Metrology Services Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430211 | Date : Nov, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Metrology Services Market Size

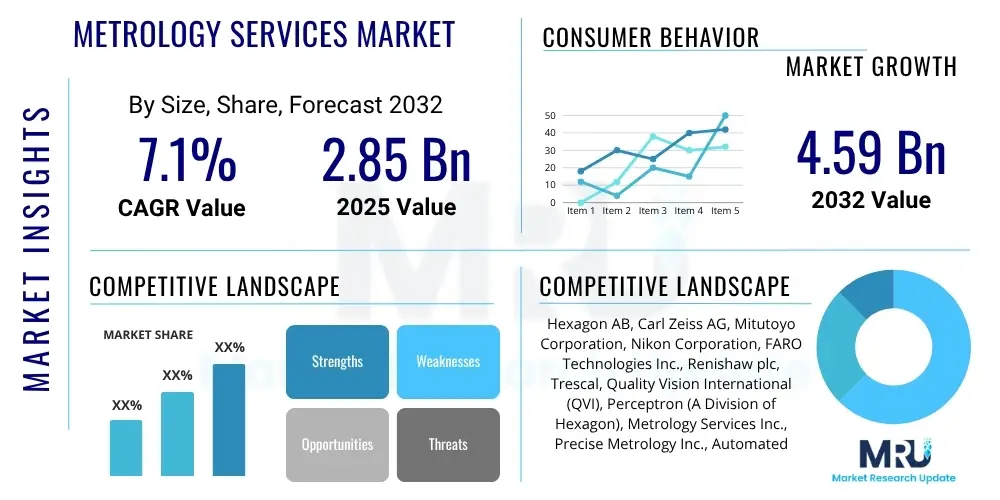

The Metrology Services Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.1% between 2025 and 2032. The market is estimated at USD 2.85 Billion in 2025 and is projected to reach USD 4.59 Billion by the end of the forecast period in 2032.

Metrology Services Market introduction

The Metrology Services Market encompasses a comprehensive range of professional offerings aimed at ensuring accuracy, precision, and compliance in measurement processes across various industries. These services are critical for maintaining quality control, facilitating product development, and adhering to strict regulatory standards in manufacturing and scientific research. Providers offer everything from routine calibration and equipment verification to advanced 3D scanning, inspection, and reverse engineering, catering to complex dimensional and surface metrology needs.

Product descriptions within this market highlight sophisticated measurement techniques and state-of-the-art equipment, including Coordinate Measuring Machines (CMMs), optical metrology systems, laser scanners, and portable metrology devices. Major applications span critical sectors such as automotive for component inspection, aerospace for precision part validation, medical devices for stringent quality assurance, and electronics manufacturing for micro-level accuracy. The inherent benefits of these services include enhanced product quality, reduced manufacturing defects, faster time-to-market, improved operational efficiency, and minimized recall risks, directly impacting profitability and brand reputation.

Driving factors propelling market growth include the increasing demand for high-precision manufacturing, the rapid adoption of Industry 4.0 and smart factory initiatives that necessitate integrated quality control systems, and the ongoing globalization of supply chains which mandates consistent measurement standards. Furthermore, the complexity of modern materials and designs, particularly in additive manufacturing and advanced composites, requires specialized metrology services to ensure structural integrity and functional performance. Regulatory compliance in highly regulated industries like medical and aerospace also acts as a significant driver, compelling companies to invest in certified and reliable metrology solutions.

Metrology Services Market Executive Summary

The Metrology Services Market is experiencing robust growth driven by significant business trends such as the pervasive adoption of automation and digitalization across manufacturing sectors, leading to a heightened demand for precise and efficient quality control solutions. Businesses are increasingly outsourcing metrology needs to specialized service providers to leverage advanced technologies without significant capital investment, optimize operational costs, and access expert knowledge. The integration of data analytics and cloud-based solutions is transforming service delivery, enabling predictive maintenance and remote monitoring capabilities, which are crucial for maintaining competitive edge and operational continuity in a dynamic industrial landscape.

Regional trends indicate that Asia Pacific is emerging as a primary growth engine, fueled by rapid industrialization, expanding manufacturing bases, and significant investments in smart factory infrastructure, particularly in countries like China, India, and South Korea. North America and Europe, while mature markets, continue to demonstrate stable demand, driven by stringent quality standards in advanced manufacturing sectors such as aerospace, medical, and automotive, alongside a strong focus on innovation and R&D. Latin America, the Middle East, and Africa are showing promising growth, albeit from a smaller base, as industrial capabilities develop and global manufacturing shifts create new opportunities for quality assurance and inspection services.

Segmentation trends highlight a notable shift towards advanced and specialized metrology services, with 3D metrology and optical inspection services witnessing accelerated adoption due to their ability to handle complex geometries and provide non-contact measurements. The demand for metrology software and data management solutions is also surging as industries seek to integrate measurement data seamlessly into their broader production and quality management systems. Furthermore, the market is seeing increased customization in service offerings, tailored to specific industry requirements and application complexities, reflecting a move towards value-added services beyond basic calibration, which is essential for meeting the evolving needs of modern manufacturing and engineering processes.

AI Impact Analysis on Metrology Services Market

Common user questions regarding AI's impact on the Metrology Services Market frequently center on its ability to enhance accuracy, automate repetitive tasks, and improve data processing capabilities. Users are keen to understand how AI can reduce inspection times, minimize human error, and provide deeper insights from vast datasets. There is a strong expectation that AI will lead to more intelligent, predictive quality control systems, allowing for proactive adjustments rather than reactive corrections. Concerns also exist around the implementation costs, the need for skilled personnel to manage AI-driven systems, and data security implications, while simultaneously anticipating benefits such as enhanced efficiency, optimized manufacturing processes, and superior product reliability.

- AI enhances data interpretation and anomaly detection in inspection results, improving accuracy and reliability.

- Predictive metrology through AI algorithms allows for proactive maintenance and adjustment of manufacturing processes, preventing defects.

- Automation of routine inspection tasks using AI-powered vision systems reduces human intervention and speeds up throughput.

- Optimized measurement strategies and path planning for CMMs and robotic inspection systems using AI algorithms.

- AI facilitates the analysis of large metrology datasets to identify trends, optimize tolerances, and improve design for manufacturability.

- Real-time quality control feedback loops driven by AI enable immediate process adjustments, minimizing waste and rework.

- Advanced defect classification and identification through machine learning models improve the precision of quality assessments.

DRO & Impact Forces Of Metrology Services Market

The Metrology Services Market is significantly influenced by a confluence of drivers, restraints, and opportunities that shape its growth trajectory and competitive landscape. Key drivers include the relentless pursuit of precision and quality across industries, propelled by increasingly stringent regulatory standards, especially in highly critical sectors like aerospace, medical, and automotive. The widespread adoption of Industry 4.0 initiatives, which integrate smart manufacturing, IoT, and automation, inherently demands advanced metrology for real-time monitoring and quality assurance. Furthermore, the proliferation of complex geometries and advanced materials in product design necessitates sophisticated measurement techniques that traditional methods cannot provide, boosting demand for specialized metrology services.

However, the market also faces notable restraints. The high initial capital investment required for state-of-the-art metrology equipment and software can be prohibitive for smaller and medium-sized enterprises (SMEs), potentially hindering widespread adoption. A significant challenge is the shortage of skilled metrology professionals capable of operating and interpreting data from advanced systems, creating a bottleneck in service delivery and technology utilization. Additionally, economic uncertainties and fluctuating manufacturing output in certain regions can lead to deferred investments in metrology services, affecting market stability and growth rates.

Despite these challenges, abundant opportunities exist for market expansion. Emerging markets, particularly in Asia Pacific, offer vast untapped potential as industrialization accelerates and quality consciousness grows. The increasing demand for advanced materials and additive manufacturing presents new complexities that require bespoke metrology solutions, opening niches for specialized service providers. Furthermore, the ongoing digitalization and integration of metrology data into wider enterprise systems (like ERP and PLM) promise to enhance efficiency and create value-added services, fostering innovative business models and collaborative partnerships within the metrology ecosystem. The drive towards sustainable manufacturing also emphasizes precision to reduce material waste, indirectly boosting metrology demand.

Segmentation Analysis

The Metrology Services Market is comprehensively segmented to address the diverse needs of various industries and applications, reflecting the specialized nature of precision measurement and inspection. These segmentations allow for a granular understanding of market dynamics, revealing key areas of growth, technological advancements, and shifting customer preferences across different service types, technologies, end-use industries, and organizational structures. Analyzing these segments helps stakeholders identify lucrative opportunities and tailor their service offerings to specific market demands, ensuring optimal resource allocation and strategic market positioning.

- By Service Type:

- Calibration Services

- Inspection Services

- CMM Programming Services

- Reverse Engineering Services

- Training and Consulting Services

- Equipment Rental and Leasing

- Software Integration and Support

- By Technology:

- Coordinate Measuring Machines (CMM) Metrology Services

- Optical Metrology Services

- Laser Scanning Services

- Vision Measuring Machines (VMM) Services

- Portable Metrology Services

- X-Ray & CT Metrology Services

- Surface Metrology Services

- By End-Use Industry:

- Automotive

- Aerospace and Defense

- Medical Devices

- Electronics and Semiconductors

- Heavy Machinery and Manufacturing

- Power and Energy

- Construction

- Plastics and Polymers

- Tool & Die

- Academia & Research

- By Measurement Type:

- Dimensional Metrology

- Surface Metrology

- Geometric Metrology

Value Chain Analysis For Metrology Services Market

The value chain for the Metrology Services Market begins with upstream activities involving the research, development, and manufacturing of sophisticated metrology equipment and software. This segment includes original equipment manufacturers (OEMs) of CMMs, optical scanners, laser trackers, and specialized metrology software providers. These players invest heavily in innovation to produce high-precision instruments and integrated platforms that form the bedrock of metrology services. Raw material suppliers for these instruments and component manufacturers also constitute a critical part of the upstream segment, ensuring the quality and availability of essential building blocks for metrology systems.

Midstream in the value chain are the metrology service providers themselves, who acquire, utilize, and maintain this advanced equipment. These providers offer a range of services from routine calibration and maintenance to complex inspection, reverse engineering, and quality consulting. They act as intermediaries, translating raw measurement data into actionable insights for their clients. Their expertise in various metrology techniques, data analysis, and industry-specific applications adds significant value, enabling end-users to achieve higher product quality and process efficiency without the need for in-house investment in equipment and specialized personnel. Training and certification bodies also play a crucial role here, ensuring a skilled workforce.

The downstream segment of the value chain consists of the diverse end-users across various industries—automotive, aerospace, medical devices, electronics, and heavy machinery, among others. These customers utilize metrology services to ensure component accuracy, product compliance, and overall quality control in their manufacturing and R&D processes. Distribution channels for metrology services are typically direct, involving a direct relationship between the service provider and the end-user, especially for customized or complex projects. However, indirect channels also exist through partnerships, authorized service centers, or integrated solutions offered by equipment manufacturers who also provide services. The growth of digital platforms and online booking systems represents an evolving indirect channel, enhancing accessibility and efficiency for standard service requests.

Metrology Services Market Potential Customers

Potential customers for the Metrology Services Market span a broad spectrum of industrial sectors, all united by a critical need for precision, quality assurance, and compliance in their manufacturing and operational processes. These end-users are primarily organizations that design, produce, or assemble products where dimensional accuracy and material integrity are paramount, impacting product performance, safety, and regulatory adherence. The diverse requirements of these industries drive the demand for a variety of metrology services, from simple calibration to complex 3D inspections and advanced material analysis.

Key industries that frequently procure metrology services include the automotive sector, which relies on precise measurements for engine components, body panels, and safety systems; the aerospace and defense industry, where extreme accuracy is non-negotiable for aircraft parts, turbines, and weapon systems; and the medical devices industry, which demands impeccable quality control for implants, surgical instruments, and diagnostic equipment due to stringent health and safety regulations. Furthermore, electronics and semiconductor manufacturers utilize metrology for micro-level inspection of circuit boards and components, while heavy machinery and industrial manufacturing firms ensure the quality and fit of large-scale parts and assemblies.

Beyond these core manufacturing segments, the Metrology Services Market also serves emerging sectors such as additive manufacturing (3D printing), where complex geometries require specialized inspection, and the renewable energy sector, which needs precise components for wind turbines and solar panels. Research and development institutions, educational facilities, and government laboratories also represent significant customer bases, requiring high-precision measurements for scientific discovery and advanced engineering projects. The need to reduce waste, improve efficiency, and ensure product reliability across all these industries solidifies their position as key buyers and beneficiaries of professional metrology expertise.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 2.85 Billion |

| Market Forecast in 2032 | USD 4.59 Billion |

| Growth Rate | 7.1% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hexagon AB, Carl Zeiss AG, Mitutoyo Corporation, Nikon Corporation, FARO Technologies Inc., Renishaw plc, Trescal, Quality Vision International (QVI), Perceptron (A Division of Hexagon), Metrology Services Inc., Precise Metrology Inc., Automated Precision Inc. (API), Creaform (A Business Unit of AMETEK), Trilion Quality Systems, ZEISS Industrial Metrology, The L.S. Starrett Company, GOM GmbH (A Hexagon Company), InnovMetric Software Inc., KUKA AG (Robotics in Metrology), National Instruments. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Metrology Services Market Key Technology Landscape

The Metrology Services Market is characterized by a dynamic and evolving technology landscape, continuously pushing the boundaries of precision, speed, and automation in measurement. At the forefront are advanced 3D metrology systems, including sophisticated Coordinate Measuring Machines (CMMs) that offer unparalleled accuracy for complex part geometries, and optical metrology solutions utilizing structured light, laser scanning, and photogrammetry. These non-contact technologies are gaining significant traction due to their ability to quickly capture dense point clouds from surfaces without physical interaction, making them ideal for delicate or high-volume inspections. Portable metrology devices like articulated arms and laser trackers provide flexibility and on-site measurement capabilities, expanding the utility of metrology beyond traditional lab environments.

Integrated software solutions form another critical pillar of the technology landscape, encompassing CAD/CAM software for design comparison, dedicated metrology software for data acquisition and analysis, and statistical process control (SPC) software for quality monitoring. The convergence of hardware and software enables comprehensive digital workflows, from initial design validation to final product inspection and quality reporting. Furthermore, the adoption of Industry 4.0 paradigms has led to the integration of IoT sensors and connectivity into metrology equipment, enabling real-time data collection, remote monitoring, and seamless data transfer to enterprise-wide systems, facilitating smarter manufacturing decisions.

Emerging technologies like Artificial Intelligence (AI) and Machine Learning (ML) are increasingly being incorporated to enhance data interpretation, automate inspection routines, and enable predictive quality control. AI algorithms can analyze vast datasets to identify subtle defects, optimize measurement strategies, and even predict potential manufacturing issues before they occur. Robotic metrology, where robots are integrated with metrology sensors, is also on the rise, offering automated and repeatable inspection for high-volume production lines. X-ray and CT metrology provide internal defect detection and non-destructive testing capabilities, becoming indispensable for complex internal structures and material analysis. These technological advancements collectively drive efficiency, accuracy, and versatility in metrology services, making them indispensable for modern industrial operations.

Regional Highlights

- North America: This region maintains a mature and robust metrology services market, driven by advanced manufacturing sectors such as aerospace, automotive, and medical devices. Stringent quality regulations and significant investment in R&D foster continuous demand for high-precision measurement and inspection. The presence of key market players and a strong adoption rate of new technologies like AI and automated metrology contribute to its consistent growth.

- Europe: Europe represents a significant market, propelled by its strong industrial base, particularly in Germany's automotive and machinery sectors, and the UK's aerospace and defense industries. The region emphasizes innovation, sustainability, and adherence to international quality standards, leading to steady demand for calibration, inspection, and consulting services. The push for Industry 4.0 initiatives further integrates metrology services into smart factory ecosystems.

- Asia Pacific (APAC): The APAC region is the fastest-growing market for metrology services, primarily due to rapid industrialization, expanding manufacturing capabilities, and increasing foreign direct investment in countries like China, India, Japan, and South Korea. Growing awareness regarding quality control, coupled with the rising adoption of advanced manufacturing techniques and automation, drives significant demand across electronics, automotive, and general manufacturing sectors.

- Latin America: This region is experiencing steady growth in metrology services, albeit from a smaller base, influenced by expanding automotive and aerospace manufacturing in countries such as Mexico and Brazil. Increasing industrialization and the need to meet global quality standards are propelling demand for accurate measurement and inspection services. Investments in infrastructure and manufacturing modernization are key growth drivers.

- Middle East and Africa (MEA): The MEA market for metrology services is emerging, driven by diversification efforts from oil-dependent economies into manufacturing, construction, and infrastructure development. Industries such as aerospace (particularly in the UAE), automotive, and general manufacturing are gradually adopting advanced metrology to ensure quality and compliance. The region presents significant long-term growth potential as industrial capabilities mature.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Metrology Services Market.- Hexagon AB

- Carl Zeiss AG

- Mitutoyo Corporation

- Nikon Corporation

- FARO Technologies Inc.

- Renishaw plc

- Trescal

- Quality Vision International (QVI)

- Perceptron (A Division of Hexagon)

- Metrology Services Inc.

- Precise Metrology Inc.

- Automated Precision Inc. (API)

- Creaform (A Business Unit of AMETEK)

- Trilion Quality Systems

- ZEISS Industrial Metrology

- The L.S. Starrett Company

- GOM GmbH (A Hexagon Company)

- InnovMetric Software Inc.

- KUKA AG (Robotics in Metrology)

- National Instruments

Frequently Asked Questions

What are Metrology Services?

Metrology Services involve professional measurement, inspection, calibration, and analysis activities performed to ensure the accuracy, precision, and compliance of products and components according to specified standards. These services utilize advanced equipment and expertise to validate dimensions, surfaces, and geometries in various industrial applications.

Which industries primarily utilize Metrology Services?

Key industries include automotive, aerospace and defense, medical devices, electronics, heavy machinery, and power and energy. These sectors require high precision and stringent quality control, making metrology services indispensable for product development, manufacturing, and regulatory compliance.

How does Industry 4.0 impact the Metrology Services Market?

Industry 4.0 significantly drives the market by integrating smart manufacturing, IoT, and automation. This paradigm shift necessitates advanced metrology for real-time quality control, predictive maintenance, and seamless data integration into smart factory ecosystems, enhancing efficiency and quality assurance.

What are the key technological advancements in Metrology Services?

Key advancements include sophisticated 3D metrology systems (CMM, optical, laser scanning), integrated software solutions for data analysis, and the incorporation of AI and Machine Learning for enhanced data interpretation and automated inspection routines. Portable metrology and robotic inspection are also crucial advancements.

What are the main challenges faced by the Metrology Services Market?

Major challenges include the high initial investment cost for advanced metrology equipment, a shortage of skilled professionals capable of operating and interpreting complex systems, and economic uncertainties that can lead to deferred investments in quality control solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager