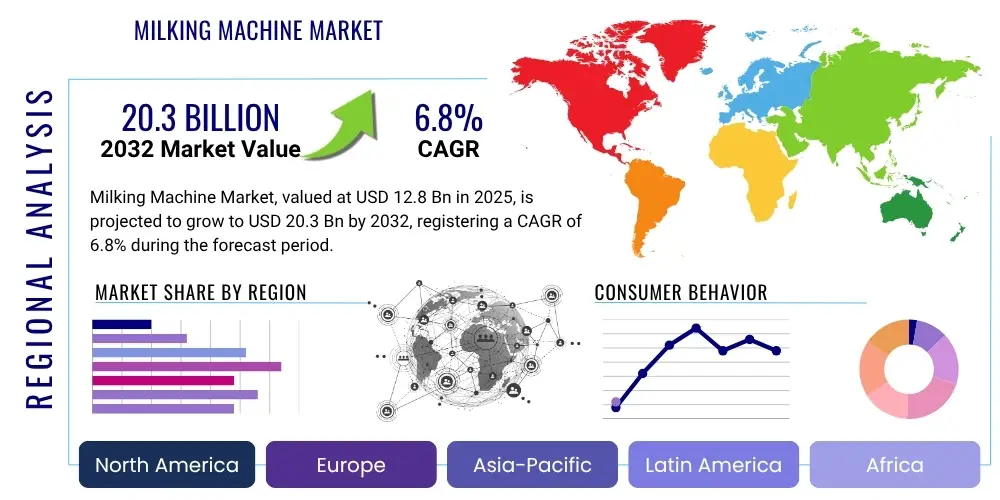

Milking Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431327 | Date : Nov, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Milking Machine Market Size

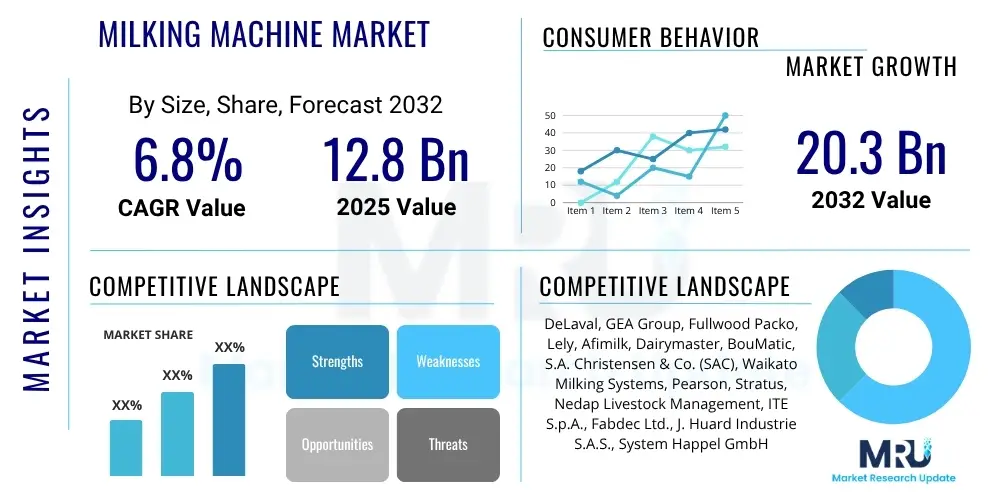

The Milking Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 12.8 Billion in 2025 and is projected to reach USD 20.3 Billion by the end of the forecast period in 2032.

Milking Machine Market introduction

The global milking machine market is experiencing robust expansion driven by increasing global demand for dairy products, the imperative for enhanced operational efficiency on dairy farms, and evolving animal welfare standards. Milking machines represent a critical technological advancement in modern dairy farming, automating the milk extraction process from cows, buffaloes, goats, and sheep. These systems range from simple bucket milkers to highly sophisticated robotic milking systems, all designed to replace or assist manual milking, thereby reducing labor intensity and improving overall farm productivity. The primary function remains consistent across all types: to efficiently and hygienically collect milk, ensuring quality and maximizing yield.

The product portfolio within the milking machine market is diverse, encompassing various types tailored to different farm sizes and operational needs. Portable milking machines cater to small and medium-sized farms, offering flexibility and cost-effectiveness. Mid-level parlor systems, such as herringbone or parallel parlors, are widely adopted by larger conventional farms, optimizing throughput and animal flow. The advent of automated and robotic milking systems represents the forefront of innovation, providing fully autonomous milking solutions that significantly reduce human intervention, monitor individual animal health, and enable precision farming. These advanced systems contribute to improved udder health, consistent milking routines, and enhanced milk quality through integrated sensing and data analytics capabilities.

Major applications for milking machines span across the entire dairy industry, from small-scale family farms to large commercial dairy operations and government-run agricultural projects. The benefits derived from adopting these machines are multifaceted, including significant labor cost reduction, improved milking consistency, enhanced milk hygiene and quality due to closed-system collection, and better animal welfare through optimized milking procedures that reduce stress on livestock. Key driving factors propelling market growth include the escalating global population and consequent demand for dairy products, increasing labor scarcity in agricultural sectors, government initiatives promoting farm modernization and mechanization, and the rising awareness among farmers regarding the long-term economic and operational advantages of automated milking solutions. Furthermore, advancements in technology, leading to more efficient and user-friendly systems, continue to fuel market penetration and adoption.

Milking Machine Market Executive Summary

The Milking Machine Market is characterized by dynamic business trends, marked by a significant shift towards automation and smart farming solutions. There is a growing emphasis on robotic milking systems, which offer unparalleled efficiency, precision, and labor savings, particularly in developed agricultural economies. Manufacturers are increasingly integrating advanced sensors, software, and data analytics into their offerings to provide farmers with comprehensive insights into herd health, milk quality, and operational performance. Sustainability and animal welfare are also emerging as critical business drivers, pushing for systems that are energy-efficient and prioritize the comfort and health of dairy animals. Strategic alliances, mergers, and acquisitions are common as companies seek to expand their technological capabilities and market reach, fostering innovation and competition.

Regional trends indicate varied growth trajectories and adoption patterns across the globe. North America and Europe, as mature markets, are witnessing a strong inclination towards advanced robotic and automated milking systems, driven by high labor costs, stringent dairy regulations, and a focus on maximizing productivity per animal. The Asia Pacific region is poised for significant growth, fueled by the modernization of traditional farming practices, rising dairy consumption, and government support for mechanization in countries like India and China. Latin America and the Middle East & Africa are emerging markets, where the adoption of conventional and semi-automatic milking machines is increasing, providing a foundation for future automation as agricultural infrastructure develops and disposable incomes rise, driving demand for dairy products.

Segmentation trends highlight the increasing prominence of robotic milking systems within the product type segment, reflecting the industry's move towards fully automated operations. While conventional milking machines maintain a substantial market share due to their affordability and suitability for smaller farms, the growth rate of robotic systems is accelerating. In terms of farm size, large-scale commercial dairy farms remain the primary adopters of advanced and integrated milking solutions, but there is also a burgeoning market for compact, efficient systems catering to small and medium-sized farms. The demand for associated services, including installation, maintenance, and software support, is also growing, indicating a shift towards a more comprehensive solutions-based approach rather than just product sales.

AI Impact Analysis on Milking Machine Market

User questions regarding AI's impact on the milking machine market frequently center on how these advanced technologies can enhance farm efficiency, improve animal welfare, and optimize milk production, while also considering the associated costs and technical complexities. Users are keen to understand the practical applications of AI, such as real-time health monitoring, predictive maintenance for equipment, and data-driven decision-making for herd management. Concerns often arise about the initial investment required for AI-integrated systems, the need for specialized technical skills among farm personnel, and the potential for job displacement in traditional farming roles. There is also significant interest in how AI contributes to higher milk quality and compliance with increasingly strict food safety regulations, as well as its role in sustainable dairy farming practices and personalized animal care.

- Precision Milking: AI algorithms analyze data from sensors to optimize milking duration, vacuum levels, and pulsator rates for individual animals, maximizing milk yield and ensuring udder health.

- Herd Health Monitoring: AI-powered cameras and sensors continuously monitor animal behavior, body condition, temperature, and milk parameters to detect early signs of illness, lameness, or reproductive issues, enabling timely intervention.

- Predictive Maintenance: AI analyzes operational data from milking machines to predict equipment failures before they occur, scheduling proactive maintenance and minimizing downtime, thereby extending machine lifespan.

- Automated Sorting and Feeding: AI-driven systems can identify individual animals and automate their sorting for specific treatments or adjust feed rations based on their production levels and health status.

- Milk Quality Analysis: AI algorithms can analyze milk composition in real-time, detecting abnormalities or deviations in fat, protein, or somatic cell count, ensuring high-quality output and identifying potential udder infections.

- Farm Management Optimization: AI platforms integrate data from various farm operations, including milking, feeding, and breeding, to provide holistic insights and recommendations for overall farm efficiency and profitability.

- Labor Reduction: Robotic milking systems enhanced with AI significantly reduce the need for manual labor, addressing agricultural labor shortages and reallocating human resources to other critical tasks.

- Resource Optimization: AI helps optimize resource usage such as water, energy, and feed, contributing to more sustainable and environmentally friendly dairy farming practices.

DRO & Impact Forces Of Milking Machine Market

The Milking Machine Market is fundamentally shaped by a confluence of driving factors, significant restraints, emerging opportunities, and various impact forces that collectively dictate its growth trajectory and evolutionary path. The increasing global demand for dairy products, driven by population growth and changing dietary preferences, acts as a primary driver for expanding dairy farm operations and subsequently, the adoption of efficient milking technologies. Concurrent labor shortages in agricultural sectors worldwide compel farmers to invest in automation, reducing reliance on manual labor and enhancing operational efficiency. Government subsidies and initiatives promoting farm modernization and mechanization further incentivize the adoption of advanced milking systems. Additionally, growing awareness about animal welfare and the need for hygienic milk production are propelling the demand for sophisticated machines that offer gentle, consistent milking and maintain high sanitary standards.

Conversely, the market faces several significant restraints that could impede its growth. The high initial capital investment required for automated and robotic milking systems poses a substantial barrier, particularly for small and medium-sized dairy farms in developing regions that may struggle to secure financing. Lack of awareness regarding the long-term benefits and return on investment of modern milking technologies, coupled with a dearth of technical expertise for operating and maintaining complex systems, also limits widespread adoption. Furthermore, the fragmented nature of the dairy farming industry in many parts of the world, with a large number of small-scale farmers, presents challenges for manufacturers in terms of market penetration and distribution logistics. Economic downturns and fluctuating milk prices can also impact farmers' purchasing power, delaying investment decisions in new equipment.

Despite these challenges, the market is rich with opportunities that promise significant future expansion. The untapped potential in emerging economies, where traditional manual milking methods are prevalent, offers a vast scope for market entry and growth as these regions modernize their agricultural practices. Innovations in sensor technology, AI, and IoT integration are creating new avenues for precision dairy farming, allowing for personalized animal care and optimized resource utilization, which will attract tech-savvy farmers. The development of more affordable and modular automated solutions tailored for small and medium-sized farms can help overcome the capital barrier. Moreover, expanding service offerings, including maintenance contracts, training programs, and data analytics support, can build stronger customer relationships and create recurring revenue streams. The increasing focus on sustainable farming practices and traceability throughout the dairy supply chain also presents an opportunity for companies offering environmentally friendly and data-transparent milking solutions.

Segmentation Analysis

The Milking Machine Market is extensively segmented to reflect the diverse needs and operational scales within the global dairy industry. This comprehensive segmentation allows for a detailed understanding of market dynamics, identifying key growth areas, and tailoring solutions to specific customer bases. The primary segmentation criteria include the type of milking machine, the size of the farm, the specific application or animal type, and the distribution channel through which these machines are sold. Each segment and sub-segment reveals unique market characteristics, growth drivers, and competitive landscapes, crucial for strategic planning and market penetration.

- By Product Type

- Automatic Milking Machines (Robotic Milking Systems)

- Semi-Automatic Milking Machines

- Manual Milking Machines

- Portable Milking Machines

- Fixed Milking Machines

- By Farm Size

- Small-Scale Farms (Less than 100 cows)

- Medium-Scale Farms (100-1000 cows)

- Large-Scale Farms (More than 1000 cows)

- By Application/Animal Type

- Cattle

- Buffalo

- Goats

- Sheep

- Other Dairy Animals

- By Sales Channel

- Direct Sales

- Distributors/Dealers

- Online Retail

- By Material

- Stainless Steel Milking Machines

- Plastic Milking Machines

- Other Materials

- By Milking Parlor Type

- Herringbone Parlors

- Parallel Parlors

- Rotary/Carousel Parlors

- Tie-Stall Parlors

Value Chain Analysis For Milking Machine Market

The value chain for the Milking Machine Market is intricate, encompassing several distinct stages from the sourcing of raw materials to the end-user adoption and post-sales support. It begins with upstream activities involving the procurement of critical components and raw materials such as stainless steel for milk contact parts, plastics for various housing and tubing, rubber for inflations and liners, and electronic components for control systems and sensors. Key suppliers in this stage include metal fabricators, plastic molding companies, rubber manufacturers, and electronics component providers. Quality control and cost efficiency at this initial stage are paramount, as they directly impact the final product's performance, durability, and competitiveness. Strong relationships with reliable suppliers ensure a steady supply chain and adherence to manufacturing standards.

The manufacturing stage involves the assembly, testing, and packaging of various milking machine types, from basic bucket milkers to complex robotic systems. This stage includes design and engineering, incorporating mechanical, electrical, and software components. Manufacturers invest heavily in research and development to innovate new technologies, improve efficiency, and enhance animal welfare features. Quality assurance, compliance with international hygiene standards (e.g., ISO), and robust testing are critical to producing reliable and high-performing equipment. Once manufactured, the products move into the distribution phase, which is crucial for reaching the diverse global customer base, including small individual farmers, large commercial dairies, and agricultural cooperatives.

Downstream activities involve the marketing, sales, installation, and after-sales service of milking machines. Distribution channels are varied, including direct sales from manufacturers to large corporate farms, an extensive network of independent distributors and dealers who serve regional and smaller farm markets, and increasingly, online retail platforms for less complex, portable units. Direct sales offer customized solutions and direct customer engagement, while distributors provide local presence, installation services, and maintenance support. After-sales services, including spare parts supply, routine maintenance, technical support, and software updates, are vital for ensuring customer satisfaction and long-term machine performance. The efficiency of the distribution network and the quality of after-sales support significantly influence customer loyalty and brand reputation in this market. This comprehensive value chain ensures that products are delivered, installed, and maintained effectively, fostering a sustainable market ecosystem.

Milking Machine Market Potential Customers

The primary potential customers for milking machines are diverse, encompassing a wide spectrum of dairy farm operations globally, each with unique requirements and purchasing capacities. At the forefront are commercial dairy farmers, ranging from medium to very large-scale enterprises, who consistently seek to maximize milk production, improve operational efficiency, and reduce labor costs. These farmers often invest in advanced automated and robotic milking systems, which provide significant benefits in terms of precision, animal welfare monitoring, and data analytics. Their purchasing decisions are typically driven by factors such as return on investment, long-term operational savings, milk quality improvements, and compliance with stringent dairy industry regulations. They often look for integrated solutions that can scale with their operations and offer comprehensive technical support and service contracts.

Another significant customer segment includes small and medium-sized dairy farms, which constitute a substantial portion of the global dairy industry, especially in developing and emerging economies. While these farms may not have the capital for full robotic systems, they are increasingly adopting semi-automatic or portable milking machines to transition away from manual milking. Their motivations are often centered on improving milk hygiene, reducing the physical burden of milking, and achieving modest gains in efficiency and productivity. Government-supported agricultural cooperatives and educational institutions also represent a consistent customer base, purchasing milking machines for collective use, research, and training purposes. The growing awareness about animal health and the desire for modernization across all farm sizes continue to expand the pool of potential customers, pushing manufacturers to offer a range of products catering to various financial and operational constraints.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 12.8 Billion |

| Market Forecast in 2032 | USD 20.3 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | DeLaval, GEA Group, Fullwood Packo, Lely, Afimilk, Dairymaster, BouMatic, S.A. Christensen & Co. (SAC), Waikato Milking Systems, Pearson, Stratus, Nedap Livestock Management, ITE S.p.A., Fabdec Ltd., J. Huard Industrie S.A.S., System Happel GmbH, Read Industrial Ltd., Interpuls S.p.A., Beijing Beiyuan Milking Machine, Milkline |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Milking Machine Market Key Technology Landscape

The Milking Machine Market is undergoing a profound technological transformation, driven by advancements that enhance efficiency, precision, and animal welfare. Central to this evolution are automation and robotics, with robotic milking systems becoming increasingly sophisticated. These systems utilize advanced sensors, vision technology, and robotic arms to autonomously attach milking cups, monitor udder health, and collect milk without human intervention. This automation not only addresses labor shortages but also ensures consistent milking routines, which is crucial for animal comfort and milk production. The integration of these robotic components requires robust engineering and sophisticated software to manage complex tasks and ensure reliable operation in challenging farm environments.

Sensor technology and the Internet of Things (IoT) are critical enablers within modern milking machines. Various sensors, including pressure sensors, temperature sensors, conductivity sensors, and flow meters, are embedded to monitor vital parameters of the milking process and animal health in real-time. For instance, conductivity sensors can detect early signs of mastitis, while flow meters track individual milk yield. This data is then transmitted via IoT networks to centralized farm management systems or cloud platforms, allowing farmers to access critical information remotely. This connectivity facilitates proactive decision-making, predictive maintenance, and optimized resource allocation, moving dairy farming towards a truly data-driven approach.

Furthermore, artificial intelligence (AI) and data analytics play an increasingly vital role in interpreting the vast amounts of data generated by these advanced milking systems. AI algorithms are used for pattern recognition in animal behavior, early disease detection, optimizing feeding regimes based on individual animal needs, and forecasting milk production trends. These analytical capabilities transform raw data into actionable insights, helping farmers improve herd management, increase profitability, and promote sustainable practices. The ongoing development in machine learning, cloud computing, and cybersecurity will continue to shape the technological landscape, leading to even smarter, more integrated, and resilient milking solutions that enhance every aspect of modern dairy operations, from individual cow care to overall farm management.

Regional Highlights

- North America: This region is a mature market characterized by large-scale commercial dairy farms and a high adoption rate of automated and robotic milking systems. The scarcity of farm labor, combined with substantial investment capabilities and government support for advanced agricultural technologies, drives demand for high-efficiency solutions. Key countries like the United States and Canada lead in technological integration, focusing on precision dairy farming and comprehensive herd management systems.

- Europe: Europe represents a significant market, particularly for robotic milking solutions, influenced by stringent animal welfare regulations, high labor costs, and a strong emphasis on milk quality and sustainability. Countries such as the Netherlands, Germany, France, and Scandinavia are at the forefront of adopting innovative milking technologies, driven by a desire to optimize farm profitability and meet consumer demand for ethically produced dairy products.

- Asia Pacific (APAC): The APAC region is projected to exhibit the highest growth rate in the milking machine market. This growth is primarily fueled by the modernization of traditional dairy farming practices, increasing dairy consumption due to rising populations and disposable incomes, and government initiatives promoting agricultural mechanization in countries like India, China, and Australia. While conventional and semi-automatic machines currently dominate, there is a growing trend towards automated systems, particularly in larger commercial farms.

- Latin America: This region presents a burgeoning market for milking machines, driven by expanding dairy industries and a gradual shift from manual to mechanized milking. Brazil, Argentina, and Mexico are key players, with a rising demand for semi-automatic and conventional milking machines to improve efficiency and hygiene on medium-sized farms. Investment in modern infrastructure and increasing awareness about the benefits of mechanization are catalyzing market growth.

- Middle East and Africa (MEA): The MEA market is an emerging region with significant growth potential, albeit from a smaller base. Government efforts to achieve food security, investments in modern dairy farms, and the increasing commercialization of dairy production are driving the adoption of milking machines. Countries like Saudi Arabia, UAE, and South Africa are investing in advanced systems, while other parts of the region focus on basic and portable solutions to improve small-scale dairy operations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Milking Machine Market.- DeLaval

- GEA Group

- Fullwood Packo

- Lely

- Afimilk

- BouMatic

- Dairymaster

- Waikato Milking Systems

- S.A. Christensen & Co. (SAC)

- Pearson

- Stratus

- Nedap Livestock Management

- ITE S.p.A.

- Fabdec Ltd.

- J. Huard Industrie S.A.S.

- System Happel GmbH

- Read Industrial Ltd.

- Interpuls S.p.A.

- Beijing Beiyuan Milking Machine

- Milkline

Frequently Asked Questions

What is a milking machine?

A milking machine is a device used in dairy farming to extract milk from dairy animals such as cows, buffaloes, goats, or sheep, by applying vacuum to the teats. It automates or semi-automates the milking process, improving efficiency and hygiene compared to manual milking.

What are the primary benefits of using milking machines?

The primary benefits include significant labor savings, improved milk hygiene and quality, increased milking efficiency, consistent milking routines that benefit animal welfare, and the potential for enhanced farm profitability through optimized operations.

How is AI impacting the milking machine market?

AI is transforming the milking machine market by enabling precision milking, real-time herd health monitoring, predictive maintenance for equipment, and data-driven farm management decisions, leading to greater automation, efficiency, and animal welfare. It analyzes sensor data to provide actionable insights.

What are the main types of milking machines available?

The main types include manual milking machines, semi-automatic milking machines (such as bucket milkers and parlor systems like herringbone or parallel), and fully automatic robotic milking systems, each suited for different farm sizes and levels of automation.

What are the key growth drivers for the Milking Machine Market?

Key growth drivers include rising global demand for dairy products, increasing labor shortages in the agricultural sector, government initiatives supporting farm modernization and mechanization, and growing awareness regarding animal welfare and milk quality standards.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager