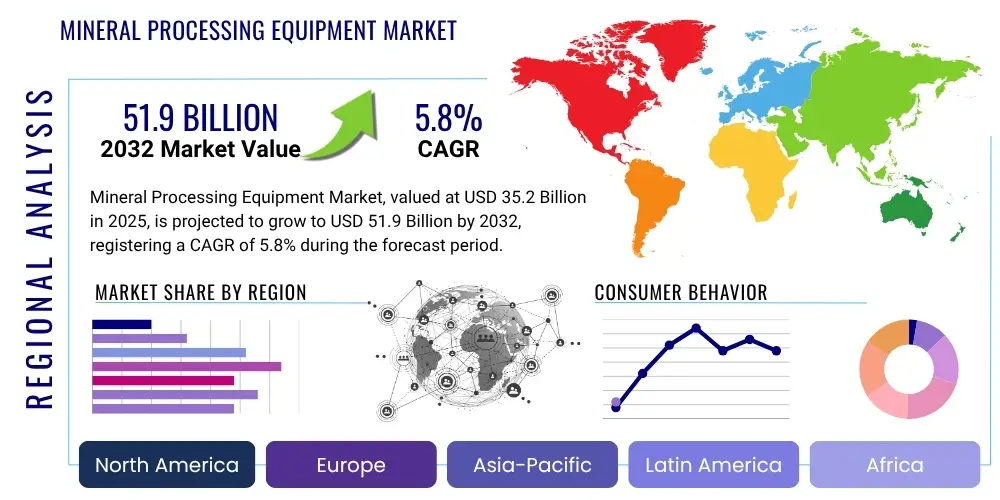

Mineral Processing Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429090 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Mineral Processing Equipment Market Size

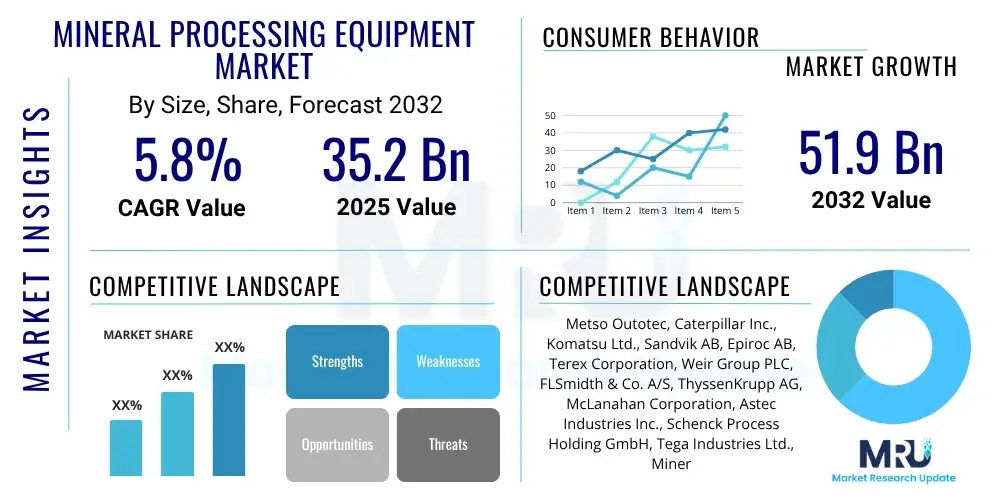

The Mineral Processing Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 35.2 Billion in 2025 and is projected to reach USD 51.9 Billion by the end of the forecast period in 2032.

Mineral Processing Equipment Market introduction

The Mineral Processing Equipment Market provides essential machinery for extracting and refining valuable minerals from raw ore. This includes crushers, grinders, screens, flotation cells, and magnetic separators, designed to prepare minerals for subsequent refining or direct industrial application. Major applications span across the mining, metallurgy, construction, and aggregate industries.

The primary benefits of these systems encompass enhanced operational efficiency, improved worker safety, stricter adherence to environmental compliance through optimized waste processing, and maximizing resource recovery from extracted materials. Key driving factors for market expansion include the accelerating global demand for critical metals and minerals, ongoing technological innovations promoting more sustainable and efficient processing, and extensive worldwide investments in infrastructure development projects.

Mineral Processing Equipment Market Executive Summary

The Mineral Processing Equipment Market is experiencing robust growth driven by increasing demand for raw materials and technological advancements. Key business trends indicate a strong focus on automation, digitalization, and the integration of smart technologies to enhance operational efficiency and reduce environmental impact. Companies are also investing in modular designs and energy-efficient solutions to meet evolving industry standards and sustainability goals.

Regionally, the Asia Pacific continues to dominate the market due to significant mining activities and infrastructure development, while emerging economies in Africa and Latin America present substantial growth opportunities. North America and Europe are focusing on upgrading existing facilities with advanced, high-efficiency equipment. Segment-wise, crushing and grinding equipment maintains the largest share, with separation technologies seeing increased demand due to stringent purity requirements and resource scarcity.

AI Impact Analysis on Mineral Processing Equipment Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize the mineral processing equipment sector, specifically concerning improvements in efficiency, predictive maintenance, and resource optimization. There is a strong interest in AI's potential to enhance operational safety, optimize complex processing parameters, and drive better decision-making through data analysis. Concerns often revolve around the initial investment costs, the availability of skilled labor for AI integration, data security, and the potential for job displacement, alongside expectations for significant leaps in productivity and sustainability.

- AI enables predictive maintenance, reducing downtime and operational costs by anticipating equipment failures.

- Optimized process control through real-time data analysis, leading to higher yield and energy efficiency.

- Enhanced automation of complex tasks, improving safety and reducing human error in hazardous environments.

- Advanced analytics for resource utilization, ensuring maximum recovery of valuable minerals from ore.

- Digital twin technology powered by AI for simulating and optimizing plant operations virtually before physical implementation.

- Improved geological modeling and resource estimation, supporting more efficient mining planning.

- Automated quality control and sorting systems, delivering consistent product specifications.

DRO & Impact Forces Of Mineral Processing Equipment Market

The Mineral Processing Equipment Market is significantly influenced by a confluence of driving forces, restraints, and opportunities. Major drivers include the increasing global demand for essential metals and minerals, fueled by rapid urbanization, industrialization, and infrastructure development worldwide. Technological advancements promoting automation, energy efficiency, and sustainable processing methods are also propelling market expansion.

However, the market faces considerable restraints such as the high capital investment required for new equipment and plant setups, stringent environmental regulations governing mining and processing operations, and the inherent volatility of commodity prices. These factors can lead to cautious investment decisions and impact project timelines. Opportunities for growth are abundant in the adoption of digital solutions like IoT and AI, the exploration of new mineral deposits in emerging economies, and the increasing focus on sustainable and circular economy practices within the mining industry.

Impact forces on the market include geopolitical shifts affecting mineral supply chains, escalating energy costs impacting operational expenditures, and growing emphasis on Environmental, Social, and Governance (ESG) criteria by investors and consumers, pressuring companies to adopt greener technologies and practices.

Segmentation Analysis

The Mineral Processing Equipment Market is comprehensively segmented based on various attributes to provide a detailed understanding of its dynamics and opportunities. These segmentations allow for a granular analysis of market trends, technological preferences, and application-specific demands, enabling stakeholders to identify key growth areas and develop targeted strategies. The market is primarily categorized by the type of equipment, its application across different industries, the specific minerals processed, and the processing stage involved.

- By Type:

- Crushing and Grinding Equipment

- Screening Equipment

- Pumping Equipment

- Flotation Equipment

- Magnetic Separation Equipment

- Filtering Equipment

- Other Equipment

- By Application:

- Mining Industry

- Construction Industry

- Metallurgy Industry

- Other Industries

- By Mineral:

- Metallic Minerals (Iron Ore, Copper, Gold, Silver, Aluminum, etc.)

- Non-Metallic Minerals (Limestone, Phosphate, Potash, Clay, etc.)

- Coal

- Other Minerals

- By Process:

- Comminution (Crushing, Grinding)

- Separation (Flotation, Magnetic Separation, Gravity Separation)

- Sizing (Screening, Classification)

- Slurry Transportation

- Dewatering

- Other Processes

Value Chain Analysis For Mineral Processing Equipment Market

The value chain for the Mineral Processing Equipment Market initiates with upstream activities, involving the sourcing of raw materials such as steel, specialized alloys, and advanced components from various suppliers. This stage also encompasses intensive research and development efforts, alongside engineering and design processes to create innovative and efficient equipment. Strategic partnerships with material and component manufacturers are crucial for ensuring quality and supply chain resilience.

Moving downstream, the value chain extends to the end-users of the equipment, primarily large-scale mining corporations, small to medium-sized mining operations, construction companies, aggregate producers, and metallurgical plants. These entities utilize the equipment for various stages of mineral processing, from initial extraction to final product refinement. The effectiveness of the equipment directly impacts their operational efficiency and profitability.

Distribution channels play a pivotal role in market reach. Direct sales are common for large, customized equipment purchases by major mining houses, often involving long-term contracts and after-sales service agreements. Indirect channels, through a network of authorized distributors, dealers, and original equipment manufacturers (OEMs), serve a broader customer base, including smaller operations, providing localized support, spare parts, and maintenance services. This dual approach ensures comprehensive market penetration and customer satisfaction.

Mineral Processing Equipment Market Potential Customers

The Mineral Processing Equipment Market serves a diverse range of potential customers whose operations depend heavily on efficient and reliable machinery for mineral extraction and processing. The primary end-users are large-scale mining corporations, including multinational entities involved in the exploration, extraction, and processing of various metallic and non-metallic minerals. These companies require high-capacity, robust, and technologically advanced equipment to sustain extensive operations and meet global demand.

Beyond the major players, small to medium-sized mining operations also represent a significant customer segment. These entities often seek cost-effective, modular, and easy-to-maintain equipment suitable for localized extraction projects. Additionally, construction companies and aggregate producers are key buyers, utilizing equipment like crushers and screens for processing materials such as sand, gravel, and crushed stone essential for infrastructure development.

Metallurgical plants and refineries form another critical customer base, relying on specialized processing equipment for the final stages of metal extraction and purification. Government entities involved in infrastructure projects, as well as research institutions focused on mineralogy and materials science, also contribute to the customer landscape, albeit on a smaller scale, through procurement for pilot projects or laboratory applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 35.2 Billion |

| Market Forecast in 2032 | USD 51.9 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Metso Outotec, Caterpillar Inc., Komatsu Ltd., Sandvik AB, Epiroc AB, Terex Corporation, Weir Group PLC, FLSmidth & Co. A/S, ThyssenKrupp AG, McLanahan Corporation, Astec Industries Inc., Schenck Process Holding GmbH, Tega Industries Ltd., Mineral Technologies Inc., Haver & Boecker Niagara, WIRTGEN GROUP (John Deere), Liebherr Group, P.C. WEEKS, General Kinematics Corporation, Sepro Mineral Systems Corp. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Mineral Processing Equipment Market Key Technology Landscape

The Mineral Processing Equipment Market is undergoing a significant technological transformation, driven by the imperative for enhanced efficiency, reduced environmental impact, and improved safety. Automation and robotics are at the forefront, integrating smart sensors and control systems to optimize operational processes, reduce manual intervention, and improve data accuracy. This shift towards intelligent operations allows for precise monitoring and adjustment of parameters, leading to better resource utilization and consistent product quality.

The adoption of the Internet of Things (IoT) and Artificial Intelligence (AI) is revolutionizing maintenance practices through predictive analytics, enabling equipment to self-diagnose potential failures and schedule maintenance proactively. This minimizes unexpected downtime and extends the lifespan of machinery. Digital twin technology is also gaining traction, allowing for virtual simulations of entire processing plants, which facilitates optimization, training, and troubleshooting in a risk-free environment. These innovations contribute to substantial operational cost reductions and productivity gains.

Furthermore, there is a strong emphasis on developing more energy-efficient and environmentally friendly equipment. This includes advanced comminution technologies that consume less power, dry processing methods to reduce water usage, and modular plant designs that offer flexibility and quicker deployment. Sustainable technologies, such as advanced filtration and tailings management systems, are crucial for complying with stringent environmental regulations and promoting a circular economy within the mineral processing sector.

Regional Highlights

- Asia Pacific (APAC): Dominates the market due to extensive mining activities, especially in China, Australia, and India. Rapid industrialization, urbanization, and large-scale infrastructure projects in the region drive high demand for minerals and, consequently, processing equipment.

- North America: Characterized by significant investment in advanced and automated equipment to modernize aging infrastructure and increase operational efficiency in countries like the US and Canada. A strong focus on technological integration and sustainability.

- Europe: A mature market with a focus on high-efficiency, environmentally compliant equipment. Countries such as Germany and the UK lead in technological innovation and the development of sustainable mining solutions, often supplying specialized machinery globally.

- Latin America: A key growth region, particularly in countries rich in metallic minerals like Chile, Brazil, and Peru. Increasing foreign investment in mining and robust demand for copper, iron ore, and gold contribute to market expansion.

- Middle East and Africa (MEA): Emerging as a significant market due to untapped mineral reserves and increasing investment in mining exploration and extraction. South Africa, Ghana, and Saudi Arabia are pivotal, with a growing need for modern processing equipment to develop their mineral resources.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Mineral Processing Equipment Market.- Metso Outotec

- Caterpillar Inc.

- Komatsu Ltd.

- Sandvik AB

- Epiroc AB

- Terex Corporation

- Weir Group PLC

- FLSmidth & Co. A/S

- ThyssenKrupp AG

- McLanahan Corporation

- Astec Industries Inc.

- Schenck Process Holding GmbH

- Tega Industries Ltd.

- Mineral Technologies Inc.

- Haver & Boecker Niagara

- WIRTGEN GROUP (John Deere)

- Liebherr Group

- P.C. WEEKS

- General Kinematics Corporation

- Sepro Mineral Systems Corp.

Frequently Asked Questions

What is the projected growth rate of the Mineral Processing Equipment Market?

The Mineral Processing Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032.

What are the primary drivers for this market?

Key drivers include the escalating global demand for essential metals and minerals, significant investments in infrastructure development, and continuous technological advancements in processing efficiency.

How is AI impacting the Mineral Processing Equipment Market?

AI is improving the market through predictive maintenance, optimized process control, enhanced automation, and advanced analytics for resource utilization, leading to greater efficiency and safety.

Which region holds the largest market share?

The Asia Pacific region currently holds the largest market share due to extensive mining activities and rapid industrialization in countries like China, Australia, and India.

Who are the leading companies in the Mineral Processing Equipment Market?

Top key players include Metso Outotec, Caterpillar Inc., Komatsu Ltd., Sandvik AB, Epiroc AB, and FLSmidth & Co. A/S, among others.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Crushing, Screening, and Mineral Processing Equipment Market Statistics 2025 Analysis By Application (Construction & Plant Modification, Mining, Foundries & Smelters, Others), By Type (Crushing & Screening Equipment, Mineral Processing Equipment), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Crushing, Screening, and Mineral Processing Equipment Market Statistics 2025 Analysis By Application (Plant Modification, Mining, Foundries & Smelters), By Type (Crushing and Screening Equipment, Mineral Processing Equipment), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager