oil and gas, power generation, water and wastewater treatment, metals and mining, cement, marine, and chemical and petrochemical sectors. These industries extensively use large motors for critical processes where energy efficiency, precise control, and high reliability are paramount.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager