Melt-Blown Polypropylene Filters Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427752 | Date : Oct, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Melt-Blown Polypropylene Filters Market Size

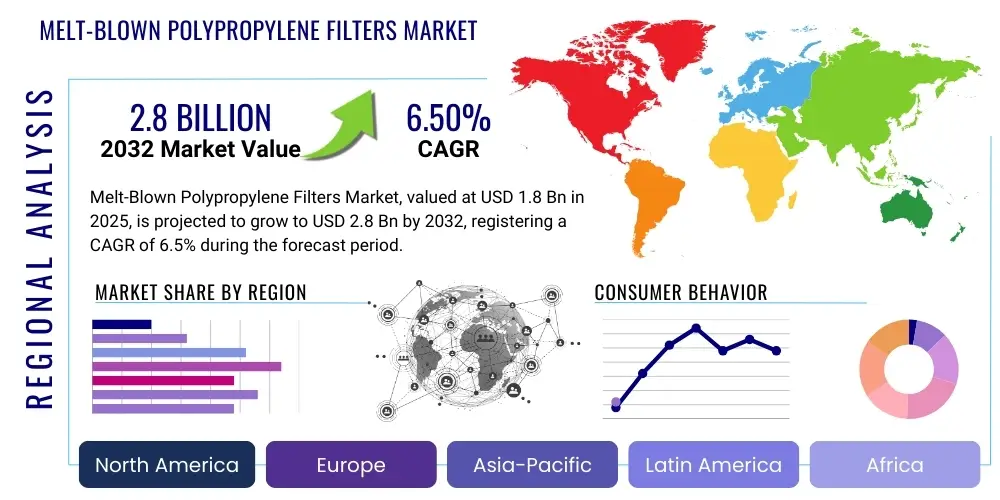

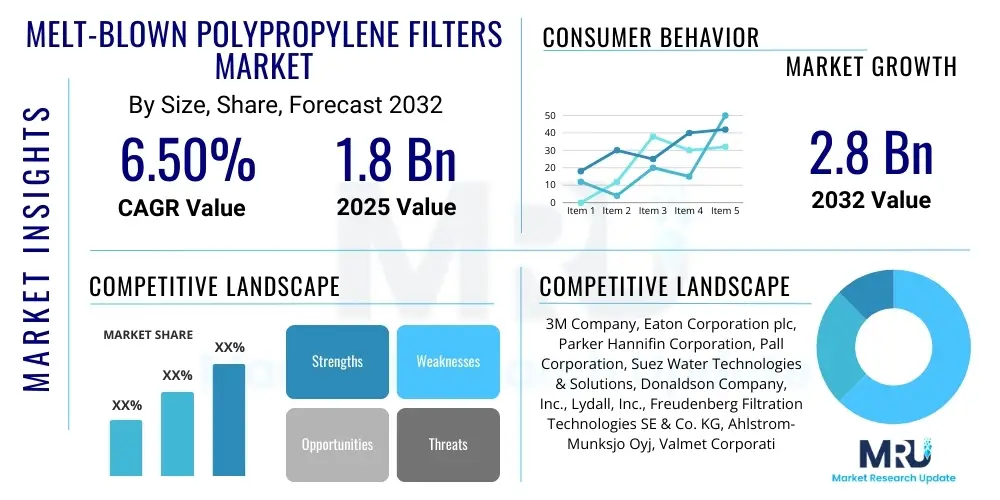

The Melt-Blown Polypropylene Filters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032. The market is estimated at USD 1.8 billion in 2025 and is projected to reach USD 2.8 billion by the end of the forecast period in 2032.

Melt-Blown Polypropylene Filters Market introduction

Melt-blown polypropylene filters are crucial components in various industrial and commercial filtration systems, renowned for their high efficiency in retaining particulates across a wide range of applications. These filters are manufactured through a process where molten polypropylene polymer is extruded through a die into fine filaments, which are then blown by high-velocity gas onto a collection screen, forming a self-bonding, non-woven fabric. This unique manufacturing method creates a depth filter media with a high void volume and a tortuous path for fluid flow, enabling exceptional dirt-holding capacity and efficient particle removal.

The inherent properties of polypropylene, such as its chemical inertness, broad chemical compatibility, and resistance to bacterial growth, make melt-blown filters suitable for demanding environments. They are extensively utilized in critical sectors including water and wastewater treatment, pharmaceuticals, food and beverage processing, chemical and petrochemical industries, and air filtration. The primary benefits include their cost-effectiveness, high efficiency in microfiltration, and the ability to offer graded density structures for progressive particle removal, thereby extending filter lifespan and enhancing overall system performance. The markets growth is predominantly driven by increasing global demand for clean water and air, stringent environmental regulations, rapid industrialization, and the continuous expansion of healthcare and manufacturing sectors requiring superior filtration solutions.

Melt-Blown Polypropylene Filters Market Executive Summary

The Melt-Blown Polypropylene Filters Market is characterized by dynamic business trends centered on technological innovation, sustainability, and market consolidation. Companies are increasingly investing in research and development to enhance filter efficiency, extend lifespan, and develop products with improved environmental footprints, including options for extended use or easier recycling. Strategic partnerships and mergers among key players are also prevalent as firms seek to expand their product portfolios, strengthen distribution networks, and gain a competitive edge in a highly fragmented market. The growing adoption of automation in manufacturing processes is further optimizing production costs and improving product consistency, addressing the rising demand for high-quality, reliable filtration media.

Regionally, Asia-Pacific emerges as the fastest-growing market, propelled by rapid industrialization, urbanization, and increasing investment in water and wastewater infrastructure across countries like China and India. North America and Europe, while mature, continue to hold significant market shares due to stringent regulatory frameworks governing industrial emissions and water quality, alongside robust pharmaceutical and food and beverage sectors. Segment-wise, depth filtration remains dominant, with a notable trend towards finer micron ratings and specialized filters tailored for specific contaminants. There is also an observable shift towards filters offering higher flow rates with minimal pressure drop, catering to energy efficiency demands in large-scale industrial applications. These trends collectively underscore a market evolving towards greater efficiency, sustainability, and application-specific customization to meet diverse global needs.

AI Impact Analysis on Melt-Blown Polypropylene Filters Market

The integration of Artificial Intelligence (AI) across various stages of the Melt-Blown Polypropylene Filters market is a burgeoning area of interest, with users frequently inquiring about its potential to revolutionize manufacturing processes, enhance product quality, and optimize supply chain operations. Common questions revolve around how AI can improve the precision of the melt-blowing process, enable predictive maintenance for machinery, streamline quality control, and inform demand forecasting. There is significant user expectation that AI will lead to more efficient resource utilization, reduce waste, and accelerate the development of advanced filter media, ultimately contributing to higher performance and more sustainable products.

The overarching themes in user inquiries highlight a desire for AI-driven solutions that address key operational challenges, such as minimizing defects, maximizing production throughput, and accurately predicting market needs to prevent overproduction or shortages. Furthermore, users are keen to understand AIs role in creating smart filters that can monitor their own performance and signal replacement needs, as well as in enabling the development of next-generation materials with superior filtration characteristics. The consensus points towards AI as a transformative force, capable of driving innovation, operational excellence, and competitive differentiation within the melt-blown polypropylene filters industry.

- AI-driven optimization of melt-blowing parameters, leading to enhanced fiber consistency and pore structure for superior filtration performance.

- Predictive maintenance for manufacturing equipment, reducing downtime and operational costs by anticipating machinery failures.

- Automated quality control systems utilizing computer vision and machine learning for real-time defect detection and quality assurance.

- Improved demand forecasting and inventory management through AI algorithms analyzing historical data, market trends, and external factors.

- Acceleration of research and development for new filter media and designs by simulating material properties and performance characteristics.

- Development of smart filtration systems incorporating AI for real-time monitoring of filter performance and remaining lifespan.

- Supply chain optimization, including logistics, supplier selection, and risk management, leading to greater efficiency and resilience.

DRO & Impact Forces Of Melt-Blown Polypropylene Filters Market

The Melt-Blown Polypropylene Filters Market is shaped by a complex interplay of drivers, restraints, opportunities, and various impact forces that influence its growth trajectory and competitive landscape. Key drivers include the escalating global demand for clean water and air, fueled by rapid industrialization, urbanization, and increasing public awareness regarding health and environmental protection. Stringent environmental regulations imposed by governmental bodies worldwide mandate efficient filtration systems in industrial processes, wastewater treatment, and air purification, thereby boosting the adoption of these filters. Furthermore, the continuous expansion of end-use industries such as pharmaceuticals, food and beverage, and chemical processing, which heavily rely on high-purity filtration for product integrity and safety, significantly propels market demand. Technological advancements leading to more efficient and durable filter media also serve as a strong market driver.

However, the market also faces considerable restraints, primarily the volatility in raw material prices, particularly polypropylene resin, which can directly impact manufacturing costs and product pricing. Intense competition among a large number of established players and new entrants often leads to price wars, compressing profit margins. Environmental concerns surrounding the disposal of single-use filters, especially in the context of growing sustainability pressures, present a long-term challenge that necessitates innovation in filter recyclability or biodegradable alternatives. Opportunities for market growth primarily stem from ongoing research and development in advanced filter technologies, including the creation of multi-layer or composite filters with enhanced performance characteristics and longer service life. Emerging applications in niche markets, such as specialized biotechnology filtration or high-purity electronics manufacturing, also offer significant avenues for expansion. The increasing focus on adopting sustainable manufacturing practices and developing eco-friendly filter solutions represents a crucial opportunity to address environmental concerns and meet evolving consumer and regulatory expectations.

The impact forces influencing this market include the bargaining power of buyers, who often seek cost-effective solutions without compromising on filtration efficiency, and the bargaining power of suppliers, particularly polypropylene resin manufacturers, whose pricing strategies can significantly affect production costs. The threat of new entrants is moderate, given the capital-intensive nature of manufacturing melt-blown media and the need for specialized technical expertise, yet technological innovations could lower these barriers over time. The threat of substitute products, such as ceramic or membrane filters, is always present, especially for highly demanding applications where their specific properties may offer advantages. Finally, competitive rivalry is high, driven by numerous global and regional players constantly innovating and vying for market share through product differentiation, pricing strategies, and expansive distribution networks. These forces collectively shape the strategic decisions and operational dynamics within the Melt-Blown Polypropylene Filters Market.

Segmentation Analysis

The Melt-Blown Polypropylene Filters Market is extensively segmented to provide a granular understanding of its diverse applications, product types, and end-user demands. This segmentation allows for a detailed analysis of market dynamics across various categories, enabling stakeholders to identify key growth areas, competitive landscapes, and strategic opportunities. The market can be categorized based on several critical parameters, including filter type, micron rating, and the specific application or end-use industry, each revealing distinct consumption patterns and technological requirements.

Understanding these segments is crucial for manufacturers to tailor their product offerings, for distributors to optimize their supply chains, and for investors to make informed decisions. For instance, the demand for filters with ultra-fine micron ratings is significantly driven by pharmaceutical and semiconductor industries, while general water treatment applications might utilize filters with broader micron ranges. Similarly, the growth in the food and beverage sector necessitates filters compliant with strict regulatory standards, differing from those used in industrial wastewater treatment. These distinct needs underscore the importance of a comprehensive segmentation analysis in navigating the complexities of the global melt-blown polypropylene filters market.

- By Type:

- Absolute-Rated Filters

- Nominal-Rated Filters

- By Micron Rating:

- Less than 1 micron

- 1 to 5 micron

- 5 to 25 micron

- Greater than 25 micron

- By Application:

- Water & Wastewater Treatment

- Chemical & Petrochemical

- Pharmaceuticals & Biotechnology

- Food & Beverage

- Air Filtration (HVAC, Cleanrooms)

- Oil & Gas

- Electronics (Semiconductor Manufacturing)

- Other Industrial Applications

- By End-Use Industry:

- Industrial

- Commercial

- Residential

Melt-Blown Polypropylene Filters Market Value Chain Analysis

The value chain of the Melt-Blown Polypropylene Filters Market begins with upstream activities, primarily encompassing the procurement and processing of raw materials. The most critical raw material is polypropylene resin, which is sourced from petrochemical companies specializing in polymer production. These suppliers transform crude oil derivatives into high-grade polypropylene pellets suitable for the melt-blown manufacturing process. Quality and consistency of these raw materials are paramount, as they directly influence the filtration performance and durability of the final product. Effective supplier relationships and robust quality control at this stage are essential for maintaining production standards and managing costs.

Moving downstream, the value chain involves the manufacturing of the melt-blown filter media, which includes the extrusion, fiberization, and collection processes that form the filter cartridges or sheets. This stage is capital-intensive and requires specialized machinery and technical expertise to produce filters with precise micron ratings and structural integrity. Following manufacturing, products move through various distribution channels to reach end-users. Distribution can be direct, where manufacturers sell directly to large industrial clients or through their own sales forces, offering tailored solutions and technical support. Alternatively, indirect distribution involves a network of distributors, wholesalers, and retailers who cater to a broader range of smaller industrial clients, commercial businesses, and even residential users. These intermediaries provide market reach, logistics support, and localized customer service. Both direct and indirect channels play a vital role in ensuring market penetration and product accessibility across diverse geographic and application segments.

Melt-Blown Polypropylene Filters Market Potential Customers

The potential customers for Melt-Blown Polypropylene Filters span a wide array of industries and applications, reflecting the universal need for efficient fluid and air purification. These filters serve as critical components in ensuring product quality, operational efficiency, and compliance with stringent regulatory standards across various sectors. The primary end-users are those industries requiring the removal of suspended solids, sediments, and other particulates from water, chemicals, gases, or air streams, making them indispensable for a multitude of industrial, commercial, and even certain residential processes.

Key segments of potential buyers include municipal water treatment plants and industrial facilities that rely on these filters for pre-filtration, potable water production, and wastewater discharge compliance. Pharmaceutical and biotechnology companies are significant consumers, utilizing melt-blown filters for sterile filtration, media preparation, and product purification, where high purity and material inertness are crucial. The food and beverage industry employs these filters for process water treatment, clarification of liquids, and pre-filtration ahead of more advanced membrane systems. Additionally, chemical and petrochemical plants use them for aggressive fluid filtration, while HVAC systems, cleanroom facilities, and oil and gas operations depend on them for air quality control and process fluid purification, respectively. Manufacturers of electronics, particularly semiconductors, also represent a high-value customer segment due to their demand for ultra-pure water and controlled environments.

Melt-Blown Polypropylene Filters Market Key Technology Landscape

The technology landscape for Melt-Blown Polypropylene Filters is characterized by continuous innovation aimed at enhancing filtration efficiency, dirt-holding capacity, and overall product lifespan. The core melt-blowing process itself has seen advancements, moving beyond conventional single-layer designs to multi-layer and graded density filter structures. These sophisticated designs allow for progressive particle retention, where larger particles are trapped in the outer layers and finer particles in the inner layers, significantly extending the filters service life and maintaining a low-pressure drop. Manufacturers are also experimenting with variations in fiber diameter and pore size distribution to optimize filtration performance for specific applications.

Beyond the fundamental melt-blown process, the technology landscape includes developments in material science and surface modification. Research into composite materials, where polypropylene is combined with other polymers or additives, aims to impart additional properties such as enhanced chemical resistance, antimicrobial characteristics, or oleophobic/hydrophobic properties. Surface treatment technologies, including plasma treatment or coating applications, are being developed to alter the filter medias surface energy, improving its ability to repel or attract specific substances. Furthermore, advancements in filter cartridge design, such as pleating technologies for increased surface area or improved sealing mechanisms, contribute to overall system efficiency and reliability. The integration of smart manufacturing techniques, including advanced sensors and real-time process control, is also becoming prevalent to ensure consistent product quality and optimize production parameters.

Regional Highlights

- North America: A mature market with stringent regulatory frameworks for water and air quality. High adoption in pharmaceuticals, food and beverage, and industrial sectors. Focus on advanced and high-performance filtration solutions.

- Europe: Driven by strict environmental regulations and a strong emphasis on sustainability. Significant demand from the chemical, automotive, and wastewater treatment industries. Increasing investment in energy-efficient filtration technologies.

- Asia-Pacific: The fastest-growing market, propelled by rapid industrialization, urbanization, and increasing population. Major demand from China, India, and Southeast Asian countries for water treatment, manufacturing, and healthcare. Emerging economies in the region are expanding infrastructure and industrial capacities, necessitating robust filtration systems.

- Latin America: An emerging market with growing industrialization and increasing investment in infrastructure projects. Demand for melt-blown polypropylene filters is rising in the regions burgeoning food and beverage, mining, and municipal water treatment sectors.

- Middle East & Africa: Characterized by significant investments in oil and gas, petrochemical, and water desalination projects. Demand is driven by the need for process water treatment and industrial fluid filtration, especially in water-scarce regions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Melt-Blown Polypropylene Filters Market.- 3M Company

- Eaton Corporation plc

- Parker Hannifin Corporation

- Pall Corporation (A Danaher Company)

- Suez Water Technologies & Solutions

- Donaldson Company, Inc.

- Lydall, Inc. (now part of Solvay)

- Freudenberg Filtration Technologies SE & Co. KG

- Ahlstrom-Munksjo Oyj

- Valmet Corporation

- GVS S.p.A.

- Veolia Water Technologies (formerly part of Suez)

- Shanghai Huitong Filter Mfg Co., Ltd.

- Brother Filtration

- Filtration Group Corporation

Frequently Asked Questions

What are melt-blown polypropylene filters primarily used for?

Melt-blown polypropylene filters are primarily utilized for fluid and air filtration in various industries, including water treatment, pharmaceuticals, food and beverage, chemical processing, and air purification, due to their high efficiency in removing particulates.

What are the main benefits of using melt-blown polypropylene filters?

Key benefits include high particle retention efficiency, superior dirt-holding capacity, broad chemical compatibility, cost-effectiveness, and the ability to offer graded density for extended service life.

How is the melt-blown polypropylene filter market growing?

The market is experiencing steady growth, projected at a CAGR of 6.5% from 2025 to 2032, driven by increasing demand for clean water/air, industrialization, and stringent environmental regulations.

What challenges does the melt-blown polypropylene filter market face?

Challenges include volatility in raw material prices (polypropylene), intense market competition, and environmental concerns regarding the disposal of single-use filters, which prompt a need for sustainable solutions.

How does AI impact melt-blown filter manufacturing and performance?

AI impacts manufacturing by optimizing process parameters, enabling predictive maintenance, improving quality control, and enhancing demand forecasting. It also accelerates R&D for advanced filter media, leading to superior performance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Melt-Blown Polypropylene Filters Market Size Report By Type (Liquid, Air), By Application (Water and Wastewater, Chemicals, Food and Beverages, Pharmaceuticals, Oil and Gas,, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Statistics, Trends, Outlook and Forecast 2025-2032

- Melt-Blown Polypropylene Filters Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Liquid Media, Air Media), By Application (Food and Beverages, Water and Wastewater, Chemical, Pharmaceuticals, Oil and Gas, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager