Metal Cord Grips Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429477 | Date : Nov, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Metal Cord Grips Market Size

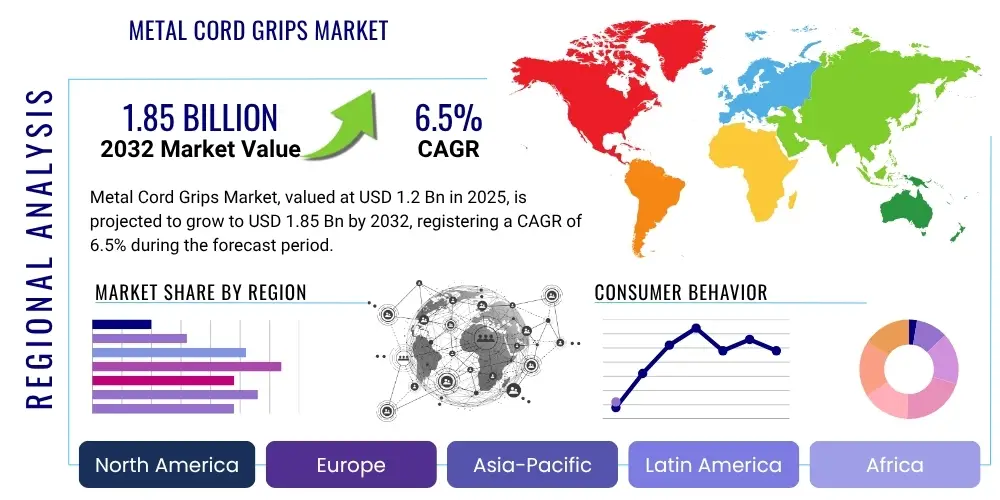

The Metal Cord Grips Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032. The market is estimated at USD 1.2 Billion in 2025 and is projected to reach USD 1.85 Billion by the end of the forecast period in 2032.

Metal Cord Grips Market introduction

The Metal Cord Grips Market encompasses the global trade and utilization of devices designed to secure and seal electrical cables as they enter or exit an enclosure or equipment. These critical components provide robust strain relief, preventing cable pull-out or damage due to tension, bending, or twisting. Furthermore, metal cord grips offer superior environmental sealing against dust, moisture, and liquids, crucial for maintaining the integrity of electrical systems in harsh environments. Product descriptions typically highlight their construction from materials such as nickel-plated brass, stainless steel, or aluminum, chosen for their durability, corrosion resistance, and electromagnetic interference (EMI) shielding capabilities. Major applications span a wide range of industrial and commercial sectors including industrial machinery, automation and robotics, electrical infrastructure, renewable energy installations, construction, transportation, and marine applications, where reliable and safe cable management is paramount. The primary benefits of employing metal cord grips include enhanced safety by preventing electrical shorts and hazards, prolonged cable lifespan, reduced maintenance costs, and compliance with stringent international safety and performance standards. Key driving factors propelling market growth include the accelerating pace of industrial automation, the global expansion of infrastructure projects, the increasing adoption of renewable energy technologies demanding robust connectivity, and the ever-tightening regulatory landscape emphasizing industrial safety and environmental protection for electrical installations across diverse applications.

Metal Cord Grips Market Executive Summary

The Metal Cord Grips Market demonstrates dynamic growth fueled by widespread industrial advancements and increasing demands for robust electrical infrastructure. Business trends indicate a strong focus on developing specialized cord grips tailored for extreme conditions, including high temperatures, corrosive chemicals, and explosive atmospheres, reflecting a shift towards high-performance solutions. Manufacturers are increasingly integrating features such as enhanced EMI RFI shielding, improved sealing capabilities, and modular designs to cater to complex industrial requirements and emerging applications in smart manufacturing and IoT deployments. Regional trends reveal Asia Pacific as a dominant and rapidly expanding market, driven by extensive industrialization, significant investments in manufacturing capabilities, and rapid urbanization, particularly in countries like China and India. North America and Europe also contribute substantially, propelled by stringent safety regulations, modernization of existing infrastructure, and a growing emphasis on renewable energy projects, demanding reliable and durable electrical connections. Segment trends highlight a sustained demand for stainless steel and nickel-plated brass grips due to their superior durability and resistance properties, making them preferred choices in heavy industrial and outdoor applications. There is also a notable surge in demand for multi-cable and specialized thread type grips as industrial setups become more intricate, requiring efficient cable routing and sealing for multiple conductors. The market anticipates continued innovation in material science and design, alongside strategic collaborations and acquisitions among key players, to maintain competitive advantage and address evolving technological landscapes and stringent regulatory environments globally.

AI Impact Analysis on Metal Cord Grips Market

User questions regarding AI's impact on the Metal Cord Grips Market frequently revolve around how artificial intelligence and machine learning technologies might influence manufacturing processes, product design, supply chain efficiencies, and the overall demand dynamics for these components. Users are keen to understand if AI can lead to more customized or intelligent cord grip solutions, optimize production lines, enhance quality control, or predict maintenance needs in systems where cord grips are critical. Common concerns include the potential for AI-driven automation to reduce manual labor in installation, the role of AI in improving material selection for specific environmental challenges, and whether AI could enable predictive analytics for cord grip performance in harsh operational settings. The key themes that emerge from this analysis are focused on efficiency gains in production and logistics, the potential for intelligent design and material innovation, and the use of AI for quality assurance and predictive maintenance within interconnected industrial ecosystems.

- AI driven automation in manufacturing facilities can optimize the production of metal cord grips by enhancing precision, reducing waste, and increasing throughput, leading to more cost-effective and consistent products.

- Predictive maintenance algorithms, powered by AI, can monitor the performance and degradation of electrical systems and cables, potentially signaling the need for cord grip inspection or replacement, thus influencing aftermarket demand.

- AI can analyze vast datasets on material performance and environmental conditions to inform the design of next-generation metal cord grips, optimizing their resistance to corrosion, extreme temperatures, or specific chemical exposures.

- Supply chain management for metal cord grip components can be significantly improved through AI, enabling better forecasting of demand, optimizing inventory levels, and streamlining logistics from raw material procurement to final product distribution.

- Quality control processes can leverage AI for automated visual inspection systems, identifying microscopic flaws or inconsistencies in manufacturing that human inspectors might miss, ensuring higher product reliability and safety standards.

- AI and machine learning can enable the development of 'smart' cord grips that might incorporate embedded sensors to monitor cable integrity, temperature, or humidity, transmitting data for real-time operational insights within an IoT framework.

- The increasing adoption of AI in industrial automation and robotics creates a direct demand for high-performance metal cord grips that can withstand the dynamic movements and robust operational requirements of AI-powered machinery.

DRO & Impact Forces Of Metal Cord Grips Market

The Metal Cord Grips Market is primarily driven by several powerful forces, including the relentless expansion of industrial automation and robotics, which necessitates reliable and secure electrical connections in dynamic operational environments. The escalating global demand for robust and durable cable management solutions, particularly in heavy industry, marine, and outdoor installations, further propels market growth as metal cord grips offer superior protection against mechanical stress, environmental ingress, and electromagnetic interference compared to their plastic counterparts. Stringent international safety regulations and industry standards, such as those related to electrical safety, explosion protection (ATEX/IECEx), and fire resistance, mandate the use of high-integrity components like metal cord grips to prevent electrical hazards and ensure operational continuity. Furthermore, the rapid growth in renewable energy sectors, including solar and wind power, requires extensive and resilient cabling infrastructure that relies heavily on metal cord grips for protection and longevity. However, the market faces restraints such as the inherent volatility in raw material prices, particularly for metals like brass, stainless steel, and aluminum, which can impact manufacturing costs and product pricing, potentially leading to price sensitivity among buyers. Intense competition from more economical plastic cord grip alternatives, especially in less demanding applications, also poses a challenge, as plastic options often offer a lower initial investment. High initial costs for specialized metal cord grips designed for niche or extreme applications can also act as a barrier to adoption in certain segments. Despite these challenges, significant opportunities abound, particularly with the expanding industrialization in emerging economies where new manufacturing facilities and infrastructure projects are continuously being developed. The growing trend towards smart cities and advanced manufacturing, often involving complex data and power networks, creates a new avenue for specialized, high-performance cord grips. Customization for extremely harsh environments, such as those found in offshore oil and gas, chemical processing, or aerospace, provides a premium market segment for manufacturers capable of engineering bespoke solutions. The potential for integrating cord grips with IoT systems, perhaps through embedded sensors for monitoring, represents a futuristic growth area. The market is also heavily influenced by impact forces such as ongoing technological advancements in material science, leading to the development of new alloys or coatings that enhance durability and performance. Global economic shifts, trade policies, and geopolitical stability can impact manufacturing costs and supply chain reliability. Evolving environmental and sustainability mandates are pushing manufacturers towards more eco-friendly production processes and recyclable materials. Additionally, dynamic changes in industry standards and certifications continually necessitate product innovation and adaptation to ensure market relevance and compliance.

Segmentation Analysis

The Metal Cord Grips market is extensively segmented to categorize products based on their specific characteristics, materials, and intended applications, allowing for a detailed understanding of market dynamics and targeted strategies. This segmentation helps both manufacturers and end-users to identify and procure the most appropriate cord grip solutions for diverse operational requirements, ranging from basic cable entry points to highly specialized, harsh environment applications. The primary segmentation criteria typically include the grip's type or form factor, the material it is constructed from, the specific thread type used for mounting, and its major end-use application sectors. Each segment addresses distinct needs within the broader industrial and electrical connectivity landscape, reflecting variances in performance requirements, environmental resilience, and cost considerations.

- By Type:

- Straight: The most common type, used when the cable enters an enclosure directly perpendicular to the surface, offering simple and effective strain relief and sealing.

- Angled: Designed for applications where cable routing requires a bend immediately at the entry point, typically 90 degrees, optimizing space and reducing cable stress.

- Multi-Cable: Engineered to allow multiple cables to pass through a single entry point, saving space and simplifying installation in complex wiring setups.

- Right-Angle: Similar to angled but specifically designed for compact spaces requiring the cable to run parallel to the mounting surface after entry, offering a clean aesthetic and functional benefit.

- By Material:

- Nickel-Plated Brass: Offers excellent corrosion resistance, high strength, good conductivity for grounding, and aesthetic appeal, making it suitable for general industrial and demanding environments.

- Stainless Steel: Provides superior corrosion resistance, especially in harsh chemical, marine, and food and beverage applications, along with high mechanical strength and hygienic properties.

- Aluminum: Lightweight, corrosion-resistant, and non-magnetic, often used in aerospace, railway, and outdoor lighting applications where weight reduction is critical.

- Galvanized Steel: A cost-effective option offering good corrosion resistance due to its zinc coating, suitable for various industrial and outdoor applications where stainless steel might be overkill.

- By Thread Type:

- Metric (M): Standardized in Europe and many parts of Asia, specified by diameter (e.g., M12, M20, M25), offering fine pitch and widespread compatibility in metric-based systems.

- NPT (National Pipe Taper): Common in North America, characterized by a tapered thread that provides a secure, pressure-tight seal without a gasket when fully tightened.

- PG (Panzergewinde): An older German standard, still found in some legacy industrial installations, though increasingly being replaced by Metric threads in new designs.

- G (BSP - British Standard Pipe): Used for parallel pipe threads, providing a mechanical seal rather than a pressure-tight seal, often requiring a washer or O-ring for sealing.

- By Application:

- Industrial Machinery: Used extensively in manufacturing equipment, robotics, and processing machinery for robust cable management and protection against industrial fluids, vibrations, and debris.

- Automation and Robotics: Critical for securing and guiding cables in highly dynamic and precise robotic arms, automated assembly lines, and control cabinets, ensuring reliable operation.

- Electrical Infrastructure: Employed in power distribution panels, control gear, switchboards, and public utility installations for durable and safe cable entry.

- Renewable Energy: Essential for solar panel installations, wind turbines, and other green energy systems, providing protection against harsh outdoor elements and ensuring long-term operational integrity.

- Construction: Utilized in building wiring, infrastructure projects, and temporary power distribution for secure and weather-resistant cable connections.

- Transportation: Applied in railway systems, automotive manufacturing, and shipbuilding for reliable cable routing in environments subject to vibration, temperature extremes, and moisture.

- Marine: Specifically designed to withstand saltwater corrosion and extreme weather conditions in marine vessels, offshore platforms, and dockside equipment.

- Food and Beverage: Stainless steel grips are paramount here due to hygienic requirements and resistance to wash-down chemicals, ensuring compliance with strict sanitation standards.

Value Chain Analysis For Metal Cord Grips Market

The value chain for the Metal Cord Grips Market encompasses a series of interconnected activities that transform raw materials into finished products delivered to the end-user, highlighting the flow of goods, information, and value creation. The upstream analysis begins with the procurement of essential raw materials, primarily various grades of metals such as brass, stainless steel, aluminum, and galvanized steel, alongside complementary materials like rubber, plastic, and synthetic elastomers for seals and gaskets. Key suppliers in this segment are metal mills, chemical companies for sealing compounds, and specialty component manufacturers. Manufacturers of metal cord grips then engage in design, engineering, machining, casting, stamping, plating, and assembly processes, often employing advanced CNC machinery and specialized finishing techniques to produce high-quality, precise components. Quality control and adherence to international standards are paramount at this stage. The downstream analysis focuses on the channels through which these finished products reach the end-users. This primarily involves a robust network of industrial distributors, electrical wholesalers, and specialized product resellers who serve as intermediaries, managing inventory, providing technical support, and facilitating sales to a diverse customer base. Distribution channels are varied, including both direct and indirect sales approaches. Direct sales involve manufacturers selling directly to large original equipment manufacturers (OEMs) or major industrial clients, often for bulk orders or highly customized solutions, allowing for closer collaboration and tailored support. Indirect distribution, which forms a significant portion of the market, leverages industrial supply houses, electrical distributors, and online marketplaces to reach a broader customer base, including small to medium-sized enterprises, contractors, and maintenance professionals. The efficiency of these distribution networks, coupled with effective logistics, plays a critical role in market penetration and customer satisfaction, ensuring timely delivery and availability of a wide range of products to meet specific application requirements across various industries.

Metal Cord Grips Market Potential Customers

The potential customers for Metal Cord Grips are diverse and span across nearly every sector that utilizes electrical wiring and requires robust, secure, and environmentally protected cable entry points. These end-users or buyers prioritize safety, reliability, and compliance with stringent industry standards, making metal cord grips an essential component in their operations. Industrial manufacturers represent a significant customer segment, encompassing sectors such as automotive, aerospace, machinery, and heavy equipment production, where reliable electrical connectivity is critical for complex automation systems and power distribution. Electrical contractors and installation companies are also key buyers, as they are responsible for wiring new buildings, upgrading existing infrastructure, and installing machinery, constantly requiring high-quality cable management solutions that meet project specifications and safety codes. Automation integrators and robotics companies extensively utilize metal cord grips to protect the delicate wiring in robotic arms, control panels, and automated production lines from mechanical stress, vibration, and environmental ingress, ensuring uninterrupted operation. Construction companies require durable and weather-resistant cord grips for temporary power setups, permanent building wiring, and infrastructure projects like tunnels and bridges. Furthermore, utility providers and energy companies, particularly in the rapidly expanding renewable energy sector (solar, wind, hydroelectric), are crucial customers, demanding specialized metal cord grips capable of withstanding extreme outdoor conditions, UV radiation, and temperature fluctuations while ensuring the longevity and efficiency of their installations. Marine and offshore industries, chemical processing plants, and food and beverage manufacturers also represent vital customer bases, given their specific needs for corrosion resistance, explosion protection, and hygienic design, respectively. These customers continually seek products that offer superior performance, longevity, and adherence to specific regulatory requirements, driving demand for advanced metal cord grip solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.2 Billion |

| Market Forecast in 2032 | USD 1.85 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., HellermannTyton Group PLC, Eaton Corporation plc, Hubbell Incorporated, Emerson Electric Co., Southwire Company LLC, Remke Industries, Inc., Roxtec Group AB, Sealcon LLC, Thomas & Betts Corporation (ABB), Wiska Hoppmann GmbH, Lapp Group, Hummel AG, Conec, OBO Bettermann Holding GmbH & Co. KG, Interflex, Heyco Products, Inc., Mencom Corporation, igus GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Metal Cord Grips Market Key Technology Landscape

The Metal Cord Grips Market's technology landscape is continuously evolving, driven by the need for enhanced performance, greater reliability, and compliance with increasingly stringent safety and environmental regulations. A fundamental aspect of this landscape involves advanced sealing technologies, employing specialized elastomers, molded gaskets, and lamellar inserts made from materials like EPDM, NBR, or silicone that offer superior resistance to chemicals, oils, UV radiation, and extreme temperatures, ensuring long-term environmental protection and maintaining ingress protection (IP) ratings. Furthermore, the development of robust electromagnetic interference (EMI) and radio frequency interference (RFI) shielding capabilities is crucial, especially in data-intensive industrial applications where sensitive electronics require protection from external electromagnetic noise. This is achieved through conductive plating, integrated grounding rings, and specialized internal designs that create a continuous shield. Corrosion-resistant coatings and material treatments are also critical, particularly for applications in marine, chemical processing, and outdoor environments, extending the lifespan and reliability of the grips. Innovations in modular designs allow for greater flexibility and easier installation, often featuring fewer components and tool-free assembly mechanisms that simplify cable routing and maintenance. The demand for explosion-proof (Ex) rated cord grips, compliant with standards such as ATEX and IECEx, is driving advancements in designs that safely contain potential sparks or explosions, making them indispensable in hazardous environments. Additionally, quick-connect and push-in technologies are gaining traction, offering faster and more efficient installation without compromising on strain relief or sealing integrity. The integration of specialized thread types and designs, optimized for specific mounting requirements and material thicknesses, further exemplifies the nuanced technological advancements within this market, ensuring that metal cord grips can meet the diverse and demanding needs of modern industrial and electrical systems with precision and durability.

Regional Highlights

- North America: This region demonstrates a mature market for metal cord grips, characterized by significant industrial automation, robust infrastructure development, and stringent safety standards. The United States and Canada are leading consumers, driven by investments in manufacturing, data centers, and the modernization of electrical grids. Demand is strong for high-performance and specialty cord grips that comply with UL and CSA certifications, particularly in energy, telecommunications, and automotive industries.

- Europe: Europe represents a highly regulated market with a strong emphasis on industrial safety, environmental protection, and energy efficiency. Countries like Germany, France, and the UK are major contributors, fueled by advanced manufacturing, renewable energy projects, and smart city initiatives. The market is significantly influenced by IEC and ATEX directives, driving demand for high-quality, certified, and explosion-proof metal cord grips, especially in the chemical, pharmaceutical, and offshore sectors.

- Asia Pacific (APAC): APAC is the fastest-growing market for metal cord grips, propelled by rapid industrialization, extensive infrastructure development, and increasing foreign direct investment in manufacturing capabilities, particularly in China, India, Japan, and South Korea. The region's expanding electronics manufacturing, automotive production, and burgeoning renewable energy sector are significant demand drivers, often prioritizing cost-effectiveness alongside growing needs for international standard compliance.

- Latin America: This region is experiencing steady growth in the metal cord grips market, primarily driven by investments in mining, oil and gas, and infrastructure development projects. Countries like Brazil and Mexico are key markets, benefiting from increased industrial activity and the expansion of their manufacturing bases. The demand is for durable and reliable solutions that can withstand challenging environmental conditions, particularly in remote and resource-rich areas.

- Middle East and Africa (MEA): The MEA region is witnessing growing demand for metal cord grips, largely due to significant investments in oil and gas infrastructure, construction, and power generation projects. Countries such as Saudi Arabia, UAE, and South Africa are leading the market, driven by large-scale industrialization and urbanization. The demand focuses on high-performance and corrosion-resistant grips suitable for harsh climatic conditions and critical industrial applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Metal Cord Grips Market.- ABB Ltd.

- HellermannTyton Group PLC

- Eaton Corporation plc

- Hubbell Incorporated

- Emerson Electric Co.

- Southwire Company LLC

- Remke Industries, Inc.

- Roxtec Group AB

- Sealcon LLC

- Thomas & Betts Corporation (ABB)

- Wiska Hoppmann GmbH

- Lapp Group

- Hummel AG

- Conec

- OBO Bettermann Holding GmbH & Co. KG

- Interflex

- Heyco Products, Inc.

- Mencom Corporation

- igus GmbH

Frequently Asked Questions

What are the primary benefits of metal cord grips over plastic alternatives?

Metal cord grips offer superior durability, corrosion resistance, and mechanical strength, making them ideal for harsh industrial environments. They also provide better electromagnetic interference (EMI) shielding, fire resistance, and enhanced security against tampering, ensuring greater safety and longevity for electrical installations compared to plastic options.

Which industries are the largest consumers of metal cord grips?

The largest consumers include industrial machinery manufacturing, automation and robotics, electrical infrastructure development, and renewable energy sectors. These industries prioritize robust cable management solutions that can withstand severe conditions and ensure reliable, safe operation.

How do safety standards and regulations influence the metal cord grips market?

Strict safety standards, such as UL, CSA, IEC, and ATEX, significantly drive market demand by mandating the use of certified, high-integrity cord grips to prevent electrical hazards, ensure environmental sealing, and guarantee operational safety, especially in hazardous or demanding applications.

What are the key material types used for metal cord grips and their typical applications?

Key materials include nickel-plated brass for general industrial and demanding environments due to its corrosion resistance and strength, stainless steel for extreme corrosion resistance in chemical, marine, and food applications, and aluminum for lightweight, non-magnetic uses in aerospace and outdoor lighting.

What impact does industrial automation have on the demand for metal cord grips?

Industrial automation drives significant demand for metal cord grips by requiring robust and reliable cable management for complex machinery, robotics, and control systems. These applications demand cord grips that offer superior strain relief, environmental protection, and EMI shielding to ensure uninterrupted and safe automated operations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager