Microcarriers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431175 | Date : Nov, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Microcarriers Market Size

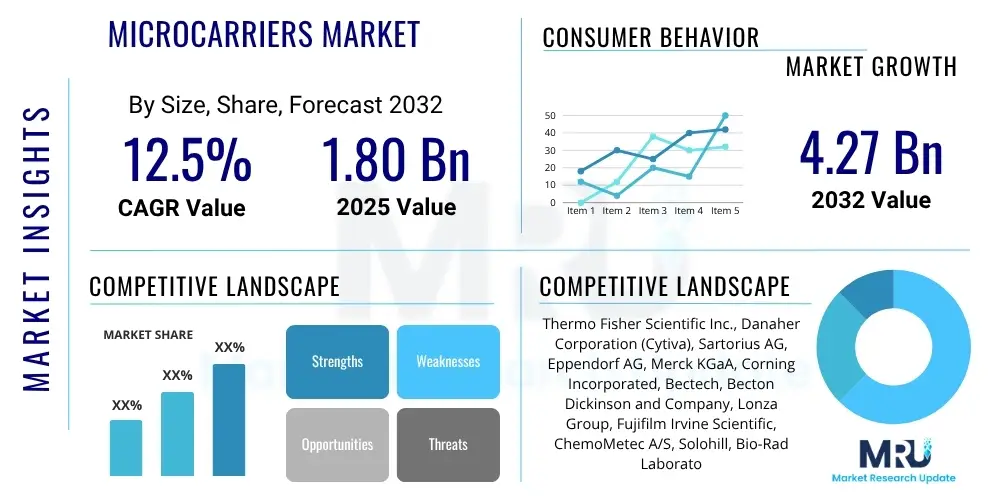

The Microcarriers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.5% between 2025 and 2032. The market is estimated at USD 1.80 Billion in 2025 and is projected to reach USD 4.27 Billion by the end of the forecast period in 2032.

Microcarriers Market introduction

The Microcarriers Market encompasses specialized beads or particles used as support substrates for the attachment and growth of anchorage-dependent cells in bioreactors. These microscopic carriers offer a large surface-to-volume ratio, facilitating high-density cell cultures crucial for the production of biologics, vaccines, and cell therapies. Microcarriers are typically composed of various materials such as dextran, collagen, glass, polystyrene, or cellulose, often modified with surface coatings to enhance cell attachment and proliferation. Their application is pivotal in scaling up cell culture processes from laboratory to industrial scales, overcoming limitations of traditional two-dimensional culture methods.

Major applications for microcarriers include the large-scale manufacturing of viral vaccines, recombinant proteins, and increasingly, advanced cell and gene therapies. In vaccine production, they enable efficient propagation of host cells required for viral replication, while in cell therapy, they support the expansion of mesenchymal stem cells, T-cells, and other therapeutic cell types. The benefits of using microcarriers are numerous, including enhanced cell viability, improved process scalability, reduced labor, and the potential for automation within closed bioreactor systems. This contributes to higher yields and cost-effectiveness in biopharmaceutical manufacturing. The market's growth is primarily driven by the escalating demand for cell-based therapeutics, the expansion of biopharmaceutical research and development activities, and advancements in bioreactor technology that optimize microcarrier usage.

Microcarriers Market Executive Summary

The Microcarriers Market is experiencing robust growth fueled by an increased global demand for advanced biopharmaceutical products and cell-based therapies. Business trends indicate a strong focus on technological innovation, with companies investing in novel microcarrier materials and surface chemistries to improve cell attachment, proliferation, and harvest efficiency. Consolidation through strategic partnerships and mergers and acquisitions is also observed as key players seek to expand their product portfolios and geographical reach, particularly into emerging markets. The shift towards single-use bioreactor systems and automated cell culture platforms is further influencing business strategies, promoting integrated solutions that streamline upstream bioprocessing.

Regional trends reveal North America and Europe as established leaders, characterized by significant R&D spending, a mature biopharmaceutical industry, and strong government support for biotechnology. However, the Asia Pacific region is rapidly emerging as the fastest-growing market, driven by increasing healthcare expenditure, a burgeoning biopharmaceutical sector, and a rise in contract manufacturing and research activities, particularly in countries like China, India, and South Korea. This shift reflects global manufacturing decentralization and the pursuit of cost-effective production hubs. Latin America, and the Middle East and Africa also show promising growth, albeit from a smaller base, owing to improving healthcare infrastructure and growing investments in life sciences.

In terms of segment trends, the application of microcarriers in cell and gene therapy manufacturing is poised for exponential growth, surpassing traditional vaccine production as the primary revenue driver. This is attributed to the unprecedented approvals of new cell and gene therapies and the robust clinical pipeline. Product-wise, dextran-based and polystyrene-based microcarriers continue to dominate due to their established utility and versatility, while innovative biodegradable and animal-component-free options are gaining traction to meet regulatory and ethical demands. End-user segments, particularly pharmaceutical and biopharmaceutical companies, are investing heavily in in-house manufacturing capabilities, while contract research and manufacturing organizations (CROs and CMOs) are also expanding their capacities to meet outsourcing demands, collectively propelling market expansion.

AI Impact Analysis on Microcarriers Market

Common user questions regarding AI's impact on the Microcarriers Market frequently revolve around how artificial intelligence can optimize cell culture processes, enhance scalability, and accelerate the development of biopharmaceutical products. Users are keen to understand if AI can predict optimal microcarrier parameters, streamline data analysis from bioreactors, or automate complex cell harvest procedures. There is significant interest in AI's role in improving yield and quality control, reducing experimental variability, and potentially lowering operational costs. Concerns often include the complexity of integrating AI systems with existing bioprocessing workflows, the need for robust datasets for training AI models, and the regulatory challenges associated with AI-driven manufacturing decisions. Users expect AI to bring unprecedented efficiency and precision, transforming the entire microcarrier-based cell culture landscape by enabling more intelligent, predictive, and autonomous biomanufacturing.

- AI-driven real-time monitoring and control of bioreactor parameters, optimizing oxygen, pH, and nutrient levels for superior cell growth on microcarriers.

- Predictive analytics for microcarrier performance, identifying optimal material types, surface coatings, and cell seeding densities to maximize yield and viability.

- Automation of cell counting, viability assessment, and aggregation detection on microcarriers through image recognition and machine learning algorithms.

- Enhanced process development and optimization, using AI to model and simulate complex cell-microcarrier interactions, reducing experimental time and costs.

- Improved quality control and anomaly detection, leveraging AI to identify subtle deviations in cell morphology or growth patterns that might indicate contamination or process failure.

- Accelerated drug discovery and development by integrating AI with high-throughput screening of microcarrier-based cell lines for therapeutic candidate identification.

- Supply chain optimization for microcarrier procurement and inventory management, using AI to forecast demand and manage supplier relationships.

- Development of smart microcarriers with integrated sensors, enabled by AI, for continuous, non-invasive monitoring of cellular activity.

DRO & Impact Forces Of Microcarriers Market

The Microcarriers Market is significantly shaped by a confluence of driving forces, inherent restraints, and emerging opportunities, all collectively contributing to the market's trajectory. A primary driver is the accelerating demand for cell and gene therapies, which rely heavily on efficient and scalable cell expansion methods that microcarriers provide. The increasing global burden of chronic diseases and the subsequent need for advanced biologics, alongside continuous innovation in vaccine development, further propels market expansion. Moreover, advancements in bioreactor technology, including the proliferation of single-use systems compatible with microcarriers, enhance operational flexibility and reduce capital expenditure for manufacturers, thus encouraging wider adoption. The growing focus on personalized medicine and regenerative medicine also creates a sustained demand for high-quality, large-scale cell production.

However, the market faces several restraints that could impede its growth. The high initial cost associated with implementing microcarrier-based cell culture systems, particularly the specialized bioreactors and auxiliary equipment, can be a significant barrier for smaller companies or those with limited budgets. Furthermore, the complexities involved in optimizing microcarrier parameters for different cell lines and achieving consistent performance across various scales present technical challenges. Regulatory hurdles, especially concerning the quality control and safety of materials used in microcarriers for therapeutic applications, add another layer of complexity. Potential issues related to cell detachment, harvesting efficiency, and downstream processing compatibility also act as limiting factors, requiring continuous R&D investment to overcome.

Despite these challenges, substantial opportunities exist for market players. Emerging markets in Asia Pacific, Latin America, and the Middle East and Africa offer untapped potential due to improving healthcare infrastructure, increasing investment in biotechnology, and growing awareness of advanced therapies. The development of novel, biodegradable, and animal-component-free microcarriers caters to specific regulatory and ethical preferences, opening new market niches. Furthermore, the integration of automation and artificial intelligence in microcarrier-based bioprocessing promises to enhance efficiency and reduce manual intervention, creating sophisticated, high-value solutions. The expanding field of stem cell research and its therapeutic applications also represents a significant growth avenue, as microcarriers are crucial for scaling up these delicate cell cultures. These impact forces—technological advancements, evolving regulatory landscapes, and competitive intensity—will continue to define the market's evolution, pushing for greater innovation and operational excellence.

Segmentation Analysis

The Microcarriers Market is meticulously segmented across various parameters to provide a comprehensive understanding of its dynamics, facilitating targeted strategic planning and investment. These segmentations typically include analyses based on product type, material, application, end-user, and regional geography, each offering unique insights into market demands and growth drivers. Understanding these segments helps manufacturers tailor their offerings to specific industry needs, optimize supply chains, and identify lucrative niche markets. The diversity of microcarrier types and their broad applicability across different biopharmaceutical processes underscore the multifaceted nature of this market.

- By Product Type:

- Dextran Microcarriers

- Polystyrene Microcarriers

- Glass Microcarriers

- Collagen Microcarriers

- Cellulose Microcarriers

- Gelatin Microcarriers

- Other Microcarriers (e.g., polyacrylamide, ceramic)

- By Material:

- Synthetic

- Natural

- Animal-Component Free

- Biodegradable

- By Application:

- Vaccine Production

- Cell & Gene Therapy Manufacturing

- Regenerative Medicine

- Biologics & Biopharmaceutical Manufacturing

- Research & Development

- Other Applications (e.g., diagnostic kits, tissue engineering)

- By End User:

- Pharmaceutical & Biopharmaceutical Companies

- Contract Research Organizations (CROs)

- Contract Manufacturing Organizations (CMOs)

- Academic & Research Institutes

- Hospitals & Diagnostic Centers

Value Chain Analysis For Microcarriers Market

The value chain for the Microcarriers Market is a complex network involving several stages, beginning with raw material sourcing and culminating in the end-use application by biopharmaceutical entities. Upstream analysis highlights the critical role of chemical and material suppliers providing high-grade polymers (dextran, polystyrene), glass, collagen, and other base materials essential for microcarrier manufacturing. These suppliers must adhere to stringent quality and purity standards to ensure the efficacy and safety of the final product. Innovation at this stage focuses on developing novel, biocompatible, and animal-component-free materials that meet evolving regulatory and ethical requirements, influencing downstream product quality and application scope.

The midstream involves the specialized manufacturing of microcarriers, where raw materials are processed, shaped into micro-sized beads, and often surface-modified with coatings to enhance cell attachment and growth. Key players in this segment invest heavily in R&D to improve microcarrier design, porosity, mechanical stability, and chemical properties. This stage also includes the manufacturing of bioreactors and associated equipment necessary for optimal microcarrier usage. Downstream activities focus on the distribution and sale of microcarriers to end-users, encompassing logistics, storage, and technical support. The distribution channel is bifurcated into direct sales and indirect channels. Direct sales are often preferred for large-scale pharmaceutical companies requiring customized solutions and direct technical assistance, fostering closer relationships between manufacturers and end-users.

Indirect channels primarily involve a network of specialized distributors and third-party logistics providers who cater to a broader range of smaller research laboratories, academic institutions, and emerging biotech firms. These distributors offer wider market reach and often bundle microcarriers with other cell culture consumables and equipment, providing comprehensive solutions. The efficiency of these distribution channels is vital for timely delivery and maintaining product integrity, especially for temperature-sensitive or sterile-packaged microcarriers. The value chain is constantly evolving, with increasing vertical integration by some major players seeking to control quality and supply, while others prefer to focus on core competencies and leverage strong partnerships across the chain to maximize efficiency and market penetration.

Microcarriers Market Potential Customers

The primary potential customers and end-users of microcarriers are diverse, stemming from various segments within the biotechnology and pharmaceutical industries, all requiring scalable and efficient cell culture solutions. These customers primarily consist of entities engaged in the research, development, and manufacturing of biological products, including vaccines, therapeutic proteins, and advanced cellular therapies. Their demand for microcarriers is driven by the necessity to grow anchorage-dependent cells in large volumes while maintaining cell viability and functionality, ultimately to achieve higher product yields and reduce production costs.

Key buyers include large pharmaceutical and biopharmaceutical companies that have extensive pipelines in biologics and vaccines, often operating at commercial production scales. These companies prioritize microcarriers that offer robust performance, regulatory compliance, and seamless integration with existing bioreactor systems. Furthermore, contract research organizations (CROs) and contract manufacturing organizations (CMOs) represent a significant customer base, as they provide outsourced services for drug development and manufacturing to various clients, necessitating versatile and efficient cell culture platforms. Their need for flexibility and cost-effectiveness makes microcarriers an attractive option for handling diverse projects.

Academic and research institutes also constitute a vital customer segment, utilizing microcarriers for fundamental research in cell biology, tissue engineering, stem cell applications, and early-stage drug discovery. Although their purchase volumes might be smaller compared to commercial entities, their continuous research activities drive innovation and future demand. Emerging biotechnology startups, particularly those focused on novel cell and gene therapies, are also crucial potential customers, seeking scalable solutions to transition their laboratory-scale processes to clinical and commercial manufacturing. These diverse customer groups collectively underscore the broad applicability and critical importance of microcarriers in advancing modern life sciences.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.80 Billion |

| Market Forecast in 2032 | USD 4.27 Billion |

| Growth Rate | 12.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Thermo Fisher Scientific Inc., Danaher Corporation (Cytiva), Sartorius AG, Eppendorf AG, Merck KGaA, Corning Incorporated, Bectech, Becton Dickinson and Company, Lonza Group, Fujifilm Irvine Scientific, ChemoMetec A/S, Solohill, Bio-Rad Laboratories Inc., Sphere Fluidics Limited, Microfluidic ChipShop GmbH, Avantor Inc., GE Healthcare, Nunc A/S, Pall Corporation, Sigma-Aldrich Co. LLC |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Microcarriers Market Key Technology Landscape

The Microcarriers Market is underpinned by a dynamic technological landscape that continuously evolves to address the complexities of large-scale cell culture and biopharmaceutical manufacturing. A critical aspect is the ongoing advancement in bioreactor design, moving from traditional stirred tank bioreactors to more sophisticated systems like packed bed, fixed bed, and wave-induced bioreactors, all optimized for microcarrier use. These innovations focus on improving oxygen transfer, nutrient delivery, and shear stress reduction, ensuring optimal conditions for sensitive cell types grown on microcarriers. The integration of single-use bioreactor technologies is particularly impactful, offering benefits in terms of reduced cleaning validation, faster turnaround times, and lower risk of cross-contamination, which are highly attractive to manufacturers of cell and gene therapies.

Another significant technological advancement lies in the development of automated cell culture systems that facilitate high-throughput screening and scale-up processes. These systems minimize manual intervention, enhance reproducibility, and allow for precise control over culture parameters, which is crucial for consistency in microcarrier-based applications. Furthermore, real-time monitoring and control technologies, including in-line sensors for pH, dissolved oxygen, glucose, and lactate, are becoming standard. These tools provide continuous data, enabling immediate adjustments to maintain optimal cell growth conditions and improve process understanding. The development of advanced perfusion systems, which allow for continuous removal of spent media and replenishment of fresh media while retaining cells and microcarriers, is also pivotal for achieving ultra-high cell densities and increased volumetric productivity.

Beyond hardware, innovations in microcarrier materials and surface modification techniques are key. The emergence of novel biocompatible polymers, biodegradable options, and animal-component-free coatings addresses specific regulatory requirements and ethical considerations, expanding the applicability of microcarriers. Techniques for efficient cell dissociation and harvesting from microcarriers without compromising cell viability are also continually being refined, utilizing enzymatic, mechanical, or chemical methods. The intersection of these technologies—advanced bioreactor designs, automation, real-time analytics, and material science breakthroughs—collectively defines the cutting-edge of the microcarriers market, driving higher efficiencies, better yields, and improved product quality in biomanufacturing.

Regional Highlights

- North America: This region holds a dominant share in the Microcarriers Market, driven by a robust biopharmaceutical industry, extensive research and development activities, and significant investment in cell and gene therapy. The presence of major market players, advanced healthcare infrastructure, and favorable government funding for biotechnological innovations contribute to its leading position.

- Europe: Europe represents a substantial market, characterized by strong academic research, a growing number of biotechnology startups, and increasing adoption of advanced cell culture techniques. Countries like Germany, France, and the UK are key contributors, supported by a well-established regulatory framework and increasing funding for regenerative medicine and biologics manufacturing.

- Asia Pacific (APAC): The APAC region is projected to be the fastest-growing market for microcarriers. This growth is fueled by expanding biopharmaceutical manufacturing capabilities, rising healthcare expenditure, and increasing government support for life sciences research, particularly in China, India, Japan, and South Korea. The region is becoming a hub for contract manufacturing and research organizations.

- Latin America: This region demonstrates emerging growth in the microcarriers market, propelled by improving healthcare infrastructure, increasing investment in biotechnology, and growing awareness of advanced therapeutic options. Countries like Brazil and Mexico are leading the adoption of modern bioprocessing techniques, albeit from a smaller base.

- Middle East and Africa (MEA): The MEA region is a nascent but promising market, showing gradual growth due to increasing healthcare investments, a rising prevalence of chronic diseases, and efforts to develop local biopharmaceutical production capabilities. Strategic collaborations and technology transfers are key drivers in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Microcarriers Market.- Thermo Fisher Scientific Inc.

- Danaher Corporation (Cytiva)

- Sartorius AG

- Eppendorf AG

- Merck KGaA

- Corning Incorporated

- Bectech

- Becton Dickinson and Company

- Lonza Group

- Fujifilm Irvine Scientific

- ChemoMetec A/S

- Solohill

- Bio-Rad Laboratories Inc.

- Sphere Fluidics Limited

- Microfluidic ChipShop GmbH

- Avantor Inc.

- GE Healthcare

- Nunc A/S

- Pall Corporation

- Sigma-Aldrich Co. LLC

Frequently Asked Questions

What are microcarriers used for in bioprocessing?

Microcarriers serve as microscopic support beads for the attachment and growth of anchorage-dependent cells in bioreactors, enabling large-scale, high-density cell cultures essential for producing vaccines, therapeutic proteins, and cell therapies.

What are the primary benefits of using microcarriers for cell culture?

The main benefits include a large surface-to-volume ratio for high cell density, enhanced scalability of cell culture processes, improved cell viability, reduced labor, and compatibility with automation for cost-effective biopharmaceutical manufacturing.

What types of materials are microcarriers typically made from?

Microcarriers are commonly made from materials such as dextran, polystyrene, glass, collagen, cellulose, or gelatin, often with surface modifications to optimize cell attachment and proliferation.

How does AI impact the Microcarriers Market?

AI enhances the Microcarriers Market by optimizing bioreactor parameters, predicting microcarrier performance, automating cell analysis, accelerating process development, and improving quality control, leading to more efficient and precise biomanufacturing.

Which applications drive the growth of the Microcarriers Market?

The market's growth is primarily driven by the increasing demand for cell and gene therapies, the expansion of vaccine production, and the growing research and development activities in the biopharmaceutical sector for various biologics.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager